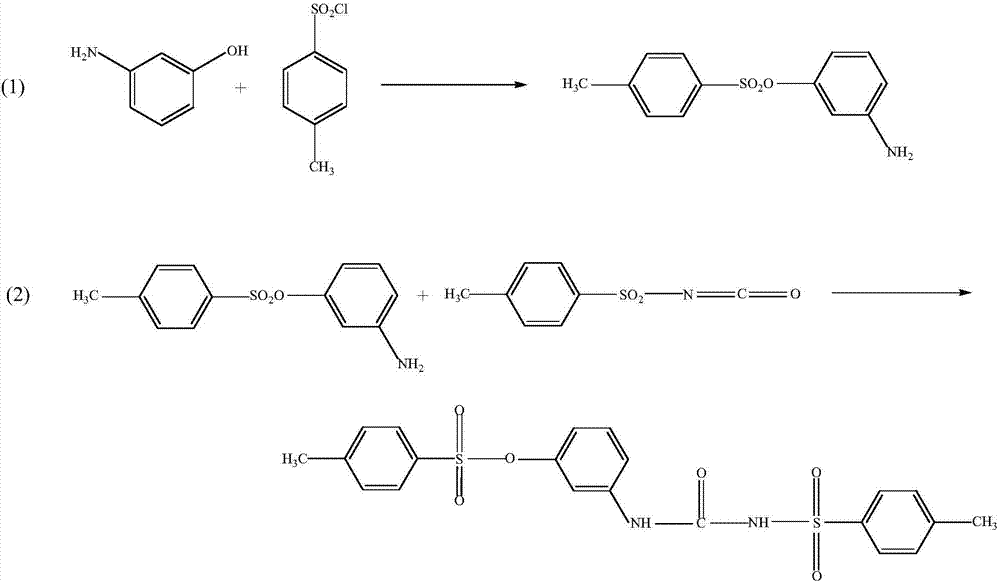

Preparation method of thermosensitive color developer containing sulfonylurea structure

A technology of sulfonylurea and color developer, applied in the field of preparation of heat-sensitive color developer, can solve the problems of destroying the chemical structure of the color developer, deterioration of by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Esterification reaction

[0037] Add 200ml of acetone into a 500ml four-neck glass flask, add 56.6g of MAP under stirring, stir at room temperature to completely dissolve, add 30g of caustic soda, cool to 17°C and stir for 2 hours to basically dissolve caustic soda, then add 99.2g of PTSC, and use 0.5 After adding PTSC, continue to react for 2 hours. Add 200ml of water, recover acetone by distillation under normal pressure until the gas phase temperature is 100°C, replenish 200ml of water, reduce to room temperature, suction filter, wash with water until neutral, dry the wet filter cake to obtain 123.1g of 3-aminophenyl p-toluenesulfonate, and collect The rate is 90.1%.

[0038] Addition reaction

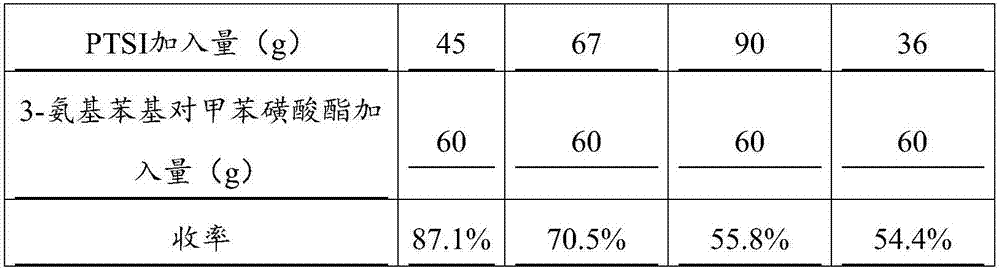

[0039] Add 300ml of acetone into a 500ml four-neck glass flask, add 60g of 3-aminophenyl p-toluenesulfonate under stirring, and add 54.0g of PTSI dropwise for 2 hours. Continue to react for 1 hour after adding PTSI, filter, wash the filter cake with 100ml of acetone, dry t...

Embodiment 2

[0043] Esterification reaction

[0044]Add 200ml of acetone into a 500ml four-necked glass flask, add 56.6g of MAP under stirring, stir at room temperature to completely dissolve, add 45g of caustic soda, cool down to 23°C and stir for 2 hours to basically dissolve the caustic soda, add 99.2g of PTSC for 0.5 hours . After the addition of PTSC, the reaction was continued for 2 hours. Add 200ml of water, recover acetone by normal pressure distillation until the gas phase temperature is 100°C, replenish 200ml of water, reduce to room temperature, suction filter, wash with water until neutral, dry the wet filter cake to obtain 128.2g of 3-aminophenyl p-toluenesulfonate, and collect The rate is 93.9%.

[0045] Addition reaction

[0046] Add 780ml of toluene to a 1000ml four-necked glass flask, add 60g of 3-aminophenyl p-toluenesulfonate under stirring, heat up to 60°C, add 5g of activated carbon, stir for 0.5 hours, filter, and wash the filtrate (toluene layer) with hot water un...

Embodiment 3

[0049] The impact of acid-binding agent on reaction in embodiment 3 esterification

[0050] Operation steps: Add 200ml of acetone into a 500ml four-neck glass flask, add 56.6g of MAP under stirring, stir at room temperature to completely dissolve, add 30g of acid-binding agent, cool down to 17°C and stir for 2 hours to basically dissolve the acid-binding agent, then add PTSC 99.2g, it takes 0.5 hours, and the reaction is continued for 2 hours after the addition of PTSC. Add 200ml of water, recover acetone by normal pressure distillation until the gas phase temperature is 100°C, make up 200ml of water, reduce to room temperature, suction filter, wash with water until neutral, dry the wet filter cake to obtain 3-aminophenyl p-toluenesulfonate, calculate the yield .

[0051] Acid-binding agent added to the group: (1) potassium hydroxide; (2) sodium hydroxide; (3) sodium carbonate; (4) sodium bicarbonate.

[0052] See Table 1 for the yield of 3-aminophenyl p-toluenesulfonate.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com