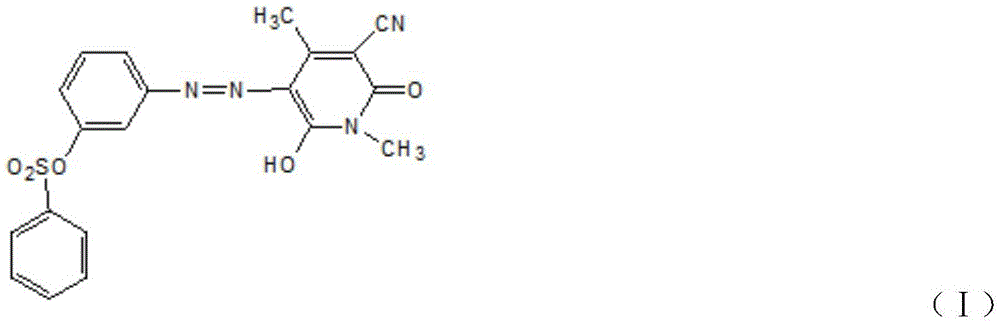

Synthesizing method of disperse yellow dye

A synthesis method and technology of dispersing yellow, applied in azo dyes, organic dyes, monoazo dyes and other directions, can solve the problems of complicated steps, large amount of sewage and high production cost, and achieve simplified reaction steps, reduce the amount of sewage, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

