Process for preparing resorcinol

A technology for resorcinol and a production process, which is applied in the field of resorcinol production technology, can solve the problems of difficulty in scaling up oxidation and extraction separation engineering, no breakthrough in industrialized production, and high technical requirements, and achieves easy control of process conditions, High product yield and the effect of on-site cleaning of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

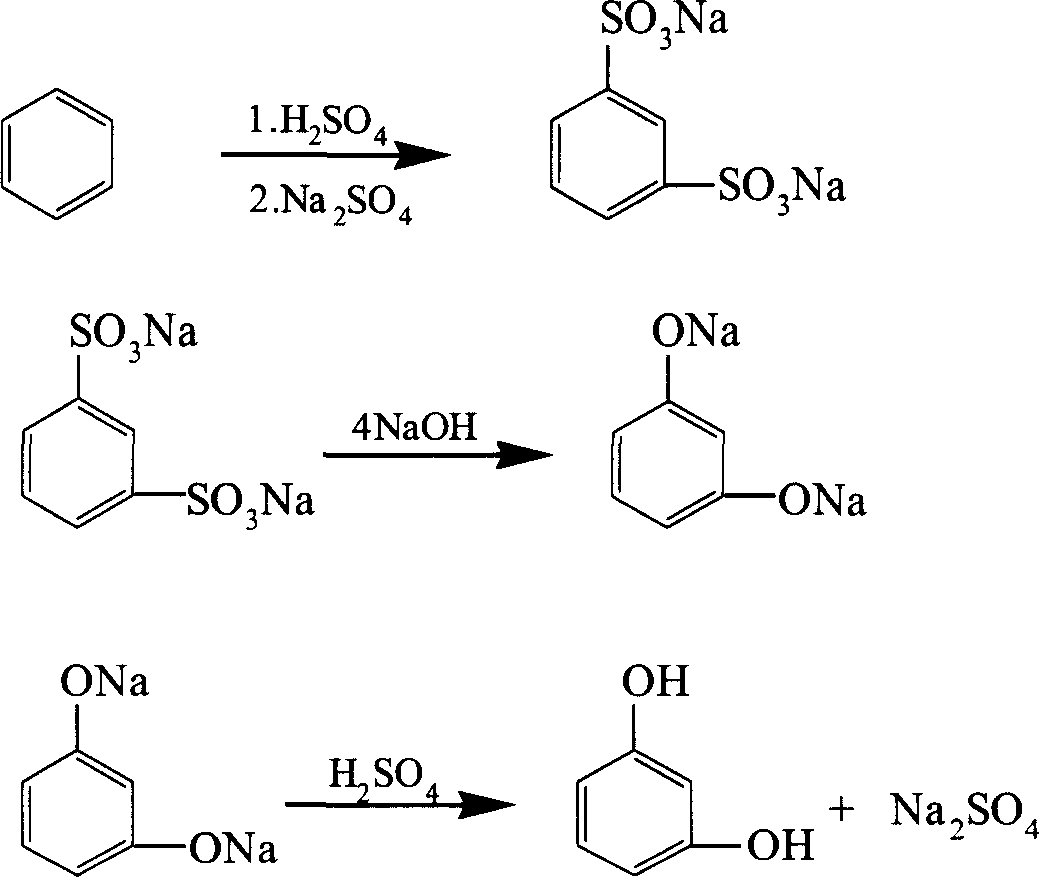

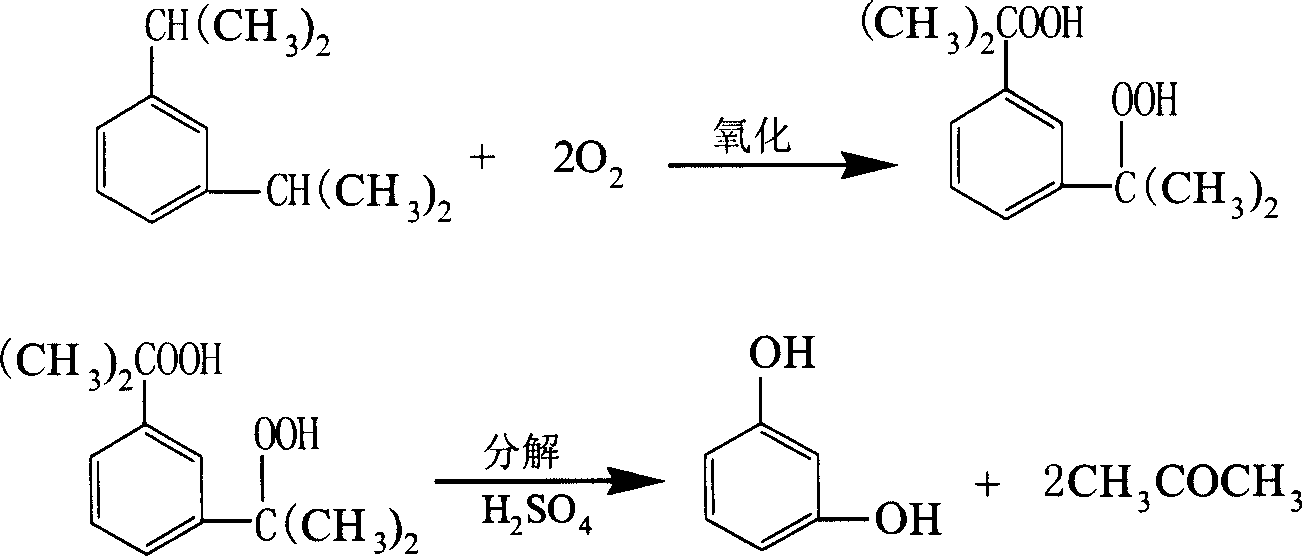

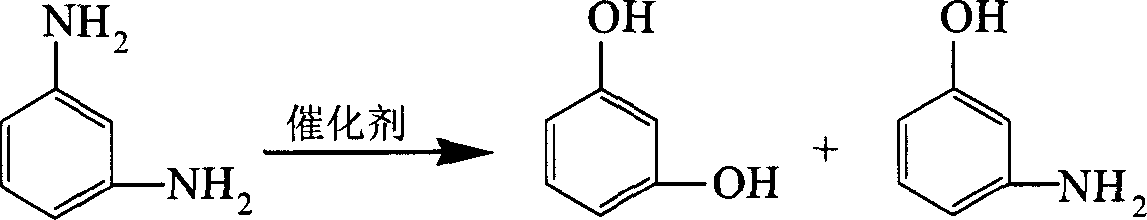

Method used

Image

Examples

Embodiment 1

[0025] Add 70g m-phenylenediamine, 160g hydrochloric acid (concentration 30%), and 2000g water into a 5L autoclave equipped with stirring and tetrafluoroethylene lined (heated by electric heating coil). After sealing, heat to 200℃ and control the temperature to 200- Reacted at 220°C for 4 hours. After the reaction, the temperature was lowered to room temperature 30°C, and gas chromatography was used to sample. In the reaction solution: the content of m-phenylenediamine is 17.07%; the content of resorcinol is 58.46%; the content of m-aminophenol is 24.47%. The conversion rate of m-phenylenediamine was 82.93%. Adjust the pH to 1-2 with hydrochloric acid, extract with isopropyl ether, and perform gas chromatography on the extract. The purity of resorcinol is 99.84%.

Embodiment 2

