Preparation method of supported solid acid catalyst for hydrolysis of m-phenylenediamine

A technology of solid acid catalyst and m-phenylenediamine, which is applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of high equipment material requirements, tedious follow-up treatment process, and corrosive reaction system Strong and other problems, to achieve the effect of inhibiting coking of polymerization, excellent chemical stability, and easy control of loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

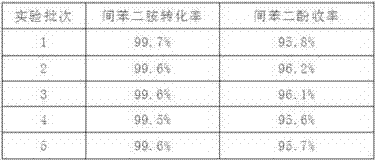

Examples

Embodiment 1

[0018] Example 1: A method for preparing a supported solid acid catalyst for the hydrolysis of m-phenylenediamine, which specifically includes the following steps:

[0019] (1) Using a hydrochloric acid solution with a mass concentration of 20%, the contrast surface area is 1200m 2 / g of nutshell charcoal powder is heated and refluxed. The washed charcoal powder is washed with deionized water until the pH remains unchanged, and then added with a 20% mass concentration nitric acid solution for heating and refluxing. The heating temperature is 65°C and the reflux time is 10h , The treated activated carbon powder is washed with deionized water until the pH remains unchanged, and dried in vacuum for use;

[0020] (2) Prepare 100g of phosphotungstic acid solution with a mass concentration of 10%, add 20g of charcoal powder from the husk obtained in step (1), stir and immerse for 15h at low speed, and filter and depressurize the carbon-supported heteropolyacid catalyst after immersion Af...

Embodiment 2

[0022] Embodiment 2: A preparation method of a supported solid acid catalyst for the hydrolysis of m-phenylenediamine, which specifically includes the following steps:

[0023] (1) Using a sulfuric acid solution with a mass concentration of 40%, the contrast surface area is 1800m 2 / g of husk charcoal powder is heated and refluxed. The washed charcoal powder is washed with deionized water until the pH remains unchanged, and then 30% hydrogen peroxide is added for heating and reflux treatment. The heating temperature is 80℃, and the reflux time is 5h. The treated activated carbon powder is washed with deionized water until the pH remains unchanged, and dried in vacuum for use;

[0024] (2) Prepare 90g of phosphomolybdic acid solution with 25% mass concentration, add 35g of nutshell charcoal powder obtained by step (1), stir and immerse for 30h at low speed, after immersion, the carbon-supported heteropolyacid catalyst is filtered and decompressed After drying, it is transferred to a...

Embodiment 3

[0028] Example 3: A preparation method of a supported solid acid catalyst for the hydrolysis of m-phenylenediamine, which specifically includes the following steps:

[0029] (1) Using 30% hydrochloric acid solution, the contrast surface area is 1500m 2 / g of husk charcoal powder is heated and refluxed. The washed charcoal powder is washed with deionized water until the pH remains unchanged, and then a 30% mass concentration ammonium persulfate solution is added for heating and reflux treatment. The heating temperature is 72℃, and the reflux time For 8 hours, the treated activated carbon powder is washed with deionized water until the pH does not change, and vacuum dried for use;

[0030] (2) Prepare 200 g of phosphotungstic acid solution with a mass concentration of 15%, add about 80 g of the charcoal powder from the husk obtained in step (1), stir and immerse for 22 hours at low speed, and after the end of immersion, the carbon-supported heteropoly acid catalyst is filtered and red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com