Stainless steel product barrel plating method and activating solution

A technology of stainless steel and activation solution, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of poor adhesion between the base and nickel-plated layer of stainless steel nickel-plated finished products, and fluctuations in coating thickness and surface quality Large, high risk of return and rework, etc., to achieve the effect of simple and labor-saving barrel plating operation, improving the uniformity of coating thickness and surface quality, and increasing the number of activated molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

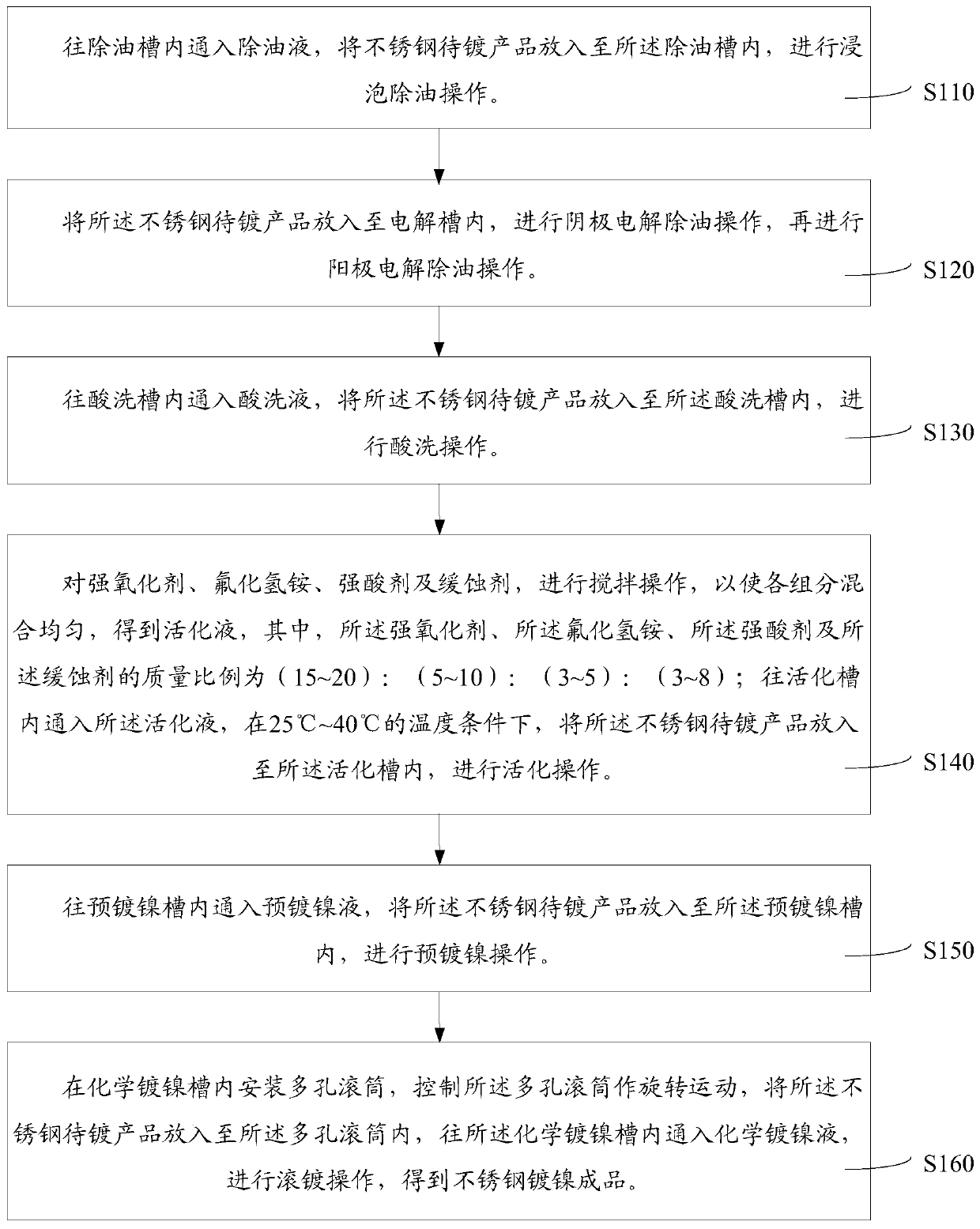

[0034] For an implementation, see figure 1 , a stainless steel product barrel plating method, comprises the following steps:

[0035] S110, pouring a degreasing solution into the degreasing tank, putting the stainless steel product to be plated into the degreasing tank, and performing immersion and degreasing operation.

[0036] It should be noted that the immersion degreasing operation uses the emulsification of the degreasing liquid to degrease the stainless steel product to be plated.

[0037] S120, putting the stainless steel product to be plated into the electrolytic tank, performing cathodic electrolytic degreasing operation, and then performing anode electrolytic degreasing operation.