[0027] In a 10L autoclave equipped with stirring and lined with tetrafluoroethylene, heated with a zirconium U-tube heat-conducting oil, add 120g m-phenylenediamine, 260g hydrochloric acid ((concentration 30%), 5000g water, heat with heat-conducting oil after leak test When the temperature reaches 220°C, the temperature is controlled at 220-250°C, the reaction is 6 hours, the temperature is lowered, and the gas chromatography is sampled. In the reaction solution: the content of m-phenylenediamine is 1.16%; the content of resorcinol is 97.38%; the content of m-aminophenol is 1.46%. The conversion rate of phenylenediamine was 98.84%. The pH was adjusted to 1-2 with hydrochloric acid, extracted with n-butanol, and the extract was tested by gas chromatography. The purity of resorcinol was 99.48%. The n-butanol was distilled out, and the residue at the bottom of the distillation flask was reduced. After pressure distillation, 85.6 g of white resorcinol was obtained with a chromatograph...

Embodiment 3

[0029] In a 3000L autoclave lined with tetrafluoroethylene, heated with a zirconium tube heat exchanger, add 40Kg of m-phenylenediamine, 80Kg of hydrochloric acid ((concentration 30%), 1600Kg of water, and heat to 220°C after leak testing. The temperature is controlled at 220-250°C, the reaction is 8 hours, and the temperature is reduced to room temperature. The sample is detected by gas chromatography. In the reaction solution: the content of resorcinol is 98.72%; the content of m-aminophenol is 1.28%. The conversion rate of m-phenylenediamine is 100%. Adjust the pH to 1-2 with hydrochloric acid, extract with n-butanol, recover the solvent and distill under reduced pressure to obtain 34Kg of white resorcinol with a yield of 83.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com