Lactobacillus plantarum exopolysaccharide and preparation method thereof

A technology of Lactobacillus plantarum and exopolysaccharides, which is applied in the field of Lactobacillus plantarum exopolysaccharides and its preparation, can solve the problems of lack of Lactobacillus plantarum exopolysaccharides and difficult preparation of Lactobacillus plantarum exopolysaccharides, and achieve purity and yield rate-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

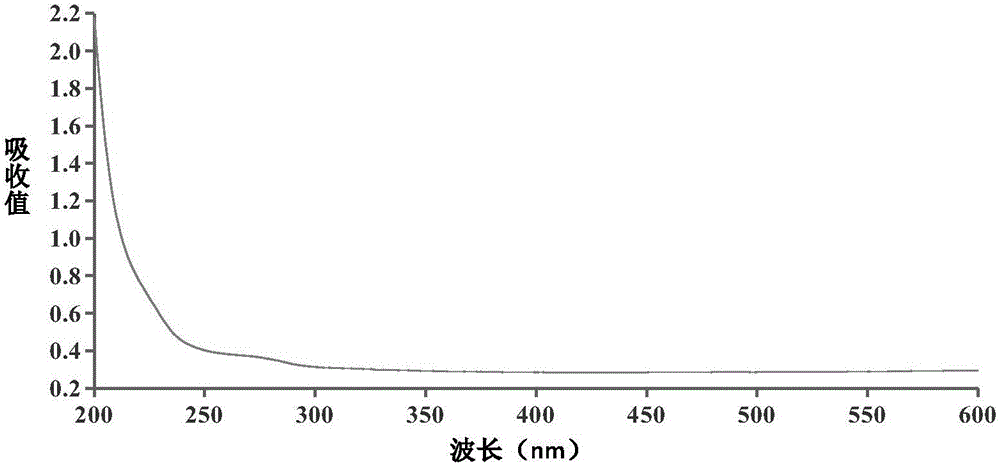

[0049] 1.1 Preparation of exopolysaccharide of Lactobacillus plantarum

[0050] (1) Take Lactobacillus plantarum with the preservation number CCTCCM2014170, ferment it in MRS medium, the fermentation time is 24h, anaerobic culture at 37°C;

[0051] (2) Use 2 times the volume of absolute ethanol to precipitate the supernatant of the fermentation broth for 48 hours, centrifuge at 12,000×g for 10 minutes, discard the supernatant, and dialyze the precipitate with a dialysis bag with a molecular weight cut-off of 8,000-14,000 Da for 3 days, and change the ultrapure water twice a day. Freeze-drying to obtain crude exopolysaccharide;

[0052] (3) Use 50mM Tris-HCl, 10mM MgSO 4 ·7H 2 O dissolve the crude polysaccharide with a final concentration of 5 mg / mL, and use nuclease DNAsetype-I with a final concentration of 2.5 μg / mL to hydrolyze the nucleic acid at 37°C for 6 hours;

[0053] (4) The hydrolyzed crude polysaccharide was hydrolyzed with protease Pronase E at a final concentra...

