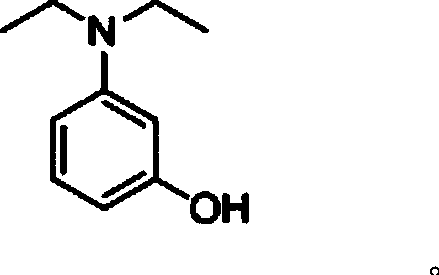

Method for continuously producing m-diethylaminophenol through channelization

An ethylaminophenol and production room technology, which is applied in the field of pipeline continuous production of m-diethylaminophenol, can solve the problems of long reaction time, unsuitability for industrialization and the like, and achieves the effects of stable product quality, suppression of side reactions and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

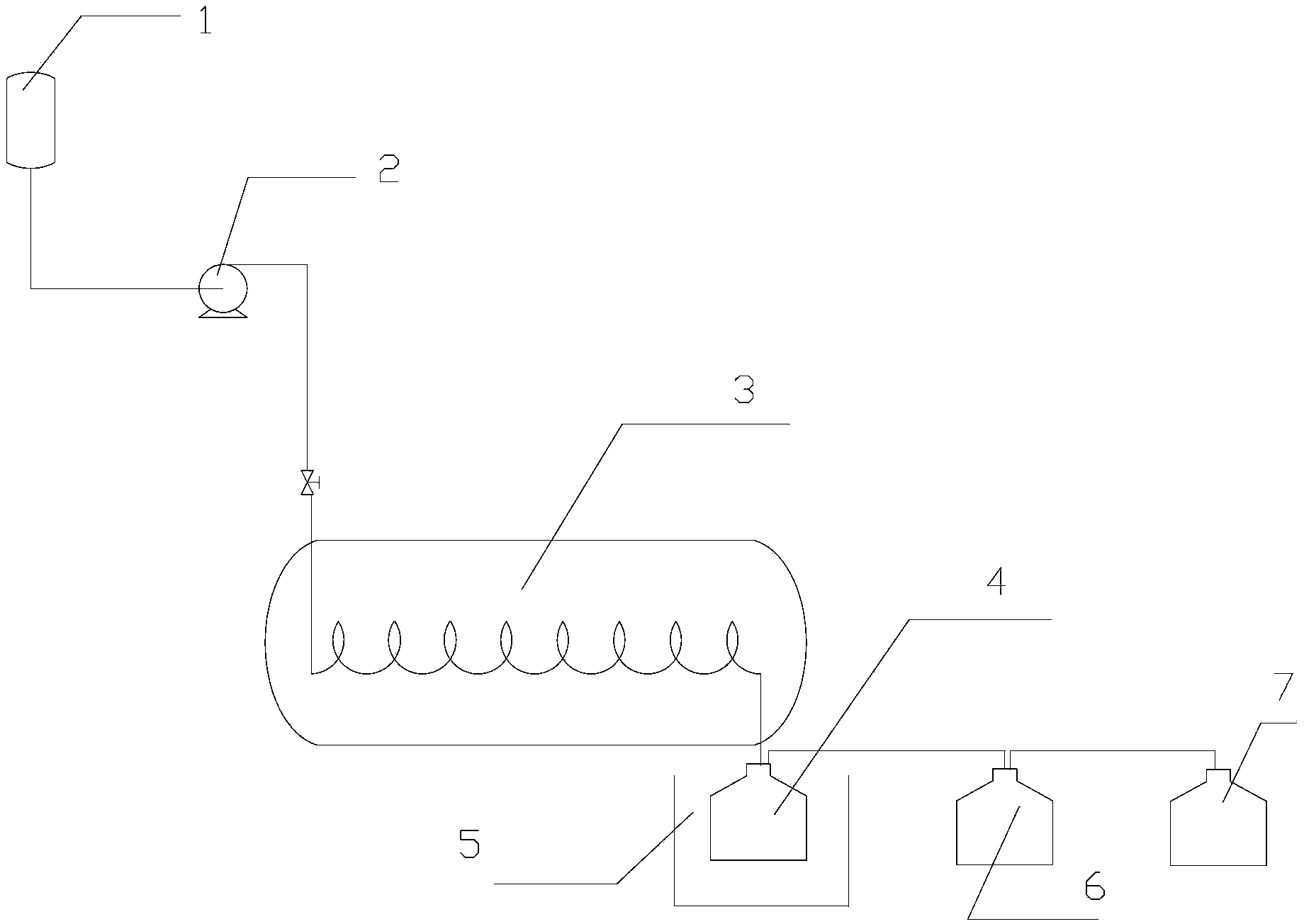

[0028] A production device for pipelined continuous production of m-diethylaminophenol, its structure is as follows figure 1 As shown, it consists of a tubular reactor connected with other equipment. Tubular reactor 3 and raw material storage tank 1 are connected by metering pump 2, and the metering pump is used to transport the material from the raw material storage tank to the stainless steel coil pipe (tube length 20m, inner diameter 4mm, cross-sectional area about 0.13cm 2 , the volume is about 260mL) in the tubular reactor, the flow rate of the material can be controlled by a metering pump, and the tubular reactor is placed in a casing with a heating medium (for controlling the reaction temperature). The material enters the tubular reactor from the left side of the tubular reactor; the reaction mixture product flows out from the right side of the tubular reactor, and then flows into the storage tank 4 located in the cooling tank 5 to be cooled (cooling down to room temper...

Embodiment 2

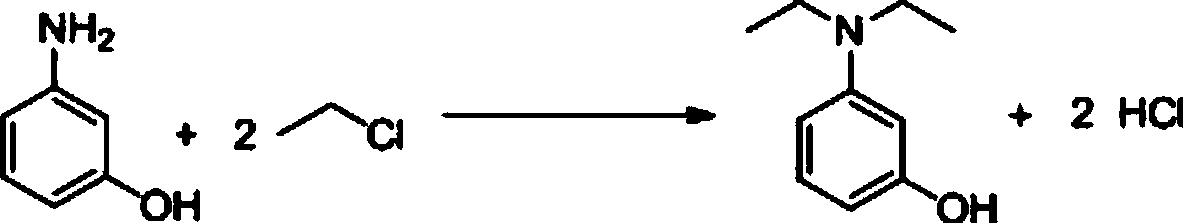

[0030] A method for pipelined continuous production of m-diethylaminophenol, adopting the device of embodiment 1, taking m-aminophenol and ethyl chloride as raw materials, and carrying out the following steps successively:

