Patents

Literature

81results about How to "Mild temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

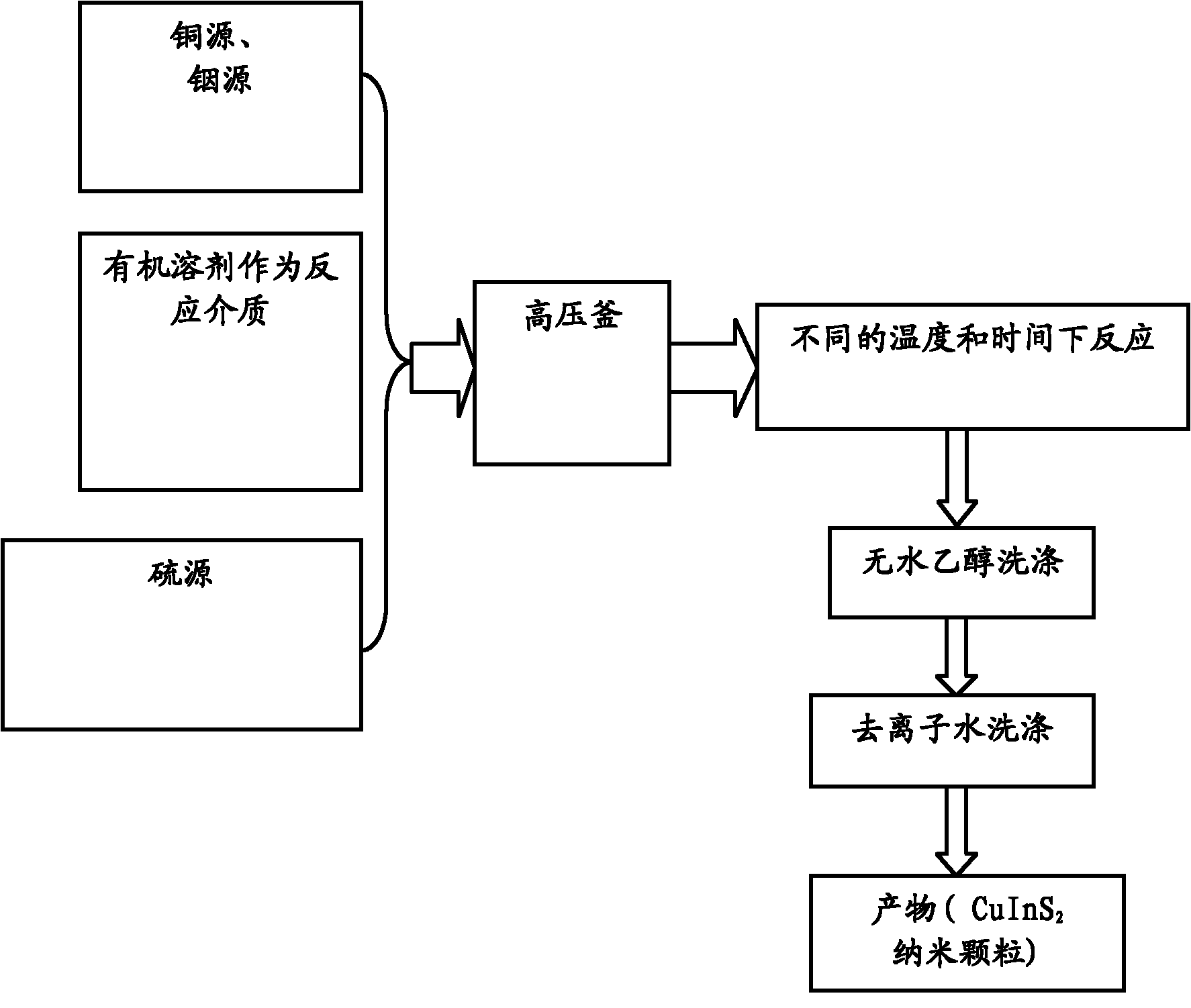

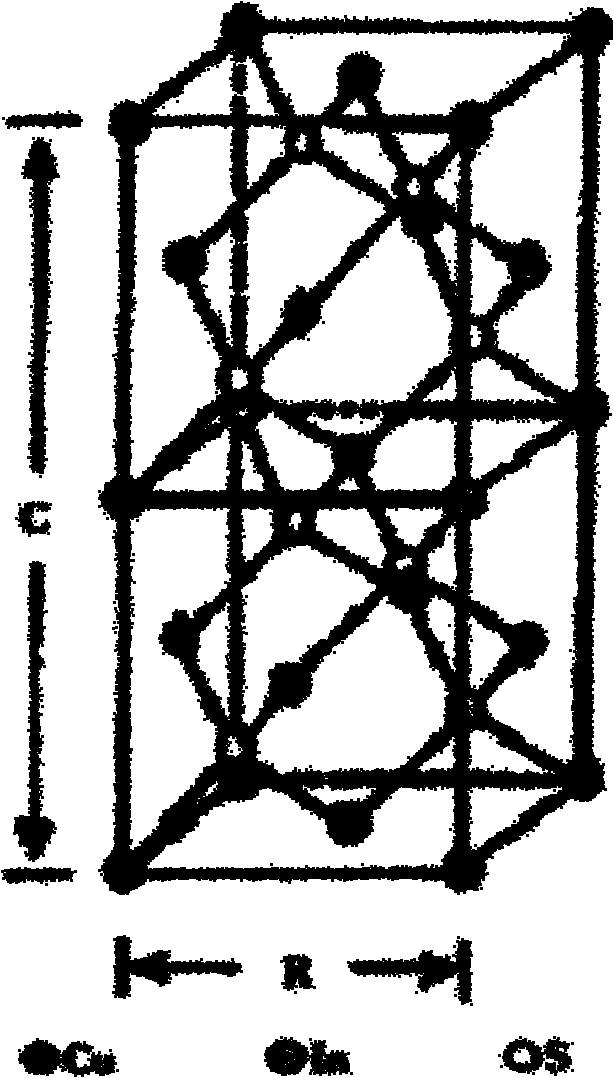

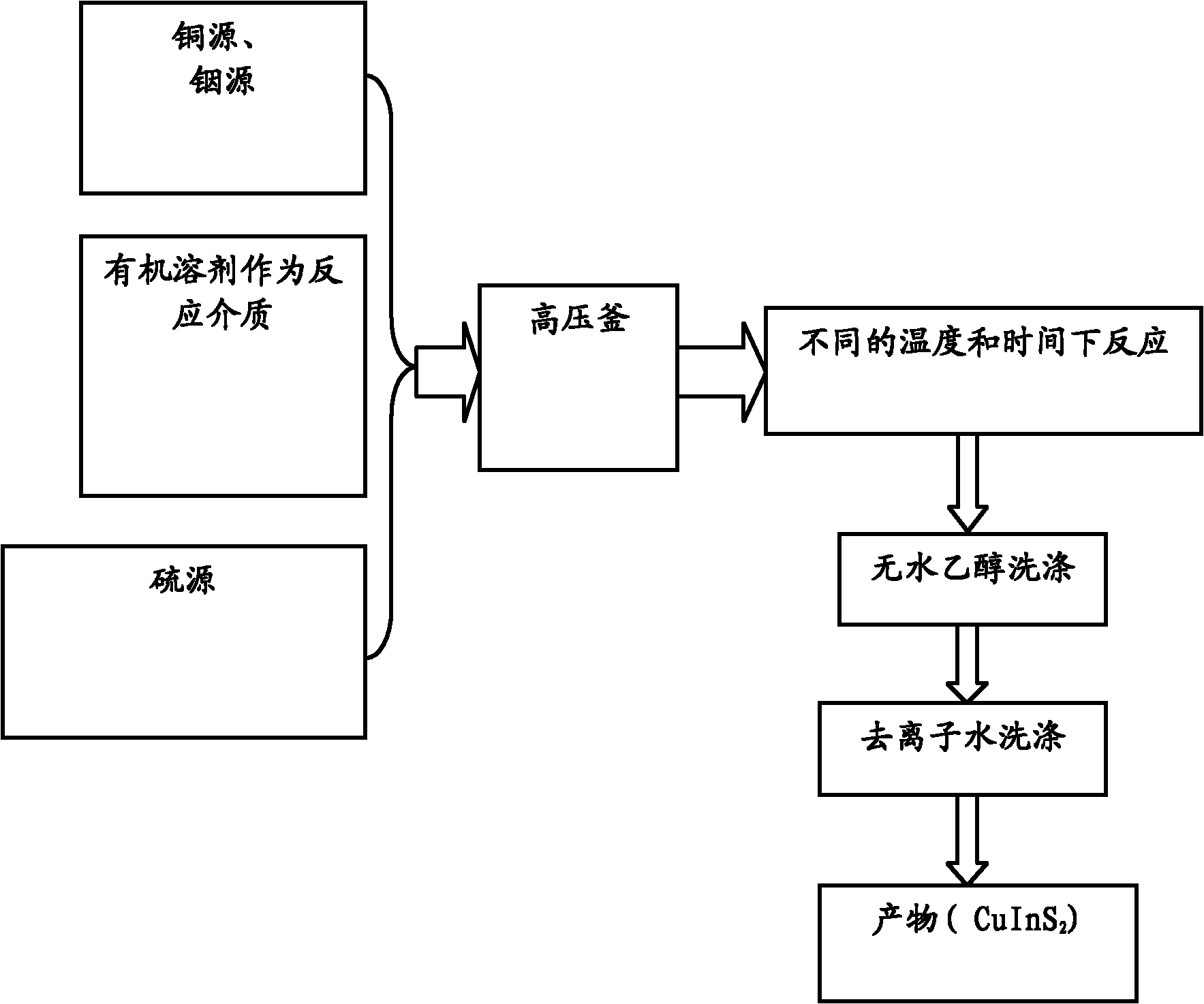

Preparation method of CuInS2 nanoparticles

InactiveCN102070184AThe synthesis steps are simpleSynthetic temperature is mildGallium/indium/thallium compoundsNanotechnologyCysteineHigh pressure

The invention relates to a method for preparing CuInS2 nanoparticles by solvent thermosynthesis using biomolecules, which comprises the following concrete steps: firstly, preparing a copper source solution, then adding an indium source into the solution, evenly mixing, and adding a sulfur source into the mixed solution; dropwise adding an inorganic alkaline solution to regulate the mixed solution to be weakly alkaline, and evenly stirring; and finally, putting the solution in a high-pressure reaction kettle, reacting at constant temperature for a period of time, cooling, washing with a solvent, and drying to obtain the CuInS2 nanoparticles. By using nontoxic biomolecule L-cysteine as the sulfur source, the invention avoids the emission of toxic gas and lowers the technique cost. The L-cysteine can be used as both a sulfur source and a guide agent for reaction, is favorable for generating products with special structure and pattern and excellent photovoltaic properties, and develops a new way for synthesizing other semiconductor photovoltaic materials.

Owner:TONGJI UNIV

Catalyst used for direct preparation of light olefin from synthetic gas, preparation method and application thereof

InactiveCN103157489ALow priceLow costHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasAlkane

The invention relates to a catalyst used for direct preparation of light olefin from synthetic gas, a preparation method and an application thereof. According to the invention, a parallel flow precipitation method is used to highly disperse Fe and auxiliary agents on surfaces of self-made alkaline carriers, and thus a catalyst load is low, a preparing technology is simple and a cost is lower than that of product with a same type. When the catalyst is used for direct preparation of the light olefin from the synthetic gas, a CO conversion rate can reach 75-85 % under a one-way catalytic condition of the synthetic gas, an alkene-alkane ratio can reach 4.5-6.0 in organic gas products, an alkene weight is 50-60 % and more than 98% of the liquid product is water. The catalyst is good in abrasion resistance and pressure resistance, and can be used for slurry beds and fixed beds. A reaction technology of the catalyst is that the temperature is 200-500 DEG C, a pressure is 0-5 MPa, and an air speed of the synthetic gas is 600-2400 <-1>.

Owner:SHANXI LUAN MINING GRP +1

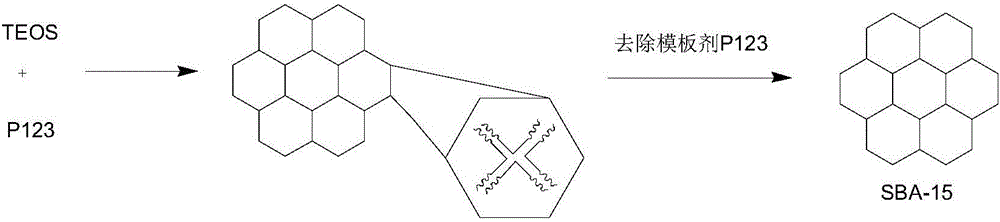

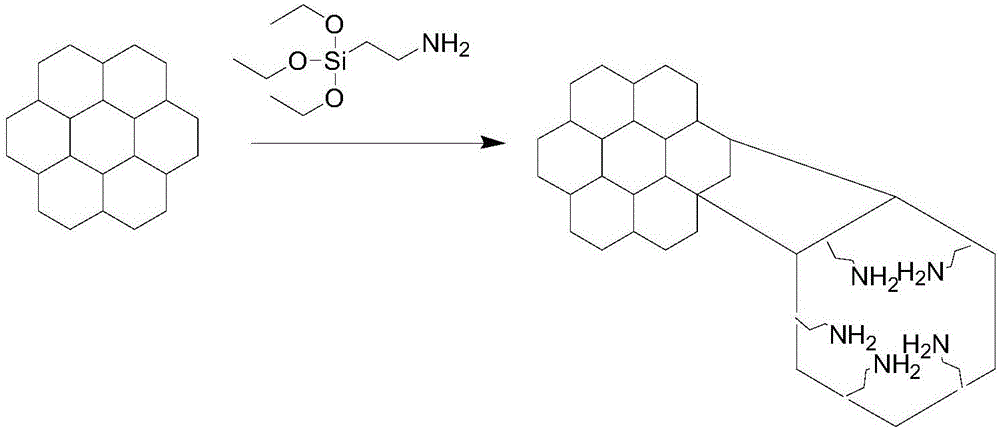

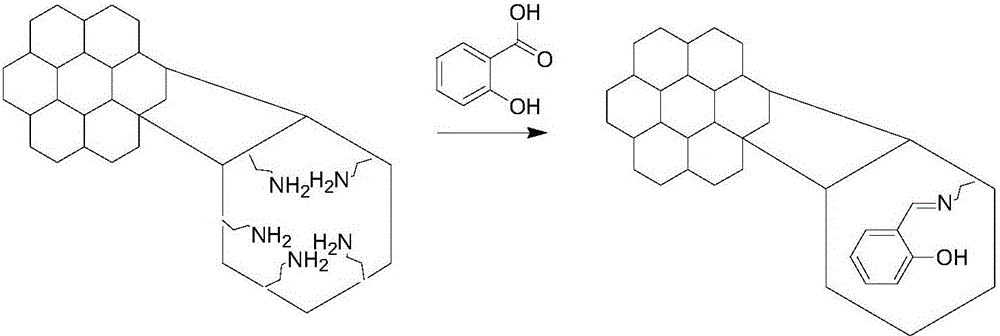

Synthesis technology of heavy metal adsorbent

InactiveCN106732461AIncrease acidityImprove mechanical stabilityOther chemical processesWater contaminantsSorbentAdsorption effect

The invention relates to a synthesis technology of a heavy metal adsorbent. The technology comprises the following steps: stirring a triblock copolymer P123 adopted as a template and ethyl orthosilicate as a silicon source in an acidic medium at room temperature, crystallizing the obtained solution, calculating obtained crystals to synthesize an ordered meso-porous material SBA-15; adding a functional group compound to the SBA-15 to carry out primary modification in order to generate an amino group and / or mercapto group modified SBA-15; and adding a compound which can react with the amino group and / or the mercapto group to the primary modified SBA-15 to carry out secondary modification in order to obtain hydroxyl modified SBA-15. Reaction conditions for synthesizing pure silicon SBA-15 are mild, the reaction is carried out at room temperature, the obtained SBA-15 has thick hole walls, the mechanical stability and the hydrothermal stability of a meso-porous molecular sieve skeleton structure are improved, and the hydroxyl, amino and mercapto modified SBA-15 improves the adsorption effect and the selectivity of heavy metal ions.

