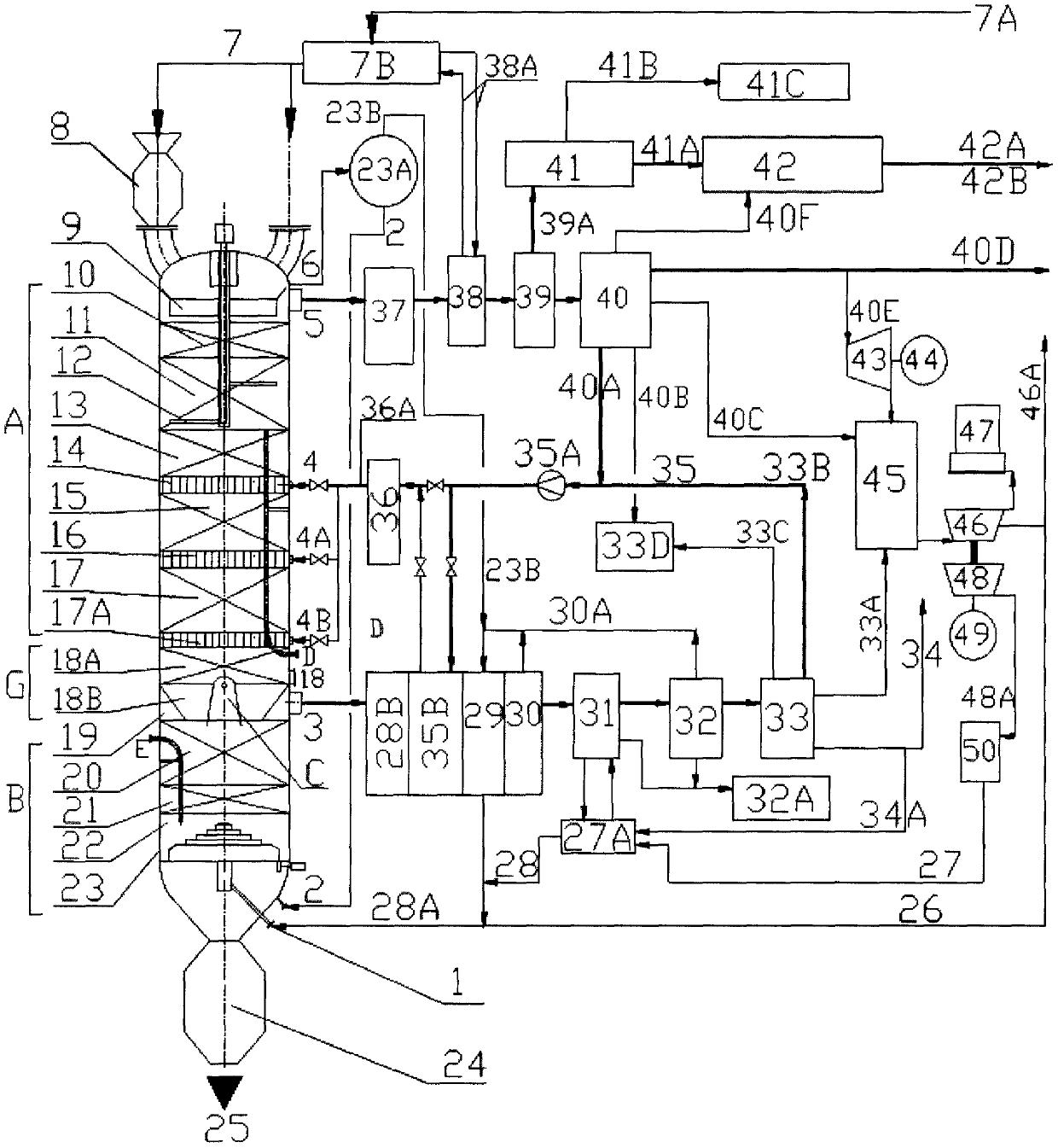

Method for producing natural gas and coproducing fuel oil and aromatic hydrocarbons from coal through multilayer hydrogenation via pressurized moving bed

A coal-to-natural gas and moving bed technology, which is applied in the direction of gas fuel, combustible gas, fuel, etc., can solve the problems of strict raw material coal quality, large equipment investment, and high process pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] About the gasifier: first, the pressurized gas furnace containing the water gas section and the hydrogen gas section, and the equipment of each process unit are designed and manufactured, and then transported to the installation site for installation, process piping, electrical instrument installation, anti-corrosion and heat preservation, and system testing. Leakage, pressure test, and debugging are qualified, so that it has the structure and function required by the design.

[0137] Then spread 300mm thick gas furnace ash on the grate of the water gas section, coke with a particle size of 20-80mm and a thickness of 2000mm required for the steam gasification layer; Add coke with a particle size of 20-80mm and a thickness of 3000mm, add semi-coke with a thickness of 3000mm in the semi-coke hydrogasification layer, add weakly caking coal or non-caking coal with a particle size of 20-80mm and a thickness of 2000mm in the dry distillation layer, and add granular coal in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com