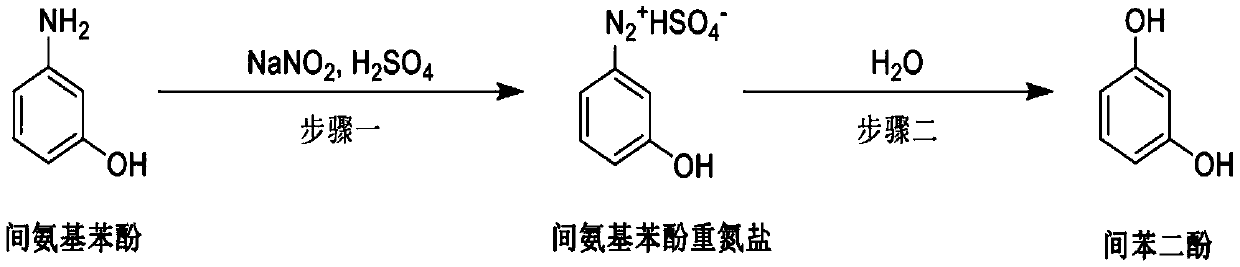

Preparation method of resorcinol

A technology of resorcinol and aminophenol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of low yield of diazotization reaction products, achieve less impurities, low risk factor, The simple effect of the three waste treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

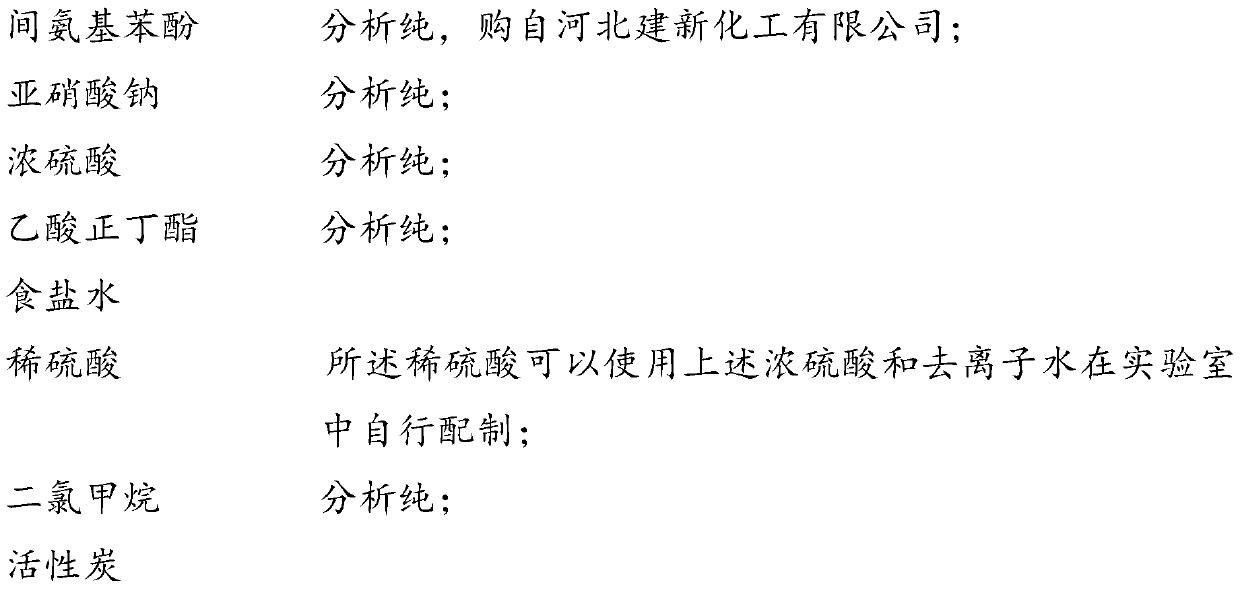

[0103] (1) Preparation of m-aminophenol diazonium salt

[0104] Add water in the diazotization reaction tank, under stirring, slowly add concentrated sulfuric acid, control the temperature below 80°C, and prepare a sulfuric acid solution with a concentration of 30wt%. The resulting sulfuric acid solution was cooled to 25 °C. Add m-aminophenol thereto then, m-aminophenol: the vitriol oil: the mol ratio of sodium nitrite is 1:2.5:1.05. Stir for 15 minutes to dissolve m-aminophenol to form a mixed solution containing water, sulfuric acid and m-aminophenol. Then the mixed solution was cooled to -8°C for use.

[0105] Enter water in another preparation tank and add NaNO 2 , prepare 25wt% sodium nitrite aqueous solution. The sodium nitrite aqueous solution was cooled to 0°C.

[0106] The sodium nitrite aqueous solution of cooling is all dropped in the diazotization reaction tank, mixes with the above-mentioned cooling mixed solution, forms the diazotization reaction liquid, car...

Embodiment 2

[0131] (1) Preparation of m-aminophenol diazonium salt

[0132] Add water in the diazotization reaction tank, under stirring, slowly add concentrated sulfuric acid, control the temperature below 80°C, and prepare a sulfuric acid solution with a concentration of 30wt%. The resulting sulfuric acid solution was cooled to 25 °C. Then add m-aminophenol wherein, m-aminophenol: the vitriol oil: the mol ratio of sodium nitrite is 0.5:2:0.5. Stir for 15 minutes to dissolve m-aminophenol to form a mixed solution containing water, sulfuric acid and m-aminophenol. Then the mixed solution was cooled to -8°C for use.

[0133] Enter water in another preparation tank and add NaNO 2 , prepare 25wt% sodium nitrite aqueous solution. The sodium nitrite aqueous solution was cooled to 0°C.

[0134] The sodium nitrite aqueous solution of cooling is all dropped in the diazotization reaction tank, mixes with the above-mentioned cooling mixed solution, forms the diazotization reaction liquid, ca...

Embodiment 3

[0159] (1) Preparation of m-aminophenol diazonium salt

[0160] Add water in the diazotization reaction tank, under stirring, slowly add concentrated sulfuric acid, control the temperature below 80°C, and prepare a sulfuric acid solution with a concentration of 30wt%. The resulting sulfuric acid solution was cooled to 25 °C. Add m-aminophenol thereto then, m-aminophenol: the vitriol oil: the mol ratio of sodium nitrite is 1.5:3:1.5. Stir for 15 minutes to dissolve m-aminophenol to form a mixed solution containing water, sulfuric acid and m-aminophenol. Then the mixed solution was cooled to -8°C for use.

[0161] Enter water in another preparation tank and add NaNO 2 , prepare 25wt% sodium nitrite aqueous solution. The sodium nitrite aqueous solution was cooled to 0°C.

[0162] The sodium nitrite aqueous solution of cooling is all dropped in the diazotization reaction tank, mixes with the above-mentioned cooling mixed solution, forms the diazotization reaction liquid, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com