Owner:上海泰坦科技股份有限公司

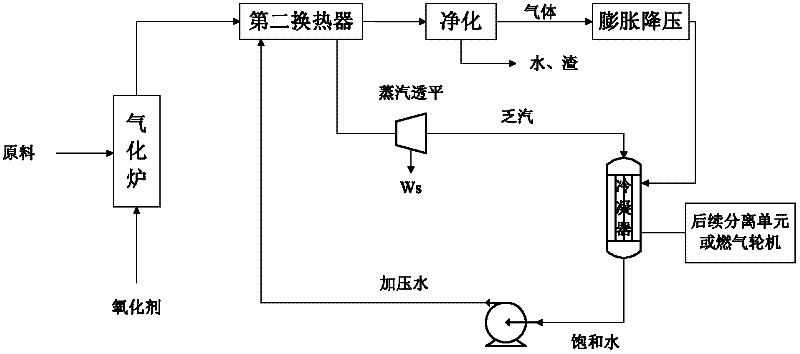

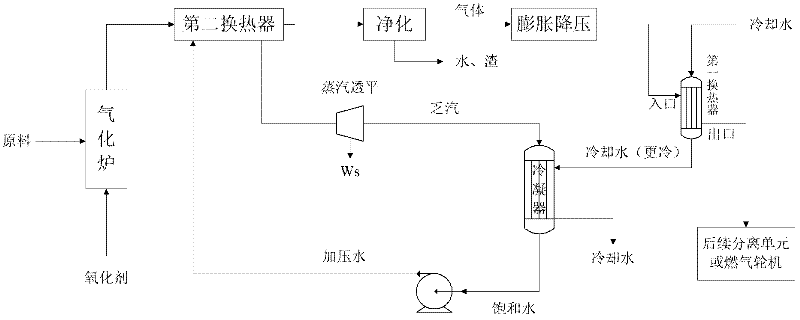

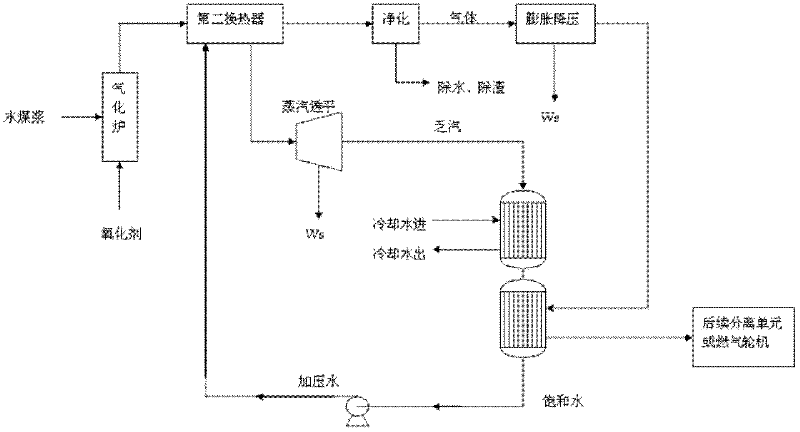

Power generation method, and device for gasified production of energy products and thermal power generation

ActiveCN102518489AImprove power generation efficiencyMore clean electricitySteam regenerationSteam useGeneration processEnergy products

The invention provides a power generation method, comprising a step of condensing exhausted steam generated in the power generation process, wherein a heat exchange operation is directly or indirectly carried out between the exhausted steam and gas obtained after expanded depressurization. The invention further provides a device for gasified production of energy sources and thermal power generation. The device comprises an expansion depressurization device and a condenser, wherein the expansion depressurization device comprises an expansion depressurization inlet for receiving gas to be subjected to an expanded depressurization operation, and an expansion depressurization outlet for discharging the gas subjected to the expanded depressurization operation; and the condenser comprises a first heat exchange channel in which a cooling medium with the refrigerating capacity of the gas subjected to the expanded depressurization operation enters, and a second heat exchange channel in which the heat exchange operation is carried out between the exhausted steam generated in the power generation process and the cooling medium. According to the method and the device disclosed by the invention, the refrigerating capacity generated by the gas subjected to the expanded depressurization operation is used, so that the temperature of the exhausted steam is reduced below an environmental temperature, therefore the pressure energy of the gas is sufficiently used, and the power generation efficiency of turbine power generation equipment is improved.

Owner:ENN SCI & TECH DEV

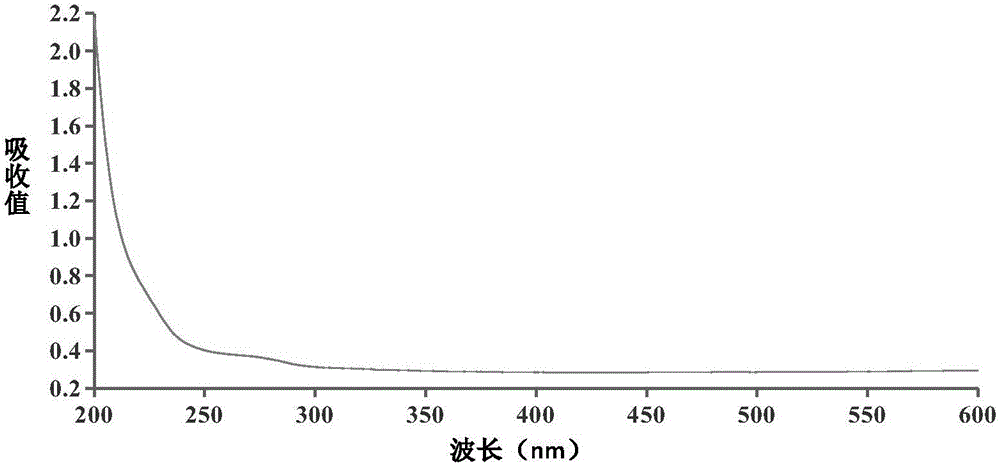

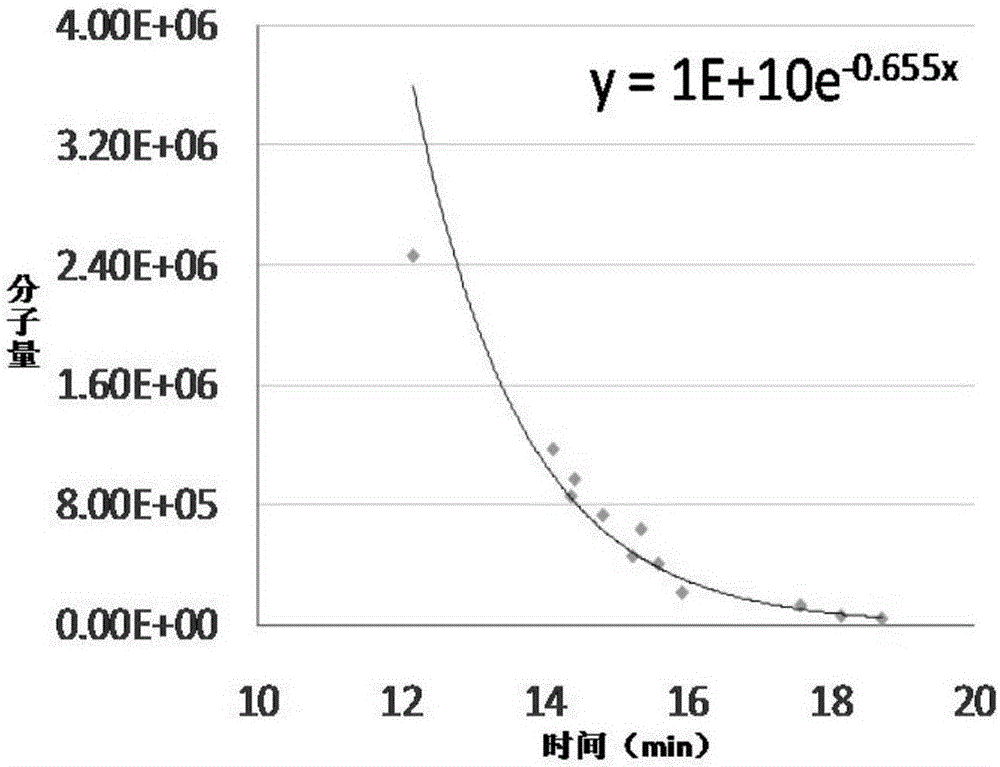

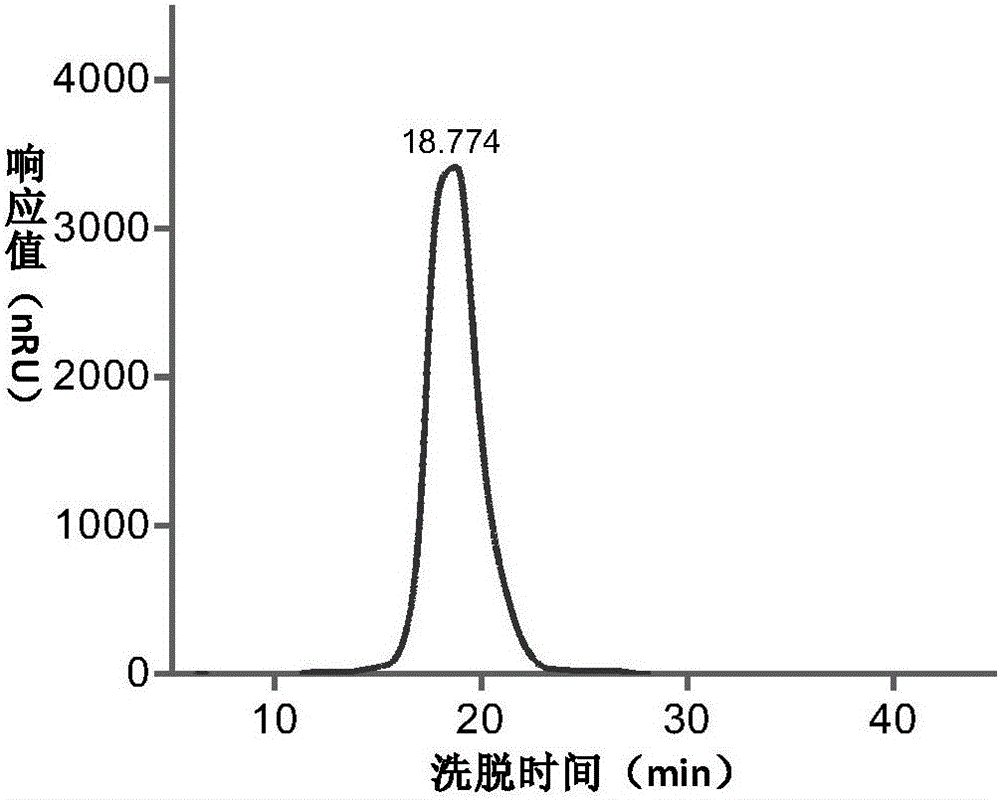

Lactobacillus plantarum exopolysaccharide and preparation method thereof

InactiveCN105821093AHigh purityHigh yieldMicroorganism based processesFermentationCross-linkPurification methods

The invention provides a lactobacillus plantarum exopolysaccharide. According to the exopolysaccharide, sugar units in the molecular structure are only xylose and galactose, the galactose accounts for 98%, and the exopolysaccharide belongs to a lactobacillus plantarum exopolysaccharide of a brand new structure. Meanwhile, the invention provides a method for preparing the exopolysaccharide. The method comprises the following steps: precipitating polysaccharides in lactobacillus plantarum fermentation solution by ethanol, dialyzing to remove small molecules, removing nucleic acid and protein impurities by the enzymolysis methods; precipitating impurity proteins by trichloroacetic acid, performing solid-liquid separation, taking the supernatant, and performing dialysis, thereby obtaining the purified target polysaccharide. According to the method, due to the property of the target polysaccharide and impurity component design process parameters of lactobacillus plantarum fermentation solution, the temperature and pH conditions are mild, purification methods capable of possibly breaking polysaccharide cross-linked bonds such as ultrafiltration are avoided, and integrity of polysaccharide glycosidic bonds and secondary structures is effectively guaranteed. The polysaccharide prepared by the method is high in purity and yield and lays a foundation for subsequent performance analysis and industrial application.

Owner:NANCHANG UNIV

Industrial production method of acrylonitrile

ActiveCN102659625AIncrease device functionFunction increaseCarboxylic acid nitrile preparationOrganic compound preparationWater vaporGas phase

The invention provides an industrial production method of acrylonitrile, which comprises that the air, propylene and ammonia are subjected to ammoxidation inside a reactor and generate a reaction gas containing the acrylonitrile; the reaction gas enters a first tower and shock cooling, neutralization and cooling are achieved; the reaction gas which is subjected to shock cooling, neutralization and cooling enters a second tower and the water absorbs organic materials contained in the reaction gas; the water absorbing liquid enters a third tower, the acrylonitrile, hydrocyanic acid and water vapor steamed out by the third tower are subjected to condensation, and then separation of an aqueous phase and an organic phase is achieved in a quantizer of the third tower; the water phase inside the quantizer of the third tower are delivered to the third tower; the water phase introduced from a last piece of tower plates of a tower kettle of the third tower is subjected to heat exchange and then serves as absorbing water of the second tower; a gas phase containing acetonitrile is extracted from the side lines of the third tower and sent into a fourth tower and a rough acetonitrile product is obtained; and the organic phase in the quantizer of the third tower enters a fifth tower and a sixth tower sequentially and hydrocyanic acid and a acrylonitrile product are respectively obtained. According to the method, the reliability of a device is improved and the energy utilization is high.

