Processing method of low-temperature instant soft gel agar

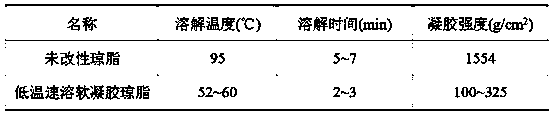

A processing method and instant technology, which is applied in the field of food processing, can solve the problems that the effect of sugar and agar may not be sufficient, the gel strength is not easy to control, and the scope of use is limited, so as to improve the solubility of agar, ensure the characteristics of soft gel, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Humidity adjustment and water balance: put agar powder in a mixer, spray atomized water on it, and stir while spraying water until the quality of water and material is 1:1, and place it in an airtight container for 2.5 hours. The agar component fully absorbs and balances water;

[0025] (2) Screw extrusion: use a twin-screw extruder to extrude the humidity-adjusted agar powder, and the temperatures of the four heating zones from the inlet to the outlet are: the temperature in zone I is 30 °C, and the temperature in zone II is 50 °C , the temperature in Zone III is 70°C, the temperature in Zone IV is 90°C, and the rotation speed of the screw is 70rpm;

[0026] (3) Flour making: cut the rubber strip extruded by the screw into 5 mm long colloidal particles, dry with hot air at 40 ℃ for 24 h, and pass through a 80-mesh sieve after crushing, and the sieved product is pretreated agar powder;

[0027] (4) Alkali treatment: Disperse the pretreated agar powder in a 75wt% et...

Embodiment 2

[0033] (1) Humidity adjustment and water balance: put agar powder in a mixer, spray atomized water on it, and stir while spraying water until the quality of water and material is 1:3, and place it in an airtight container for 2 hours to make the agar Fully absorb and balance moisture;

[0034] (2) Screw extrusion: Use a twin-screw extruder to extrude the humidity-adjusted agar powder. The temperatures of the four heating zones from the inlet to the outlet are: the temperature in zone I is 40°C, and the temperature in zone II is 60°C. , the temperature in zone III is 80°C, the temperature in zone IV is 100°C, and the rotation speed of the screw is 90rpm;

[0035] (3) Flour making: Cut the rubber strips extruded by the screw into 3 mm long colloidal particles, dry them with hot air at 40 °C for 24 h, and pass through a 80-mesh sieve after crushing, and the sieved product is pretreated agar powder;

[0036] (4) Alkali treatment: Disperse the pretreated agar powder in a 60wt% eth...

Embodiment 3

[0042] (1) Humidity adjustment and water balance: put agar powder in a mixer, spray atomized water on it, and stir while spraying water until the quality of water and material is 1:5, and place it in an airtight container for 1 hour to make the agar Fully absorb and balance moisture;

[0043] (2) Screw extrusion: Use a twin-screw extruder to extrude the humidity-adjusted agar powder. The temperatures of the four heating zones from the inlet to the outlet are: 50°C for zone I and 70°C for zone II , the temperature in Zone III is 90°C, the temperature in Zone IV is 120°C, and the rotational speed of the screw is 120rpm;

[0044] (3) Flour making: Cut the rubber strips extruded by the screw into 2mm-long rubber particles, dry them with hot air at 40°C for 24 hours, and pass through a 80-mesh sieve after crushing, and the under-sieve is pretreated agar powder;

[0045] (4) Alkali treatment: Disperse the pretreated agar powder in a 50wt% ethanol solution with a mass ratio of 1:10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com