Embodiment 2

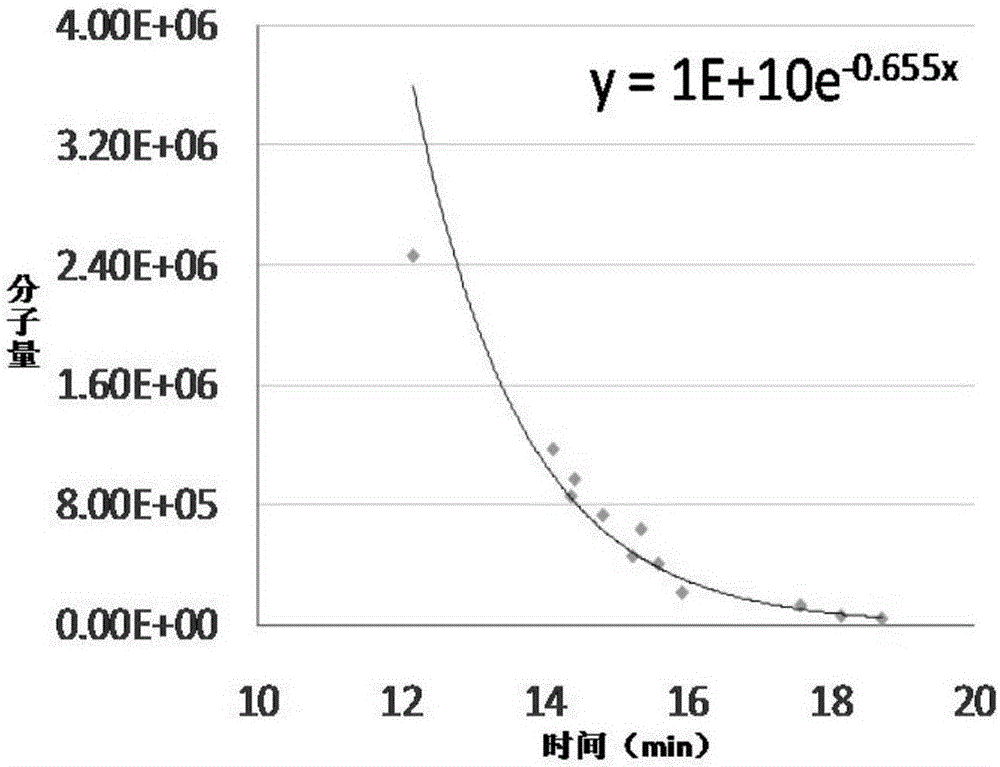

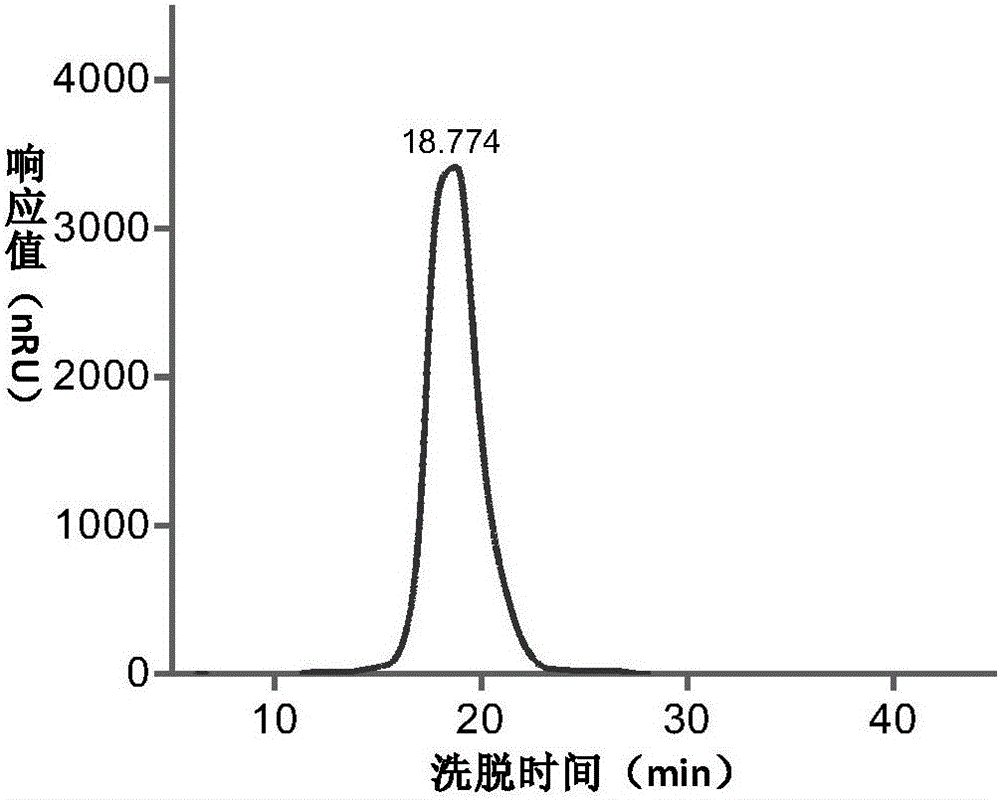

[0071] The exopolysaccharide of Lactobacillus plantarum is composed of xylose and galactose connected by glycosidic bonds, wherein the molar content of galactose is 98%. The number of elution peaks of the exopolysaccharide of Lactobacillus plantarum through space exclusion chromatography is one.

[0072] The preparation method of the above-mentioned exopolysaccharide of Lactobacillus plantarum comprises the following steps:

[0073] 1) Take the Lactobacillus plantarum fermentation liquid, separate the solid from the liquid and get the supernatant;

[0074] 2) adding ethanol to the supernatant in step 1), ethanol precipitation, solid-liquid separation to take the precipitate, dialysis with a dialysis bag with a molecular weight cut-off of 8KDa, and drying the contents of the dialysis bag to obtain crude polysaccharide;

[0075] 3) To contain 40mM Tris-HCl, 5mM MgSO 4 ·7H 2 The solution of O is used as the crude polysaccharide solution, dissolves the crude polysaccharide desc...

Embodiment 3

[0081] The exopolysaccharide of Lactobacillus plantarum is composed of xylose and galactose connected by glycosidic bonds, wherein the molar content of galactose is 98.3%.

[0082] The preparation method of the above-mentioned exopolysaccharide of Lactobacillus plantarum comprises the following steps:

[0083] 1) Take the Lactobacillus plantarum fermentation liquid, separate the solid from the liquid and get the supernatant;

[0084] 2) adding ethanol to the supernatant in step 1), ethanol precipitation, solid-liquid separation to take the precipitate, dialysis with a dialysis bag with a molecular weight cut-off of 14KDa, and drying the contents of the dialysis bag to obtain crude polysaccharide;

[0085] 3) to contain 60mM Tris-HCl, 15mM MgSO 4 ·7H 2 The solution of O is used as the crude polysaccharide solution, dissolves the crude polysaccharide described in step 2), and then adds nuclease DNAsetype-I to a final concentration of 3 μg / mL for hydrolysis;

[0086] 4) Then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com