Owner:CHINA TIANCHEN ENG +3

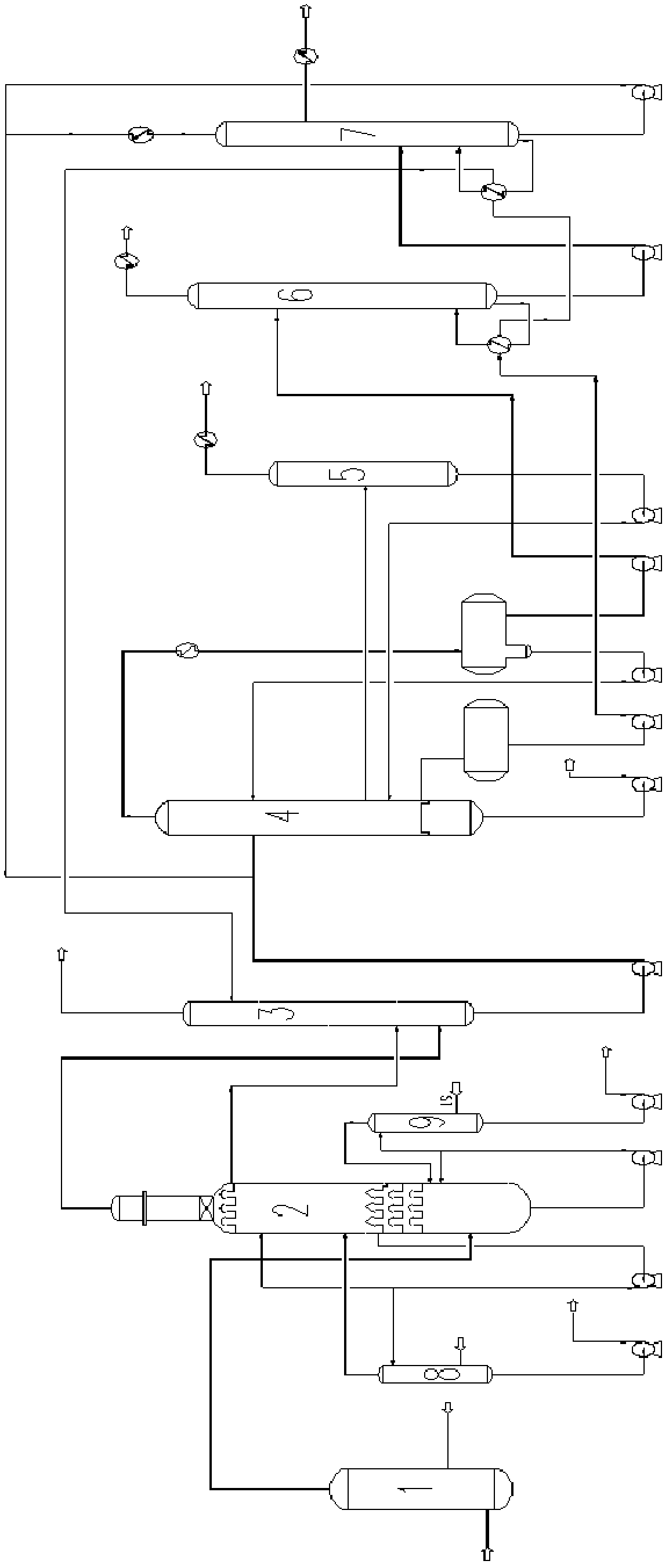

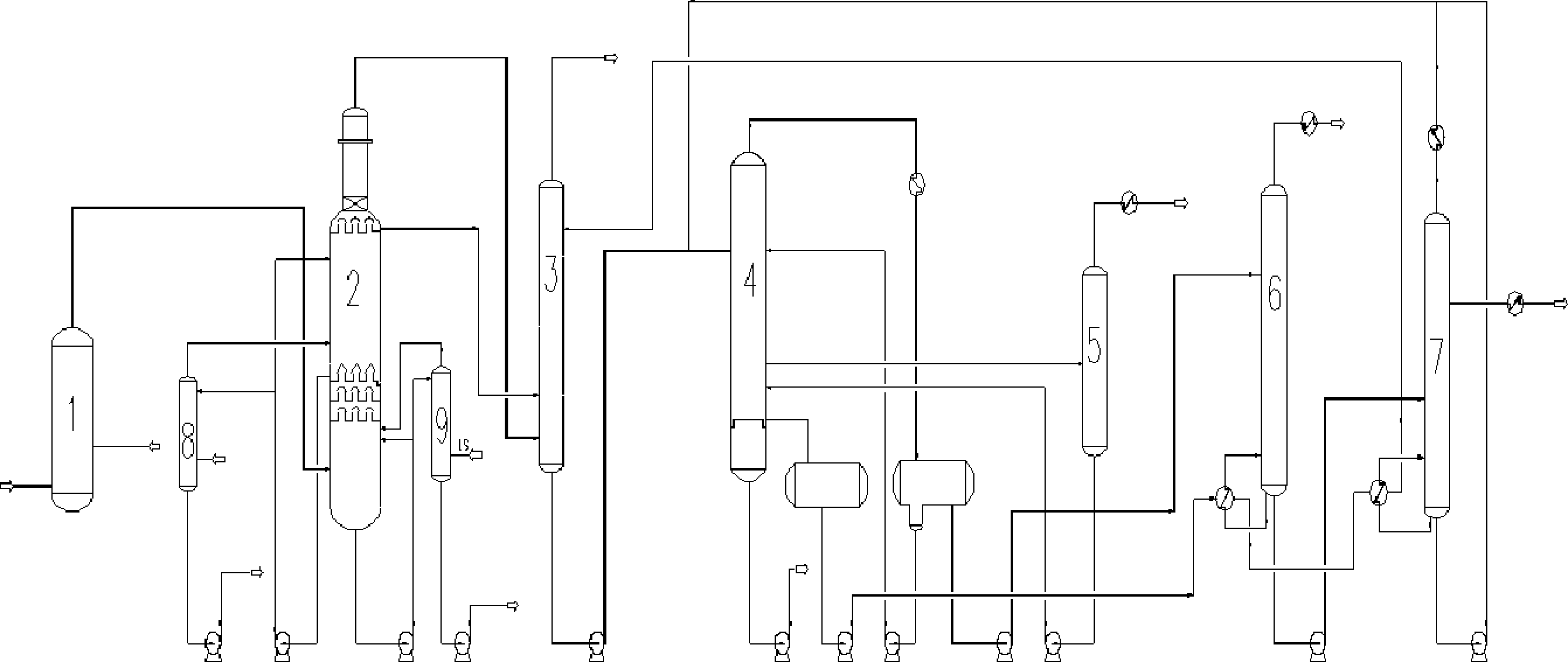

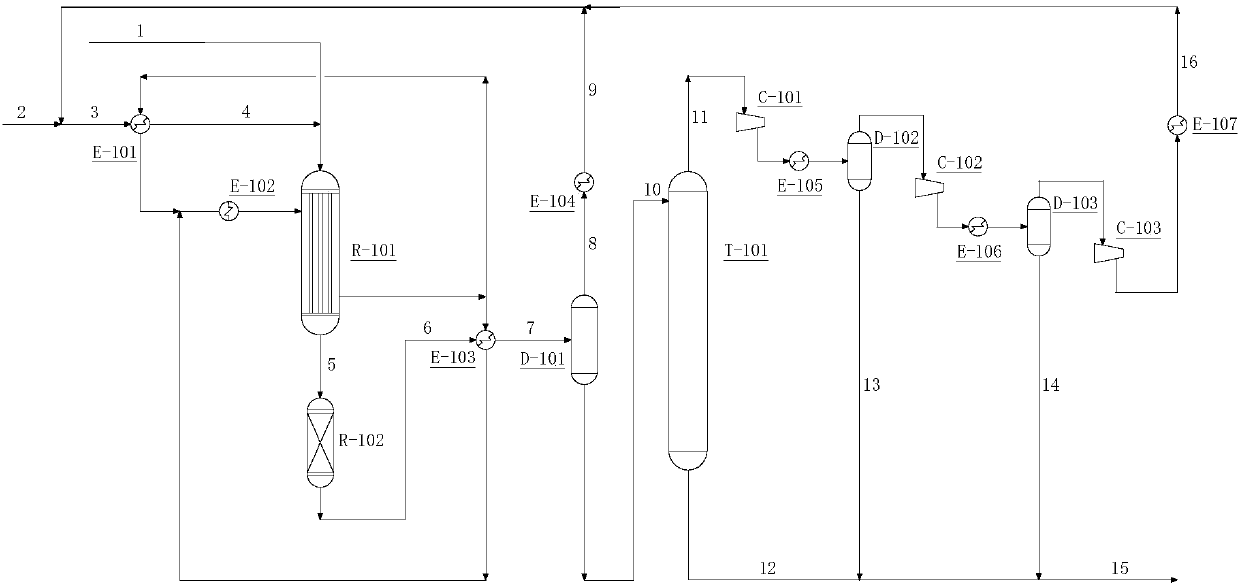

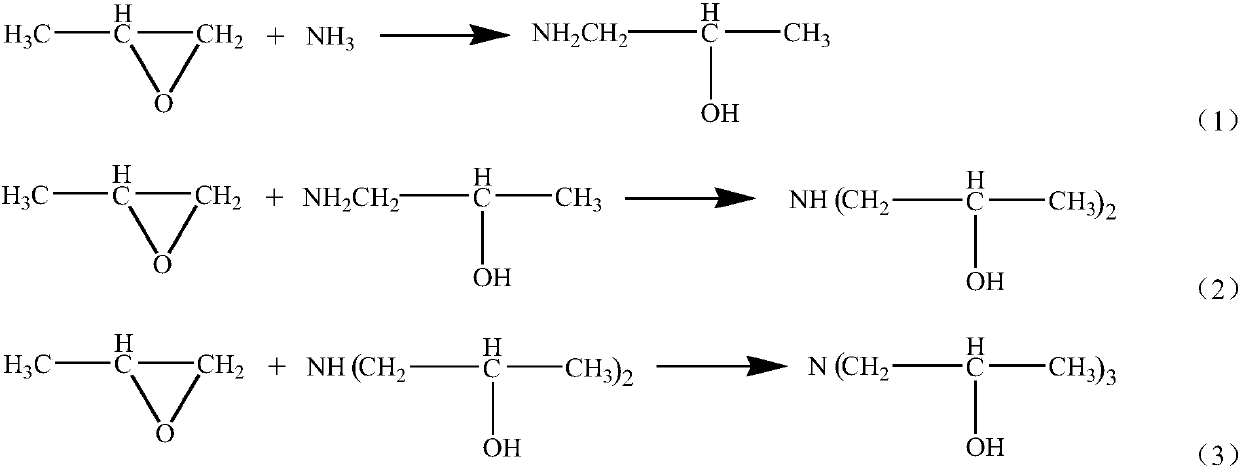

Method for producing isopropanolamine by liquid ammonia process

ActiveCN109748805AGuaranteed conversionReduce volumeOrganic compound preparationAmino-hyroxy compound preparationHigh energyTower

The invention relates to a method for producing isopropanolamine by a liquid ammonia process, mainly solving the problems such as high device investment, high energy consumption in dehydration and many by-products due to the fact that water is used as a catalyst in the prior art. The method has the advantages that anhydrous liquid ammonia and propylene oxide are used as raw materials for reaction,a tubular fixed bed reactor and an adiabatic fixed bed reactor are provided to ensure complete conversion of the propylene oxide, and the tubular fixed bed reactor removes heat of the hot water preheated reaction raw materials and reaction products under reduced pressure through heat removal of circulating hot water, so that most of reaction heat can be recycled; most of ammonia of the reaction products is recycled through a flash tank, and residual ammonia is recycled by an ammonia stripping tower with an compressor at the top; few by-products are generated, equipment investment and device energy consumption can be reduced, and the method can be applied to industrial production of the isopropanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

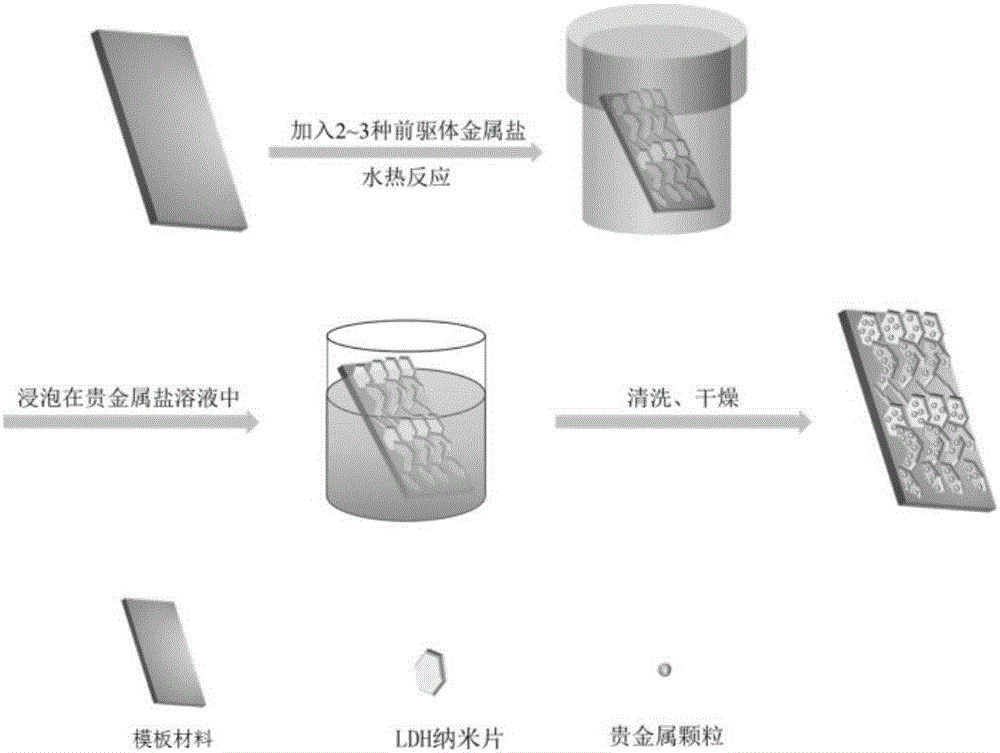

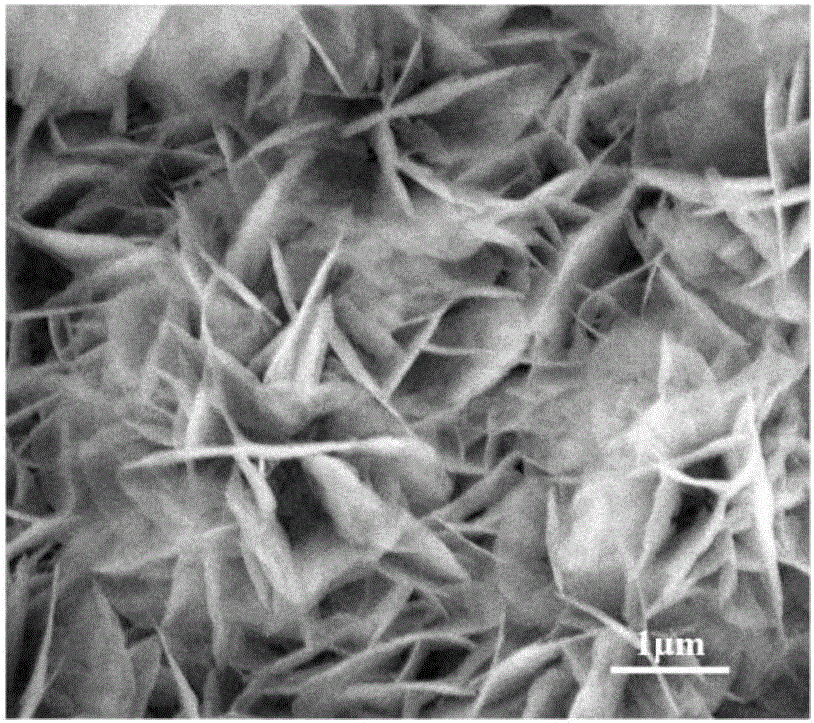

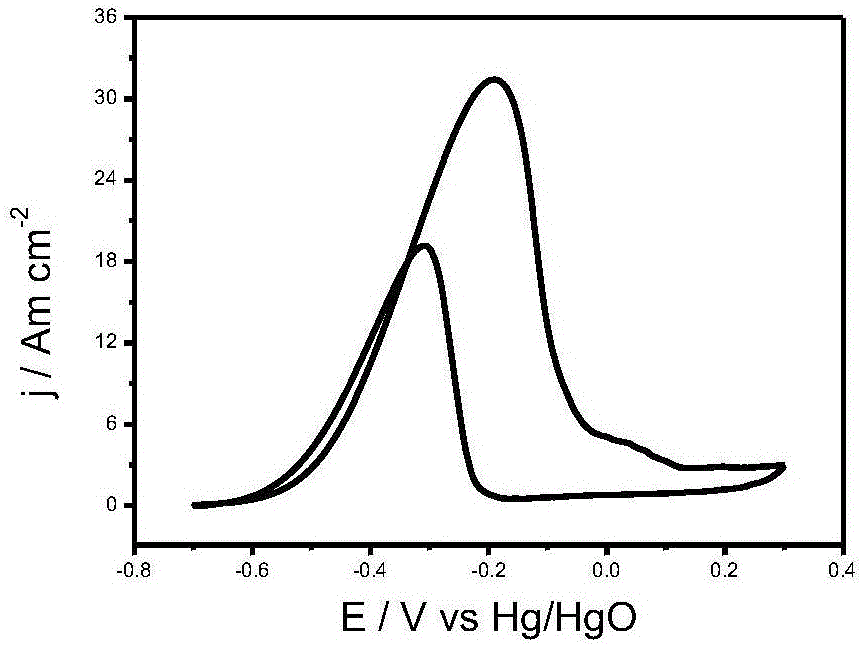

Noble-metal/vertical-grown layered-double-hydroxide (LDH) nanosheets for methanol fuel-cell catalyst and preparation method of noble-metal/vertical-grown LDH nanosheets

ActiveCN106784881AGood rigid structureLarge specific surface areaCell electrodesFuel cellsMethanol fuelHydrotalcite

The invention discloses noble-metal / vertical-grown layered-double-hydroxide (LDH) nanosheets for a methanol fuel-cell catalyst and a preparation method of the noble-metal / vertical-grown LDH nanosheets. The method comprises the steps: firstly, washing a template required for LDH growth, and then, carrying out etching; then, putting the template material into a mixed solution of two or three precursor metal salts required for LDH growth by using a hydrothermal reaction, adding a certain mass of cetyl trimethyl ammonium bromide (CTAB) into the solution, carrying out a reaction at a certain temperature, and then, carrying out cooling, so as to obtain LDH nanosheets which are vertically grown on the surface of the template material; finally, placing the obtained vertically-grown LDH nanosheets into a solution of one or more noble metal salts, of which the pH is adjusted to be in a certain range, and carrying out a redox reaction, thereby obtaining the noble-metal / vertical-grown LDH nanosheets. According to the noble metal support prepared by using the method disclosed by the invention, the LDH nanosheets are vertically grown on the surface of the template material, so that a larger specific surface area is provided for the loading of a noble metal catalyst, and LDH grown on the template material has a better rigid structure.

Owner:QINGDAO UNIV

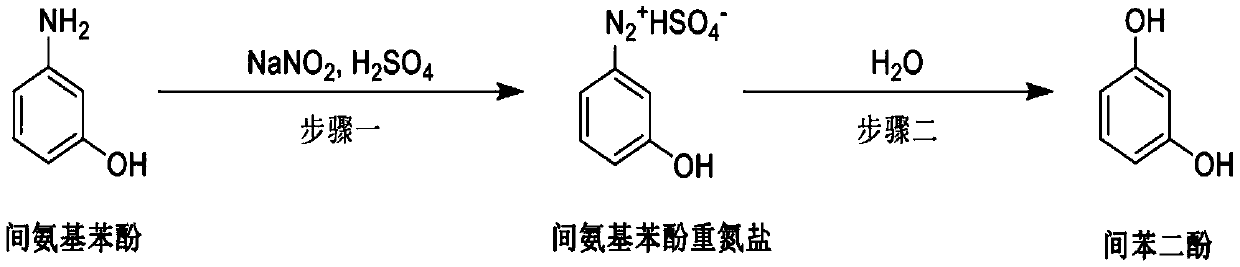

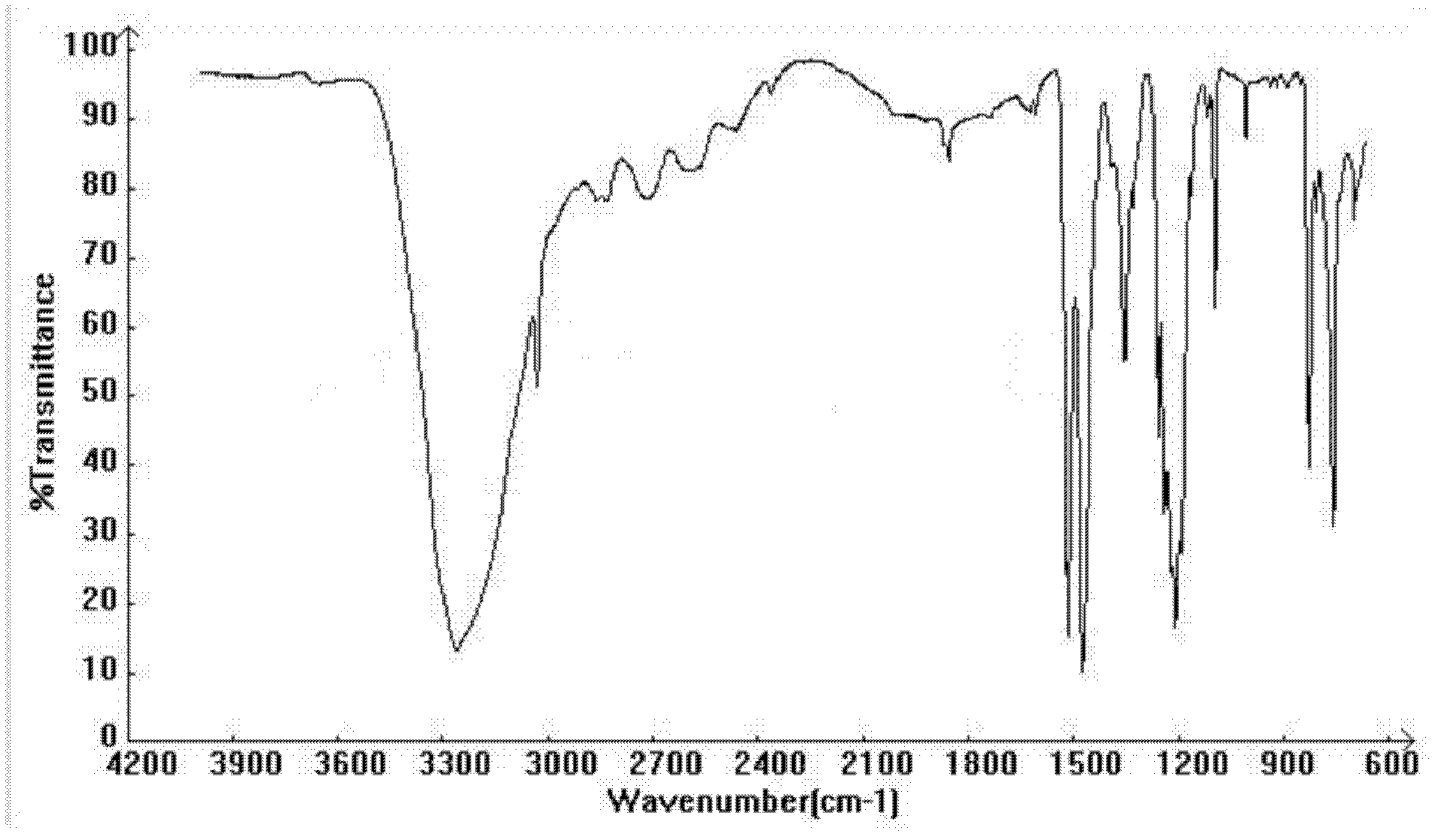

Preparation method of resorcinol

PendingCN111592447ALess side effectsHigh yieldOrganic chemistryOrganic compound preparationOrganic solventHydrolysis

The invention belongs to the field of chemical engineering, and particularly relates to a preparation method of resorcinol, which comprises: (1) carrying out a diazotization reaction on m-aminophenoland a sodium nitrite solution in a dilute solution of concentrated sulfuric acid to generate m-aminophenol diazonium salt, with the diazotization reaction temperature being 0 DEG C or below; (2) carrying out a hydrolysis reaction on the m-aminophenol diazonium salt in the presence of an organic solvent and water to obtain a resorcinol crude product, with the volume ratio of the water to the organic solvent being (0.5-1.5):(4-6); (3) carrying out post-treatment on the resorcinol crude product to obtain a product resorcinol, wherein the post-treatment step sequentially comprises: (i) an extraction stage; (ii) a vacuum distillation stage; (iii) a pickling stage; and (iv) refining, washing and drying stages. By using the method disclosed by the invention, the resorcinol yield can be greatly improved.

