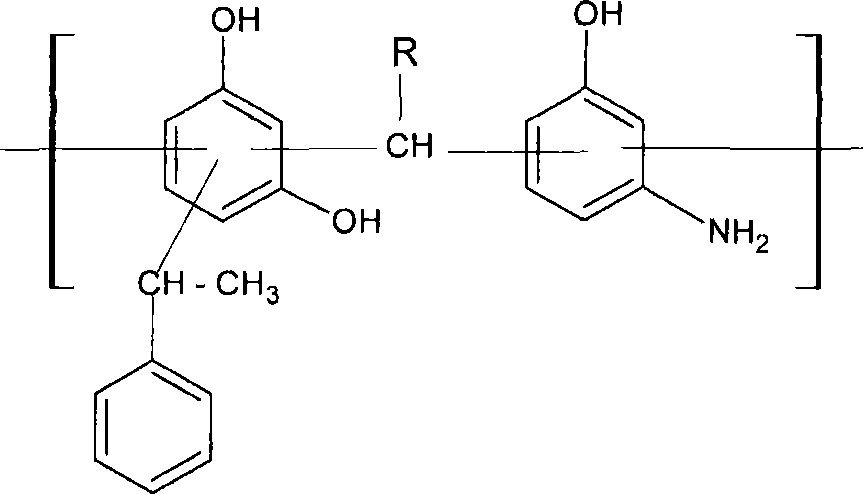

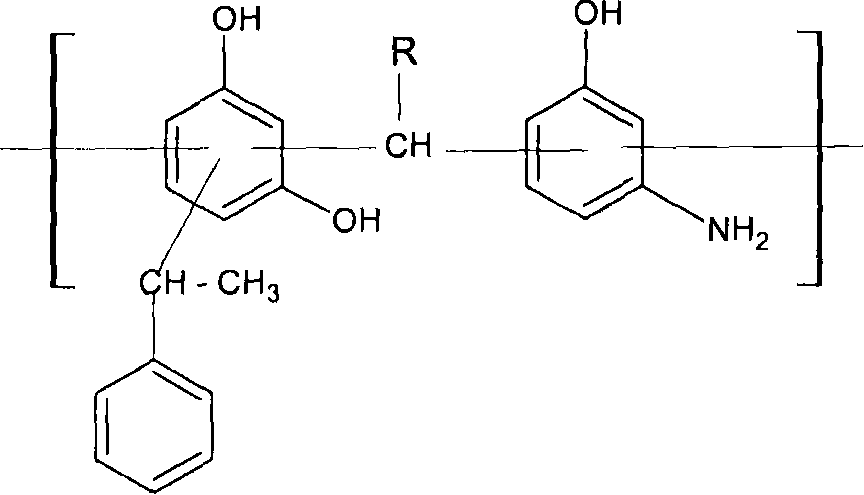

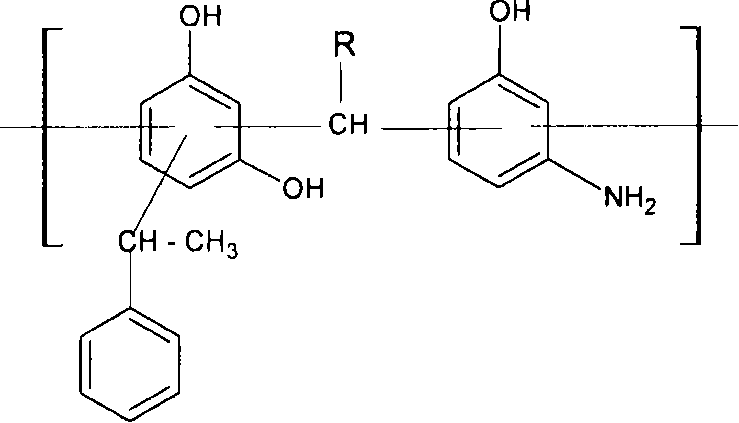

M-aminophenol modified aralkylresorcinol-aldehydes compound resin used for rubber formulation and application

A technology of aralkyl resorcinol and m-aminophenol, applied in the field of aralkyl resorcinol-aldehyde compound resin, can solve the problem of slowing down the reaction rate or speed of methylene, reducing the vulcanization rate and the active point Problems such as reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] To a 500ml round bottom reaction flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, add 110.1g (1.0mol) of resorcinol and 1.0g of p-toluenesulfonic acid (PTSA), and heat to 120-130°C. Then 52.1 g of styrene (0.5 moles) were added dropwise over a period of about 30-45 minutes. During the dropwise addition of styrene, the temperature of the reaction mixture was maintained between 125°C and 135°C. After the styrene addition was completed, the reaction mixture was reacted at this temperature for another 15 minutes. The PTSA catalyst was neutralized by adding 0.5 g of 50% aqueous NaOH. Thereafter, 10.9 g of m-aminophenol (0.1 mol) was added to the reaction mixture. Then, 48.9 g (0.6 mol) of 36.8% formaldehyde solution was slowly added dropwise to the flask within 45 to 60 minutes, and the temperature was controlled at 95° C. to 120° C. Finally, vacuum dehydration to make the softening point of the resin 101.5°C.

[0046] HPLC analysi...

Embodiment 2

[0048] To a 500ml round bottom reaction flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, add 110.1g (1.0mol) of resorcinol and 1.0g of p-toluenesulfonic acid (PTSA), and heat to 120-130°C. Then 52.1 g of styrene (0.5 moles) were added dropwise over a period of about 30-45 minutes. During the styrene addition process, the temperature of the reaction mixture was maintained between 125°C and 135°C. After the styrene addition was completed, the reaction mixture was reacted at this temperature for another 15 minutes. The PTSA catalyst was neutralized by adding 0.5 g of 50% aqueous NaOH. Thereafter, 21.8 g of m-aminophenol (0.2 mol) was added to the reaction mixture. Then, 44.8 g (0.55 mol) of 36.8% formaldehyde solution was slowly added dropwise to the flask within 45 to 60 minutes, and the temperature was controlled at 95° C. to 120° C. The reaction mixture was then reacted under reflux for 15 to 30 minutes. Finally, vacuum dehydration t...

Embodiment 3

[0051] To a 500ml round bottom reaction flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, add 110.1g (1.0mol) of resorcinol and 1.0g of p-toluenesulfonic acid (PTSA), and heat to 120-130°C. Then 52.1 g (0.5 moles) of styrene were added dropwise over a period of about 30-45 minutes. During the styrene addition process, the temperature of the reaction mixture was maintained between 125°C and 135°C. After the styrene addition was completed, the reaction mixture was reacted at this temperature for another 15 minutes. Thereafter, 21.8 g of m-aminophenol (0.2 mol) was added to the reaction mixture. Then, 44.8 g (0.55 mol) of 36.8% formaldehyde solution was slowly added dropwise to the flask within 45 to 60 minutes, and the temperature was controlled at 95° C. to 120° C. The reaction mixture was then reacted under reflux for 15 to 30 minutes. The PTSA catalyst was neutralized by adding 0.5 g of 50% aqueous NaOH. Finally, vacuum dehydration t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com