Method for removing nickel coating on rack and deplating solution

A technology for stripping solution and nickel coating, which is applied in the field of stripping nickel coating method and stripping solution for hangers, can solve the problems of large environmental pollution, corrosion of hangers, etc., achieve reasonable component distribution ratio, reduce strip cost, and improve The effect of adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

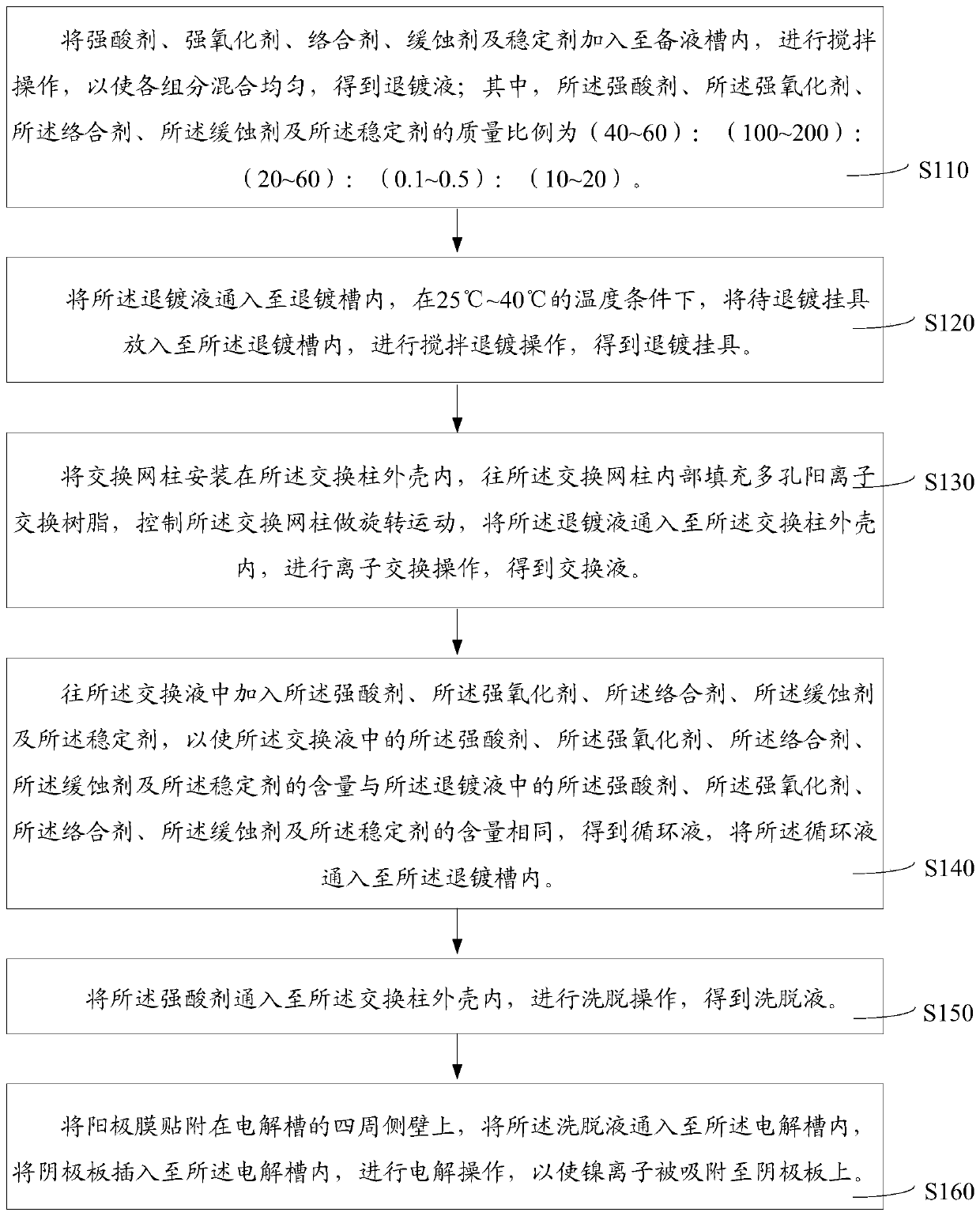

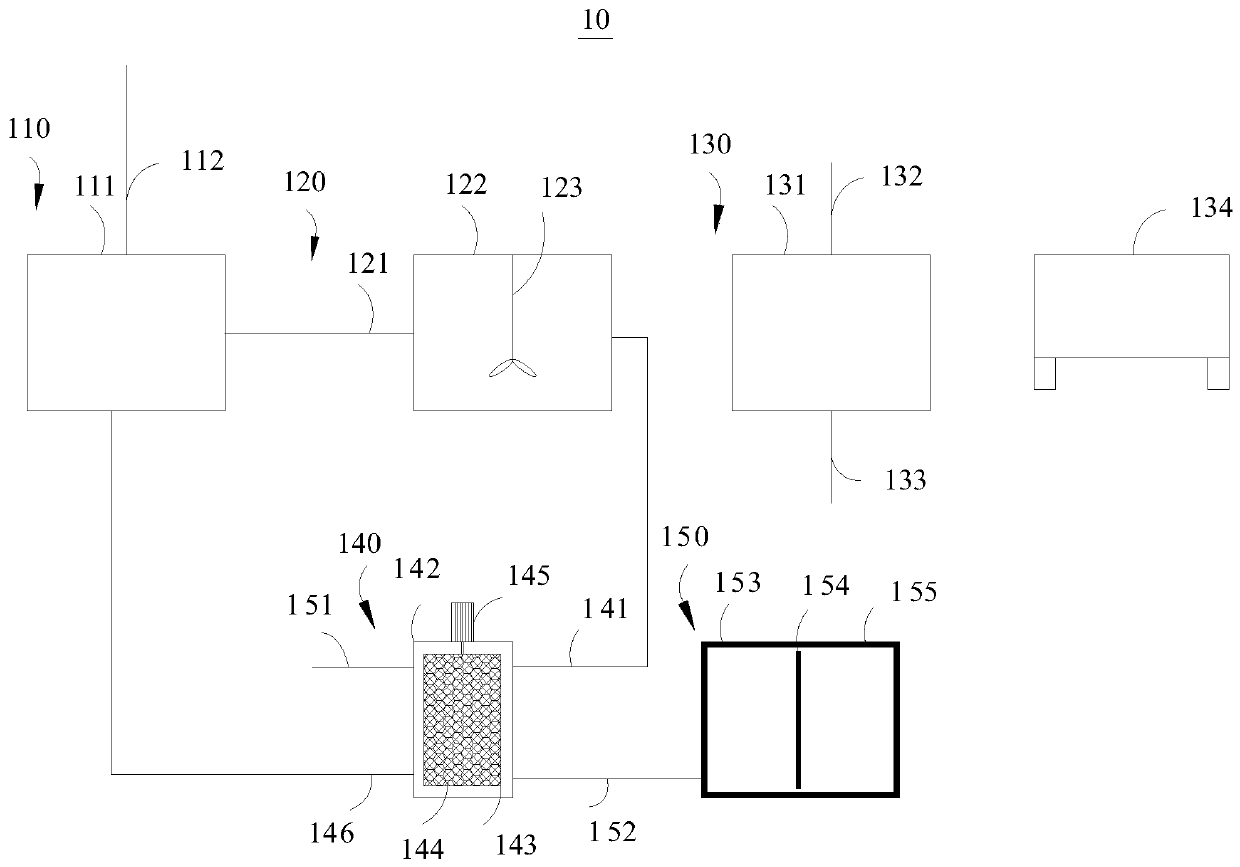

[0031] For an implementation, see figure 2, a nickel coating stripping system 10 for hangers, including a liquid preparation component 110 , a deplating component 120 , a circulation component 140 and a nickel recovery component 150 . The liquid preparation assembly 110 includes a reagent inlet pipe 111 and a liquid preparation tank 112, the reagent inlet pipe 111 communicates with the liquid preparation tank 112, and the reagent inlet pipe is used to sequentially feed a strong acid and a strong oxidant