Owner:INNER MONGOLIA SHENG TANG INT MONGOLIAN MEDICINE RES INST CO LTD +1

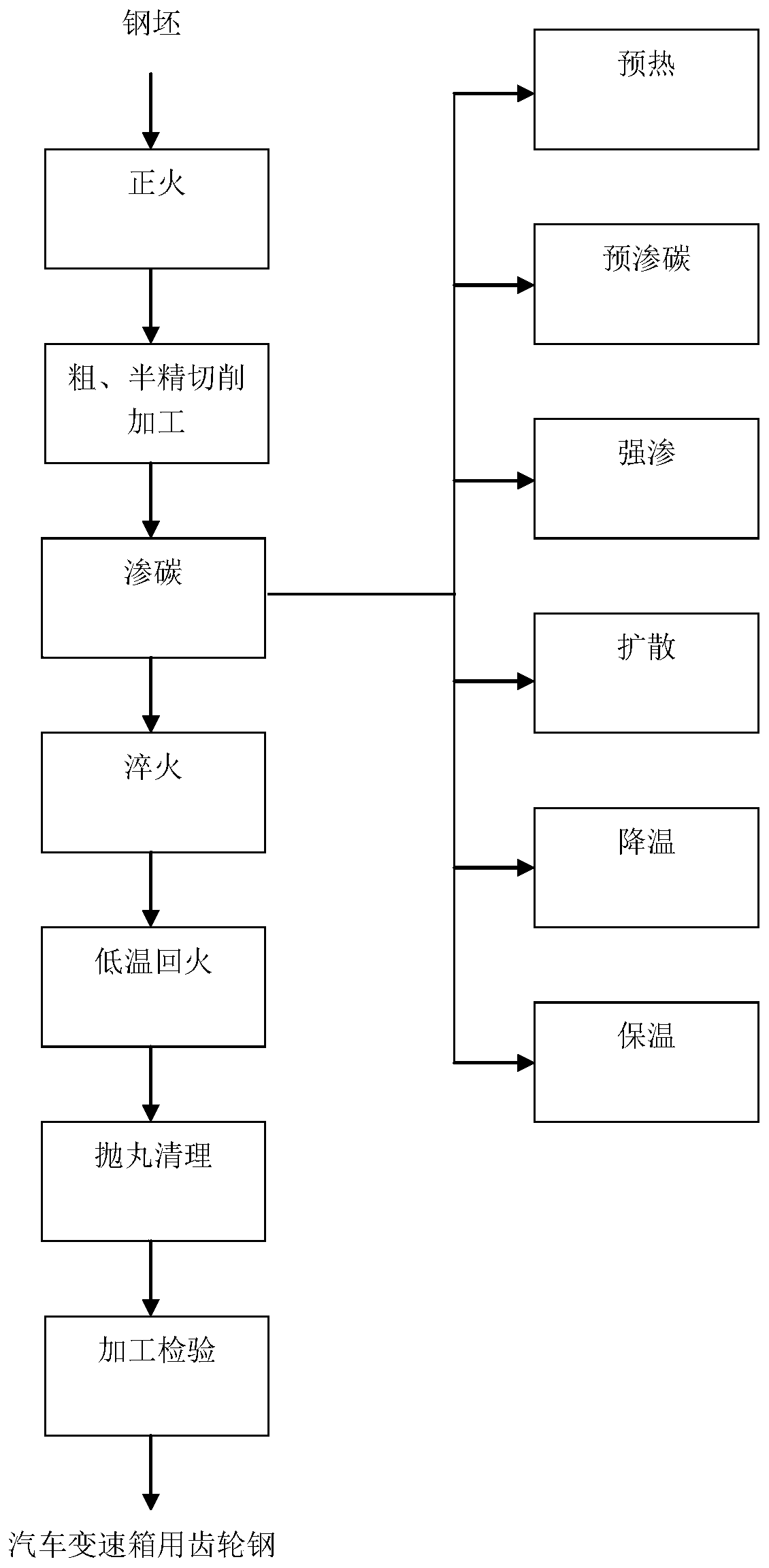

Heat treatment process of gear steel for automobile gearbox

InactiveCN111500834AImprove mechanical propertiesImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialTempering

The invention provides a heat treatment process of gear steel for an automobile gearbox. The heat treatment process comprises the steps of normalizing, coarse semi-finished cutting processing, carburizing, quenching, low temperature tempering, shot blasting and processing inspection; in the carburizing process, preheating and pre-carburizing processes are increased to clean impurities, oil stainsand the like attached to the surface of a billet, so that the internal temperature and external temperature of the billet is the consistent, a basis is laid for further temperature rise, heating timeis shortened, and energy consumption is reduced; the temperature and carburizing time in the carburizing process are controlled to obtain flat carbon concentration distribution, stress caused by carburizing heat treatment is reduced, and the mechanical property and wear-resisting property of the surface of the billet are effectively improved; and meanwhile, the billet ingredients, the heating temperature, heat preservation time, cooling speed and other process parameters are controlled, the billet is subjected to carbon potential rising and falling treatment, the process of normalizing, quenching and tempering is optimized, a production cycle is shortened, the energy consumption and production cost are reduced, and the heat treatment process is suitable for producing the gear steel for automobile gearboxes with various specifications.

Owner:江苏联峰实业有限公司

Synthesis method of hydroquinone

InactiveCN102351656BMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Synthesis method of hydroquinone

InactiveCN102351656AMild reaction conditionsIncrease conversion rateOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention relates to a synthesis method of hydroquinone. The method is characterized by comprising the following steps: carrying out catalytic oxidation on phenol and oxygen to generate a mixture of p-benzoquinone and o-benzoquinone, wherein a catalyst is copper and sodium complex salt; distilling to remove solvent, adding water in residual materials, and separating p-benzoquinone and o-benzoquinone by distillation; reducing separated p-benzoquinone with a reducing agent to obtain hydroquinone, filtering out hydroquinone crude product and recrystallizing so as to obtain hydroquinone crystal; and concentrating a mother liquid obtained by filtering out hydroquinone or catechol crude product to obtain an ammonium sulfate fertilizer. The synthesis method has simple process, mild reaction conditions and short reaction period, and the yield of hydroquinone in the product is larger than that of catechol.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Crude glycerin treatment and applications of the same in epichlorohydrin production

ActiveCN104591967ALow costReduce manufacturing costOrganic compound preparationHydroxy compound separation/purificationGlycerolHydrogen chloride

The present invention relates to a crude glycerin treatment and applications of the same in epichlorohydrin production. The present invention relates to a crude glycerin treatment method, which comprises: (a) adding hydrogen chloride gas to crude glycerin to precipitate insoluble solids; and (b) filtering to remove the precipitated solids to obtain the treated glycerin.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

Process for preparing bamboo-wood floor capable of repelling ants and mosquitoes

InactiveCN104859020AFully reveal the natural textureFull colorWood treatment detailsCane mechanical workingMaterials preparationZanthoxylum bungeanum

The invention discloses a process for preparing bamboo-wood floor capable of repelling ants and mosquitoes. The process includes the following steps: (1) material preparation; (2) rough milling; (3) cooking and carburization; (4) drying; (5) artificial selection; (6) finish milling; (7) splicing and pressing; (8) trying plane; (9) all-side slotting; (10) end face mortising; (11) soaking; (12) secondary drying; (13) polishing and carving; (14) painting. According to the process provided by the invention, zanthoxylum bungeanum and lavandula angustifolia ingredients permeate through the bamboo-wood floor; zanthoxylum bungeanum has the function of repelling ants, and lavandula angustifolia has the function of repelling mosquitoes, so that the bamboo-wood floor can prevent ants from boring and repel mosquitoes during the using process; in addition, the natural fragrance of lavandula angustifolia can emanate slowly and make the living environment more pleasant; the floor is coated with only one layer of varnish which is good in air permeability and transparency; under the condition of not affecting the function of repelling ants and mosquitoes, the natural textures and colors of the bamboo-wood are fully exposed, which are elegant and dignified.

Owner:安徽浩峯塑业有限公司

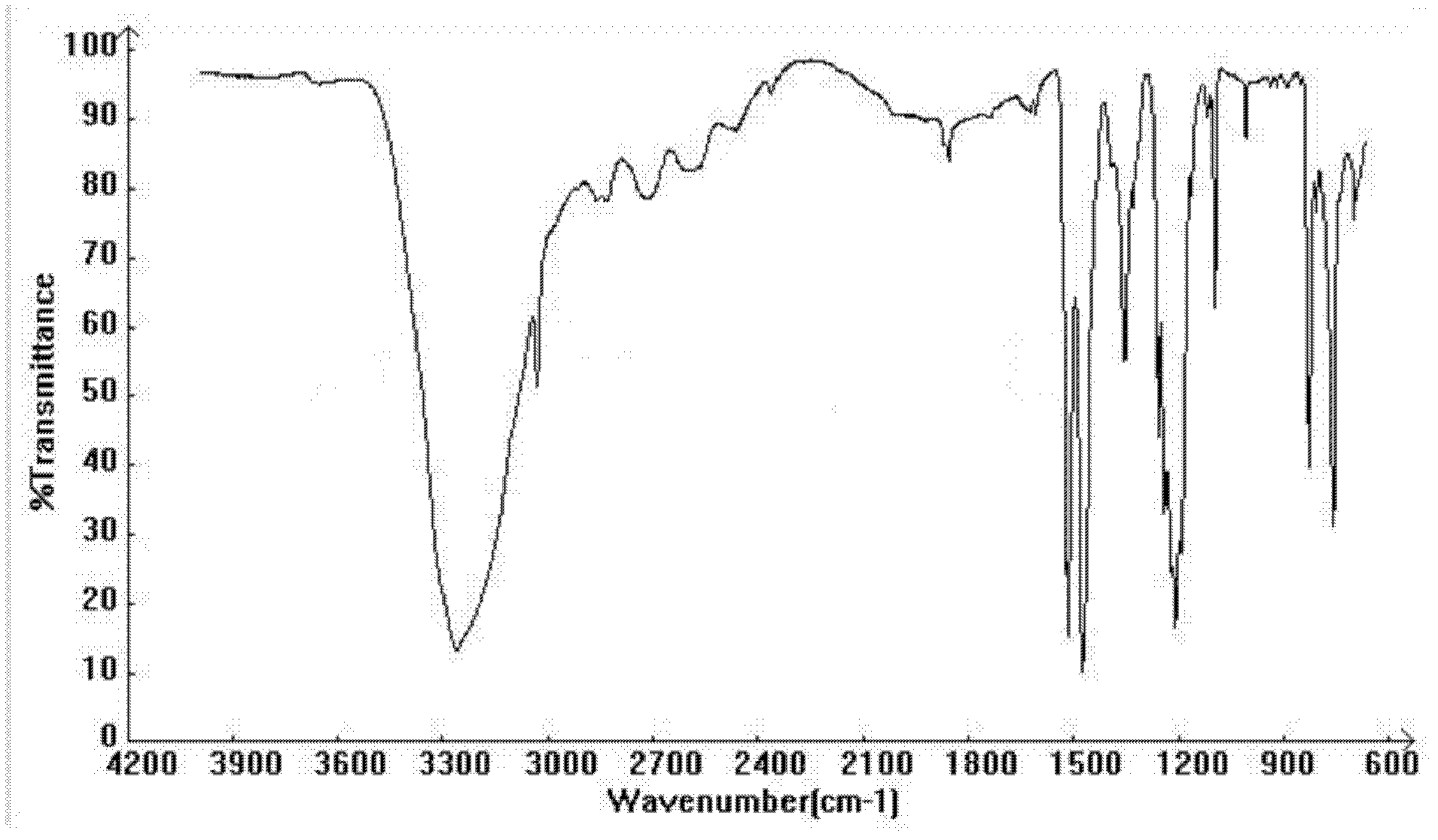

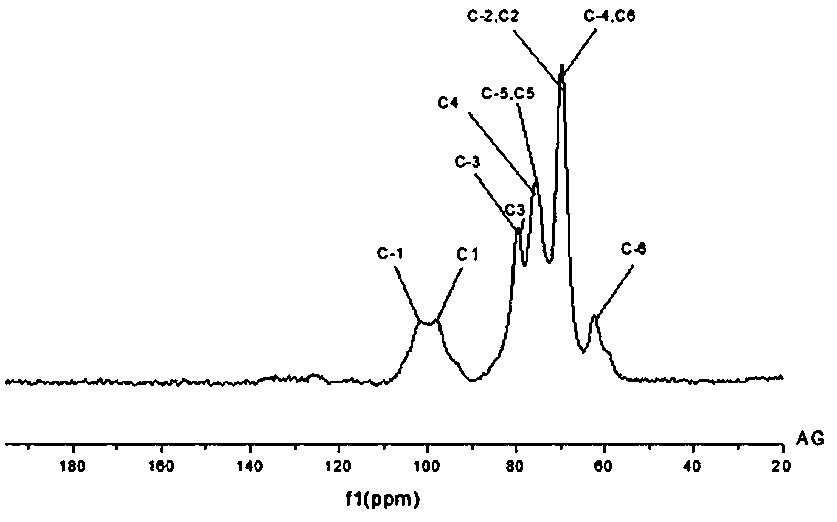

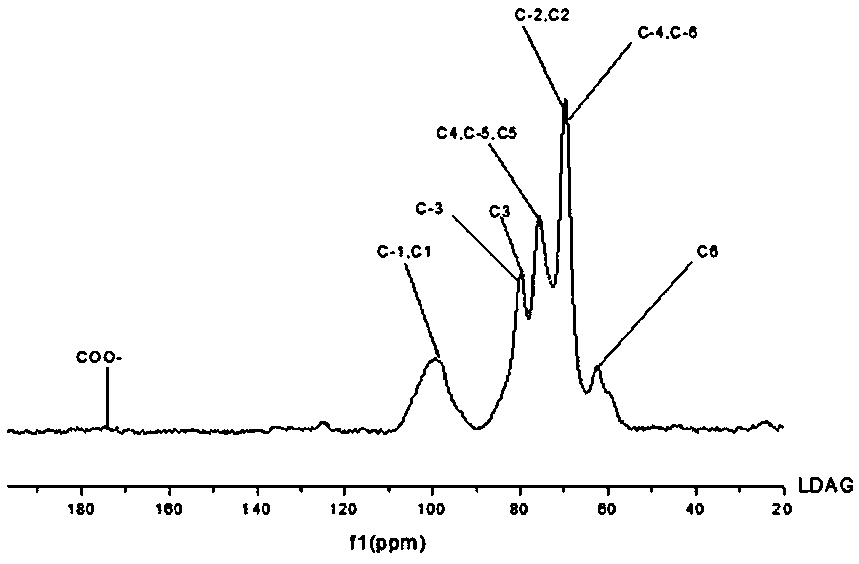

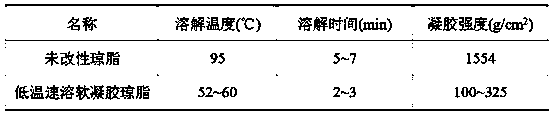

Processing method of low-temperature instant soft gel agar

The invention discloses a processing method of low-temperature instant soft gel agar and belongs to the field of food processing. Agar powder is used as a raw material, and the low-temperature instantsoft gel agar is obtained through agar powder humidity regulation and moisture balance, screw extrusion, powder making, alkali treatment, carboxymethylation reaction, neutralization, washing, dryingand smashing. The process conditions are mild, the technical method is simpler, the prepared modified agar is low in dissolution temperature, short in time and good in soft gel performance, the low-temperature instant soft gel agar can be dissolved at the temperature of 52-60 DEG C, the dissolution time is 2-3 minutes, and the gel strength is up to 100-325 g / cm<2>. The processing method is reasonable technologically, wide in product application range and good in expected economic and social benefits.

