Patents

Literature

123 results about "Meta-aminophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

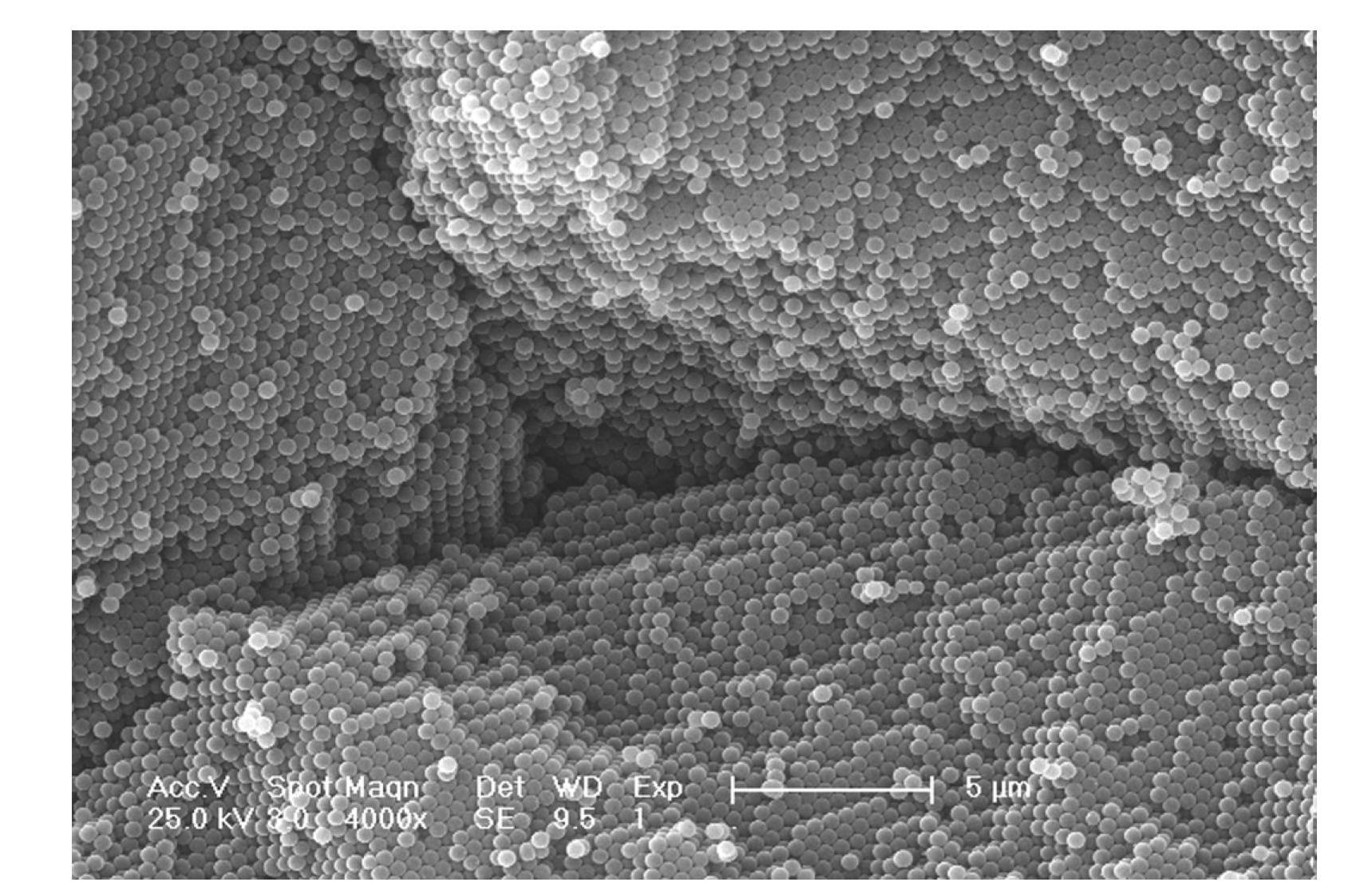

Method for preparing porous spherical manganese oxide/carbon compound

InactiveCN109659145AIncrease productionSimple processHybrid capacitor electrodesM-aminophenolCarbonization

The invention relates to a method for preparing a porous spherical manganese oxide / carbon compound. The method comprises the steps of: 1) adding a manganese oxide precursor of a certain concentrationinto a dispersion liquid of m-aminophenol formaldehyde resin spheres, stirring the mixture for several hours and then carrying out centrifugal separation on the mixture to obtain a m-aminophenol formaldehyde resin sphere / manganese oxide precursor compound; 2) placing the m-aminophenol formaldehyde resin sphere / manganese oxide precursor compound obtained in the step 1) into an oven, allowing it tostand for a period of time and then carrying out heat treatment thereon; 3) subjecting the m-aminophenol formaldehyde resin sphere / manganese oxide precursor compound after heat treatment to high temperature carbonization in a nitrogen atmosphere to obtain the porous spherical manganese oxide / carbon compound. Compared with the prior art, the method is simple and mild, the content of manganese oxidein the compound and the size of pores in the compound can be adjusted by changing the concentration of the manganese precursor, the equipment and process are simple, the cost is low, the cycle is short, and the yield is high.

Owner:SHANGHAI INST OF TECH

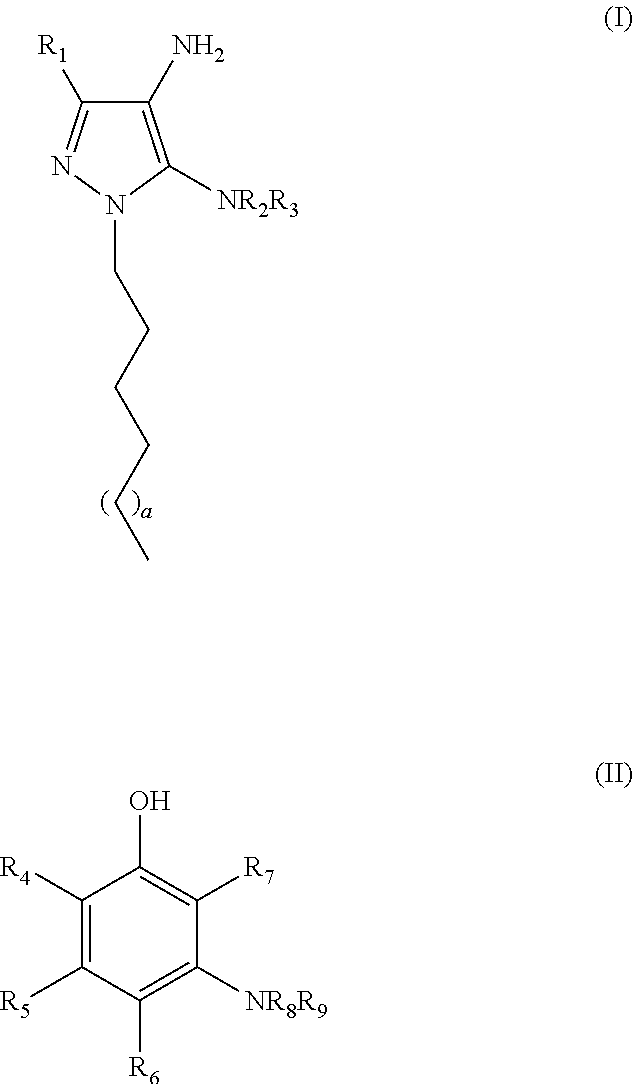

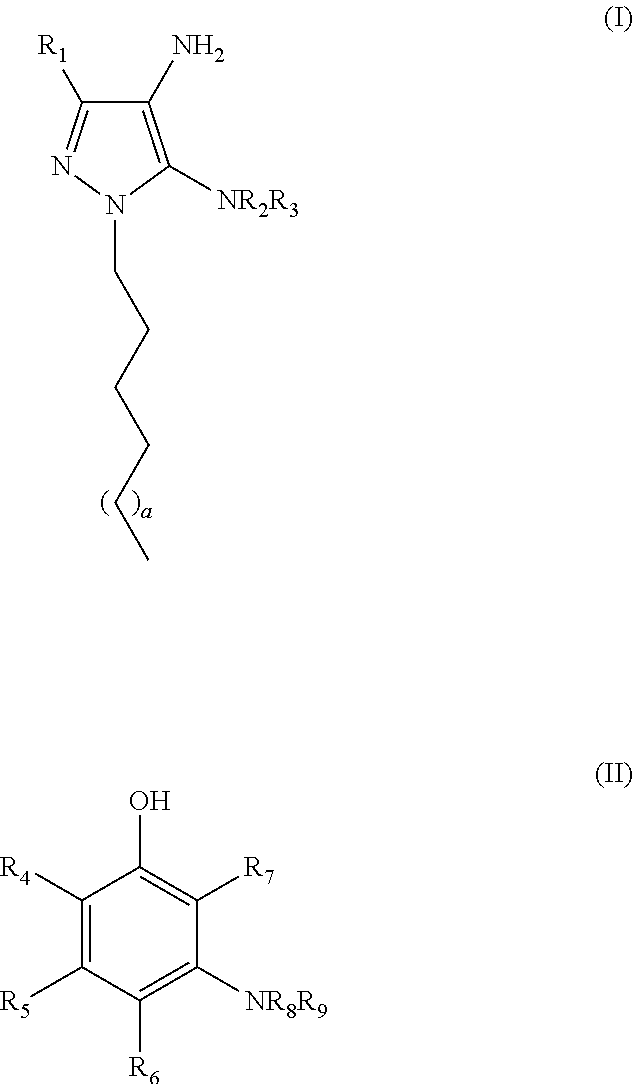

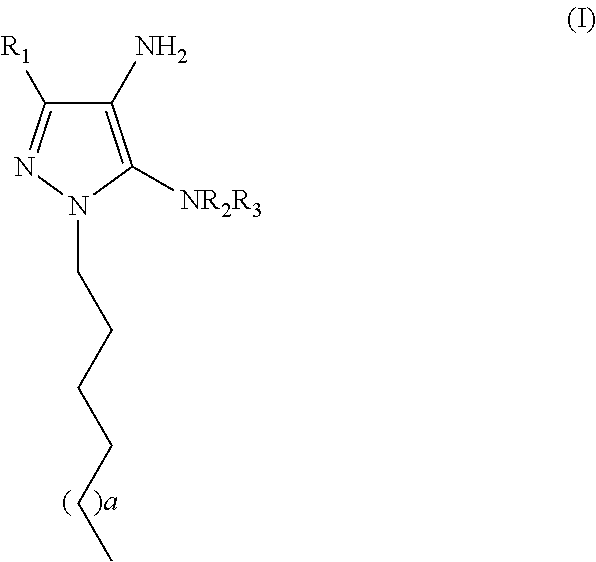

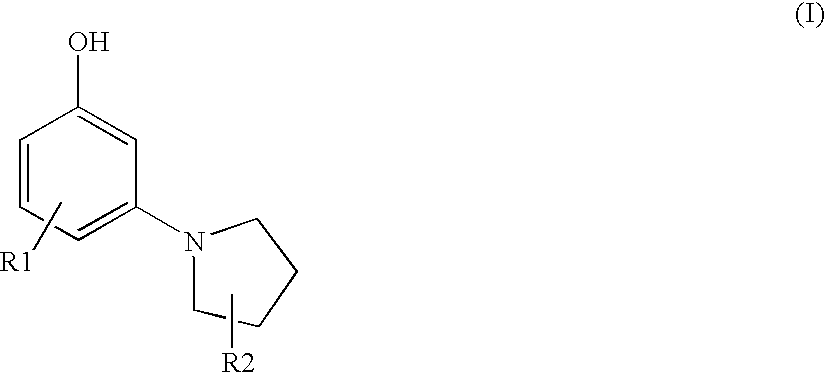

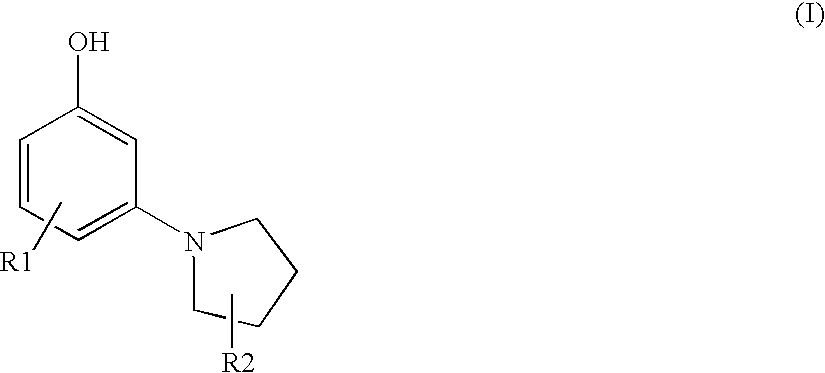

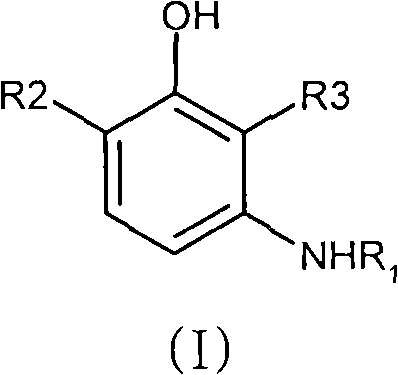

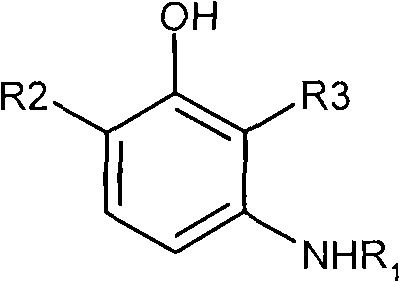

Oxidative Dyeing Compositions Comprising an 1-Hexyl/Heptyl-4,5-diaminopyrazole and a m-Aminophenol and Derivatives Thereof