into the liquid preparation tank , complexing agent, corrosion inhibitor and stabilizer. Described deplating assembly 120 comprises deplating solution circulation pipe 121, deplating tank 122 and stirring device 123, and the first end of described deplating solution circulation pipe 121 communicates with described liquid preparation tank 112, and described deplating solution circulates The second end of the tube 121 communicates with the deplating tank 122 , and the stirring ...

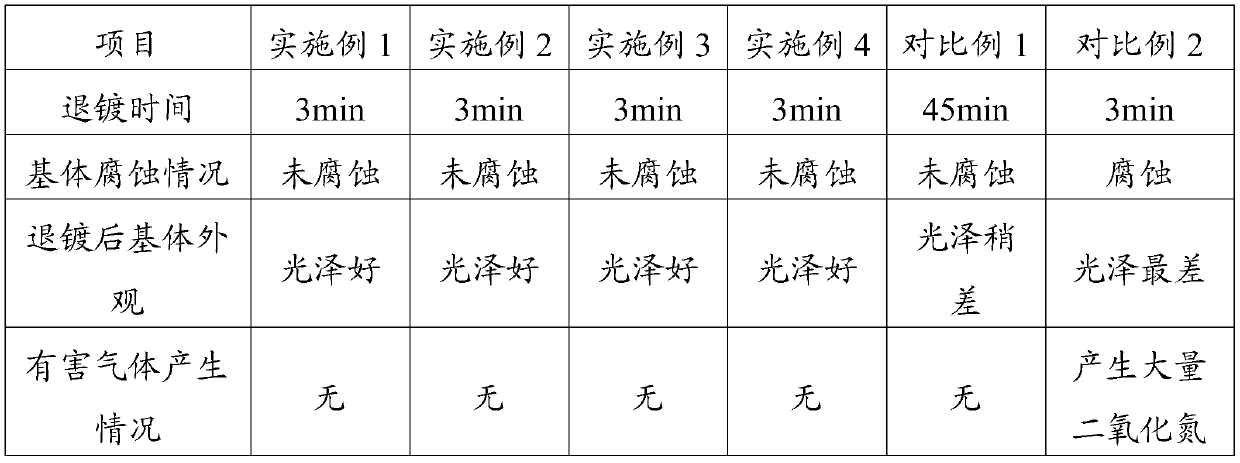

Embodiment 1

[0067] S111, add 40ml / L98% sulfuric acid, 200ml / L50% hydrogen peroxide, 20g / LEDTA, 0.5g / L glycerin and 10g / L hydroxyethylidene diphosphonic acid into the liquid preparation tank, add water to replenish the volume of the solution to 1L, carry out stirring operation, so that the components are mixed evenly, and the deplating solution is obtained.

[0068] S121, the deplating solution is passed into the deplating tank, and under the temperature condition of 25°C, the rack to be stripped is put into the deplating tank, and the stirring and deplating operation is performed to obtain the deplating rack. Tool.

[0069] S131, filling porous cation exchange resin into the exchange mesh column, controlling the exchange mesh column to rotate, passing the deplating solution into the exchange mesh column, performing an ion exchange operation, and obtaining an exchange solution.

Embodiment 2

[0071] S112, add 60ml / L sulfuric acid, 100ml / L ozone, 60g / L citric acid, 0.1g / L hexamethylenetetramine and 20g / L 8-hydroxyquinoline to the liquid preparation tank, add water to make up the volume of the solution It is 1L, and the stirring operation is carried out so that the components are mixed uniformly to obtain the deplating solution.

[0072] S122, the deplating solution is passed into the deplating tank, and under the temperature condition of 40°C, the rack to be stripped is put into the deplating tank, and the stirring and deplating operation is performed to obtain the deplating rack. Tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com