Owner:FUJIAN AGRI & FORESTRY UNIV

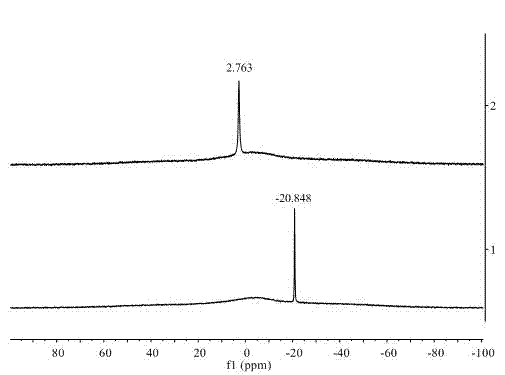

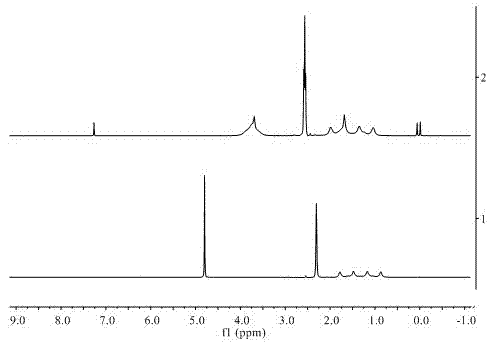

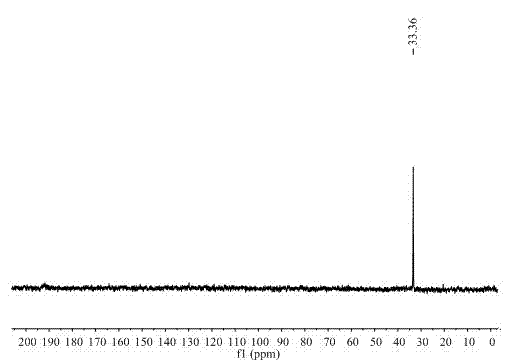

Preparation method of amino borane

InactiveCN103113397AHigh priceHigh yieldGroup 3/13 element organic compoundsOrganic solventChemical reaction

The invention relates to a preparation method of amino borane. According to the method, through taking ammonium salts and sodium borohydride as raw materials, taking an organic solvent as a reaction medium, and taking ethyl ether as a purification medium, methylamine borane is synthesized through common chemical reaction. The invention provides a method capable of synthesizing amino borane in the air, which provides great convenience for future industrial production and applications. The preparation method disclosed by the invention is simple in reaction method, low in cost and moderate in temperature; an operation of reaction can be performed at room temperature, and obtained products are high in purity and high in yield.

Owner:WUHAN UNIV

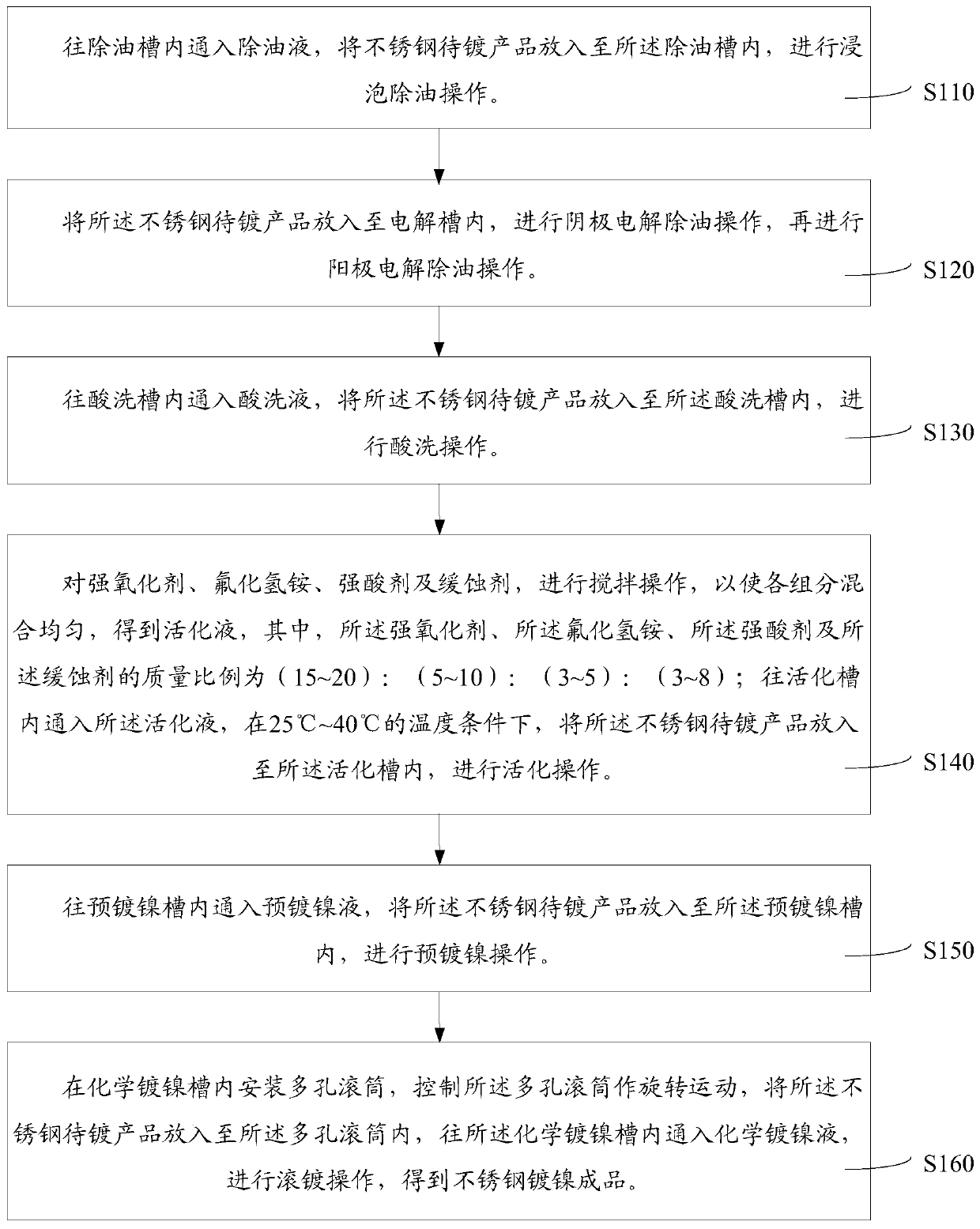

Stainless steel product barrel plating method and activating solution

ActiveCN110423995AAvoid corrosionImprove surface activityLiquid/solution decomposition chemical coatingHydrogen fluorideStrong acids

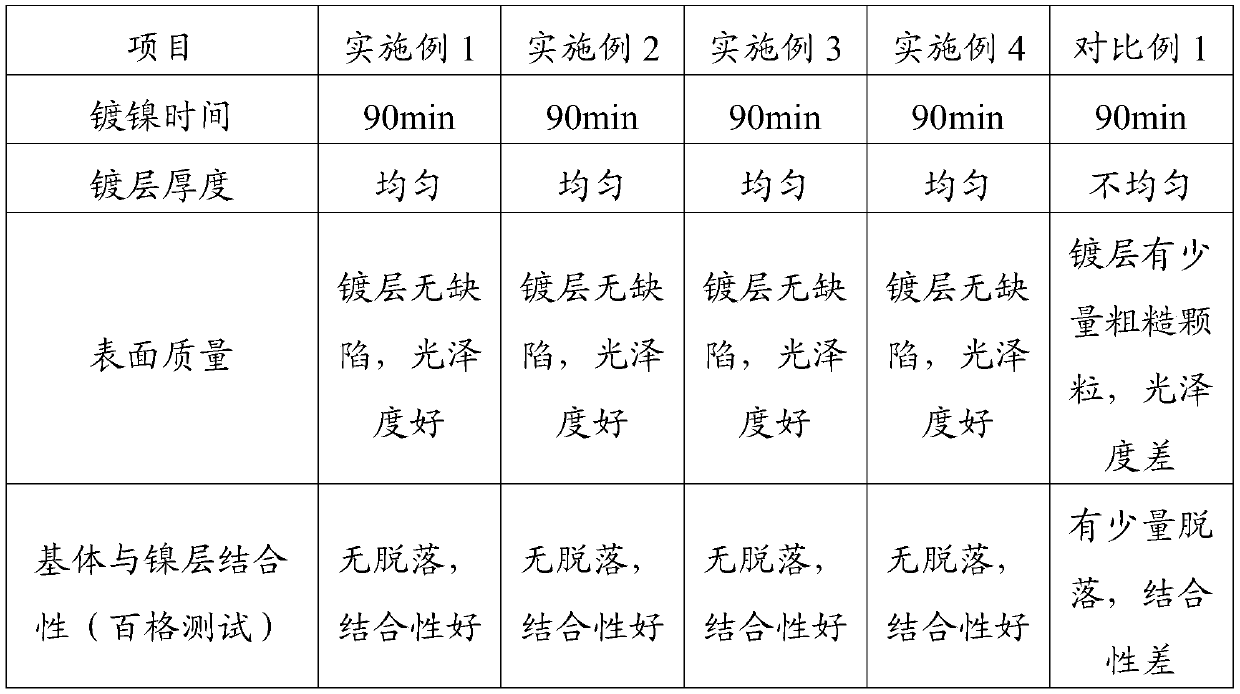

The invention relates to the field of chemical nickel plating methods and discloses a stainless steel product barrel plating method and an activating solution. The barrel plating method comprises thefollowing steps: soaking to deoil; electrolytically deoiling; pickling; stirring a strong oxidant, ammonium hydrogen fluoride, a strong acid agent and a corrosion inhibitor to uniformly mixing components to obtain the activating solution, wherein the mass ratio of the strong oxidant, ammonium hydrogen fluoride, the strong acid agent and the corrosion inhibitor is (15-20): (5-10): (3-5): (3-8); introducing the activating solution into an activating groove and putting a stainless steel to-be-plated product into the activating groove for activation; carrying out nickel preplating; and controllinga porous roller to rotate, putting the stainless steel to-be-plated product in the porous roller, and introducing a chemical nickel-plating solution into a chemical nickel-plating groove for barrel plating to obtain a stainless steel nickel plating product. According to the stainless steel product barrel plating method, the bonding property of a matrix and a nickel layer can be improved, and theplating thickness and the surface quality uniformity can be improved.

Owner:惠州市安泰普表面处理科技有限公司

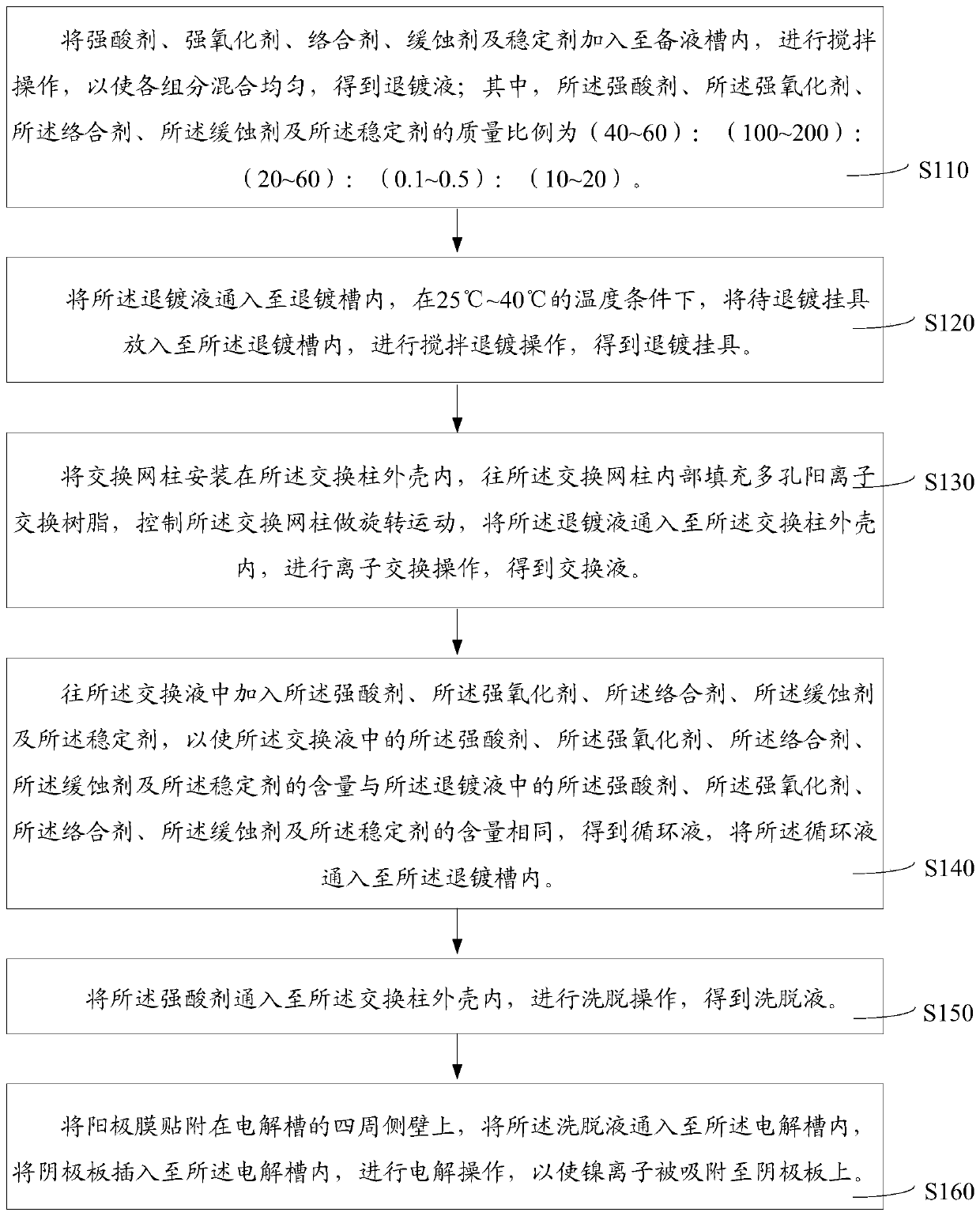

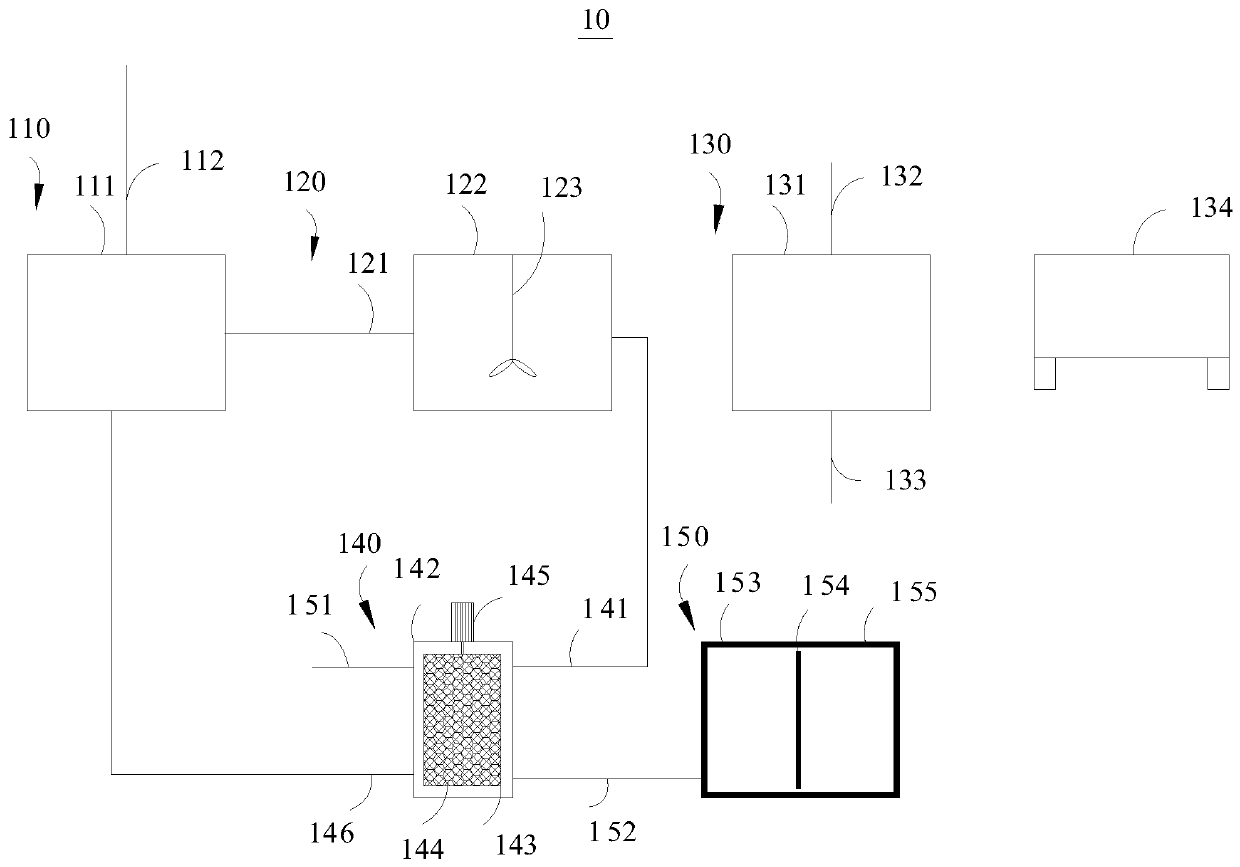

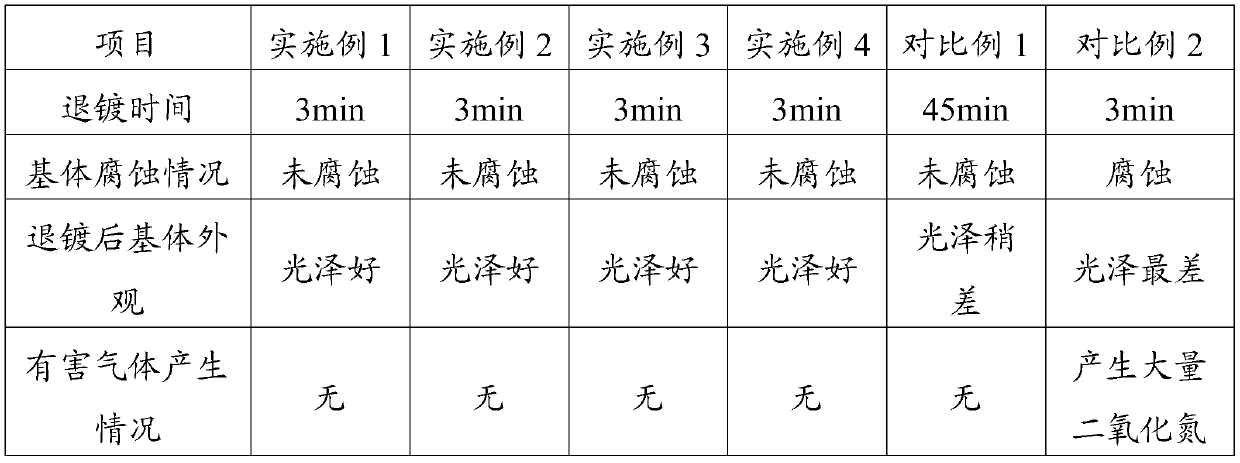

Method for removing nickel coating on rack and deplating solution

ActiveCN110512212AThe group ratio is reasonableHas strong oxidizing propertiesStrong acidsCorrosion inhibitor

