Method for producing isopropanolamine by liquid ammonia process

A technology of isopropanolamine and liquid ammonia, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve the problems of high equipment investment, high product by-products, and high dehydration energy consumption, and achieve the reaction The effect of temperature controllable, adjustable product structure and convenient heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

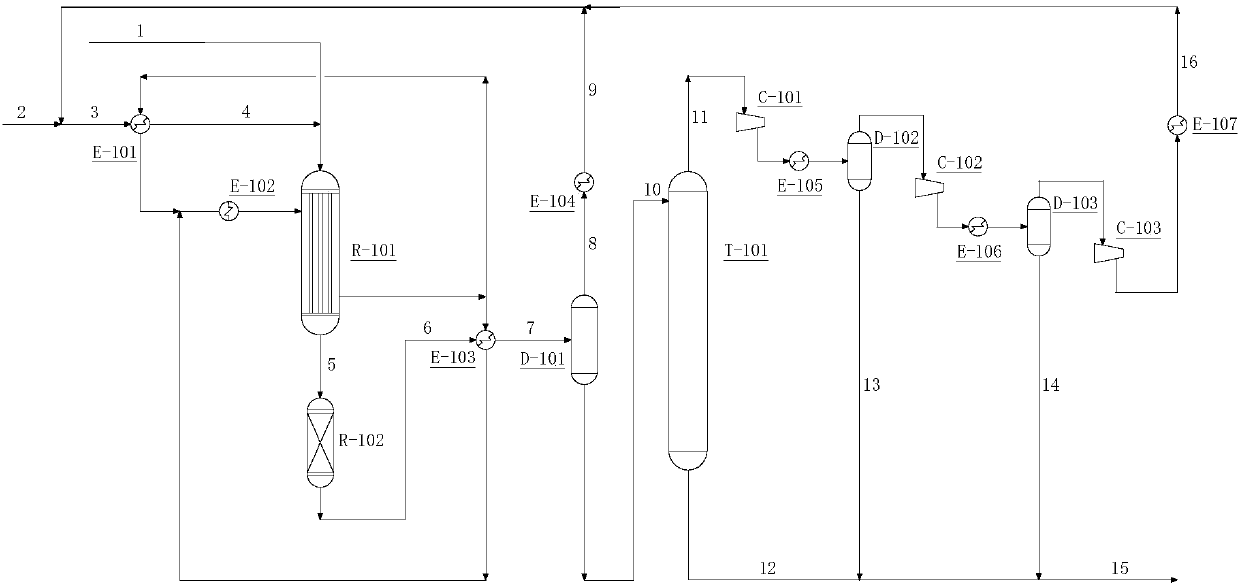

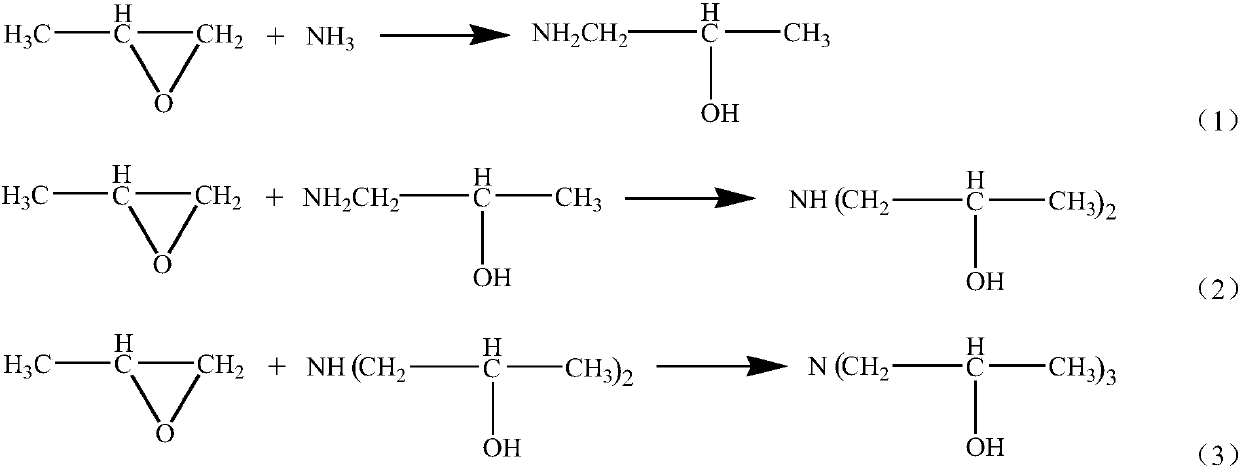

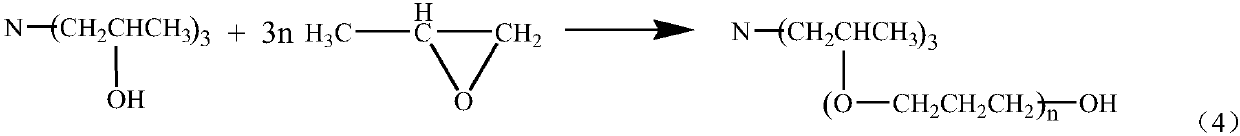

[0045] Fresh liquid ammonia 2 is mixed with condensed liquid ammonia 9 and compressed condensed liquid ammonia 16 to form liquid ammonia feed 3, which is mixed with propylene oxide feed 1 after preheating and sent to the tubular fixed bed reactor R-101, the first stage The reaction product 5 enters the adiabatic fixed-bed reactor R-102, and both R-101 and R-102 are filled with a binder-free ZSM-5 zeolite molecular sieve catalyst. After preheating, it is sent to the flash tank D-101. The top stream 8 of D-101 is condensed and then circulated to the reaction unit. The bottom stream 10 is sent to the ammonia stripper T-101. The top stream 11 of T-101 is condensed by three stages of compression. Stream 16 is recycled to the reaction unit, and there is also a gas-liquid separation tank D-102 and D-103 between the primary compression and the secondary compression, the secondary compression and the tertiary compression, and the liquid phase of D-102 and D-103 The output stream 13 and...

Embodiment 2