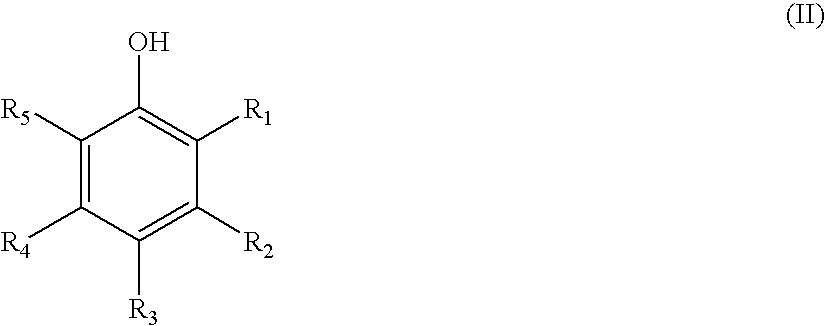

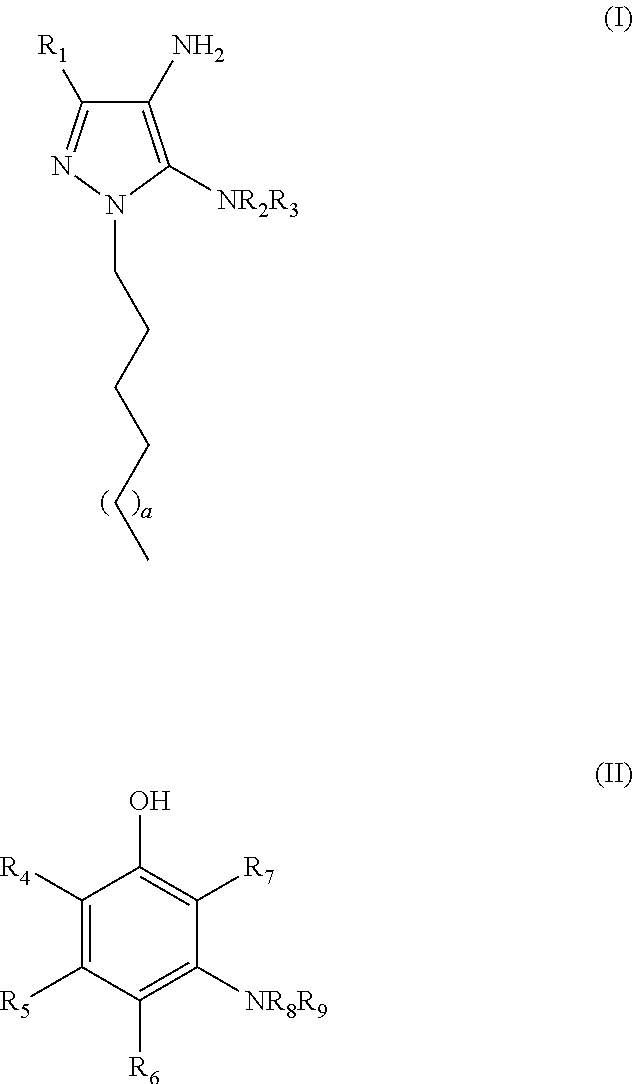

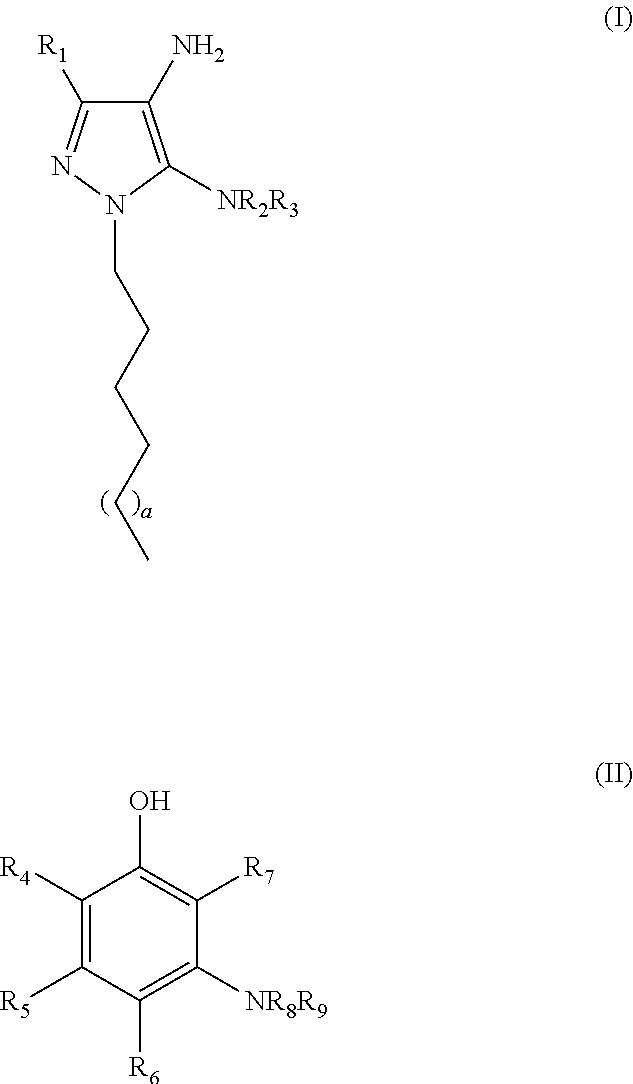

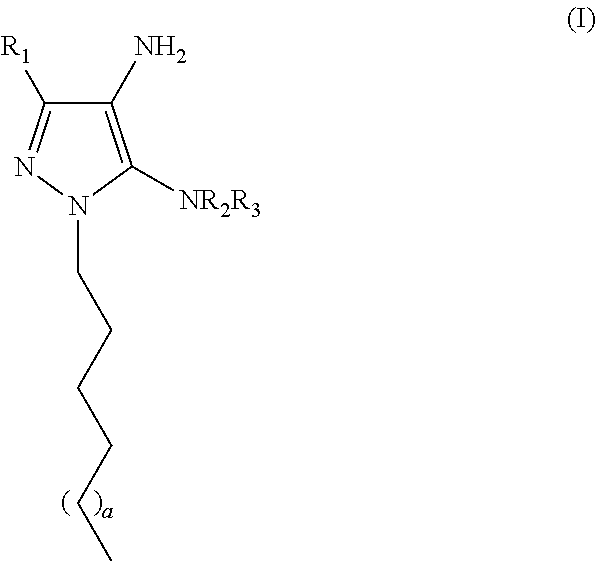

Compositions for the oxidative dyeing of keratin fibers, in particular human keratin fibers, comprising (A) a 1-hexyl / heptyl-4,5-diaminopyrazole compound of the general formula (I), its physiologically compatible water-soluble salt, or mixtures thereof and; (B) a m-aminophenol compound of the general formula (II), its physiologically compatible water-soluble salt, or mixtures thereof; and (C) an oxidizing agent.wherein R1, R2, R3, R4, R5, R6, R7, R8 and R9 are as defined herein and a=1 or 2.