The invention relates to the field of rack deplating methods, and discloses a method for removing a nickel coating on a rack and a deplating solution. The method comprises the following steps: addinga strong acid agent, a strong oxidant, a complexing agent, a corrosion inhibitor and a stabilizer into a liquid preparation tank, and carrying out stirring operation to uniformly mix all the components to obtain the deplating solution, wherein the mass ratio of the strong acid agent, the strong oxidant, the complexing agent, the corrosion inhibitor and the stabilizer is (40-60):(100-200):(20-60):(0.1-0.5):(10-20); and feeding the deplating solution into a deplating tank, placing the rack to be deplated into the deplating tank at the temperature of 25-40 DEG C, and carrying out stirring and deplating operation to obtain the deplating rack. Compared with the prior art, the method has the advantages that the nickel coating of the rack can be quickly removed after being soaked at normal temperature instead of heating and electrifying, the service life of the deplating solution is long, no corrosion is caused to a rack substrate, no harmful gas is generated, the cost can be saved, and the environment-friendly and economical purposes of social multi-requirements are met.

Owner:惠州市安泰普表面处理科技有限公司

Catalytic combustion reactor and process for removing hydrogen in tail gas

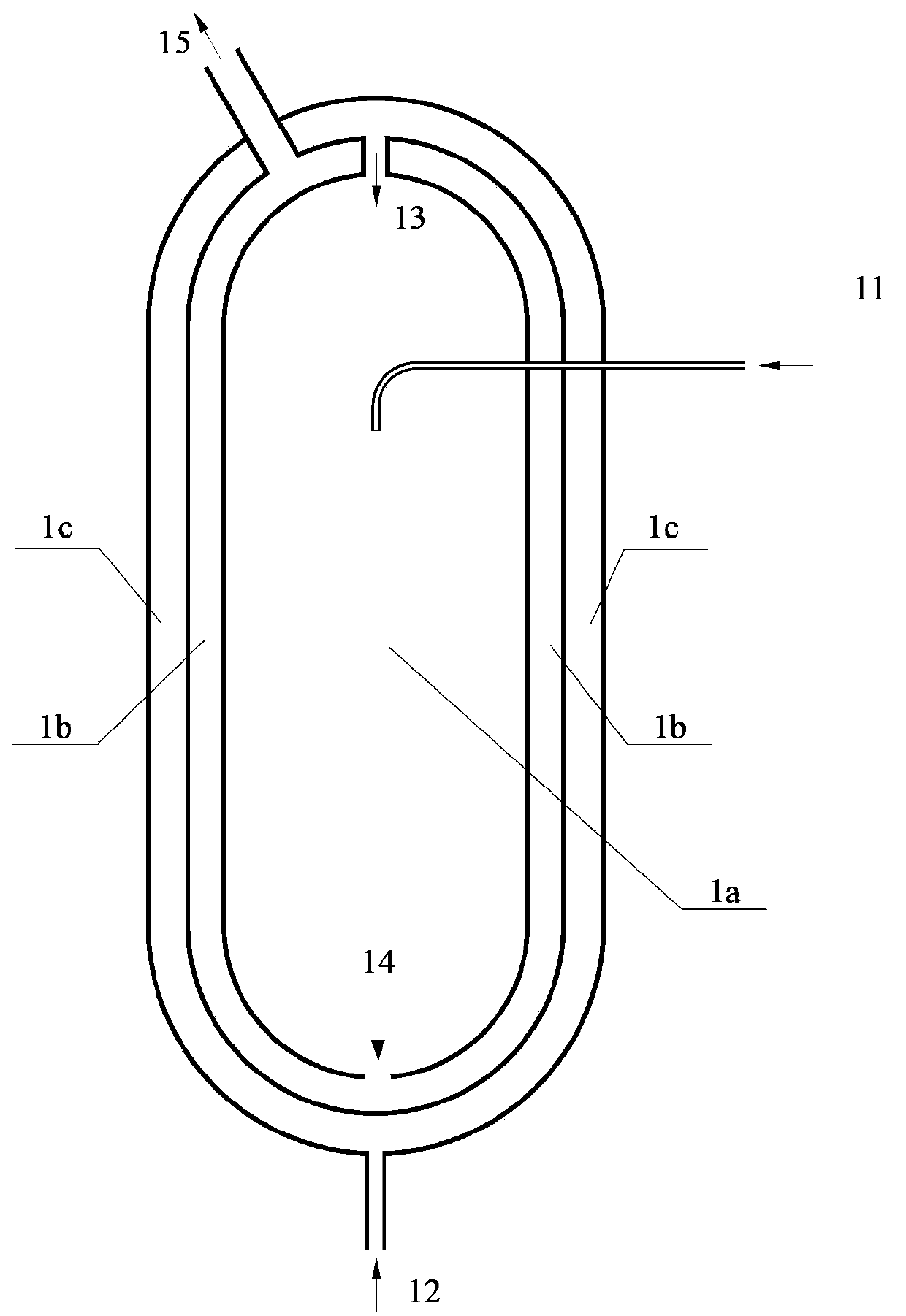

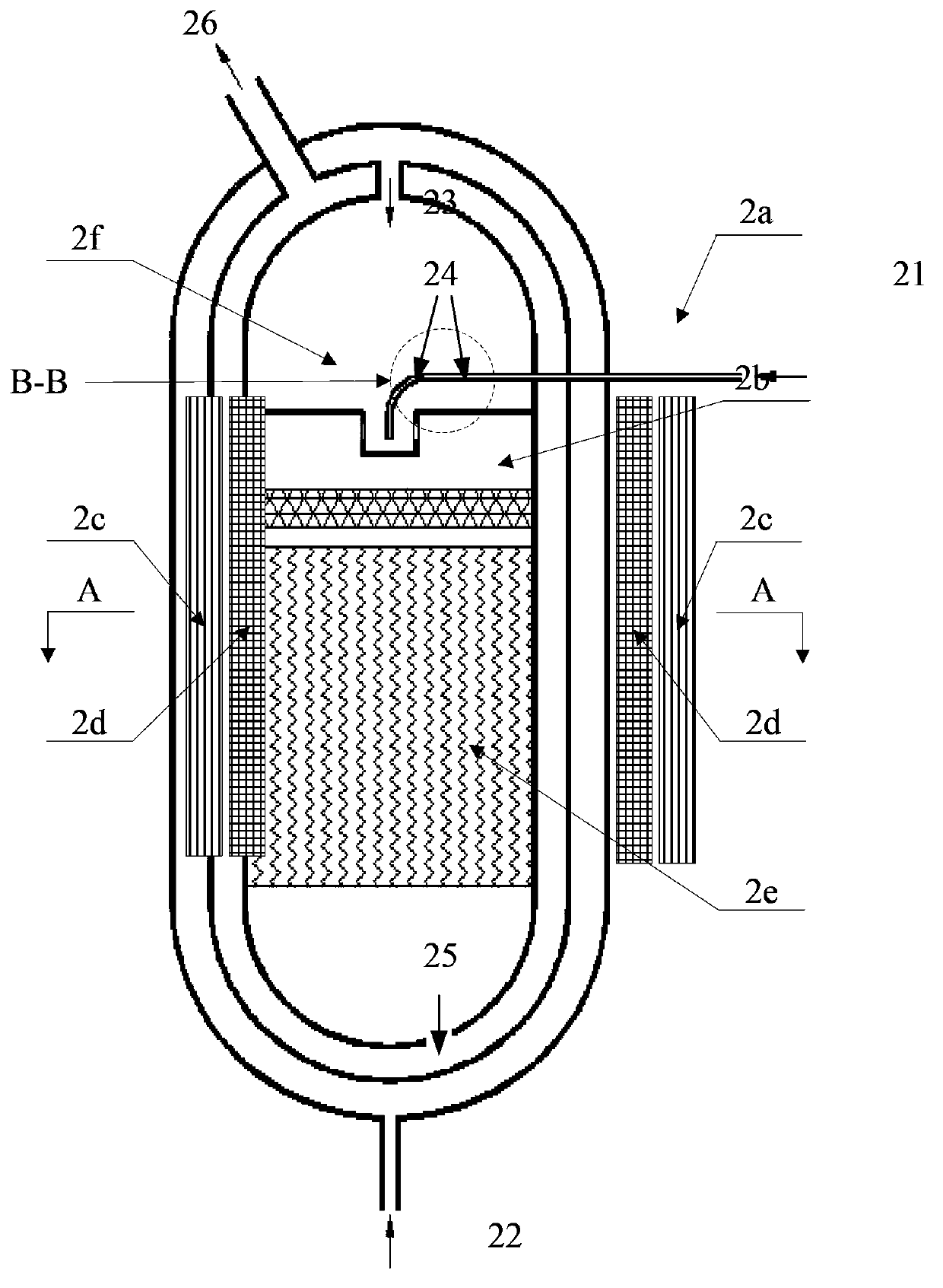

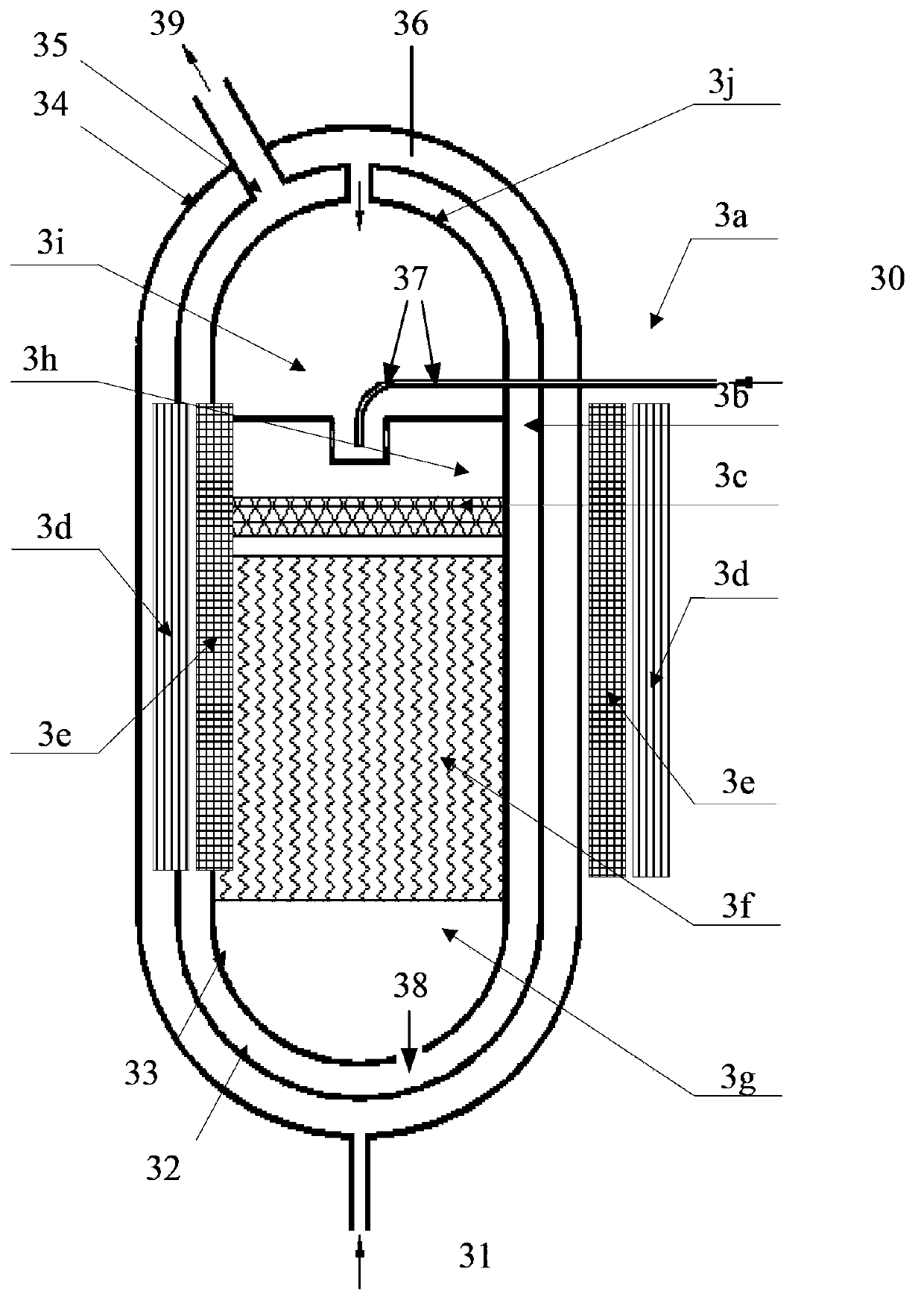

InactiveCN103968395AMild temperatureImprove energy efficiencyIncinerator apparatusExhaust gasChemistry

The invention relates to a catalytic combustion reactor and process for removing hydrogen in tail gas. The reactor comprises three cavities from center to outer sides. The center of the reactor is filled with catalyst for catalyzing the chemical reaction of gas containing hydrogen and the air, so that catalytic combustion reaction of the tail gas containing the hydrogen and the oxygen in the air by the aid of the catalyst without heating and pressurizing, and the hydrogen can be removed. The reactor is widely applicable to hydrogen removing of the industrial tail gas, also capable of removing CO and reducing substances such as alcohol like methyl alcohol and ethyl alcohol and hydrocarbons in the tail gas, and especially suitable for processing the anode tail gas of fuel batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