[0038]It should be noted that the cathodic electrolytic degreasing operation and the anode electrolytic degreasing operation are performed in an alkaline solution, with the stainless steel product to be plated as the anode or cathode, and a stainless steel plate, nickel plate, nickel-pl...

Embodiment 1

[0068] S111, pouring naphtha into the degreasing tank, putting 100 identical stainless steel products to be plated into the degreasing tank, and performing immersion degreasing operation.

[0069] S121, putting the 100 identical stainless steel products to be plated into the electrolytic tank, performing cathodic electrolytic degreasing operation, and then performing anode electrolytic degreasing operation.

[0070] S131, injecting phosphoric acid into the pickling tank, putting the 100 identical stainless steel products to be plated into the pickling tank, and performing pickling operation.

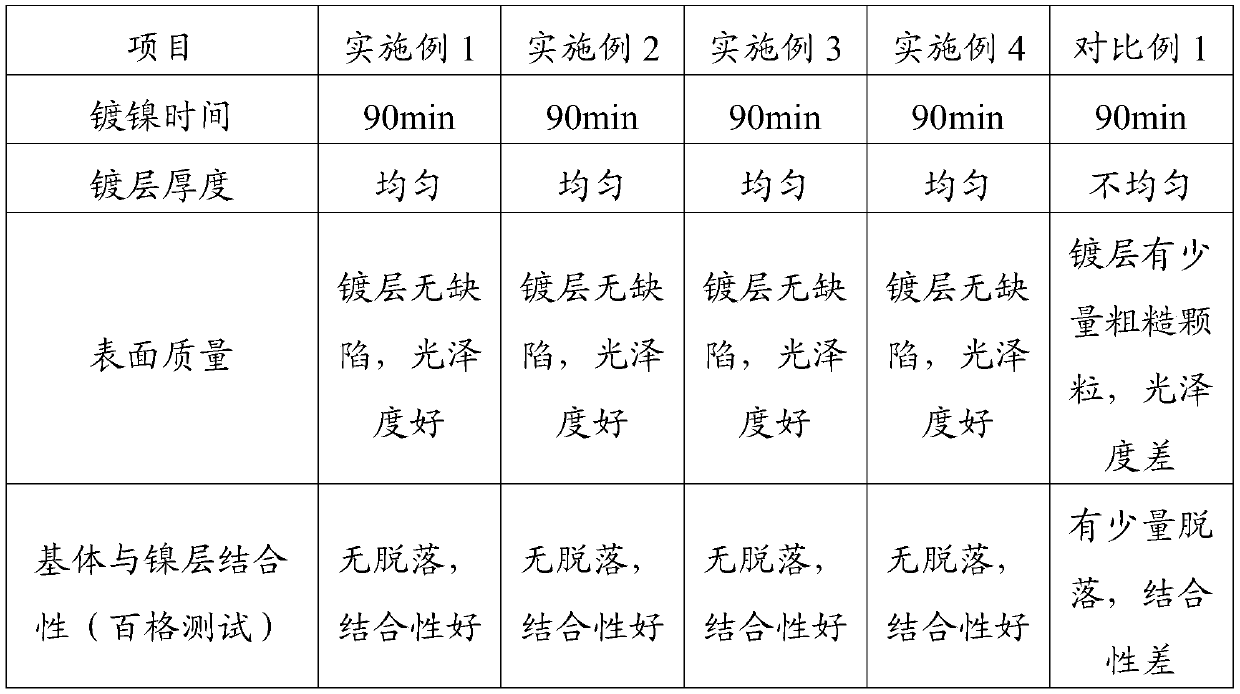

[0071] S141, for 15g / L sodium peroxide, 10g / L ammonium bifluoride, 3g / L acetic acid and 8g / L glycerin, add water to make up the volume of the solution to 1L, and then carry out stirring operation so that the components are mixed evenly and activated The activation solution is passed into the activation tank, and the 100 identical stainless steel products to be plated are put into the act...

Embodiment 2

[0075] S112, feeding trichlorethylene into the degreasing tank, putting 100 pieces of the same stainless steel products to be plated into the degreasing tank, and performing immersion degreasing operation.

[0076] S122, putting the 100 identical stainless steel products to be plated into the electrolytic tank, performing cathodic electrolytic degreasing operation, and then performing anode electrolytic degreasing operation.

[0077] S132, passing hydrochloric acid into the pickling tank, putting the 100 identical stainless steel products to be plated into the pickling tank, and performing pickling operation.

[0078] S142, for 20g / L ozone, 5g / L ammonium bifluoride, 5g / L hydrochloric acid and 3g / L hexamethylenetetramine, add water to make up the volume of the solution to 1L, and then perform stirring operation to make the components mix evenly , to obtain an activation solution, pass the activation solution into the activation tank, and put the 100 identical stainless steel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com