Stripping agent for pickling undrawn wire as well as preparation and using methods of stripping agent

A stripper and pre-acid technology, which is applied in the field of metal surface treatment, can solve the problems of uneven waste acid treatment cost, over-corrosion of wires, and occasional fracture of the film layer, etc., to achieve inhibition of corrosion, strong adhesion and resistance Corrosion performance and the effect of reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A stripping agent for pickling treatment before wire drawing, consisting of the following components in mass percentage:

[0034] Concentrated phosphoric acid: 20%, citric acid: 2.0%, tartaric acid: 2.0%, malic acid: 1.0%, semicarbazide: 0.5%, benzotriazole: 0.5%, sodium persulfate: 1.5%, secondary alkylsulfonic acid Sodium: 0.10%, fatty alcohol polyoxyethylene (15) ether (Pingpingjia OS-15): 0.05%, water: 72.35%.

[0035] At room temperature, mix concentrated phosphoric acid and water in proportion, then add semicarbazide, benzotriazole and sodium persulfate into the diluted phosphoric acid aqueous solution, stir until completely dissolved, then add secondary alkylsulfonate sodium, flat Add OS-15, citric acid, tartaric acid, and malic acid, and stir well to get the peeling agent product.

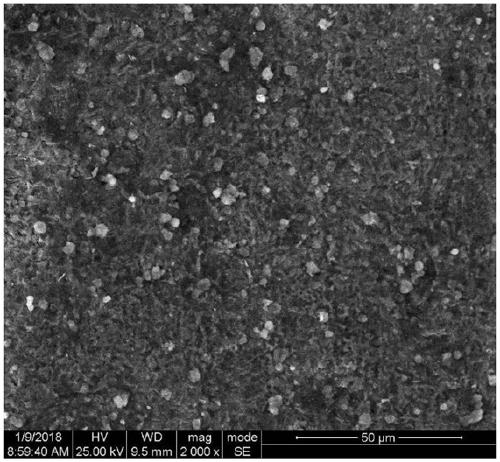

[0036] Cut the workpiece to be treated into two equal parts, one part is placed in the stripping agent solution, soaked at 50±5°C for 7 minutes, then taken out, washed with water an...

Embodiment 2

[0055] A stripping agent for pickling treatment before wire drawing, consisting of the following components in mass percentage:

[0056] Concentrated phosphoric acid: 5%, citric acid: 5.0%, tannic acid: 5.0%, malic acid: 10.0%, carbamide peroxide: 0.15%, benzotriazole: 0.05%, potassium nitrate: 2.5%, potassium chlorate: 2.5 %, sodium secondary alkyl sulfonate: 0.02%, fatty alcohol polyoxyethylene ether (Pingpinga O-20): 0.03%, water: 69.75%.

[0057] At room temperature, mix concentrated phosphoric acid and water in proportion, then add carbamide peroxide, benzotriazole, potassium nitrate, and potassium chlorate into the diluted phosphoric acid aqueous solution, stir until completely dissolved, and then add sodium secondary alkyl sulfonate , Pingping add O-20, citric acid, tannic acid, and malic acid, and stir well to get the peeling agent product.

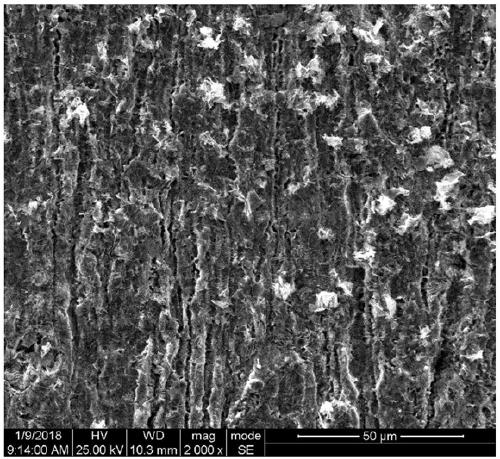

[0058] Place the workpiece to be treated in the stripping agent solution, soak it at 45±5°C for 10 minutes, take it out, wash i...

Embodiment 3

[0061] A stripping agent for pickling treatment before wire drawing, consisting of the following components in mass percentage:

[0062] Concentrated phosphoric acid: 50%, tannic acid: 0.1%, tartaric acid: 0.9%, 1,3-dimethylurea: 9.0%, benzotriazole: 1.0%, magnesium persulfate: 0.1%, magnesium chlorate: 0.4%, sodium secondary alkyl sulfonate: 2.9%, fatty alcohol polyoxyethylene (9) ether: 0.1%, water: 35.5%.

[0063] At room temperature, mix concentrated phosphoric acid and water in proportion, then add 1,3-dimethylurea, benzotriazole, magnesium persulfate, and magnesium chlorate into the diluted phosphoric acid aqueous solution, and stir until completely dissolved. Then add sodium secondary alkyl sulfonate, fatty alcohol polyoxyethylene (9) ether, tannic acid, tartaric acid, and stir well to obtain a stripping agent product.

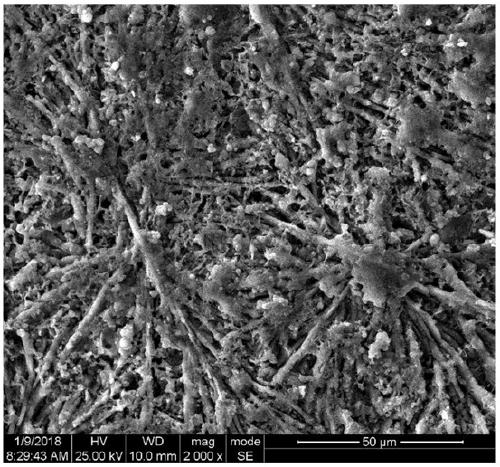

[0064] Place the workpiece to be treated in the stripping agent solution, soak it at 55±5°C for 5 minutes, take it out, wash it with water, and then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com