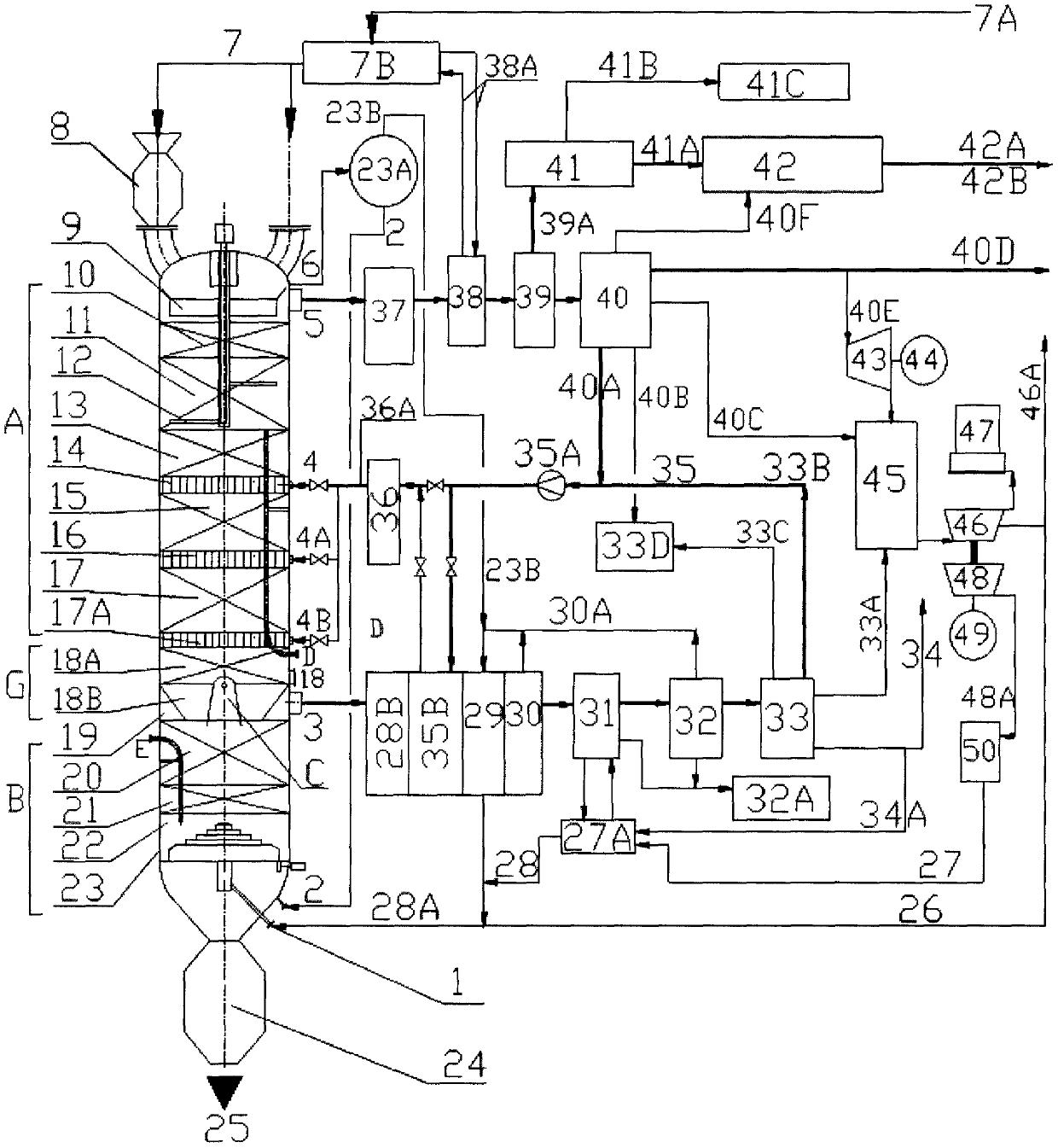

Method for producing natural gas and coproducing fuel oil and aromatic hydrocarbons from coal through multilayer hydrogenation via pressurized moving bed

The invention discloses a method for producing natural gas and coproducing fuel oil and aromatic hydrocarbons from coal through multilayer hydrogenation via a pressurized moving bed. According to theinvention, a pressurized moving-bed coal gasification bed is designed into a hydrogen gas section, an inter-section transition section and a water gas section from top to bottom; in the hydrogen gas section, multilayer hydrogenation is employed to optimize gas-solid countercurrent and H<2> / CH<4> partial pressure conditions and to increase the yield of coal tar and the reaction power of C and 2H<2>to CH<4>; discharged hydrocarbon-rich hydrogen gas is purified and separated to obtain coal tar, methane and hydrogen; the coal tar is subjected to hydrogenation reforming fractionation to prepare fuel oil and aromatic hydrocarbons; hydrogen is pressurized by a circulator and is then cyclically utilized; residual coke obtained after production of CH<1> is subjected to gasification, CO conversionand acid gas removal in the water gas section, and then becomes supplementary hydrogen for coal hydrogenation and coal tar hydrogenation; electricity for normal production is provided by self-producednatural gas in virtue of gas turbine power generation; power steam is provided by a gas turbine waste heat boiler; and a coal-fired steam boiler is not used. The method can greatly improve product energy efficiency and reduce water consumption, investment and environmental pollution.

Owner:成都聚实节能科技有限公司

Preparation method of sea cucumber product

InactiveCN104544296ARetain biological activityPromote absorptionFood preparationReady to eatAdditive ingredient

The invention discloses a preparation method of a sea cucumber product. The preparation method of the sea cucumber product comprises the following steps: (a) pretreating sea cucumber, (b) carrying out heat treatment on the sea cucumber, (c) carrying out primary ultrasonic rehydration, (d) carrying out secondary ultrasonic rehydration, (e) carrying out ternary ultrasonic rehydration, (f) carrying out ultrasonic seasoning, (g) carrying out cold air drying, (h) packaging, and (i) sterilizing. The preparation method of the sea cucumber product has the advantages that dried sea cucumber is taken as a raw material, ultrasonic rehydration, ultrasonic seasoning and a mild processing technology are combined, and the problems of long rehydration time and difficulty tasty of the sea cucumber product processed by taking the dried sea cucumber as the raw material are solved; temperature during processing is mild, so that the sea cucumber product remains biological activity of sea cucumber, and nutritional ingredients are easy to absorb; and sea cucumber is more tasty, tender property and specific fresh fragrance of the sea cucumber are maintained, and the sea cucumber product is ready to eat and convenient to carry.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

Phase-change hot compress eye mask

InactiveCN107595474ARealization of hot compressMild temperatureEye-masksTherapeutic coolingReusabilityEngineering

The invention discloses a phase-change hot compress eye mask. The phase-change hot compress eye mask comprises a heating bag and a hot compress bag. The heating bag and the hot compress bag are arranged separately and connected mechanically. The hot compress bag is used for hot compress of eyes. A phase-change heat storage bag is arranged in the hot compress bag. A heating device is arranged in the heating bag, and is used for heating the phase-change heat storage bag. The invention further discloses a phase-change hot compress eye mask. The phase-change hot compress eye mask comprises a hot compress bag used for hot compress of the eyes. At least one phase-change heat storage bag and at least one heating device are arranged in the hot compress bag. The heating devices are used for heatingthe phase-change heat storage bags. The phase-change hot compress eye masks have the advantages of safety in use, convenience, rapidness, good hot compress effect, reusability and low cost.

Owner:BEIJING AEROSPACE NEW MATERIALS TECH CO LTD

Production method for preparing sorbic acid by catalyzing depolymerization of sorbic acid polyester with solid base catalyst

InactiveCN111454142ANo wasteWith green cleaningOxygen-containing compound preparationMolecular sieve catalystsPolyesterMolecular sieve

The invention belongs to the technical field of preparation of sorbic acid and relates to a production method for preparing sorbic acid by catalyzing depolymerization of sorbic acid polyester with a solid base catalyst. The production method comprises the following steps: (1) putting sorbic acid polyester into a reaction kettle, then adding deionized water and the solid base catalyst, stirring, heating to a catalytic temperature of 30-60 DEG C, and carrying out a base catalytic reaction for 10-20 min, (2) after the reaction is finished, raising the temperature to 100-150 DEG C for sublimation,and condensing and collecting sorbic acid to obtain a crude sorbic acid product, and (3) washing the crude sorbic acid with hot water at 80-100 DEG C, cooling, crystallizing and drying to obtain sorbic acid, wherein the solid base catalyst is a catalyst which takes a molecular sieve as a carrier and is loaded with an alkali metal compound. The method does not generate a waste liquid, has the advantages of environment friendliness, cleanness, high atom economy and no three wastes, is mild in reaction and low in energy consumption, and can increase the yield of sorbic acid and reduce tar byproducts.

Owner:江苏润普食品科技股份有限公司

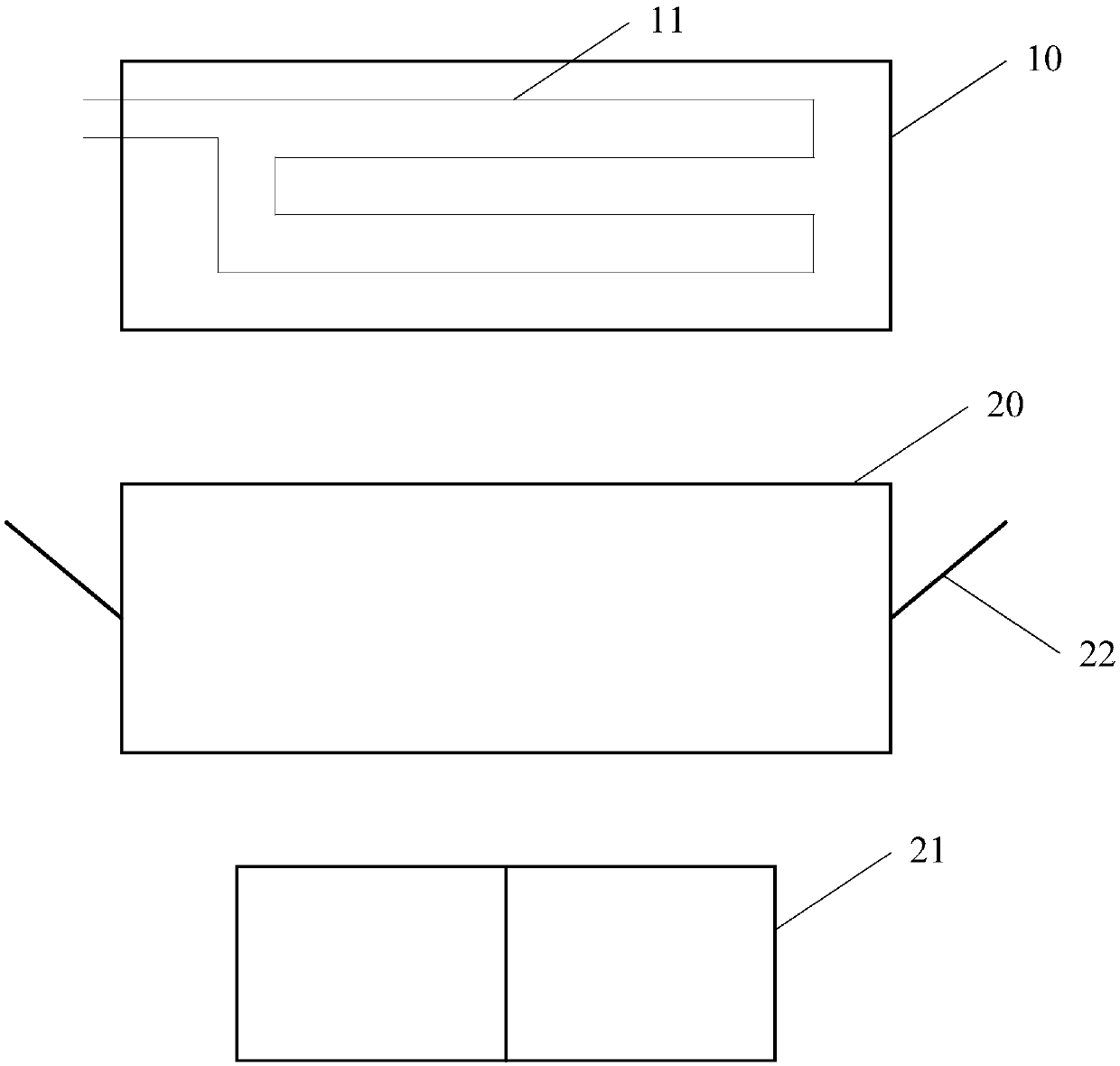

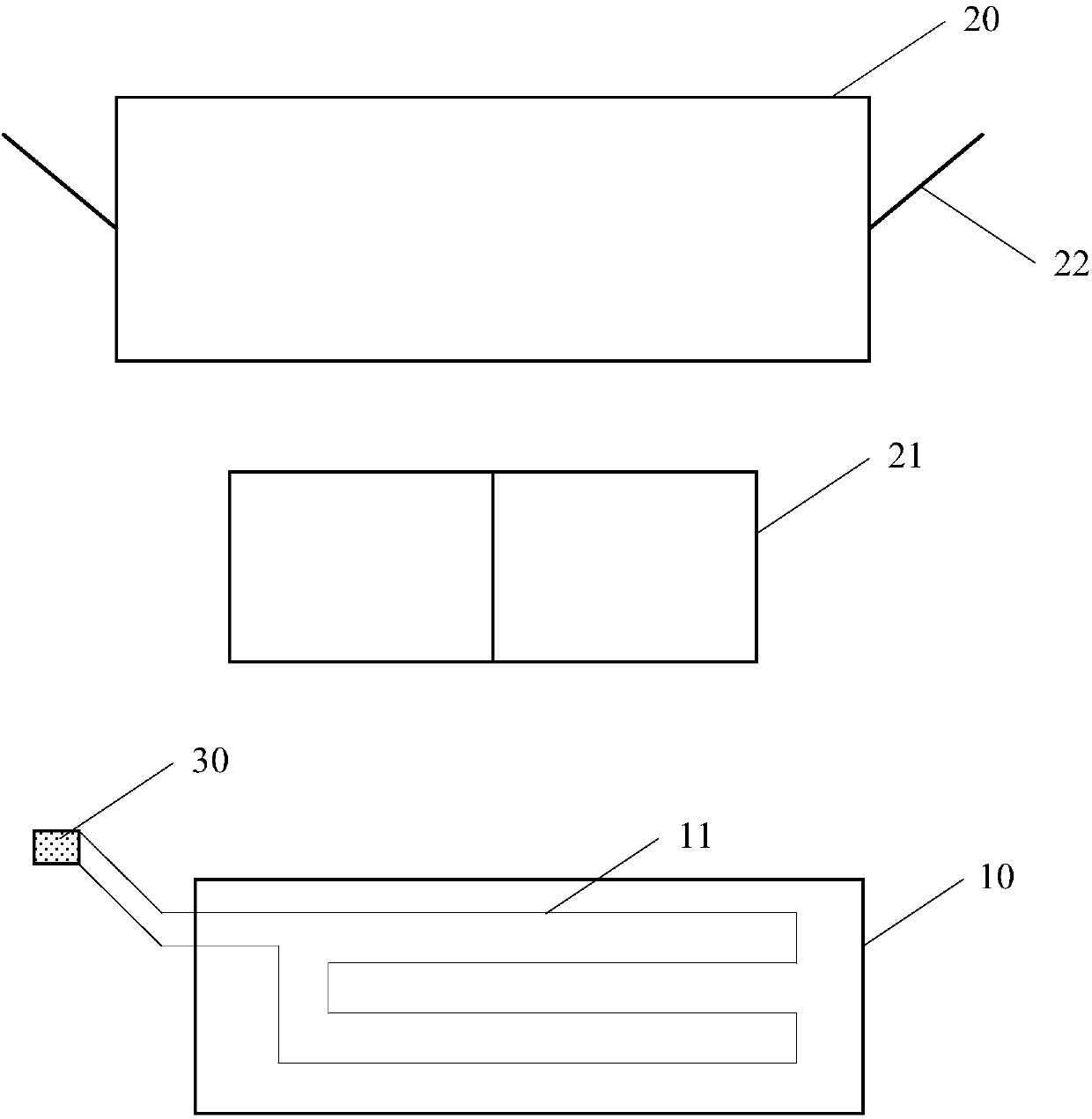

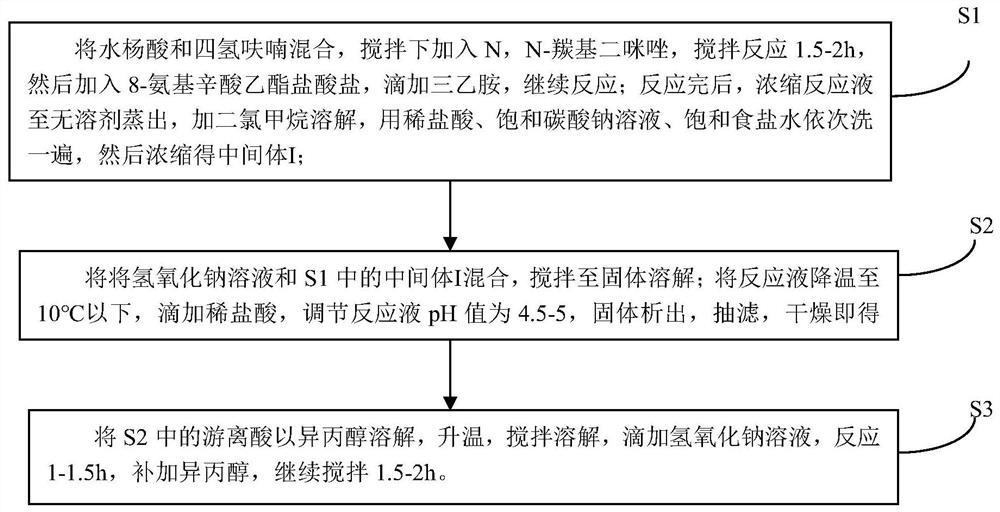

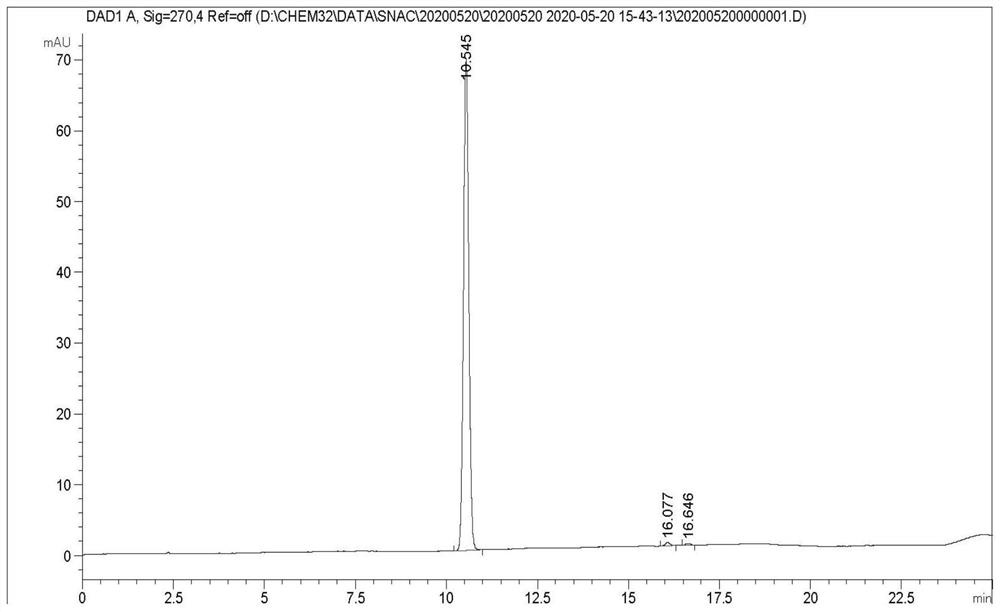

Sodium 8-(2-hydroxylbenzamido)caprylate and preparation method therefor

InactiveCN111978193ADoes not affect yieldGood for stirring reactionOrganic compound preparationCarboxylic acid amide separation/purificationSalicylic acidAmidogen

The invention discloses sodium 8-(2-hydroxylbenzamido)caprylate and a preparation method therefor and belongs to the field of preparation of compounds. A key of the technical scheme of the invention is as follows: the preparation method comprises the steps: mixing salicylic acid with tetrahydrofuran, adding N,N-carbonyl diimidazole, adding 8-amino ethyl caprylate hydrochloride, and dropwise addingtriethylamine; carrying out a concentrating reaction solution until no solvent is distilled off, adding dichloromethane for dissolving, and carrying out washing once separately with diluted hydrochloric acid, a saturated sodium carbonate solution and a saturated saline solution, so as to obtain an intermediate I; mixing a sodium hydroxide solution with the intermediate I, and carrying out stirring until solids are dissolved; cooling the temperature of a reaction solution to 10 DEG C or below, dropwise adding diluted hydrochloric acid, adjusting a pH value of a reaction solution to 4.5 to 5, and carrying out solid precipitation, so as to obtain free acids; and dissolving the free acids with isopropanol, dropwise adding a sodium hydroxide solution, carrying out a reaction for 1 to 1.5 hours, supplementing isopropanol, and continuing to carry out stirring for 1.5 to 2 hours. The method has the advantages that steps are few, the yield of each step is high, the product purity is good, impurities are more easily controlled, and raw materials are more readily available.

