Patents

Literature

89results about How to "High processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for purifying catering oil smoke by utilizing synergistic effect of low temperature plasma and catalysts

ActiveCN103785276AReduce purification efficiencyMeet emission control requirementsDispersed particle separationParticulatesPartial oxidation

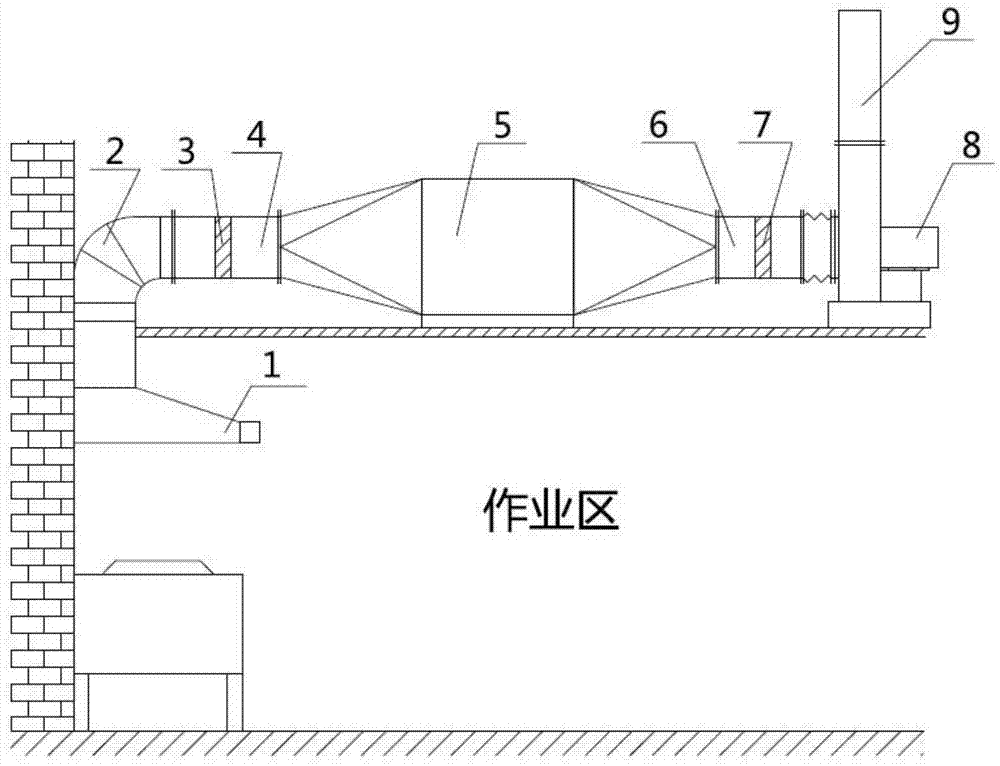

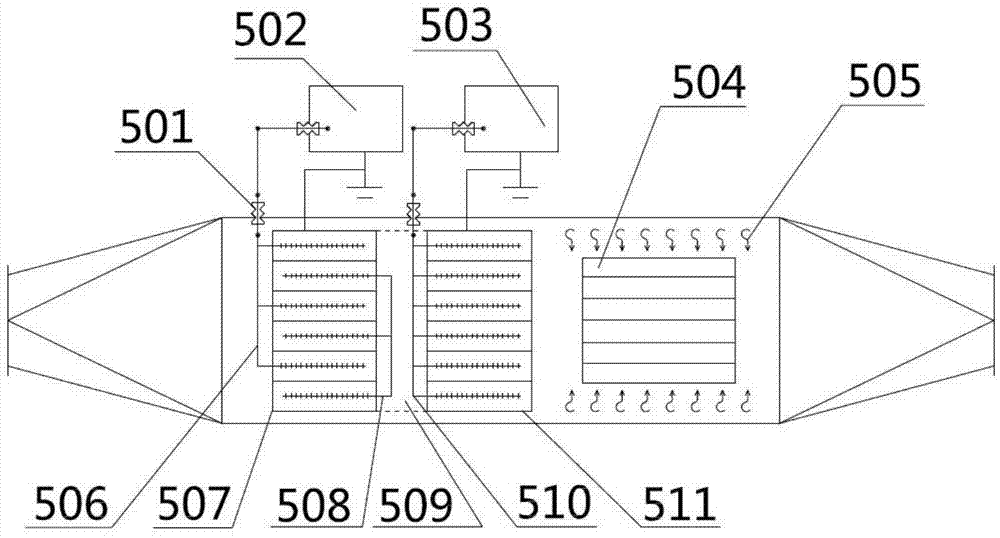

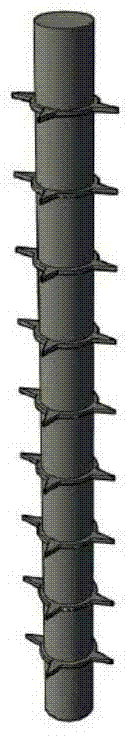

The invention discloses a method and device for purifying particulate matters and volatile organic compounds in catering oil smoke by utilizing a synergistic effect of low temperature plasma and catalysts. The method comprises the following steps: enabling the oil smoke to sequentially pass through a low temperature plasma reaction area and a catalytic reaction area, wherein the volatile organic compounds contained in the oil smoke are partially oxidized in the low temperature plasma reaction area and are further oxidized in the catalytic reaction area. On the front section of the low temperature plasma reaction area, the particulate matters contained in the oil smoke are separated, removed or charged by alternately arranged positive and negative polarity high-voltage discharge; on a transition section of the low temperature plasma reaction area, particles with positive charges and negative charges are close and are subjected to coagulation growth; on a rear section of the low temperature plasma reaction area, the particles are continuously subjected to the coagulation growth and are captured and separated. According to the method, the function of efficiently purifying the volatile organic compounds is increased; the efficiency of removing the particulate matters contained in the oil smoke is relatively high; the normal temperature operation can be realized, the fouling resistance is high, and the method is particularly suitable for being used for performing oil smoke treatment in public places such as various dining halls, public houses and hotels.