Owner:WELLA OPERATIONS US LLC

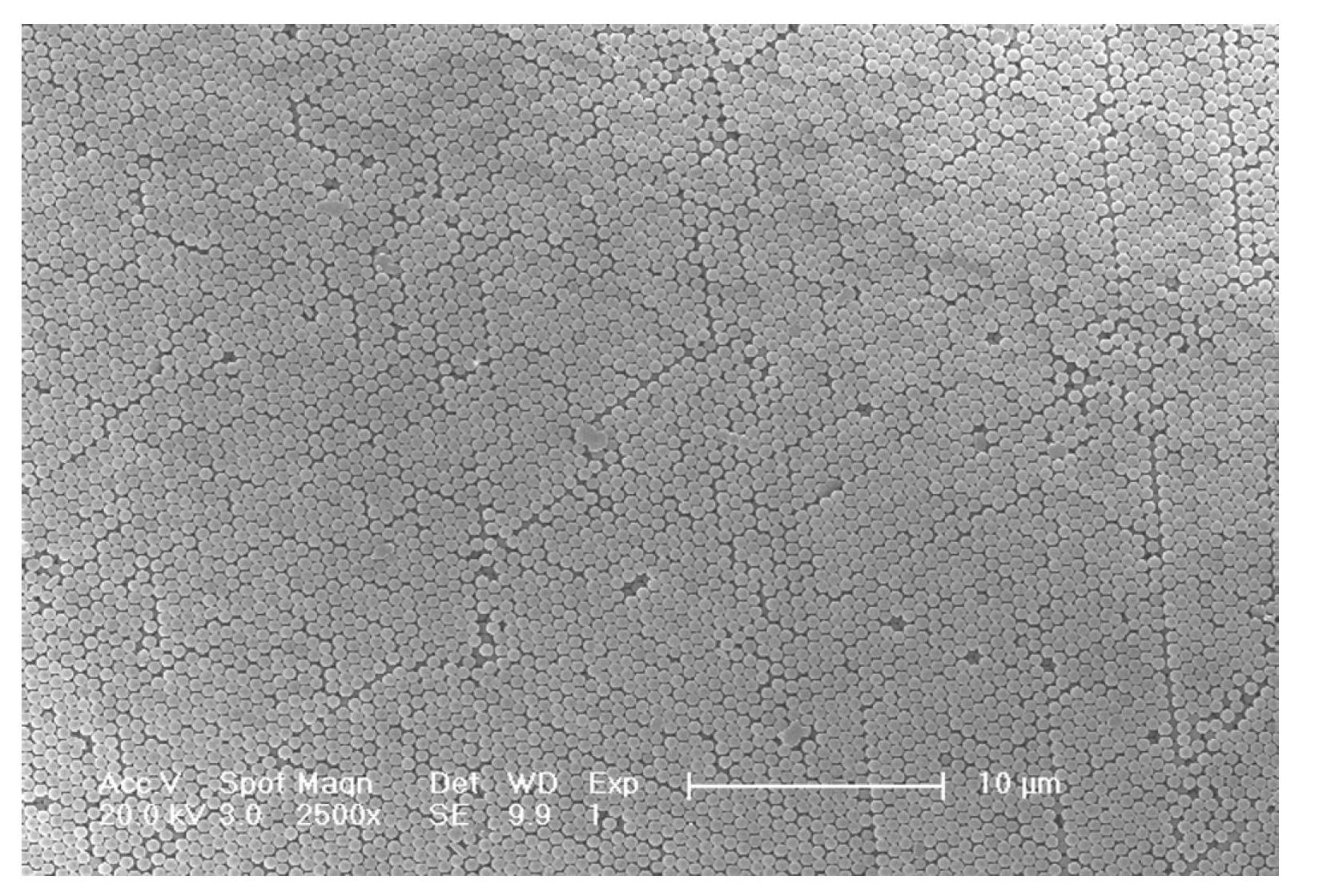

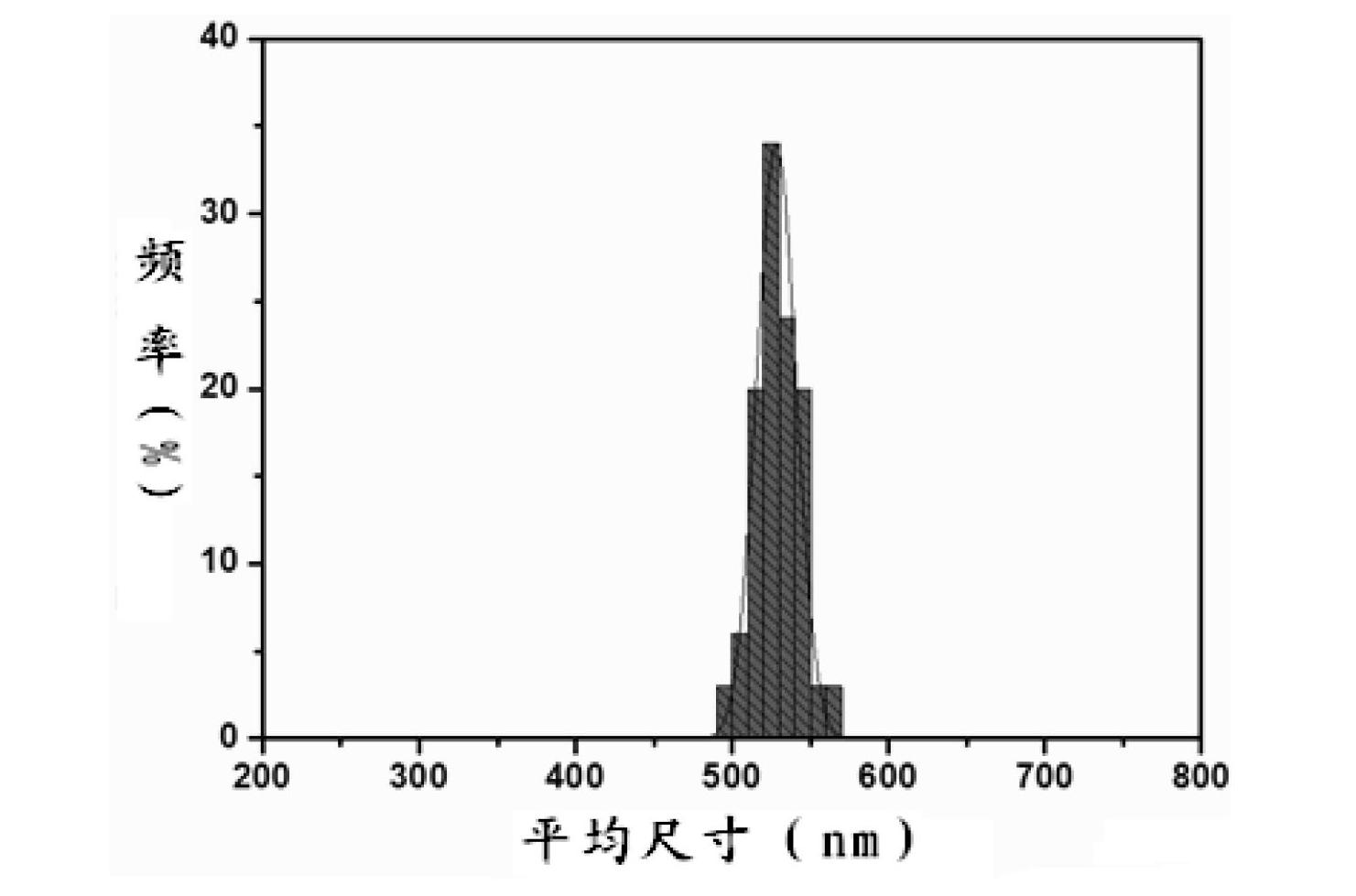

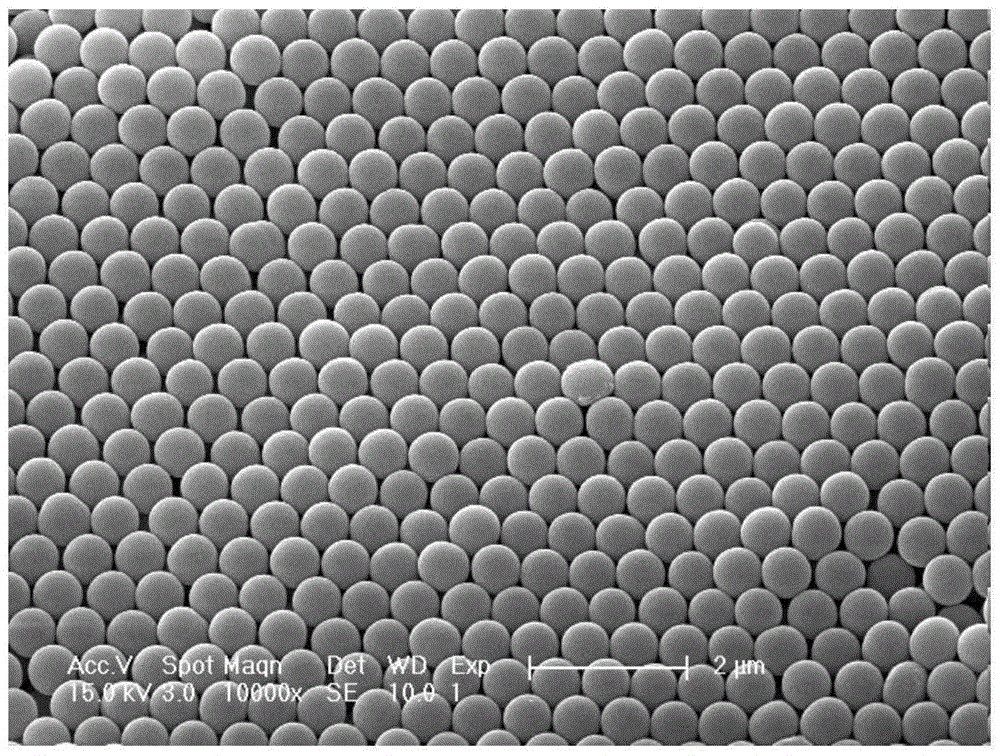

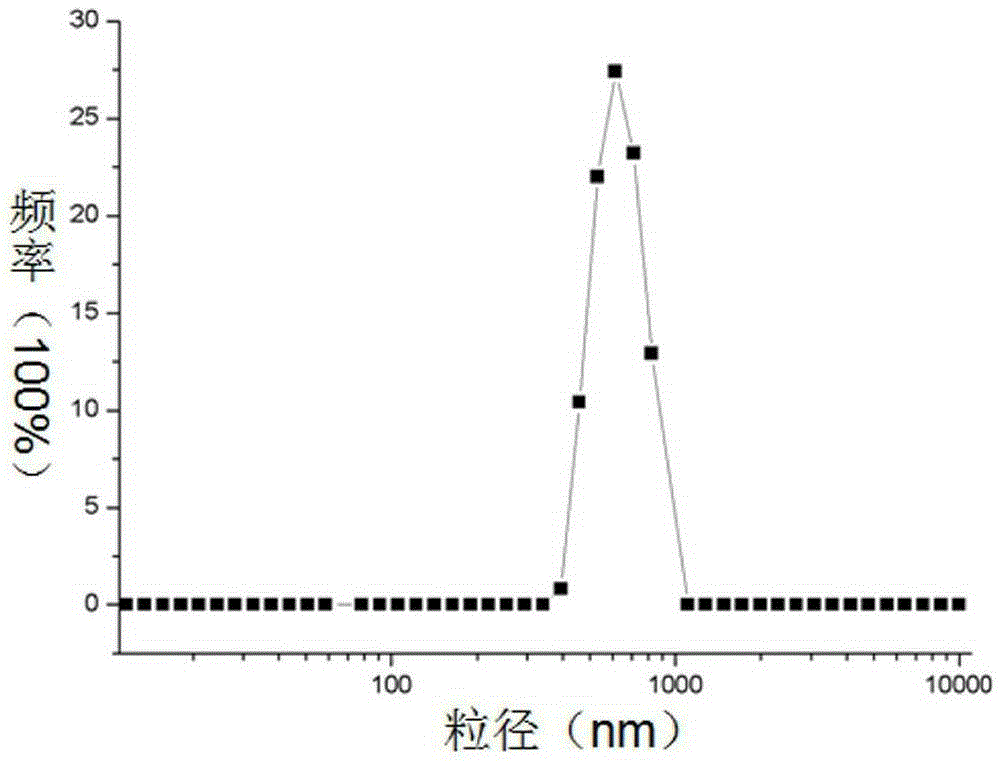

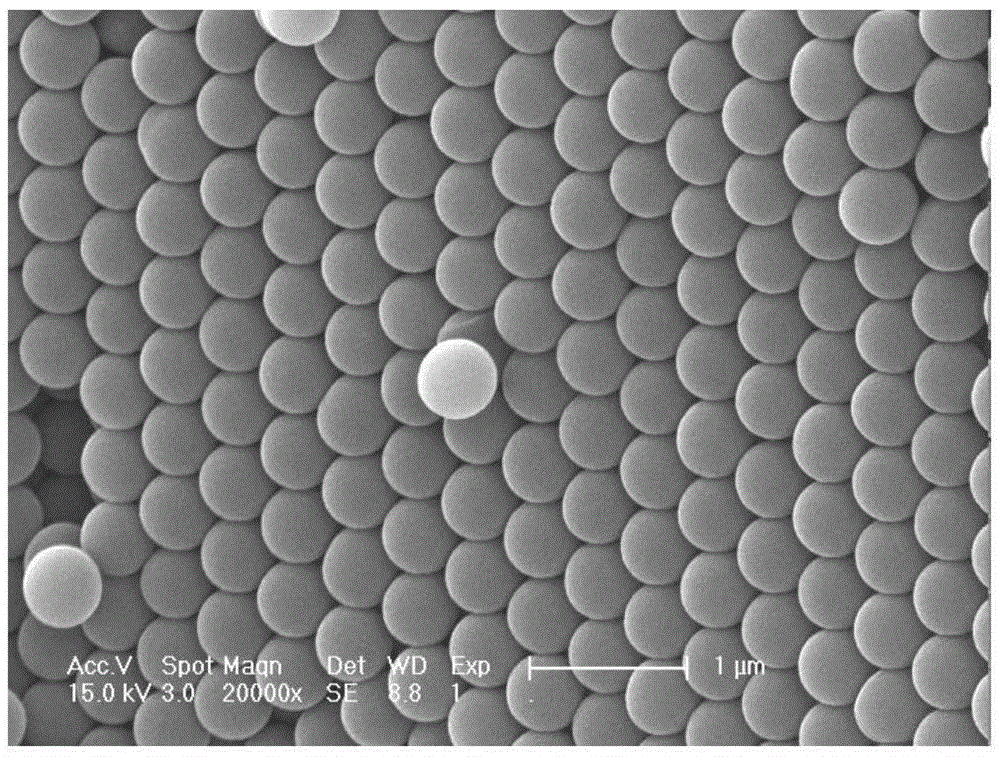

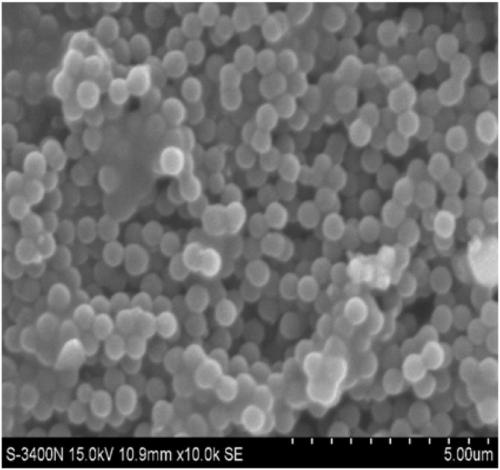

Preparation method of meta-aminophenol-formaldehyde resin spheres and preparation method of carbon spheres

ActiveCN102643513AGood monodispersityAvoid stickingCarbon preparation/purificationEthylenediamineSolvent

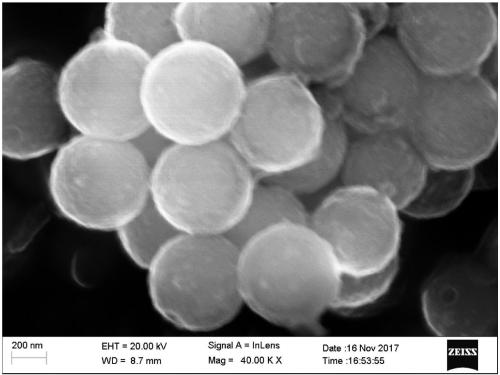

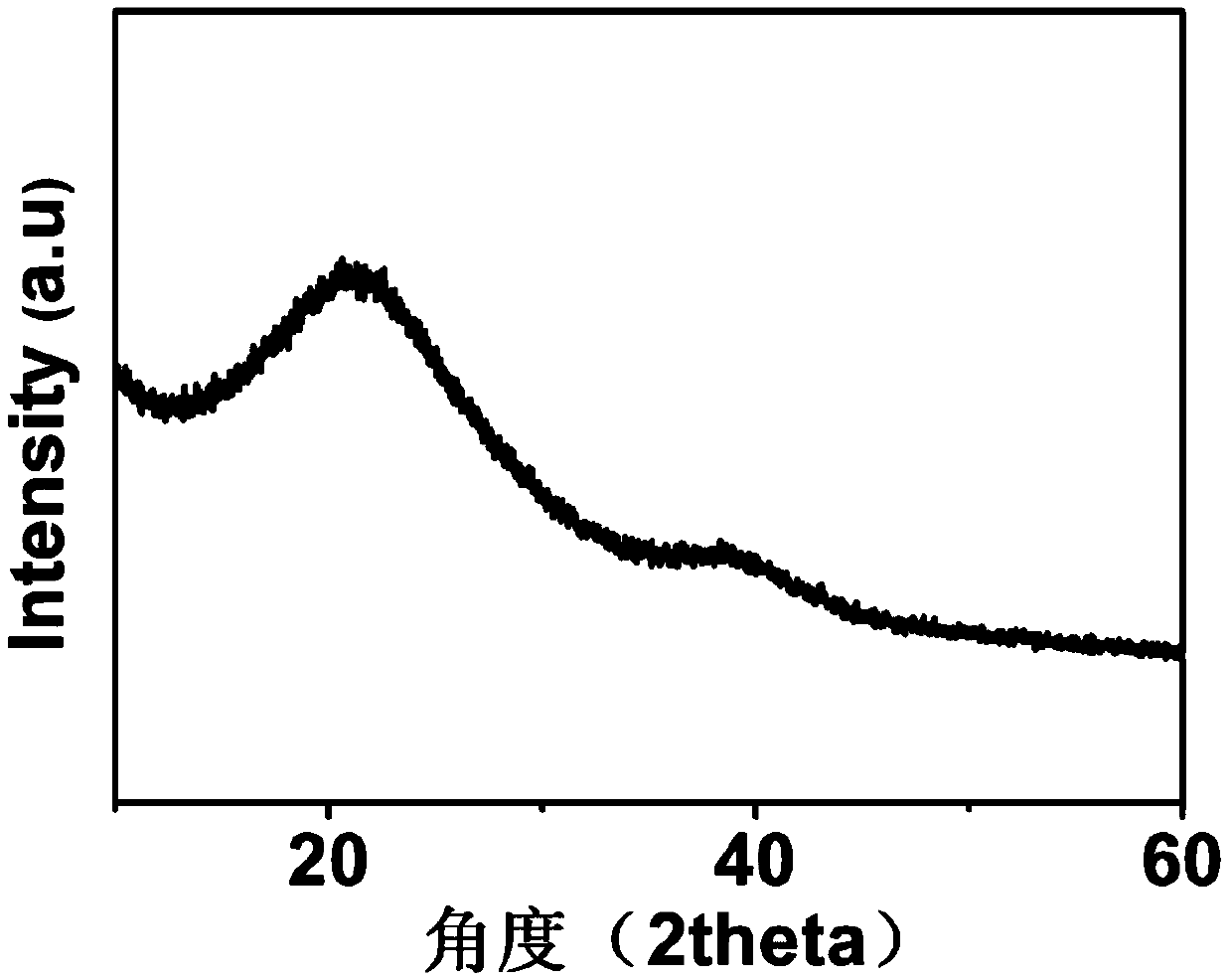

The invention provides a preparation method of meta-aminophenol-formaldehyde resin spheres and a preparation method of carbon spheres. Meta-aminophenol and formaldehyde are subjected to polymerization reaction in the presence of ammonia water and / or ethylene diamine. In the polymerization reaction process, the formaldehyde, the meta-aminophenol and the ammonia water and / or ethylene diamine as the catalyst form a micelle in the solvent; in the micelle, the meta-aminophenol and the formaldehyde are subjected to polymerization reaction under the catalytic action of the ammonia water and / or ethylene diamine to obtain the meta-aminophenolformaldehyde resin spheres; and meanwhile, part of the ammonia water and / or ethylene diamine are / is distributed on the surface of the micelle to form positive charges, and the electrostatic repulsion action inhibits the bonding of the micelle. Thus, the obtained meta-aminophenol-formaldehyde resin spheres have high monodispersity, and the dimensions of the resin spheres can be adjusted within a wide range. The meta-aminophenol-formaldehyde resin spheres are calcined to obtain the corresponding carbon spheres, and the carbon spheres also have high monodispersity, thereby being beneficial to the application of the carbon spheres.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

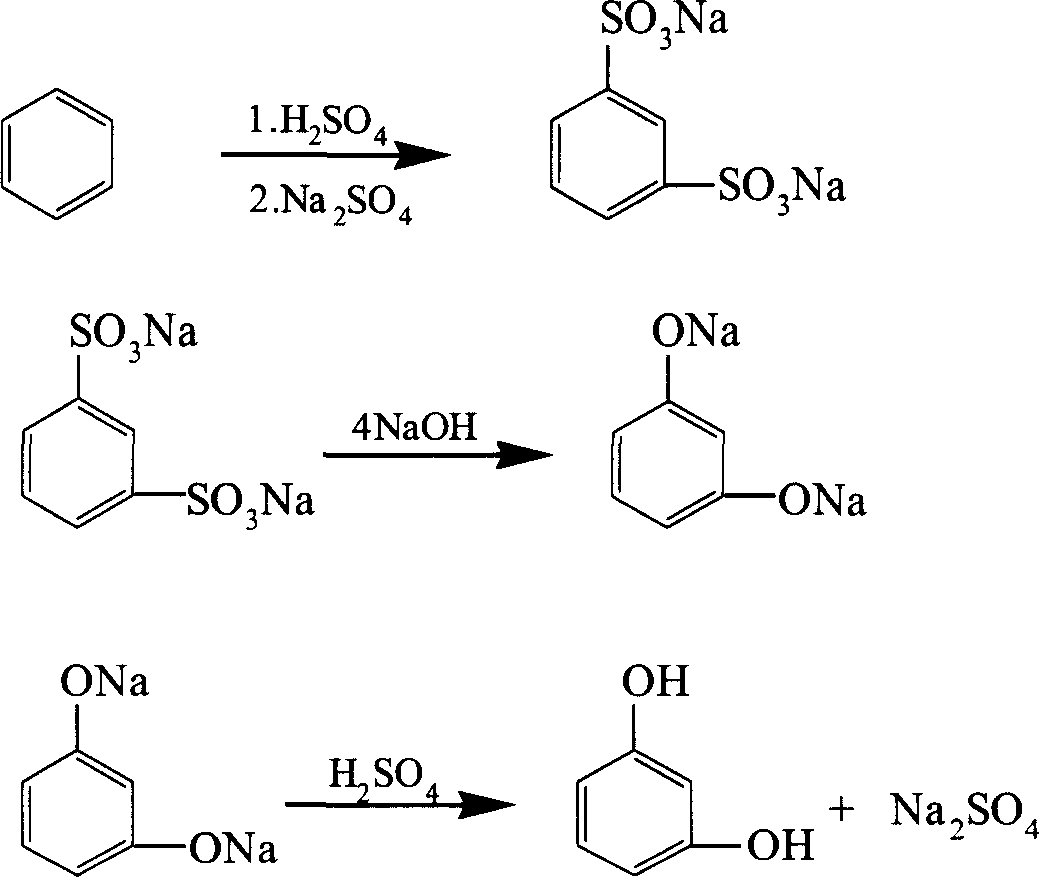

Process for preparing resorcinol

InactiveCN1830933ANo emissionsSolve pollutionOrganic chemistryOrganic compound preparationMeta-aminophenolResorcinol

Owner:HUIFENG CHEM PLANT WUJIANG CITY

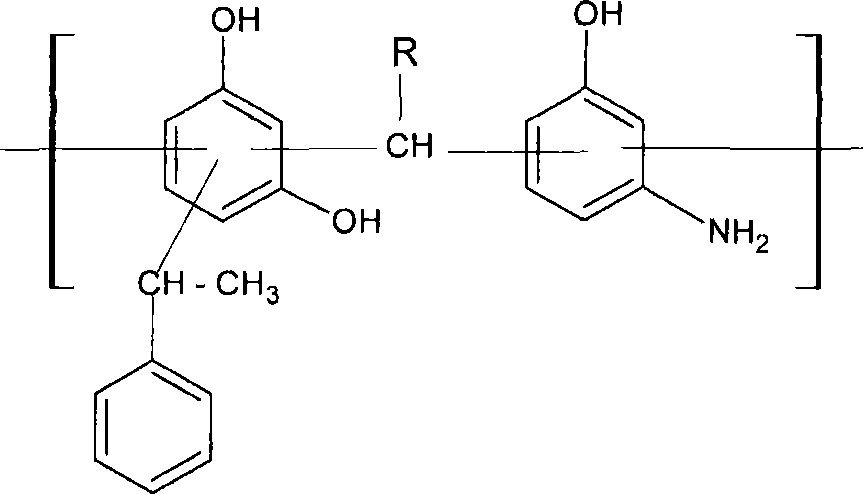

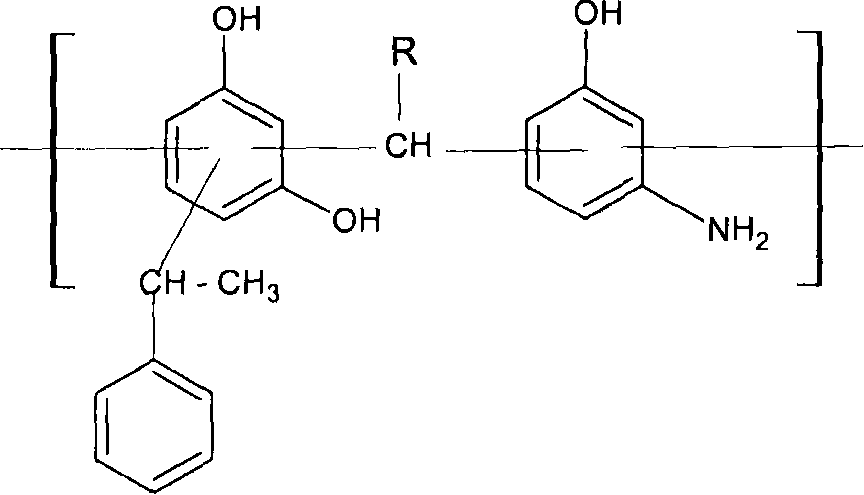

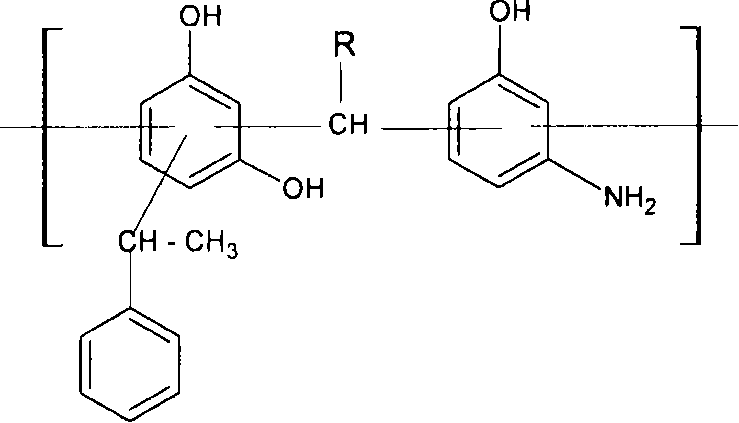

M-aminophenol modified aralkylresorcinol-aldehydes compound resin used for rubber formulation and application

The invention relates to a modified cured rubber compound which comprises (i) the rubber components of natural rubber or synthetic rubber, (ii) methano donator, (iii) aralkyl resorcin-aldehyde resin as the methano acceptor, which is modified by m-aminophenol. The inventive methano acceptor has lower smoke degree than R-80 and higher vulcanizing speed than Penacolite B-20-S. The tension and tearing tests prove that the rubber added with the aralkyl resorcin-aldehyde resin modified by m-aminophenol has better performance than R-80 and B-20-S.