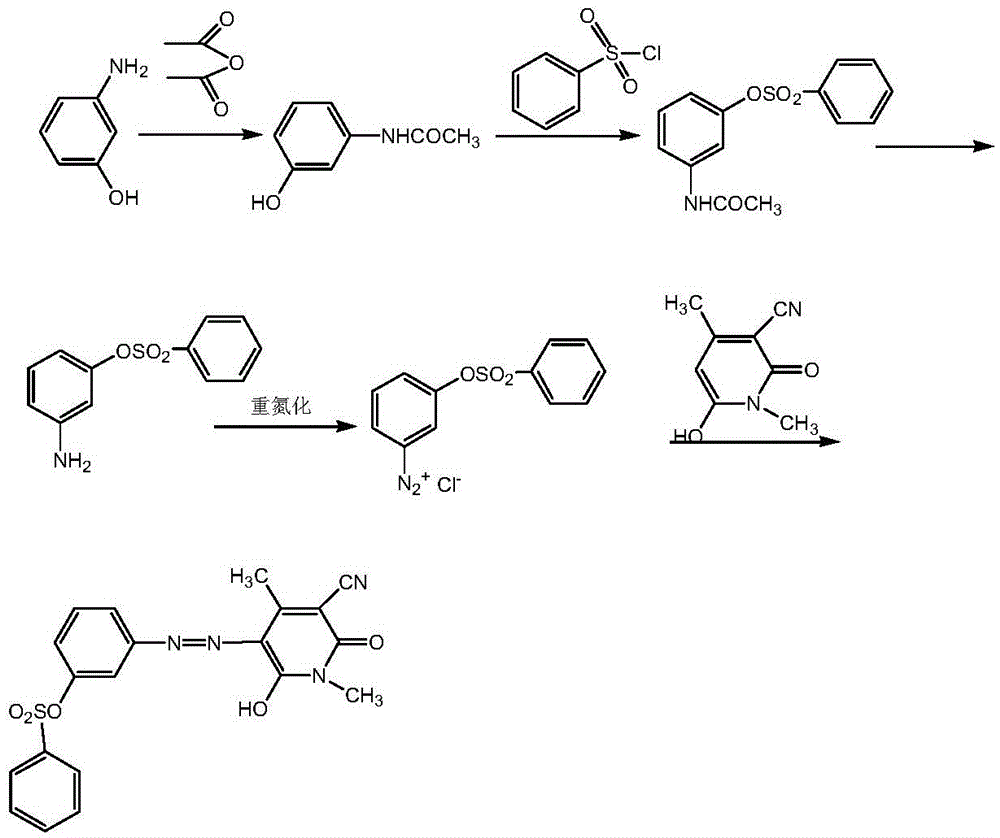

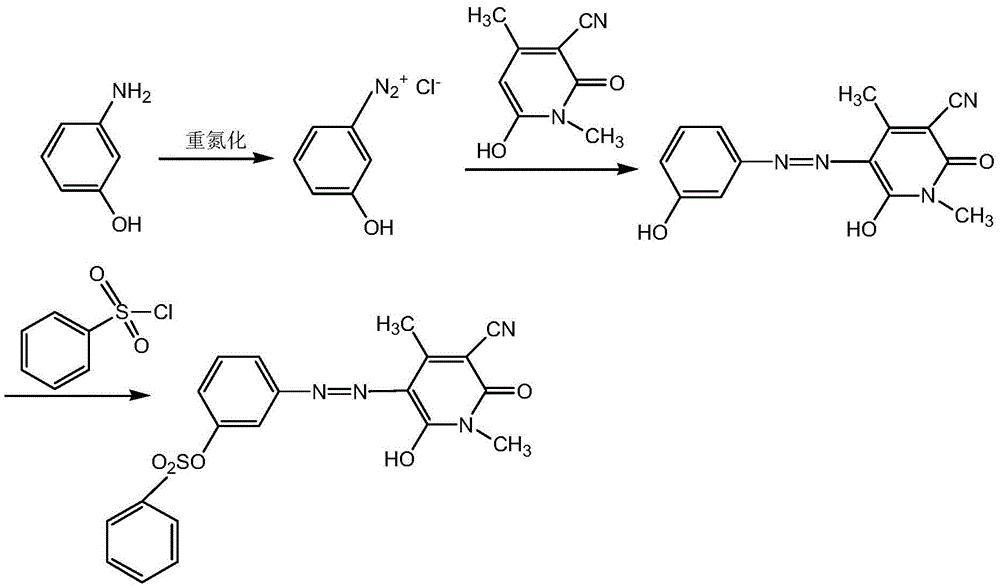

Method used

Image

Examples

Embodiment 1

[0028] Add 200g of water to a 500ml beaker, put in 10.90g of m-aminophenol, 80g of hydrochloric acid with a mass percentage of 10%, start stirring, throw in flakes of ice to cool the material to 0°C, and make a 30% solution of 5.84g of sodium nitrite in advance , drop the sodium nitrite solution into the beaker within 15 minutes under the condition of 0-5°C, continue to keep stirring for 30 minutes under the condition of 0-5°C after dropping, when the heat preservation is completed, the diazonium solution is clear and there is no insoluble matter, add 0.5g For urea, after stirring for 5 minutes, test it with starch potassium iodide test paper. If it does not show purple, add 0.3g Pingpingjia and wait for coupling.

[0029] Add 100g water in another beaker, 10g sodium acetate and 13.1g methylpyridone, start stirring, methylpyridone is dissolved in the sodium acetate solution, stand-by.

[0030] The picoline solution is evenly dropped into the diazo solution within 60 minutes, t...

Embodiment 2

[0033] Add 200g of water to a 500ml beaker, put in 10.90g of m-aminophenol, 60g of hydrochloric acid with a mass percentage of 18%, start stirring, throw in pieces of ice to cool the material to 0°C, and make a 30% solution of 5.84g of sodium nitrite in advance , drop the sodium nitrite solution into the beaker within 15 minutes under the condition of 0-5°C, continue to keep stirring for 30 minutes under the condition of 0-5°C after dropping, when the heat preservation is completed, the diazonium solution is clear and there is no insoluble matter, add 0.5g For urea, after stirring for 5 minutes, test it with starch potassium iodide test paper. If it does not show purple, add 0.3g Pingpingjia and wait for coupling.

[0034] Add 100g water in another beaker, 10g sodium acetate and 13.1g methylpyridone, start stirring, methylpyridone is dissolved in the sodium acetate solution, stand-by.

[0035] The picoline solution is evenly dropped into the diazo solution within 60 minutes, t...

Embodiment 3

[0038] Add 200g of water to a 500ml beaker, put in 10.90g of m-aminophenol, 60g of hydrochloric acid with a mass percentage of 18%, start stirring, throw in pieces of ice to cool the material to 0°C, and make a 30% solution of 5.84g of sodium nitrite in advance , drop the sodium nitrite solution into the beaker within 15 minutes under the condition of 0-5°C, continue to keep stirring for 30 minutes under the condition of 0-5°C after dropping, when the heat preservation is completed, the diazonium solution is clear and there is no insoluble matter, add 0.5g For urea, after stirring for 5 minutes, test it with starch potassium iodide test paper. If it does not show purple, add 0.3g Pingpingjia and wait for coupling.

[0039] Add 100g water in another beaker, 10g sodium carbonate and 13.1g picoline, start stirring, picoline is dissolved in the sodium acetate solution, stand-by.

[0040] The picoline solution is evenly dropped into the diazo solution within 60 minutes, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com