Owner:BEIHANG UNIV

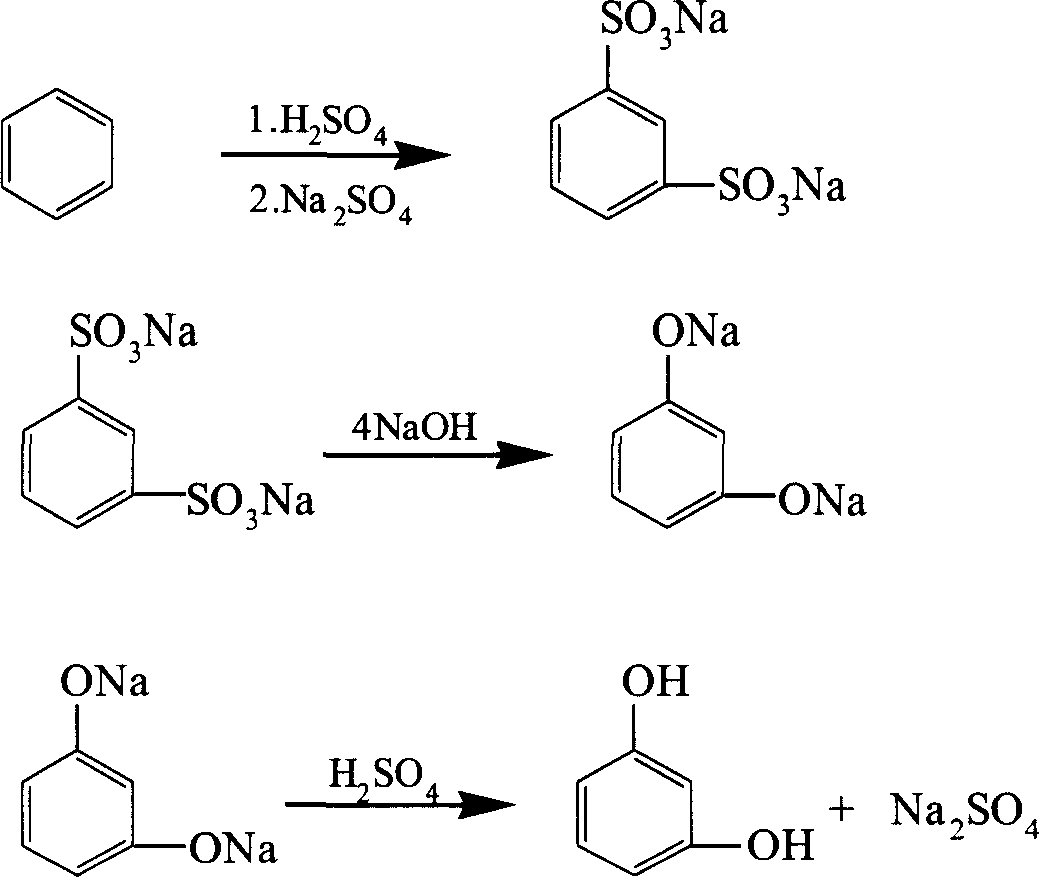