[0054] Fresh liquid ammonia 2 is mixed with condensed liquid ammonia 9 and compressed condensed liquid ammonia 16 to form liquid ammonia feed 3, which is mixed with propylene oxide feed 1 after preheating and sent to the tubular fixed bed reactor R-101, the first stage The reaction product 5 enters the adiabatic fixed-bed reactor R-102, and both R-101 and R-102 are filled with a binder-free ZSM-5 zeolite molecular sieve catalyst. After preheating, it is sent to the flash tank D-101. The top stream 8 of D-101 is condensed and then circulated to the reaction unit. The bottom stream 10 is sent to the ammonia stripper T-101. The top stream 11 of T-101 is condensed by three stages of compression. Stream 16 is recycled to the reaction unit, and there is also a gas-liquid separation tank D-102 and D-103 between the primary compression and the secondary compression, the secondary compression and the tertiary compression, and the liquid phase of D-102 and D-103 The output stream 13 and...

Embodiment 3

[0063] Fresh liquid ammonia 2 is mixed with condensed liquid ammonia 9 and compressed condensed liquid ammonia 16 to form liquid ammonia feed 3, which is mixed with propylene oxide feed 1 after preheating and sent to the tubular fixed bed reactor R-101, the first stage The reaction product 5 enters the adiabatic fixed-bed reactor R-102, and both R-101 and R-102 are filled with a binder-free ZSM-5 zeolite molecular sieve catalyst. After preheating, it is sent to the flash tank D-101. The top stream 8 of D-101 is condensed and then circulated to the reaction unit. The bottom stream 10 is sent to the ammonia stripper T-101. The top stream 11 of T-101 is condensed by three stages of compression. Stream 16 is recycled to the reaction unit, and there is also a gas-liquid separation tank D-102 and D-103 between the primary compression and the secondary compression, the secondary compression and the tertiary compression, and the liquid phase of D-102 and D-103 The output stream 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com