Owner:RACHEM CHINA CO LTD

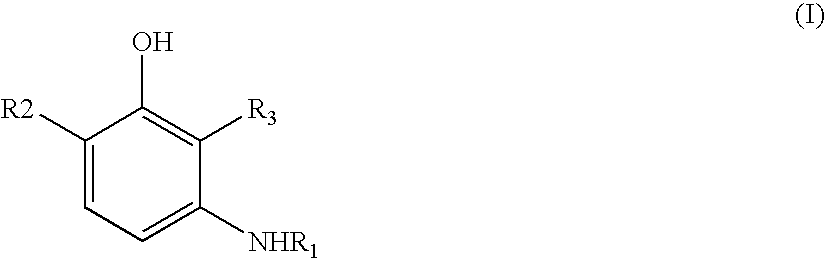

Agent for dyeing keratin fibers containing 2-amino-5-methyl-phenol and m-aminophenoles

The present patent application relates to an agent for oxidative coloring of keratin fibers, containing a combination of 2-amino-5-ethylphenol and at least one m-aminophenol of general Formula (I) wherein R1=H or C2H4OH; R2=CH3 or C2H5, and R3=H or CH3; wherein R2 is not equal to CH3, if R1 and R3 equal H; or physiologically compatible, water-soluble salts thereof.

Owner:THE PROCTER & GAMBLE COMPANY

In-situ nitrogen-doped hollow carbon ball and preparation method thereof and preparation method and application of electrode material

InactiveCN109626355AWide variety of sourcesLow priceNon-aqueous electrolyte accumulatorsCell electrodesM-aminophenolP-Aminophenol

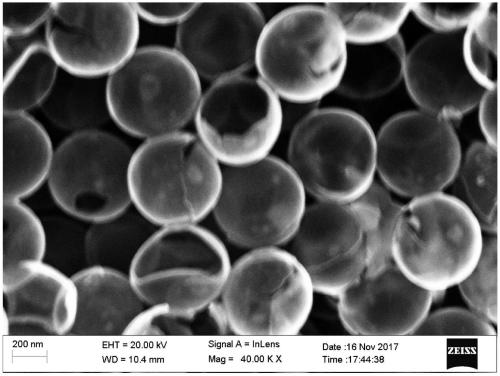

The invention provides an in-situ nitrogen-doped hollow carbon ball and a preparation method thereof and a preparation method and application of an electrode material and relates to the technical field of electrochemistry energy materials. According to the in-situ nitrogen-doped hollow carbon ball, the SiO2 ball is used as a rigid membrane plate, formaldehyde is used as a carbon source, and one ormore of p-acetamidophenol, 2-acetamidophenol, p-aminophenol and m-aminophenol are used as a nitrogen source; the rigid membrane plate, the carbon source and the nitrogen source are placed in a reaction system of ethyl alcohol, water and ammonium hydroxide; through a sol-gel process, the SiO2 ball is wrapped by phenolic resin prepared through an aldol condensation reaction, the SiO2 / phenolic resinball with a core-shell structure is prepared, and the nitrogen-doped hollow carbon ball is obtained through carbonization and silicon removal. The prepared nitrogen-doped hollow carbon ball has the advantages of being small in nanoscale, even in shape, high in specific surface area and the like and has wide application prospects in the aspects such as energy storage, catalysis and adsorption.

Owner:YANSHAN UNIV

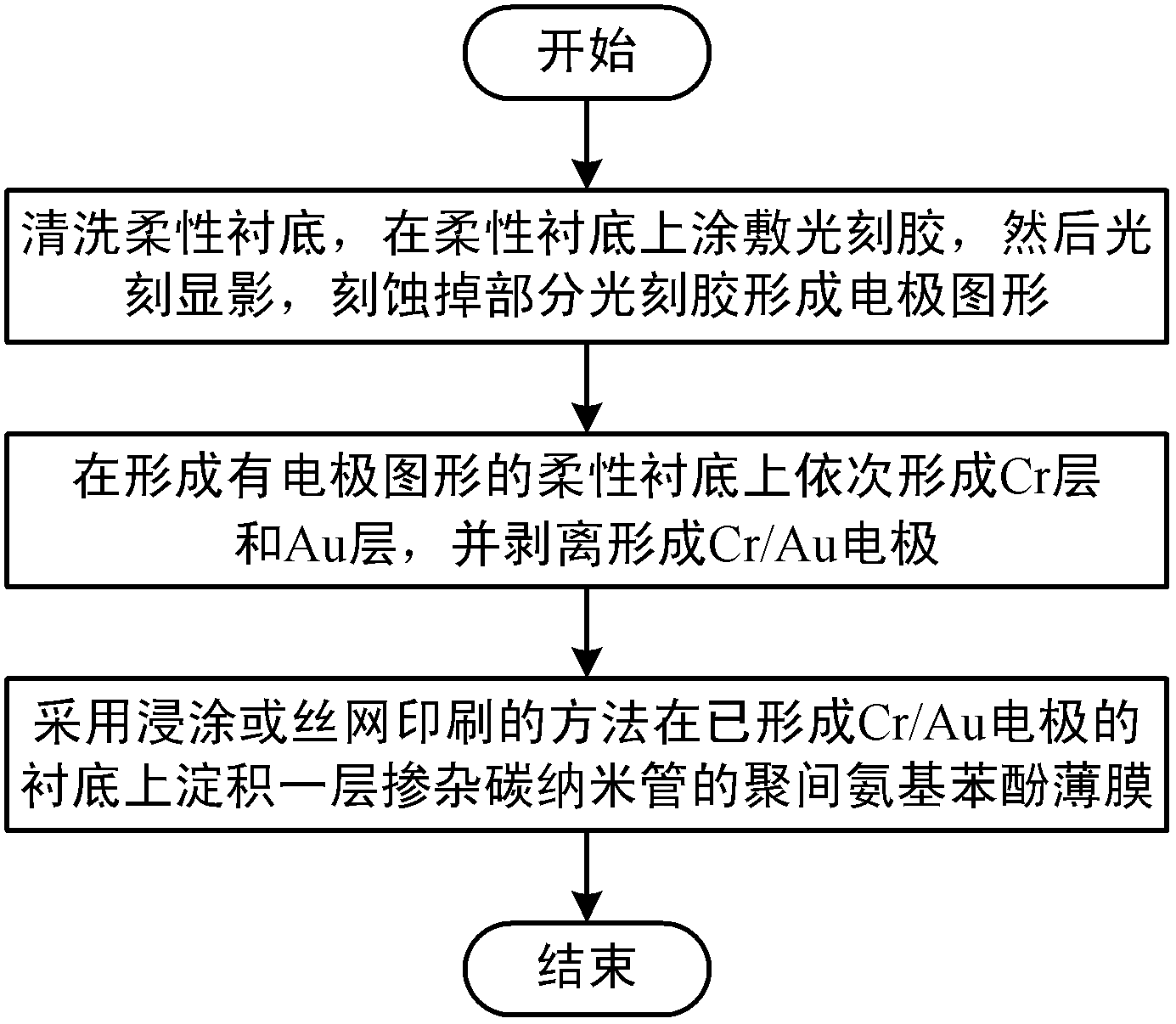

Method for preparing sensor membrane material based on flexible substrate

InactiveCN102798648AGood dispersionHigh sensitivityMaterial analysis by electric/magnetic meansScreen printingM-aminophenol

The invention discloses a method for preparing a flexible substrate-based sensitive membrane material of a sensor for detecting gases. The method comprises the following steps of: cleaning a flexible substrate, coating a photoresist on the flexible substrate and then performing photoetching development so as to etch off partial photoresist, thereby forming an electrode pattern; orderly forming a Cr layer and a Au layer on the flexible substrate with the electrode pattern formed thereon, and peeling off the two layers to form a Cr / Au electrode; and then depositing a layer of carbon nano-tube doped poly-m-aminophenol film on the substrate on which the Cr / Au electrode is formed already by methods such as dip-coating, screen printing and the like. According to the flexible substrate-based sensitive membrane material provided by the invention, the doping of the carbon nano-tubes completely takes the place of a concentrated strong acid traditionally doped in poly-m-aminophenol; in addition, the doping of the carbon nano-tubes also improves the sensitivity of the poly-m-aminophenol material to the detection of alcohols and ammonia at the normal temperature, and also realizes operability on the flexible substrate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Oxyalkylene-substituted aminophenol intermediate

InactiveUS6040482AGood choiceLow costOrganic chemistryDiaryl/thriaryl methane dyesM-aminophenolPhenol

This invention relates to very specific oxyalkylene-substituted aminophenol compounds as intermediates for the production of poly(oxyalkylene)-substituted xanthene (or other type) colorants. Such an inventive intermediate compound is produced in a single step by reacting an oxyalkylene oxide having from 3 to 12 carbon atoms (branched or unbranched), glycidol, or a glycidyl directly with aminophenol without the use of a catalyst and at a relatively low temperature. Propylene oxide and m-aminophenol are the preferred reactants. The propylene oxide selectively reacts with the amine group on the m-aminophenol without propoxylating the phenolic hydroxyl group. Such a specific method thus does not require extra time- and cost-consuming steps of protecting the phenolic hydroxyl group from attack. After production, this intermediate may be reacted with suitable compounds to ultimately form any number of different colorants, including xanthenes, oxazines, coumarins, and the like. The resultant oxypropylene groups may subsequently be reacted with electrophile compounds to produce any number of different colorants. Resultant colorants produced through the reaction of the inventive intermediate are also contemplated within this invention.

Owner:MILLIKEN & CO

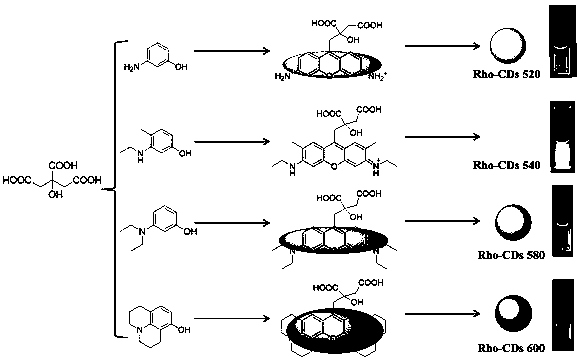

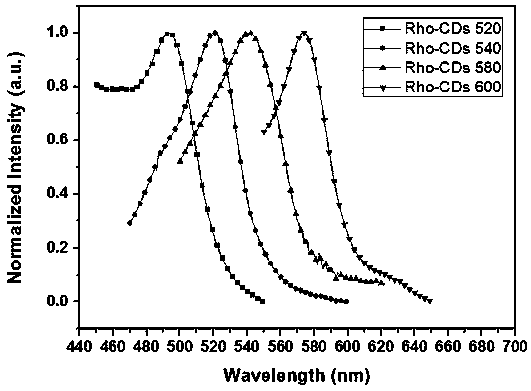

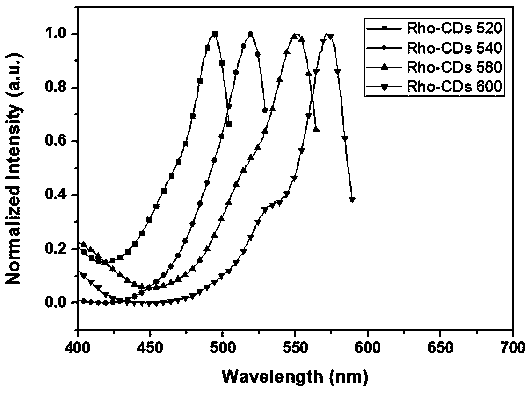

Preparation method of rhodamine hybridized carbon dots and application of rhodamine hybridized carbon dots in mitochondrion target recognition

ActiveCN108504349AThe preparation process is easy to controlPredictable preparationMaterial nanotechnologyNanoopticsLength waveCitric acid

The invention relates to a preparation method rhodamine hybridized carbon dots and application of the rhodamine hybridized carbon dots in mitochondrion target recognition. The preparation method disclosed by the invention has the beneficial effects that a microwave assisted method is utilized, citric acid and an m-amino phenol compound are used as raw materials, fluorescence emission wavelength can be regulated and controlled through a way of changing an amino group in a meta position of phenol, rhodamine molecular fluorogen hybridized carbon dots are generated, and preparation of controllableand divinable fluorescence emission wavelength carbon dots is realized. The preparation method disclosed by the invention is simple in operation, can easily obtain the raw materials and is green andenvironment-friendly, and a new strategy for synthesizing molecular fluorogen hybridized carbon dots is created. The rhodamine hybridized carbon dots prepared by the invention can be used for the mitochondrion target recognition in cells, and has potential application value in the fields of biology, medical treatment and the like.