[0031] (1) Preheat the tubular reactor 3 to 100°C, inject 260ml of ethanol (as a solvent) into the tubular reactor with the flow pump 2, so that the tubular reactor is filled with ethanol. Dissolve 16.4g (0.15mol) of m-aminophenol and 19.8g (0.31mol) of ethyl chloride in 200ml of ethanol to prepare about 225ml of material solution. The material solution is stored in raw material storage tank 1, and the temperature of the material solution is maintained at 10°C about. Use a flow pump to inject the material solution into the tubular reactor for reaction at a flow rate of 2ml / min;

[0032] The reaction temperature is 100°C, and the reaction time (that is, the residence time of the material in the tubular reactor) and the time for injecting the material solut...

Embodiment 3

[0038] A method for pipelined continuous production of m-diethylaminophenol, adopting the device of embodiment 1, taking m-aminophenol and ethyl chloride as raw materials, and carrying out the following steps successively:

[0039] (1) Preheat the tubular reactor to 80°C, inject 260ml of methanol (as a solvent) into the tubular reactor with a flow pump, so that the tubular reactor is filled with methanol. Dissolve 16.4g (0.15mol) of m-aminophenol and 25.6g (0.4mol) of ethyl chloride in 200ml of methanol to prepare about 230ml of material solution. The material solution is stored in the raw material storage tank, and the temperature of the material solution is maintained at about 10°C . Use a flow pump to inject the material solution into the tubular reactor for reaction at a flow rate of 2ml / min;

[0040] The reaction temperature is 80°C, and the reaction time (that is, the residence time of the materials in the tubular reactor) is about 115 minutes.

[0041] (2) Use the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com