Method for preparing porous titanium dioxide ball

A technology of porous titanium dioxide and titanium dioxide, which is applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of high yield, simple and mild preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

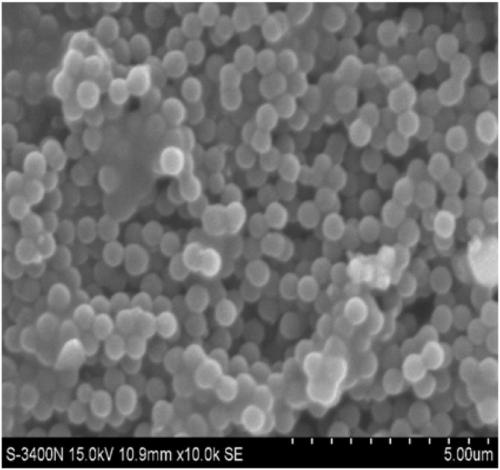

Image

Examples

Embodiment 1

[0022] (1) Preparation of m-aminophenol formaldehyde resin balls: add 2.0 g of 25% ammonia water to a 30 degree solution containing 24 g of deionized water and 10 ml of absolute ethanol, add 0.71 g of m-aminophenol, stir to dissolve, and then Add 1.0 g of 35% formaldehyde solution, continue to stir for 24 hours, centrifuge, and dry the sample in an oven at 50 degrees for 12 hours.

[0023] (2) Preparation of titanium dioxide precursor solution: Disperse 1 ml of tetrabutyl titanate into deionized water, stir for 30 minutes, centrifuge and filter, wash with absolute ethanol three times, dry in an oven at 50 degrees for 2 hours, and take 1 gram of sample Use 0.1-2.0mol.L -1 Dissolve 15 ml of HCl to obtain a titanium tetrachloride solution with low acidity.

[0024] (3) Disperse 0.5 g of m-aminophenol formaldehyde resin ball into 20 ml of water, add 15 ml of 0.1 mol.L -1 Titanium tetrachloride solution (containing 1ml of tetrabutyl titanate), stir for 24 hours, take it out, put it in a...

Embodiment 2

[0027] (1) Preparation of m-aminophenol formaldehyde resin balls: add 2.0 g of 25% ammonia water to a 30 degree solution containing 24 g of deionized water and 10 ml of absolute ethanol, add 0.71 g of m-aminophenol, stir to dissolve, and then Add 1.0 g of 35% formaldehyde solution, continue to stir for 24 hours, centrifuge, and dry the sample in an oven at 50 degrees for 12 hours.

[0028] (2) Preparation of titanium dioxide precursor solution: Disperse 1 ml of tetrabutyl titanate in deionized water, stir for 30 minutes, centrifuge and filter, wash three times with absolute ethanol, dry in a 100 degree oven for 24 hours, and take 1 gram of sample Use 1.0mol.L -1 Dissolve 15 ml of HCl to obtain a titanium tetrachloride solution with low acidity.

[0029] (3) Disperse 1.0 g of m-aminophenol formaldehyde resin ball into 20 ml of water, add 15 ml of 0.5 mol.L -1 Titanium tetrachloride solution (containing 1ml of tetrabutyl titanate), stir for 24 hours, take it out, put it in an oven at...

Embodiment 3

[0031] (1) Preparation of m-aminophenol formaldehyde resin balls: add 2.0 g of 25% ammonia water to a 30 degree solution containing 24 g of deionized water and 10 ml of absolute ethanol, add 0.71 g of m-aminophenol, stir to dissolve, and then Add 1.0 g of 35% formaldehyde solution, continue stirring for 24 hours, and centrifuge. The sample was dried in an oven at 50 degrees for 12 hours.

[0032] (2) Preparation of titanium dioxide precursor solution: Disperse 1 ml of tetrabutyl titanate into deionized water, stir for 30 minutes, centrifuge and filter, wash with absolute ethanol three times, dry in an oven at 50 degrees for 2 hours, and take 1 gram of sample Use 0.1-2.0mol.L -1 Dissolve 15 ml of HCl to obtain a titanium tetrachloride solution with low acidity.

[0033] (3) Disperse 1.5 g of m-aminophenol formaldehyde resin balls into 20 ml of water, add 15 ml of 1.0 mol.L -1 Titanium tetrachloride solution (containing 1 ml of tetrabutyl titanate), stir for 24 hours, take it out, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com