Owner:ZHENGZHOU UNIV

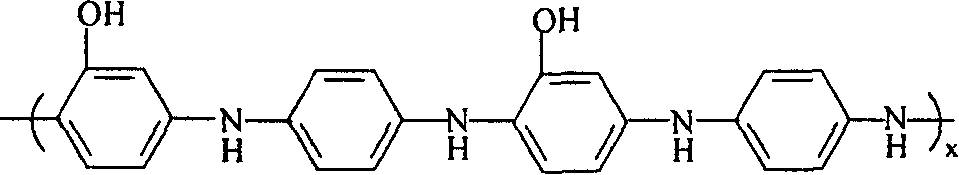

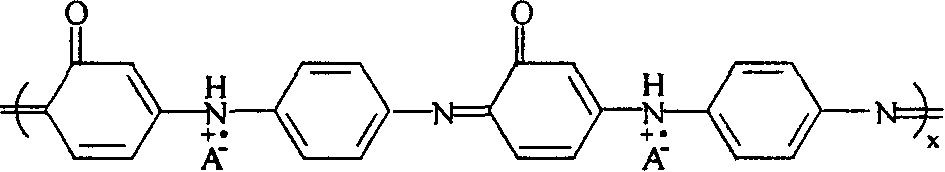

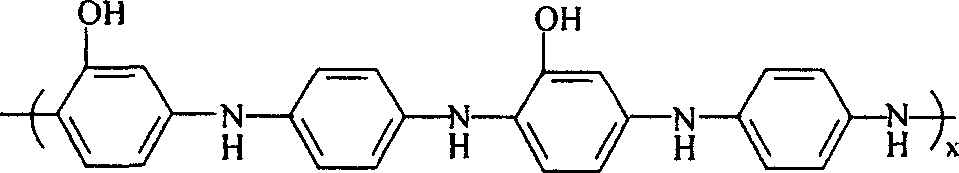

Copolymer of conductive polyaniline and m-aminophenol and its synthesis process

The present invention is aniline-m-aminophenol copolymer as one kind of conductive polymer and its synthesis. Inside an electrolytic bath with Pt electrode or C electrode, aniline, m-aminophenol and sulfuric acid or hydrochloric acid are electrolyzed to obtain the conductive polymer, aniline-m-aminophenol copolymer, which is washed with dilute hydrochloric acid solution and dried. The conductive polymer has excellent characteristic similar to that of polyaniline, and capacity of maintaining high chemical activity in strong acid solution and pH 1.0-11.0 sodium sulfate solution. When the pH value of the copolymer raises from 5.0 to 11.0, it has chemical activity lowered to 58.3 %. The copolymer has wide application potential range,(-0.2 to 0.80 Vú¼vs.SCE), conductivity of 0.8-1.4S / cm, and lower dependence on pH value.

Owner:YANGZHOU UNIV

Oxidative dyeing compositions comprising an 1-hexyl/heptyl-4,5-diaminopyrazole and a m-aminophenol and derivatives thereof

Compositions for the oxidative dyeing of keratin fibers, in particular human keratin fibers, comprising (A) a 1-hexyl / heptyl-4,5-diaminopyrazole compound of the general formula (I), its physiologically compatible water-soluble salt, or mixtures thereof and; (B) a m-aminophenol compound of the general formula (II), its physiologically compatible water-soluble salt, or mixtures thereof; and (C) an oxidizing agent.wherein R1, R2, R3, R4, R5, R6, R7, R8 and R9 are as defined herein and a=1 or 2.

Owner:WELLA OPERATIONS US LLC

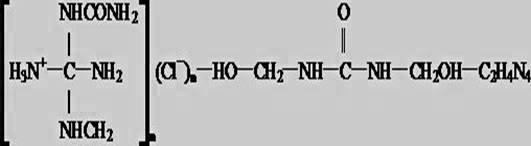

Low-temperature deep gel profile-modification plugging agent and preparation method thereof

InactiveCN102304354AImprove stabilityImprove salt resistanceDrilling compositionWater diversionMeta-aminophenol

The invention relates to a plugging agent for oil field production, particularly a low-temperature deep gel profile-modification plugging agent and a preparation method thereof. The profile-modification plugging agent is prepared from the following components in percentage by weight: 0.08-0.2% of high polymer coagulant, 0.18-0.25% of dicyandiamide modified urea formaldehyde resin delayed crosslinker, 0.05-0.20% of industrial soda ash, 0.01-0.02% of meta-aminophenol and the balance of water. The invention performs the certain functions of mechanical plugging, endurable movable plugging, dynamic water diversion, pressure wave oscillation and oil washing and carrying, and satisfies the demands for low-temperature oil reservoir high-dose deep profile-modification water plugging and displacement in the oil field.

Owner:盘锦市庆联油田工程技术服务有限公司

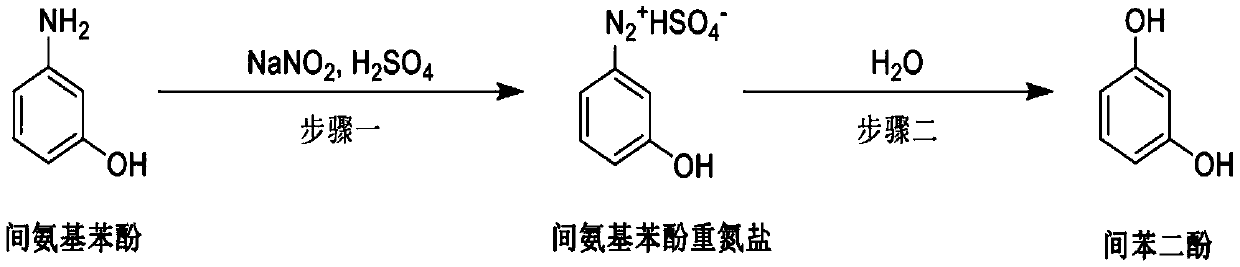

Preparation method of resorcinol

PendingCN111592447ALess side effectsHigh yieldOrganic chemistryOrganic compound preparationOrganic solventHydrolysis

The invention belongs to the field of chemical engineering, and particularly relates to a preparation method of resorcinol, which comprises: (1) carrying out a diazotization reaction on m-aminophenoland a sodium nitrite solution in a dilute solution of concentrated sulfuric acid to generate m-aminophenol diazonium salt, with the diazotization reaction temperature being 0 DEG C or below; (2) carrying out a hydrolysis reaction on the m-aminophenol diazonium salt in the presence of an organic solvent and water to obtain a resorcinol crude product, with the volume ratio of the water to the organic solvent being (0.5-1.5):(4-6); (3) carrying out post-treatment on the resorcinol crude product to obtain a product resorcinol, wherein the post-treatment step sequentially comprises: (i) an extraction stage; (ii) a vacuum distillation stage; (iii) a pickling stage; and (iv) refining, washing and drying stages. By using the method disclosed by the invention, the resorcinol yield can be greatly improved.

Owner:INNER MONGOLIA SHENG TANG INT MONGOLIAN MEDICINE RES INST CO LTD +1

Autocatalysis preparation method of copolymer benzoxazine-resin polymer sphere and autocatalysis preparation method of resin-based carbon sphere

The invention provides an autocatalysis preparation method of a copolymer benzoxazine-resin polymer sphere and belongs to the technical field of polymers. According to the method, on the condition that no catalyst is added, m-aminophenol and formaldehyde are dissolved in a solvent, and after a polymerization reaction, the copolymer benzoxazine-resin polymer sphere is obtained; the solvent is a mixed solution of water and alcohol compounds. The invention further provides a preparation method of a copolymer benzoxazine-resin-based carbon sphere; the method comprises the step that the obtained copolymer benzoxazine-resin polymer sphere is sintered to obtain the corresponding carbon sphere. The obtained copolymer benzoxazine-resin polymer sphere and carbon sphere have the high monodispersity, the size of the resin sphere can be adjusted in a wide range, and the application of the resin sphere is facilitated. The copolymer benzoxazine-resin polymer sphere prepared through the method has the high concentration in a unit reaction system.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

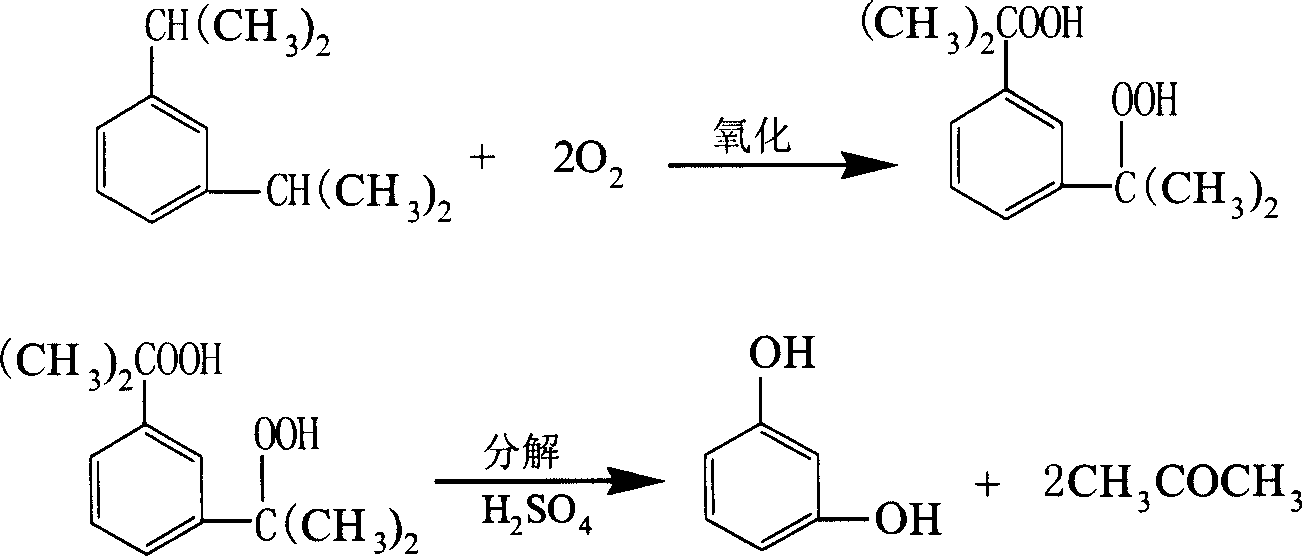

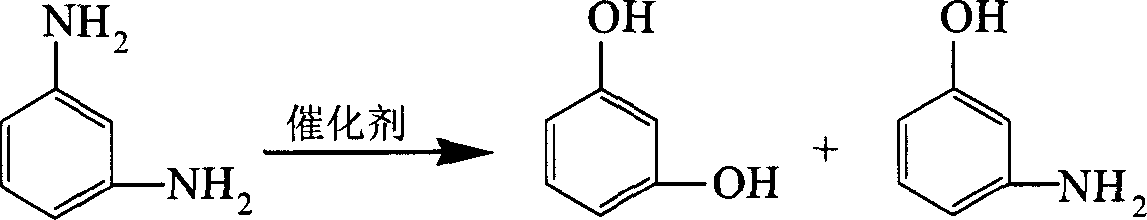

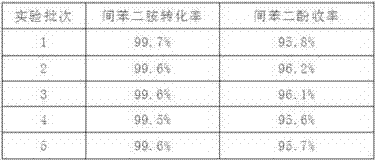

Method for preparing m-aminophenol by catalytic hydrolysis of m-phenylenediamine

InactiveCN101538211ALow costHigh yieldOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolReaction temperature

The invention provides a method for preparing m-aminophenol by the catalytic hydrolysis of m-phenylenediamine, which comprises the following steps: under the condition of the existence of inorganic acid catalysts, m-phenylenediamine is hydrolyzed at the temperature of 180 DEG C to 230 DEG C and the pressure of 0.9 to 3.0 MPa for 2 to 10 hours; a solvent is adopted to extract hydrolysis products to respectively obtain m-dihydroxybenzene extraction liquid, m-phenylenediamine extraction liquid and m-aminophenol extraction liquid according to different pH values, and then the m-phenylenediamine extraction liquid is processed to be used as raw material for hydrolysis next time; the m-aminophenol extraction liquid is processed by vacuum distillation after being processed by exsolution, and then active carbon is decolourized and recrystallized to obtain m-aminophenol whose purity is more than 99 percent; and the m-dihydroxybenzene extraction liquid is processed by vacuum distillation after being processed by exsolution to obtain the m-dihydroxybenzene whose purity is 99 percent. The method for preparing m-aminophenol by catalytic hydrolysis of m-phenylenediamine is adopted, and proper technological conditions are controlled in the reaction process. The method has the advantages of low cost of raw material and high product yield.

Owner:台州市经纬化工有限公司 +1

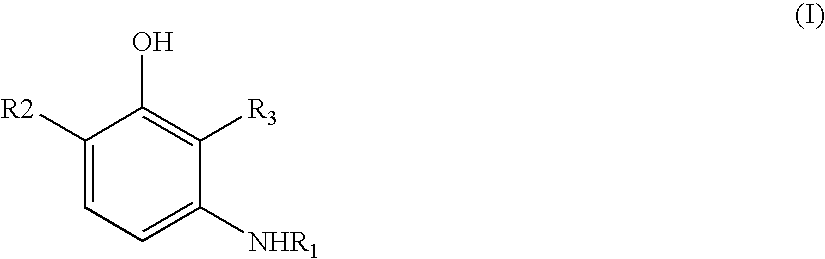

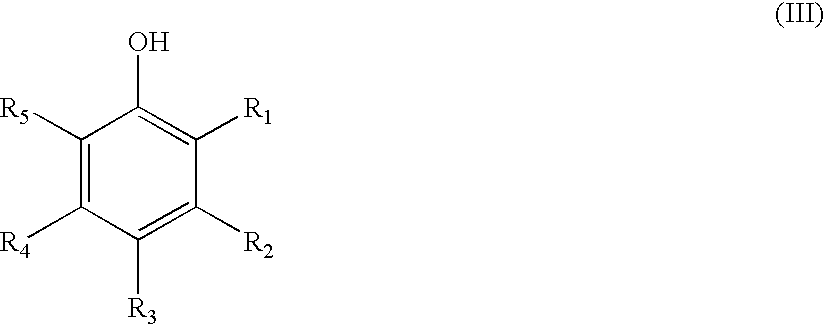

Oxidizing hair coloring agents containing m-aminophenol derivatives

InactiveUS7491244B2Meet the requirementsNatural colorCosmetic preparationsHair cosmeticsM-aminophenolHydrogen

The object of the present patent application are agents for the oxidative coloring of keratin fibers, particularly hair, based on a developer substance-coupler substance combination, characterized in that they contain at least one meta-aminophenol derivative of general formula (I)whereinR1 denotes hydrogen, a C1-C6 alkyl group, a C2-C4 hydroxyalkyl group, a C2-C4 dihydroxyalkyl group, a C1-C4 alkoxy group or a halogen atom; and R2 denotes hydrogen, a hydroxy group, a carboxylic group, an aminocarbonyl group or a hydroxymethyl group.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of supported solid acid catalyst for hydrolysis of m-phenylenediamine

ActiveCN107262150AGood chemical stabilityStrong consumptionOrganic chemistryOrganic compound preparationActivated carbonM-aminophenol

The invention relates to the technical field of production of m-phenylenediamine and in particular relates to a preparation method of a supported solid acid catalyst for hydrolysis of m-phenylenediamine. The preparation method of the supported solid acid catalyst for hydrolysis of m-phenylenediamine is characterized by comprising the following steps: heating, refluxing and washing activated carbon powder by adopting an acid solution, and washing with deionized water until the pH value is invariable; adding a pretreatment agent for heating and refluxing, washing the treated activated carbon powder with deionized water until the pH value is invariable, and performing vacuum drying for later use; adding heteropolyacid impregnation liquid into the activated carbon powder, filtering the carbon powder subjected to complete impregnation, performing reduced pressure drying, and curing at a high temperature, thereby obtaining the product. The method disclosed by the invention is simple in steps, the prepared catalyst is easily controllable in active ingredient capacity, high in catalytic activity, high in stability and long in service life; and the product is applied to a reaction for preparing resorcinol and m-aminophenol through hydrolysis of m-phenylenediamine, high conversion ratio and yield can be obtained, and polymerized coke and other side reactions can be effectively controlled.

