Alkyl glycoside refining bleaching method and equipment

A technology of alkyl glycoside and equipment, which is applied in the field of alkyl glycoside preparation technology, can solve the problems of unsuitability for industrial production, difficult bleaching process, expensive metal borohydride, etc., achieve thorough bleaching, reduce foam generation, and facilitate control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

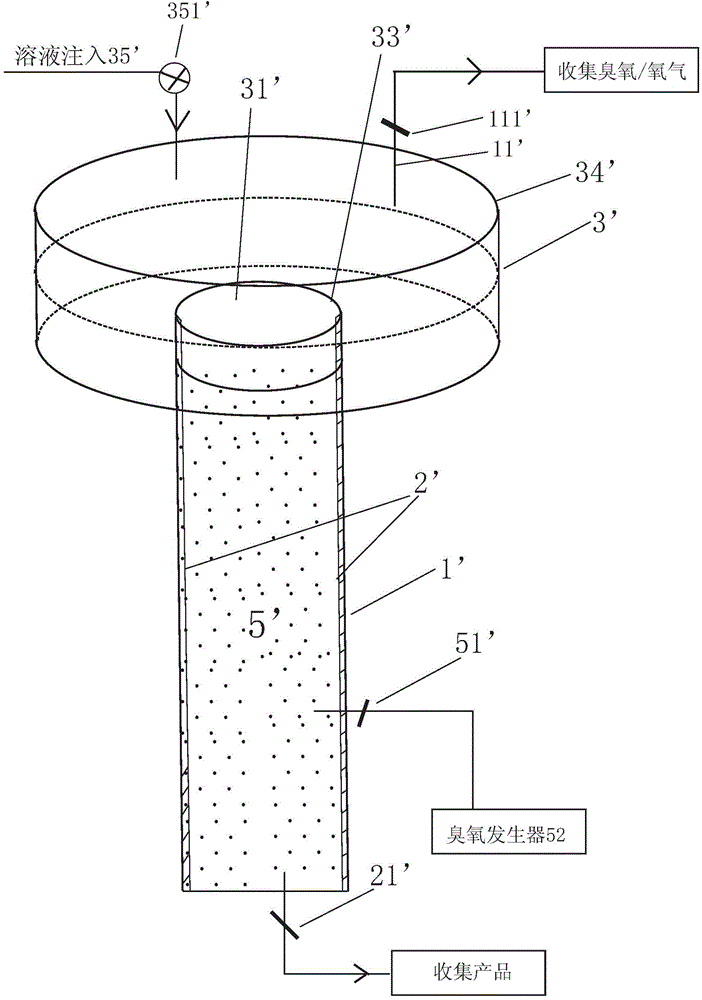

[0040] Example 1: The crude alkyl glycoside after dealcoholization was made into a 50% aqueous solution, adjusted to pH 11.5, and its color was 500 Hazen, put it in a rotary evaporator, heated to 70°C, turned on the ozone generator, and adjusted the gas flow to 100ml / min, ozone concentration 30mg / L, introduced from the center of the rotary evaporator, the rotation speed of the rotary evaporator is 15rpm, the material forms a uniform film on the glass wall, the color of the film becomes obviously lighter with time, sampling after 6 hours to test the product color 30Hazen, pH The value is 9.5, almost no bubbles are generated, the free fatty alcohol content is 0.8%, and the average degree of polymerization is 1.3.

Embodiment 2

[0041] Example 2: Take the same aqueous alkyl glycoside solution of Example 1, pH 11.5, color 500 Hazen, put it into a rotary evaporator, heat up to 70 ℃, rotary evaporator rotation speed 15rpm, the material forms a uniform film on the glass wall, the concentration is 30 % Hydrogen peroxide was added to the flask, heated to boiling, steam was introduced from the middle of the rotary evaporator, and the color of the film became obviously lighter with time. After 8 hours, the color of the product was 28Hazen, the pH value was 9.5, almost no bubbles were generated, and the free fatty alcohol content was 0.8 %, the average degree of polymerization is 1.3.

Embodiment 3

[0042] Example 3: Take the same aqueous alkyl glycoside solution of Example 1, pH 11.5, color 500 Hazen, put it into a rotary evaporator, heat up to 90 ℃, rotary evaporator rotation speed 15 rpm, the material forms a uniform film on the glass wall, turn on ozone generation Adjust the gas flow to 100ml / min, the ozone concentration is 30mg / L, the color of the film becomes obviously lighter with time, and the color of the product is 25Hazen after 4 hours, pH value is 8, basically no bubbles, free fatty alcohol content 0.8%, average Degree of polymerization 1.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com