Owner:无锡紫杉药业股份有限公司

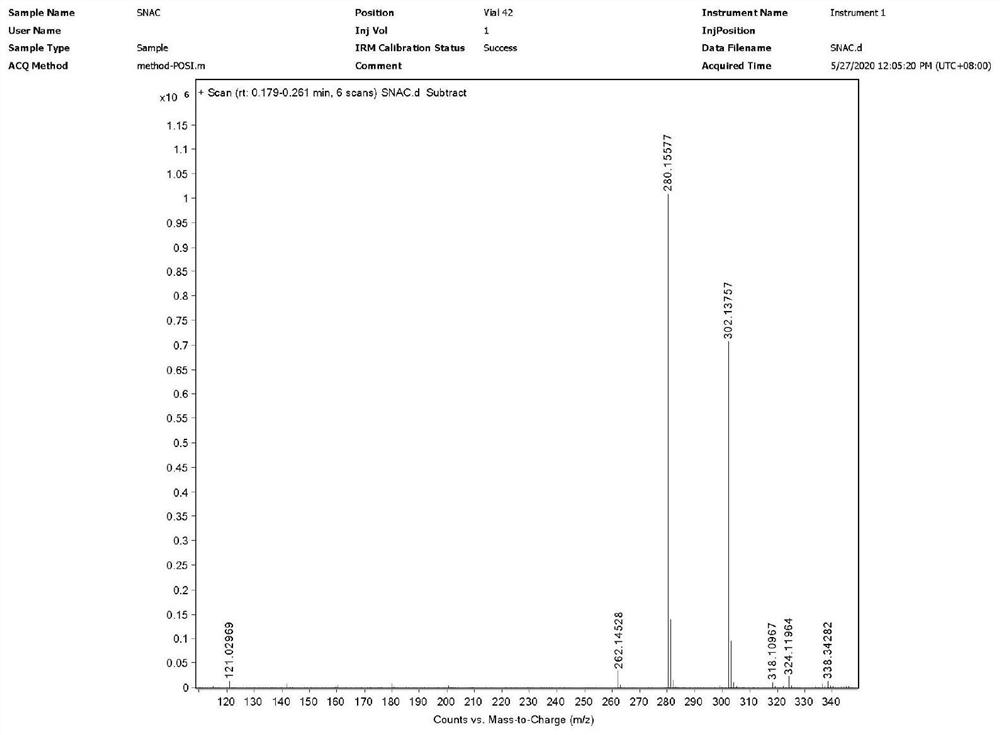

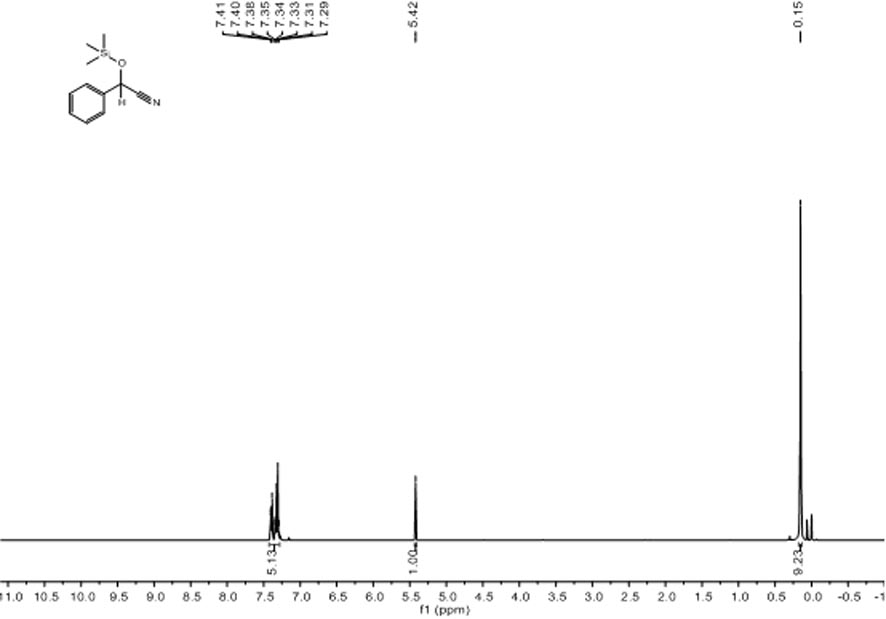

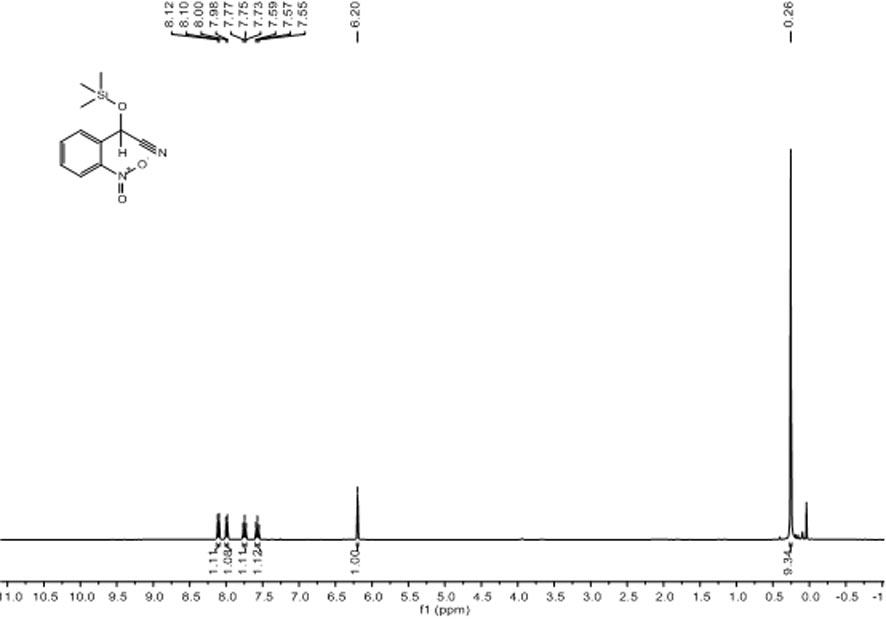

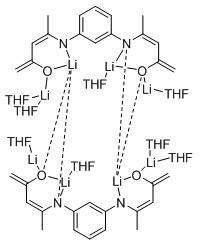

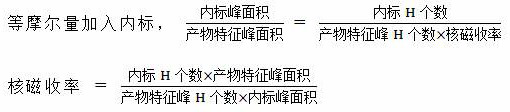

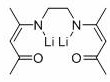

Application of deprotonated phenyl bridged beta-ketimine lithium complex in cyanosilylation reaction

PendingCN111992254AHigh activityReduce dosageGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureCombinatorial chemistry

The invention discloses application of a deprotonated phenyl bridged beta-ketimine lithium complex in a cyanosilylation reaction. In the complex, each beta-ketimine unit is a dianion, and the dianionbeta-ketimine group is a group with high activity, for example, the dianion beta-ketimine group can react with micromolecules containing active hydrogen and unsaturated bond organic micromolecules. Meanwhile, the complex can also be used as a precursor for further synthesizing the dianion beta-ketimine rare earth metal complex. The complex is applied to a cyanosilylation reaction of aldehyde, thereaction temperature is room temperature, and efficient reduction of aldehyde and TMSCN can be realized within a short reaction time.

Owner:SUZHOU UNIV

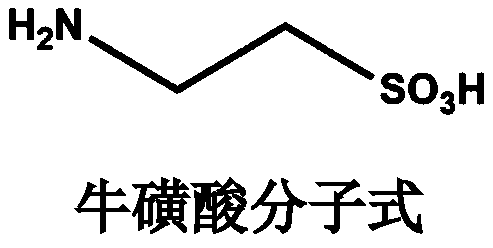

Method for preparing taurine

ActiveCN111574412AEasy to removePromote offenseOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystHomotaurine

The invention provides a method for preparing taurine. An adopted heterogeneous catalyst system can greatly improve the technological conditions for preparing taurine from sodium isethionate, and in addition, byproducts including ethanolamine, ethylene glycol and dipolyethylene glycol are removed through a high-temperature spray dryer, and complete application of effective components of mother liquor is achieved. Compared with the traditional process, the process has the advantages that the reaction temperature and pressure conditions required by the ammonolysis reaction of the sodium isethionate are milder, and meanwhile, the reaction time is also shortened. The method realizes complete application of effective components in the mother liquor, significantly improves the total yield of taurine, is easy for industrial production, and reduces the production cost of the product.

Owner:WANHUA CHEM GRP CO LTD

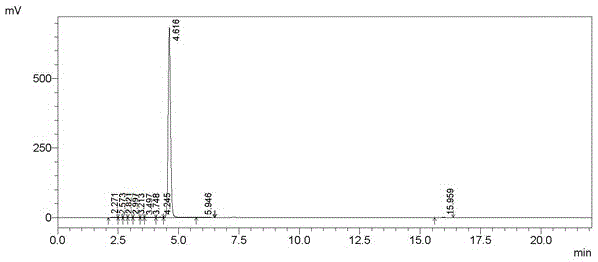

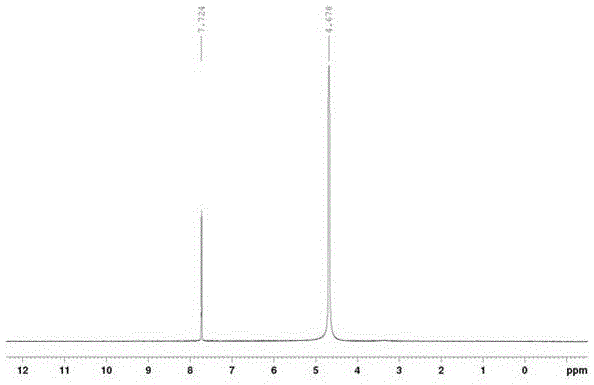

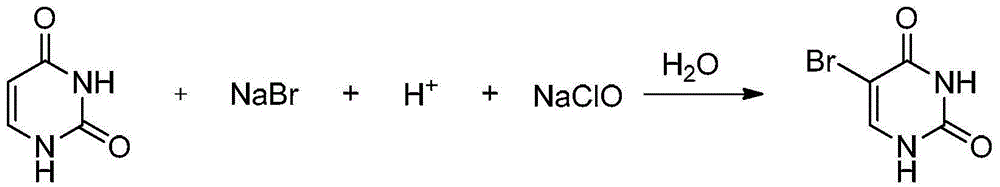

Preparation method for 5-bromouracil

ActiveCN105111153AReduce stepsThe reaction system is green and environmentally friendlyOrganic chemistryUracilSolvent

The invention discloses a preparation method for 5-bromouracil. By taking uracil as an initial raw material, sodium bromide and sodium hypochlorite as a green bromating agent, and water as a solvent, a mild brominating reaction is carried out under an acidic condition to obtain a high purity target product. The preparation method disclosed by the invention is green and environmental-friendly in synthetic process, convenient in post-treatment and suitable for large-scaled industrial production.

Owner:日照新睿招商发展有限公司

Bamboo floor preparation method

InactiveCN108638278APrevent Ants from UndercuttingPleasant living environmentWood treatment detailsCane mechanical workingVarnishCorrosion

The invention discloses a bamboo floor preparation method. The bamboo floor preparation method comprises the process steps of (1) material preparation, (2) rough milling, (3) cooking and carbonization, (4) drying, (5) manual picking, (6) finish milling, (7) extrusion, (8) flat planing, (9) four-surface grooving, (10) end surface tenoning, (11) dipping, (12) secondary drying, (13) polishing and carving and (14) painting. Pure bamboo boards are used for manufacturing floors; through special process treatment, the bamboo floors are impregnated in the components of peppers and lavenders; the peppers achieve the ant dispelling effect, and the lavenders achieve the mosquito dispelling effect, so that the ant drilling corrosion can be prevented in the use process, and mosquitoes are dispelled; natural fragrance of the lavenders is slowly dissipated, so that the living environment is more pleasant; and a layer of ventilation varnish with good transparency is only sprayed on the floors, so thatnatural textures and colors of the bamboos are fully shown under the condition of not influencing the mosquito dispelling function to achieve elegance.

Owner:甄春风

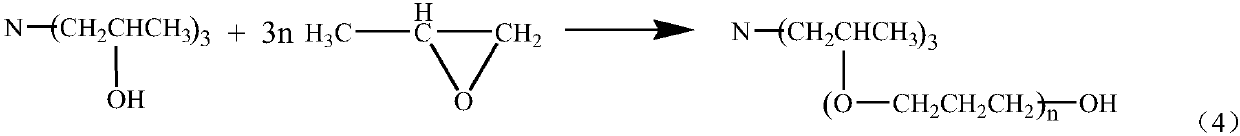

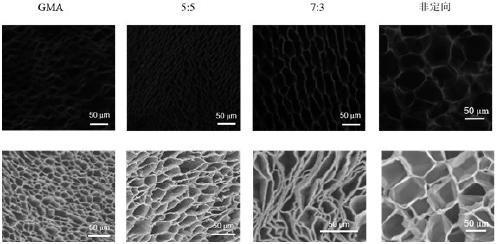

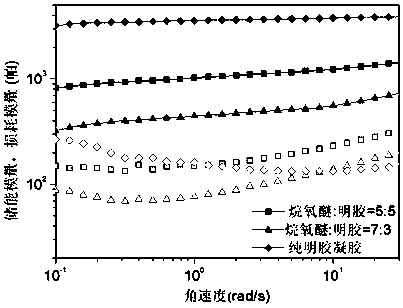

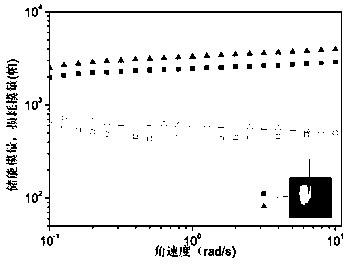

Alkoxyether dendrimer/gelatin composite cryogel, preparation method and applications thereof

InactiveCN110183595AThe process is simple and feasiblePolymerization conditions are mildCell culture supports/coatingGeneral culture methodsTissue engineeringChemistry

The invention relates to an alkoxyether dendrimer / gelatin composite cryogel, a preparation method and applications thereof. According to the present invention, a series of intelligent hydrogels with characteristics of moderate mechanical properties, oriented porous structure and temperature response are prepared by using gelatin modified with methacrylic anhydride and alkoxyether dendron with excellent temperature sensitive behavior as raw materials and by adopting a redox reaction through a one-way freezing method, wherein the pore size and the mechanical properties of the gel can be adjustedby regulating the ratio of different components and the cooling rate; the method is simple, safe and effective, and does not use organic solutions; the results of cell culture show that the gel has good adhesion to cells, the cells have high survival rate, and the growth morphology of the cells is controlled by the pore size and the morphology of the gel; and the obtained hydrogel can be used forthe simulation of cell matrixes, and can further be used in other tissue engineering and drug controlled release.

Owner:SHANGHAI UNIV

Hydroboration reaction method of carbonic ester

InactiveCN111763226AReduce dosageHigh activityGroup 1/11 organic compounds without C-metal linkagesLithium organic compoundsCarbonate esterCombinatorial chemistry

The invention relates to a hydroboration reaction method of carbonic ester, in particular to a hydroboration reaction method taking carbonic ester and borane as raw materials. As an important non-metallocene ligand, beta-ketimine is easy to synthesize; the charge and space effect of the beta-ketimine can be conveniently regulated and controlled through the change of substituents at the alpha position and the beta position, and the beta-ketimine can be coordinated with metal through various coordination modes, so that metal complexes with diversified structures are formed. The novel carbonic ester hydroboration reaction method provided by the invention has a wide substrate application range.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com