Owner:QINGDAO UNIV OF SCI & TECH

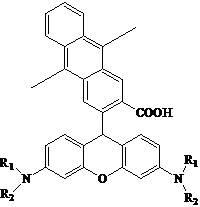

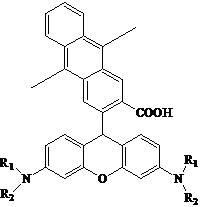

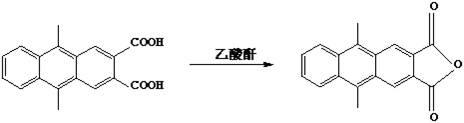

Rhodamine-based fluorescent indicator for indicating aging degree of rubber and preparation method of indicator

InactiveCN102146069AHas a chemical structureOrganic chemistryLuminescent compositionsAcetic anhydrideFiltration

The invention relates to an indicator for indicating the aging degree of rubber, which is characterized in that: 9,10-dimethyl-2,3-anthracenedicarboxylate is mixed with acetic anhydride to obtain 9,10-dimethyl-2,3-anthracenedimethanoic anhydride by means of reflux reaction; and 9,10-dimethyl-2,3-anthracenedimethanoic anhydride and meta-aminophenol which is twice in weight as much as 9,10-dimethyl-2,3-anthracenedimethanoic anhydride are dissolved in a strongly acidic medium, reaction is performed for 9 to 12 hours at 68 to 90 DEG C, and a 9-[2-(3-carboxyl-9,10-dimethyl)anthracene]-6-amino-3H-xanthene ring-3-imine indicator is obtained by filtration, drying, extraction and benzene recrystallization. The compound prepared according to the method disclosed by the invention can be reacted with singlet oxygen, oxyradical or peroxy radical to generate fluorescent light. The fluorescent light of the indicator gets stronger as the concentration of active oxygen in the rubber increases. By mixing the indicator with various rubbers by certain weight proportions, the aging degree of rubber can be indicated vividly through color change.

Owner:FUJIAN NORMAL UNIV

Method for preparing porous titanium dioxide ball

InactiveCN109626423AIncrease productionThe preparation method is simple and gentleMaterial nanotechnologyTitanium dioxideM-aminophenolCarbonization

The invention relates to a method for a preparing porous titanium dioxide ball. The method comprises the following steps that 1), a titanium dioxide precursor is added into dispersion liquid of an m-aminophenol formaldehyde resin ball, after the mixture is stirred for several hours, centrifugal separation is conducted, and a compound of the m-aminophenol formaldehyde resin ball and the titanium dioxide precursor is obtained; 2), the obtained compound of the m-aminophenol formaldehyde resin ball and the titanium dioxide precursor in the step one is placed in an oven for standing for some time,and thermal treatment is conducted; 3) after thermal treatment, the compound of the m-aminophenol formaldehyde resin ball and the titanium dioxide precursor is placed in a nitrogen atmosphere for hightemperature carbonization and further roasted to remove carbon, and the porous titanium dioxide ball is obtained; compared with the prior art, the preparation method is simple and mild, the size of titanium dioxide holes can be adjusted by adjusting the concentration of the titanium dioxide precursor, the cost is low, the period is shorter, and the yield is higher.

Owner:SHANGHAI INST OF TECH

Agent to color keratin fibers containing 2-amino-5-methylphenol and m-aminophenoles

InactiveCN101312707AFulfilling Oxidative Dyes NeedsCosmetic preparationsHair cosmeticsM-aminophenolWater soluble

The present patent application relates to an agent for oxidative coloring of keratin fibers, containing a combination of 2-amino-5-ethylphenol and at least one m-aminophenol of general Formula (I) with Rl = H or C2H4OH; R2 = CH3 or C2H5, and R3 = H or CH3; wherein R2 is not equal to CH3 if Rl and R3 equal H; or physiologically compatible, water-soluble salts thereof.

Owner:PROCTER & GAMBLE CO

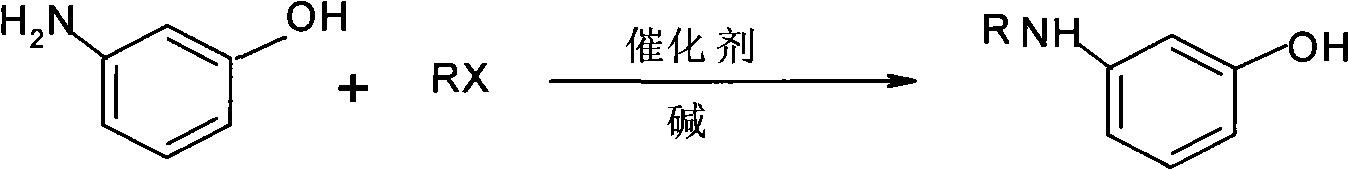

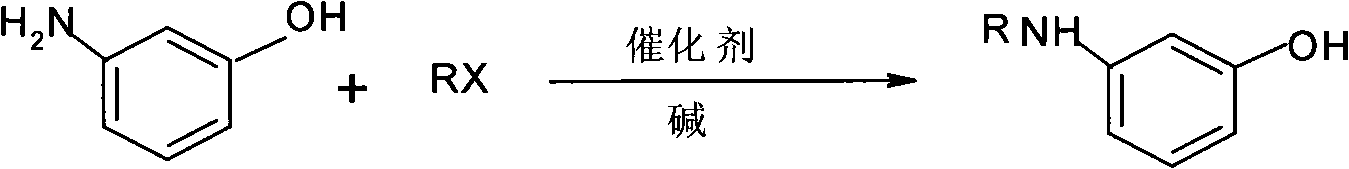

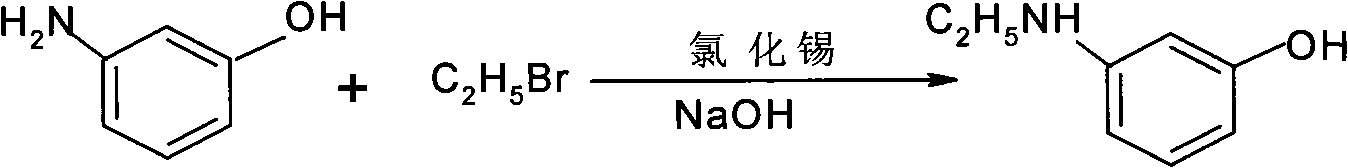

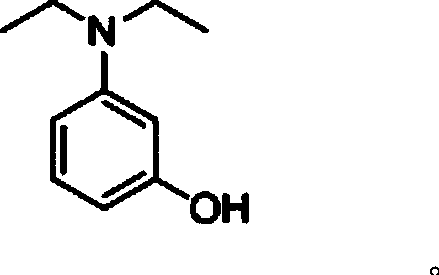

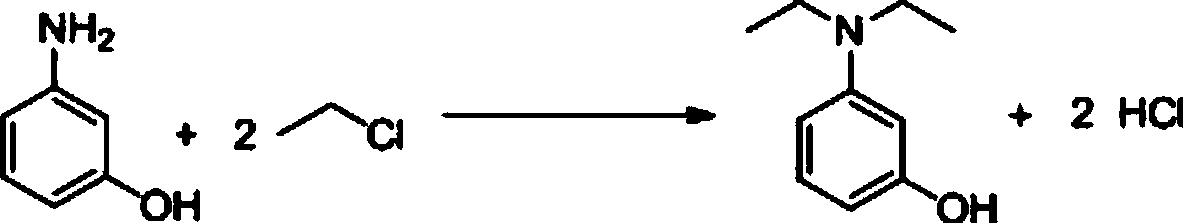

Preparation method of N-alkyl m-aminophenol

ActiveCN101671261AHigh selectivityHigh yieldOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolSolvent

The invention relates to a preparation method of N-alkyl m-aminophenol, which comprises the following steps: placing m-aminophenol and halogenated hydrocarbon in a reaction vessel containing a solvent, adding stannic chloride as a selective catalyst, then stirring while heating, starting reflux when the temperature reaches 30-90 DEG C, then adding an alkaliferous aqueous solution step by step, continuing to react for 1-10 hours to obtain a reaction liquid after the alkaliferous aqueous solution is added, then adding toluene into the reaction liquid, carrying out still standing, sedimentation and then extraction delamination to separate out an upper organic substance and a lower organic substance, filtering or rectifying the upper organic substance separated out through extraction delamination to obtain the high purity N-alkyl m-aminophenol. The reaction using water or corresponding alcohol as the solvent and stannic chloride as the catalyst has high selectivity, the product purity canreach more than 98 percent without refined purification, and the yield is high, the purification process in a traditional production method is saved, and the production cost is lowered.

Owner:山东瑞康精化有限公司

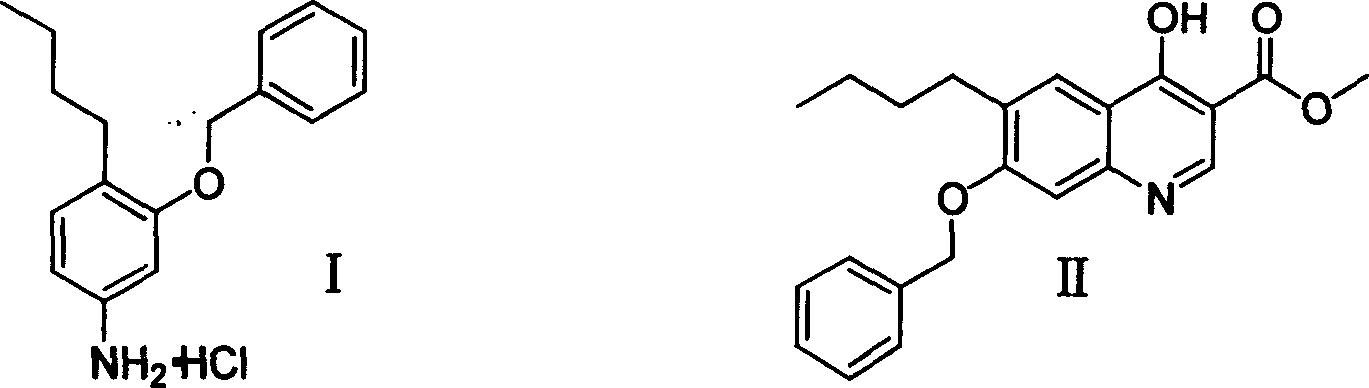

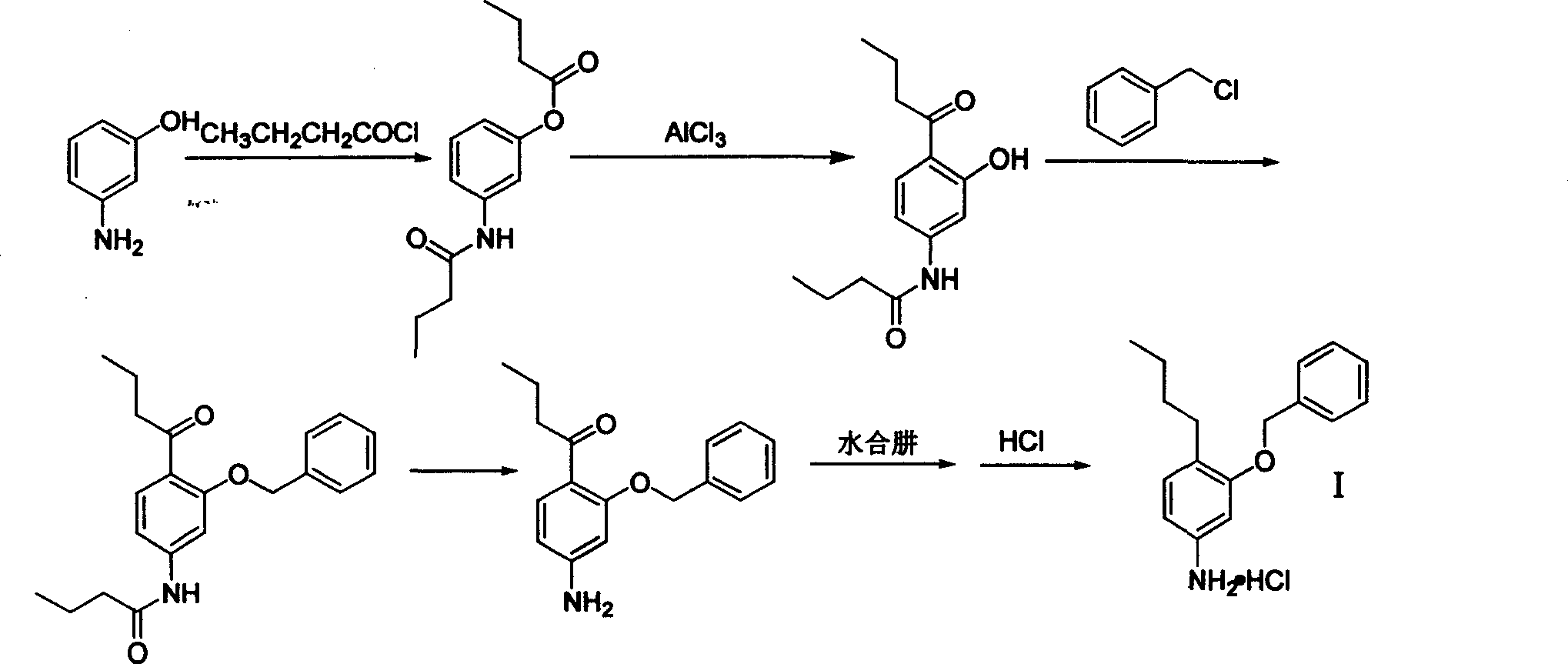

3-benzyloxy-4-butylaniline hydrochloride preparation method

InactiveCN1733703AReduce stirringStir wellOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolFries rearrangement

The invention provides a process for preparing 3-benzyloxy-4-butylaniline hydrochlorides, which comprises using m-aminophenol as raw material, carrying out butanoylation reaction and Fries rearrangement, obtaining 2-butyryl-5-butyramidophenol, under the action of alkali, reacting 2-butyryl-5-butyramidophenol with benzyl halides, obtaining 2-butyryl-5-butyramidophenyl benzyl ether, hydrolyzing to obtain 3-benzyloxy-4-butyryl benzeneamine, finally carrying out Huangminglong reduction reaction to obtain 3-benzyloxy-4-butylaniline hydrochlorides.

Owner:ZHEJIANG UNIV

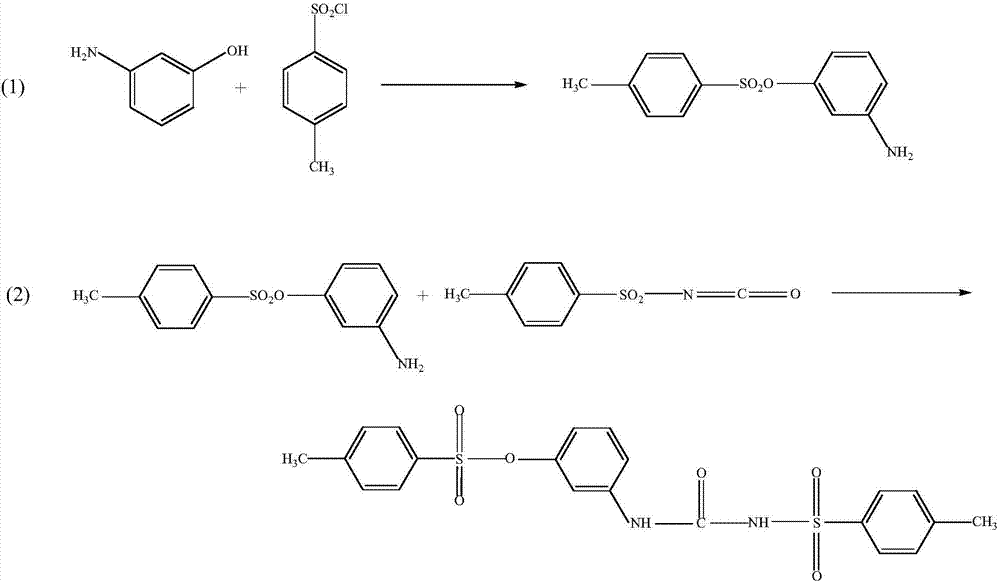

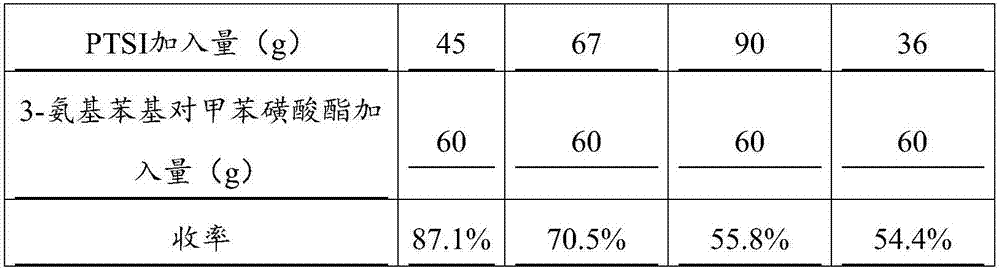

Preparation method of thermosensitive color developer containing sulfonylurea structure

ActiveCN106866471AHas color effectProcess stabilitySulfonic acid amide preparationM-aminophenolOrganic solvent

The invention discloses a preparation method of thermosensitive color developer containing a sulfonylurea structure. The preparation method comprises the following steps: (1) esterification: m-aminophenol and p-toluenesulfonyl chloride react under alkaline conditions to obtain 3-amino phenyl p-toluenesulfonate; (2) addition: the obtained 3-amino phenyl p-toluenesulfonate reacts with p-toluenesulfonyl isocyanate (PTSI) to obtain a crude product of the thermosensitive color developer containing the sulfonylurea structure; and (3) refining: the crude product obtained in the step (2) is dissolved into an alkaline solution and acidification and organic solvent treatment are carried out to obtain the thermosensitive color developer containing the sulfonylurea structure.

Owner:康爱特维迅(蓬莱)化学有限公司

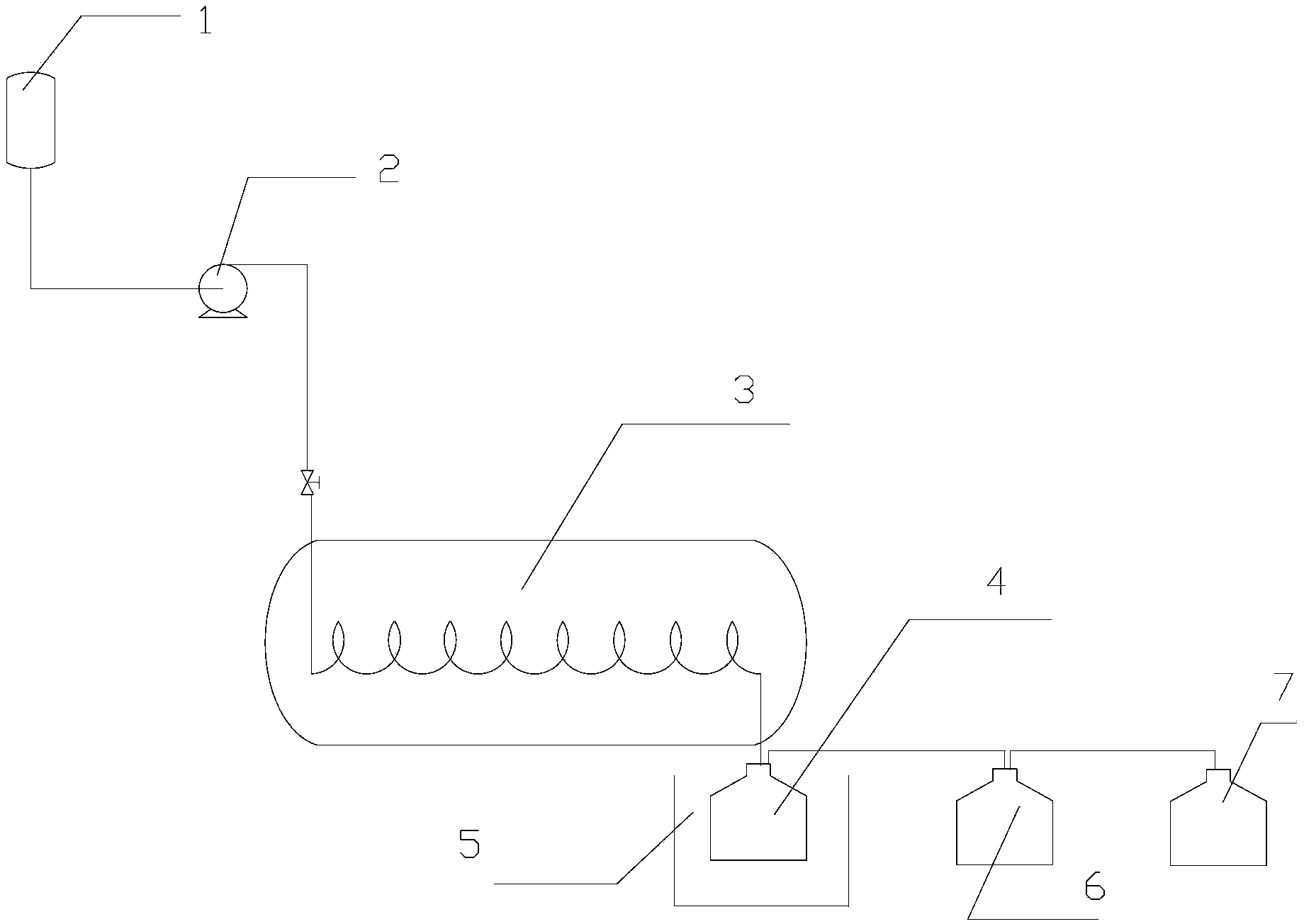

Method for continuously producing m-diethylaminophenol through channelization

ActiveCN103012164BIncrease production capacityLess investmentOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolOrganic synthesis

The invention belongs to the field of organic synthesis, and relates to a method for continuously producing m-diethylaminophenol through channelization. The method comprises the steps: (1) injecting a solvent into a pipe type reactor by a flow pump; dissolving the m-aminophenol and chloroethane into alcohol solvent according to the mole ratio of 1:(2-1.5) to prepare material solution; and injecting the material solution into the pipe type reactor by the flow pump, wherein the reaction temperature is 80-150 DEG C; (2) collecting reactive product flowing out of the pipe type reactor, removing the solvent and adding excessive alkaline for cleaning; and (3) extracting after the liquid is subjected to alkaline cleaning, taking water phase, adding acid for neutralizing to be neutral. The method is mild in reaction conditions, high in yield, good in selectivity, capable of effectively controlling the back-mixing and inhibiting the occurrence of side reaction, and suitable for large-scale production.

Owner:上海鸿源鑫创材料科技有限公司 +2

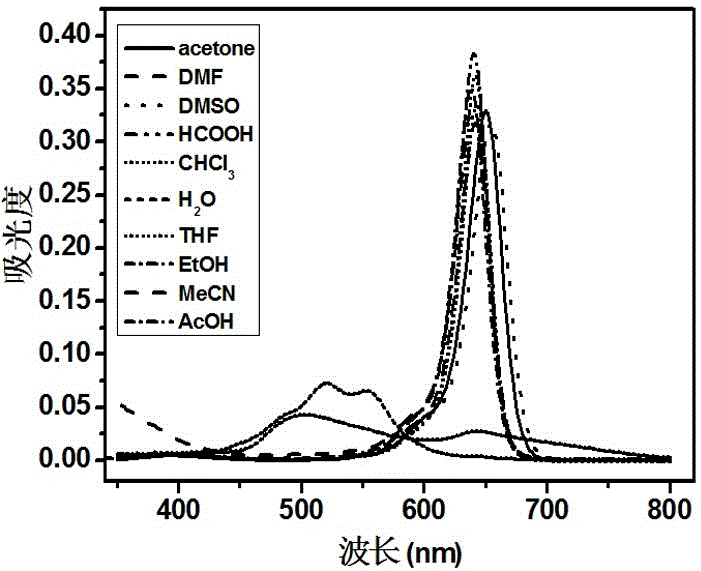

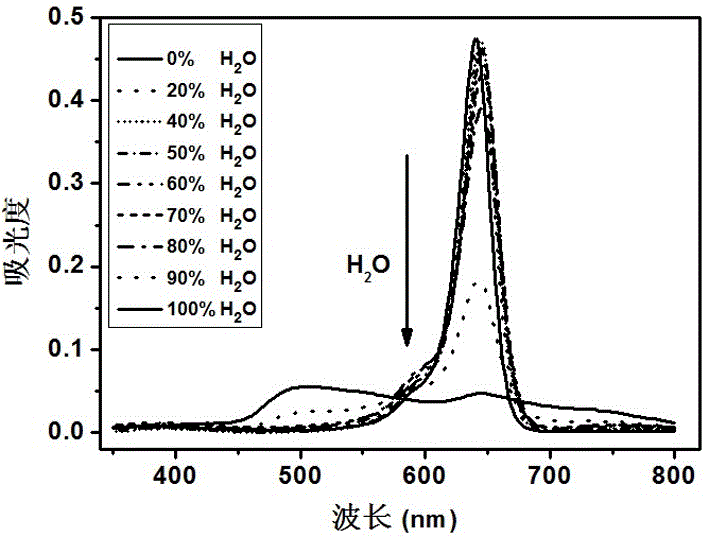

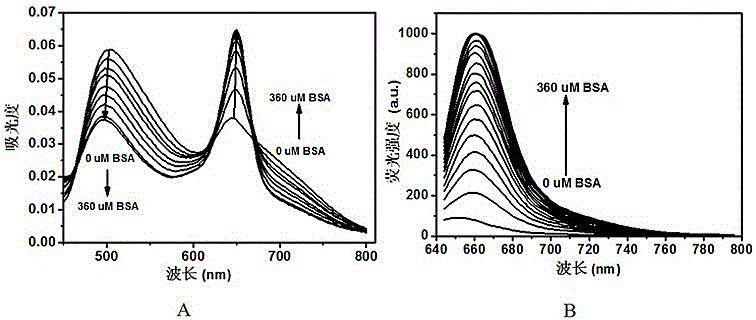

Asymmetric near-infrared squaraine dye, preparation method thereof and application thereof

InactiveCN105001666AAdjust solubilityRegulate aggregation behaviorAzo dyesFluorescence/phosphorescenceBio moleculesProtein labeling

The invention discloses an asymmetric near-infrared squaraine dye, a preparation method thereof and an application thereof. According to the invention, an m-aminophenol derivative and the squaric acid are mixed to dissolve in an appropriate solvent, and then are subjected to the backflow water-diversion treatment in the nitrogen protection environment. After that, the resultant obtained reaction mixture is cooled to be at the room temperature and subjected to the decompression treatment to remove the solvent. The resultant crude product is purified through the silica gel column chromatography process to prepare the asymmetric near-infrared squaraine dye. According to the technical scheme of the invention, through introducing an oxygen-ether chain, the dissolvability of the squaraine dye in an aqueous solution can be effectively improved. The obtained asymmetric near-infrared squaraine dye is good in stability and excellent in optical performance, which can be used as a protein biomarker for dual responses of fluorescence reaction and colorimetric reaction. The asymmetric near-infrared squaraine dye can be applied in multiple fields of biological molecule marking, analyzing, separating, and the like.

Owner:FUZHOU UNIV

First agent for oxidative hair dye and method for stabilizing color tone of oxidative hair dye composition

ActiveUS20180021600A1Excellent in fading inhibitionThe implementation process is simpleCosmetic preparationsHair cosmeticsHair dyesM-aminophenol

A first agent for oxidative hair dye of the present disclosure includes: an (A) component, which is at least one selected from the group consisting of resorcin, derivatives thereof, and salts thereof, in a content not exceeding 0.15% by mass; a (B) component, which is a coupler such as m-aminophenol, a (C) component, which is a dye intermediate such as p-phenylenediamine in a content between 0.01% by mass and 0.45% by mass; and a (D) component, which is an alkanolamine.

Owner:HOYU CO LTD

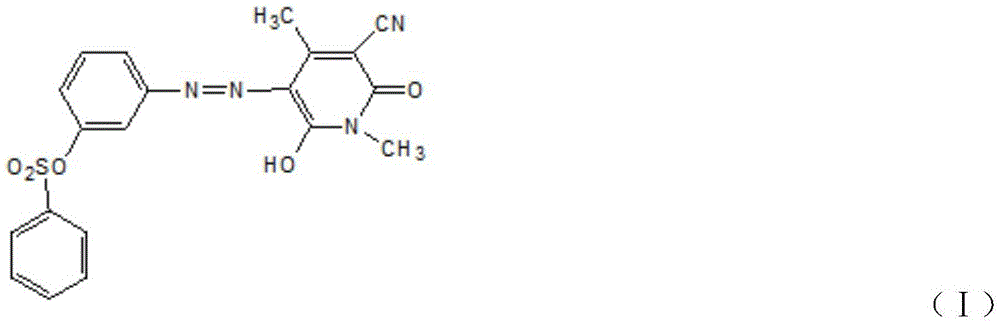

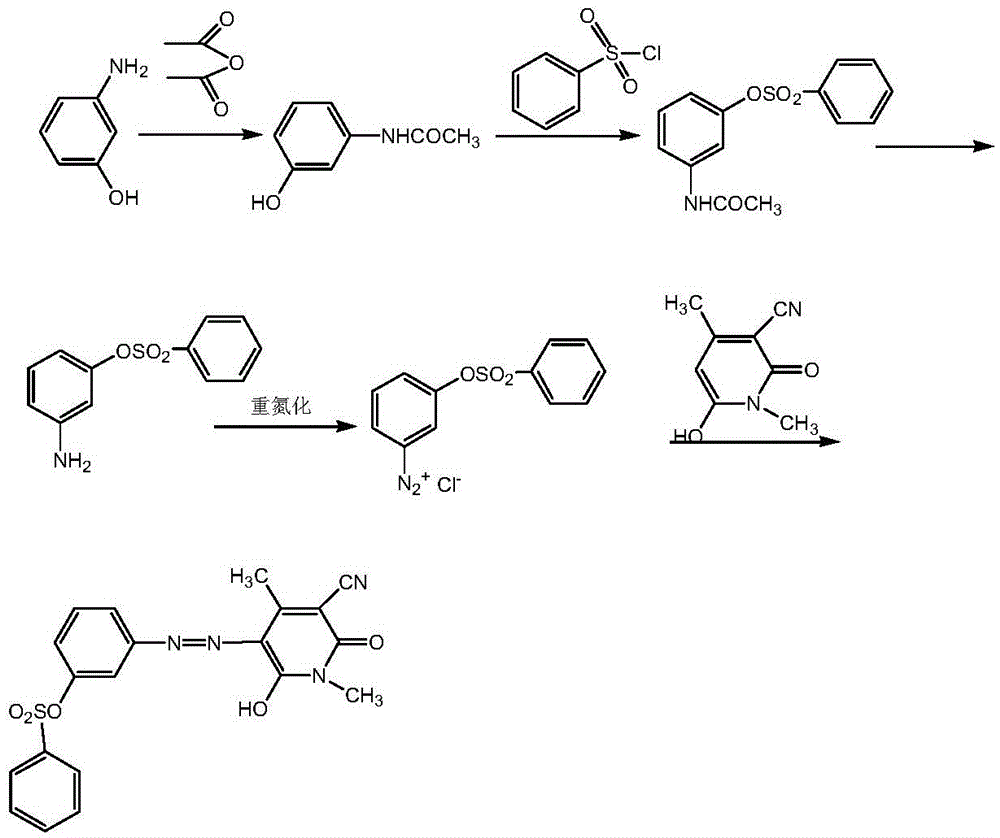

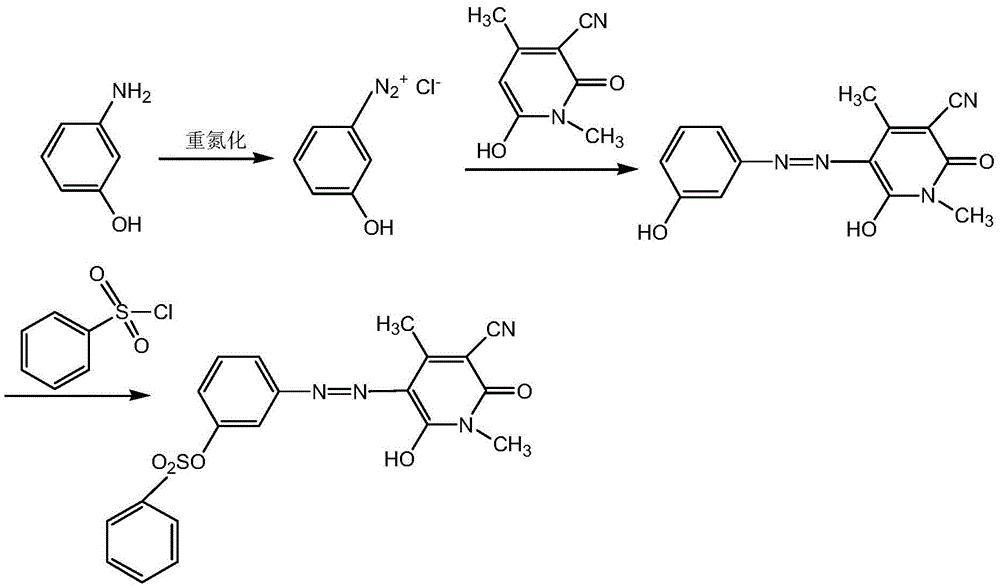

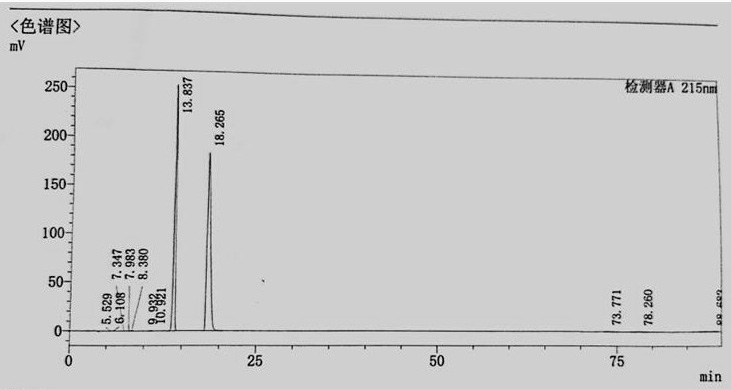

Synthesizing method of disperse yellow dye

ActiveCN105462286AEliminate the step of hydrolysisTo meet the needs of energy saving, consumption reduction and emission reductionMonoazo dyesSulfonyl chlorideSynthesis methods

The invention discloses a synthesizing method of a disperse yellow dye. The synthesizing method includes the following steps that 1, metha amino phenon and sodium nitrite are subjected to a diazo-reaction under the acidic condition, and metha amino phenon diazonium salt is obtained; 2, the metha amino phenon diazonium salt obtained in step 1 and a methyl ketone pyridine solution are subjected to a coupling reaction, and a coupling product is obtained; 3, the coupling product obtained in step 2 and benzene sulfonyl chloride are subjected to an esterification reaction, and after the reaction is completed, the disperse yellow dye is obtained through posttreatment. The synthesizing method is easy and convenient to operate, short in process and less in sewage quantity, and the performance is consistent with that of filter cake synthesized through a traditional synthesis method.

Owner:ZHEJIANG RUNTU INST

Synthesis method of 3-(3-hydroxyphenyl)-1, 1-dimethylurea, intermediate and application

PendingCN113651723ARaw materials are cheap and easy to getSimple operation processGroup 4/14 element organic compoundsUrea derivatives preparationPhenyl groupPhenol

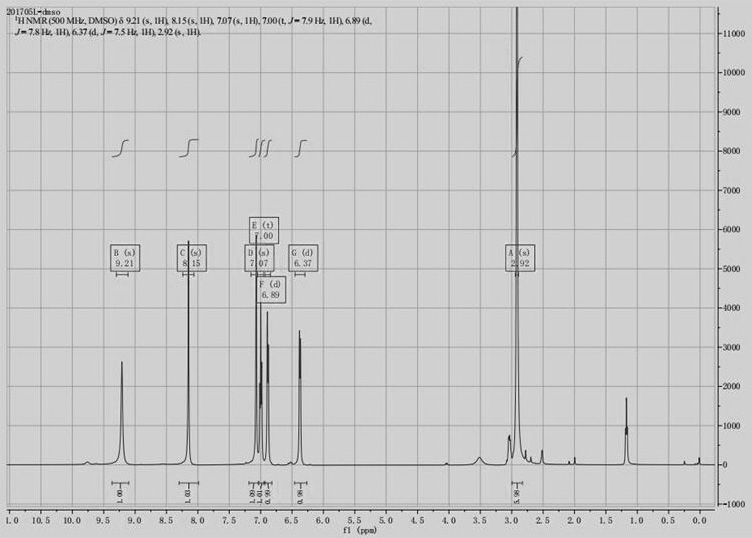

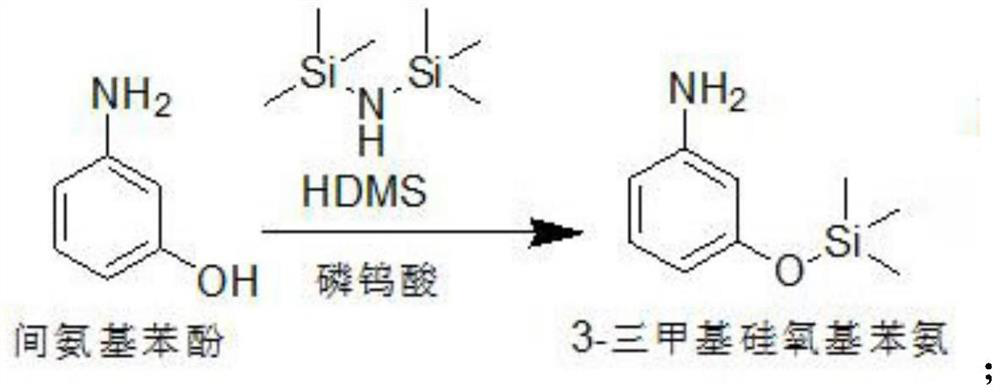

The invention discloses a synthesis method of 3-(3-hydroxyphenyl)-1, 1-dimethylurea, an intermediate and application. The synthesis method comprises the steps of: generating 3-trimethylsiloxy phenylamine from m-aminophenol as a raw material under the catalysis of HDMS and phosphotungstic acid, then reacting with dimethylamino formyl chloride to obtain 1, 1,-dimethyl-3-(3-trimethylsiloxy phenyl) urea, and then removing TMS to obtain 3-(3-hydroxyphenyl)-1, 1-dimethylurea. The method has the advantages of simple synthesis route, simplicity in operation, high yield and no pollution.

Owner:ZHEJIANG CHEMSYN PHARM

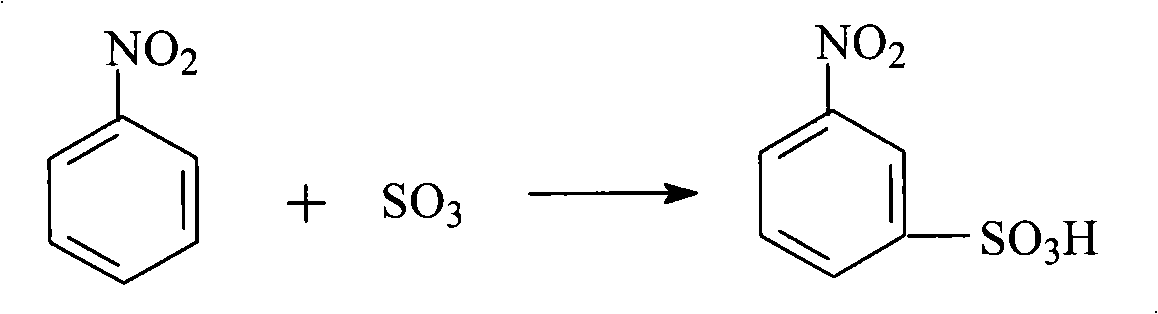

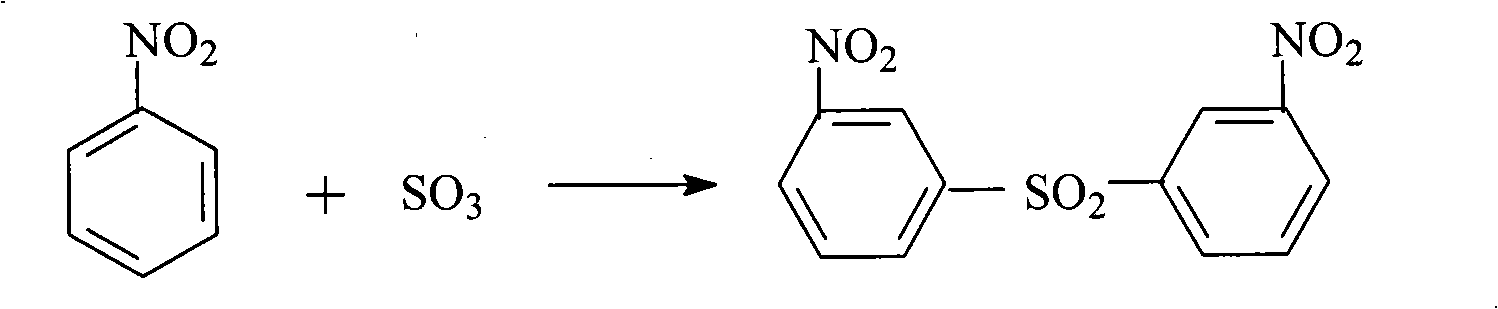

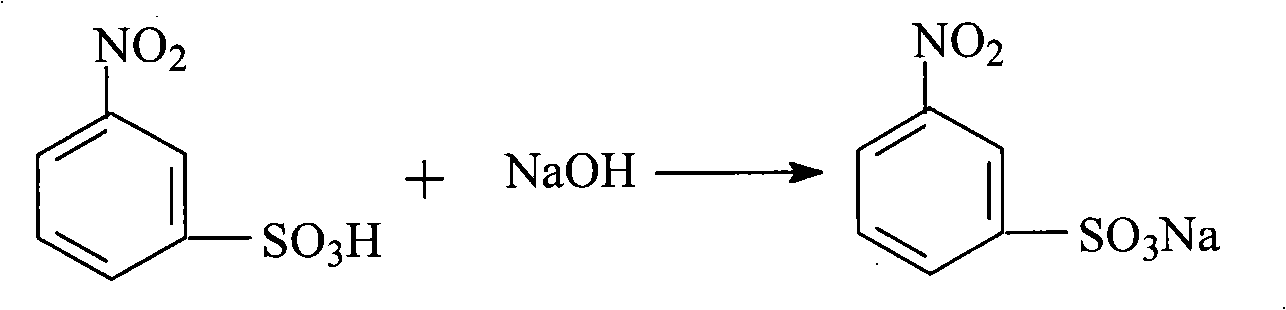

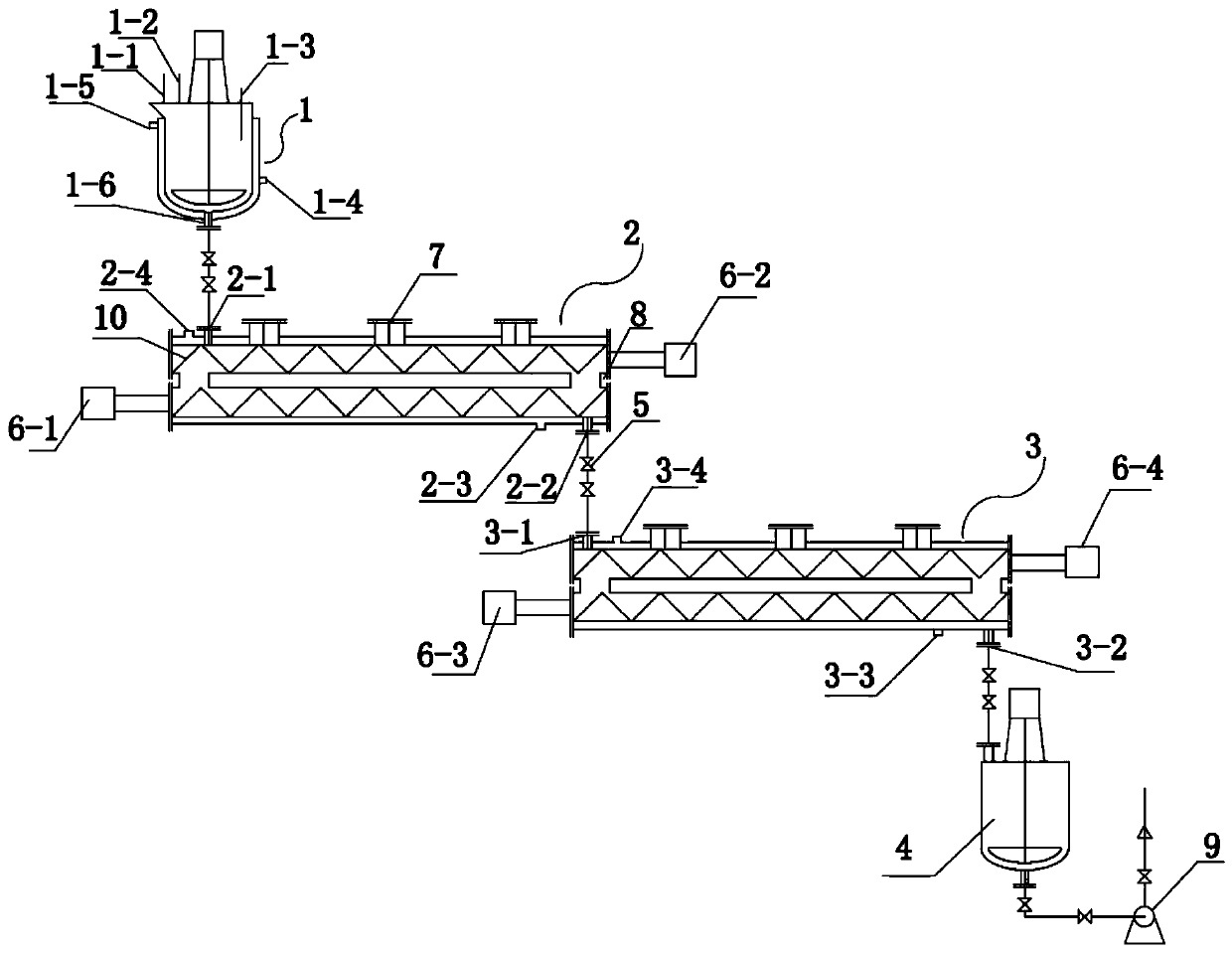

Method and device for continuously producing m-aminophenol

ActiveCN110283086AEnhanced mass transferImprove heat transfer performanceOrganic compound preparationTransportation and packagingTemperature controlM-aminophenol

A method for continuously producing m-aminophenol is implemented to produce the m-aminophenol through alkali fusion continuous reaction and specifically includes the production steps of preparing materials, wherein a sodium m-sulfamate solution and a strong base are sequentially added into a material preparing tank according to a certain ratio, and stirring and heating are conducted; conducting heating reaction, wherein the materials in the material preparing tank are continuously discharged into a heating spiral pipeline reactor, and heating reaction is conducted for a certain period of time; conducting heat preserving, wherein the materials are pushed into the heating spiral pipeline reactor through the heating spiral pipeline reactor, and heat preserving is conducted at 280-310 DEG C for a certain period of time; conducting diluting, wherein qualifiedly-diluted materials at the bottom of an impregnation and dilution tank are transferred to the subsequent process section for subsequent processing to obtain a crude m-aminophenol product. Continuous feeding, heating, heat preserving and continuous discharging are realized, the continuity of alkali fusion and the precision of temperature control in the production process of the m-aminophenol are realized, the operation intensity of alkali fusion is relieved, the requirement for the operation level of workers is lowered, and production efficiency is improved.

Owner:HEBEI JIANXIN CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com