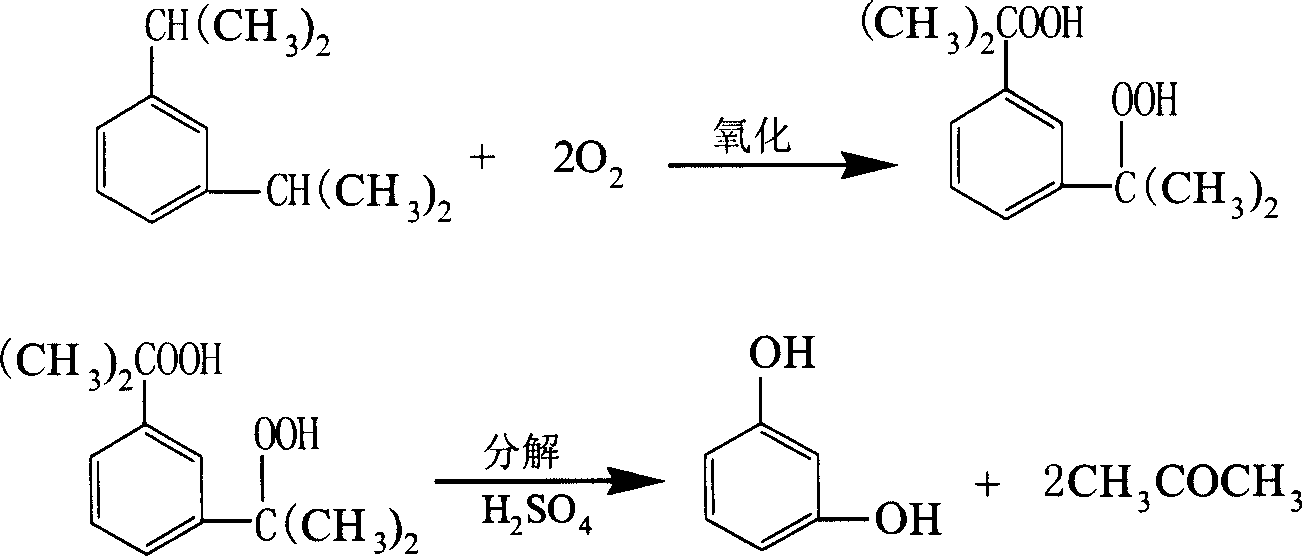

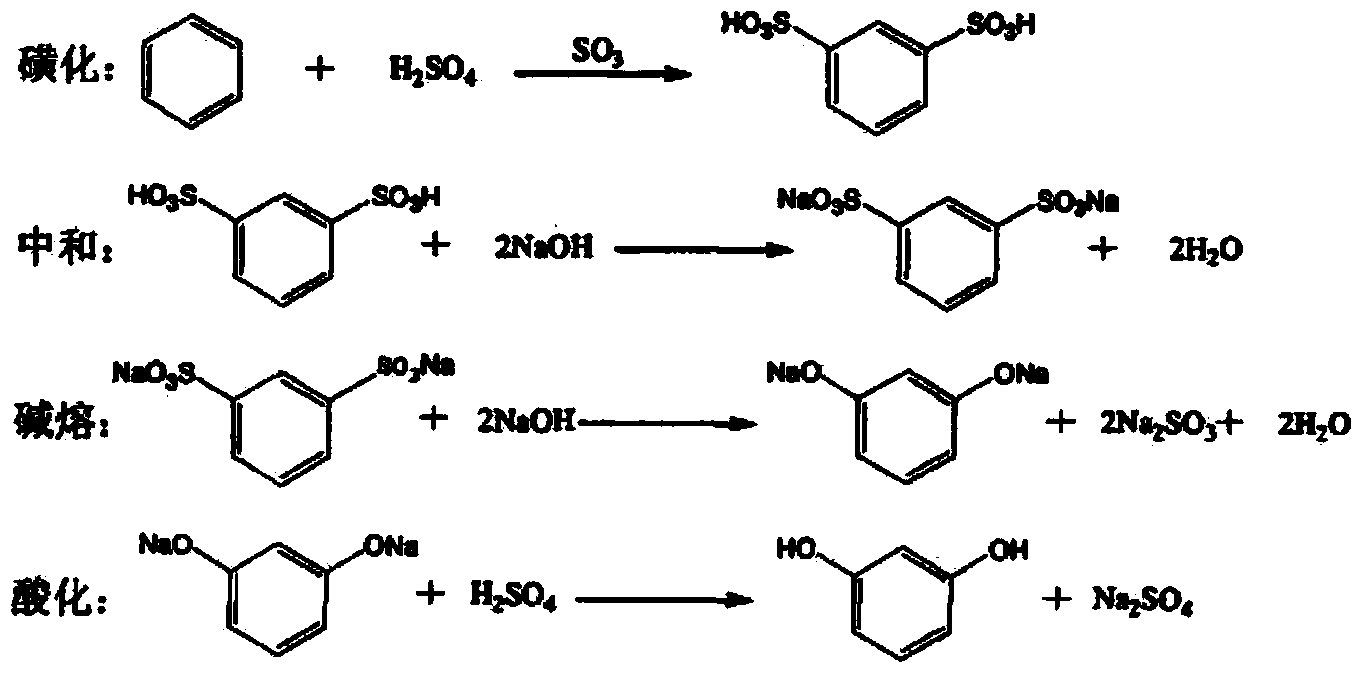

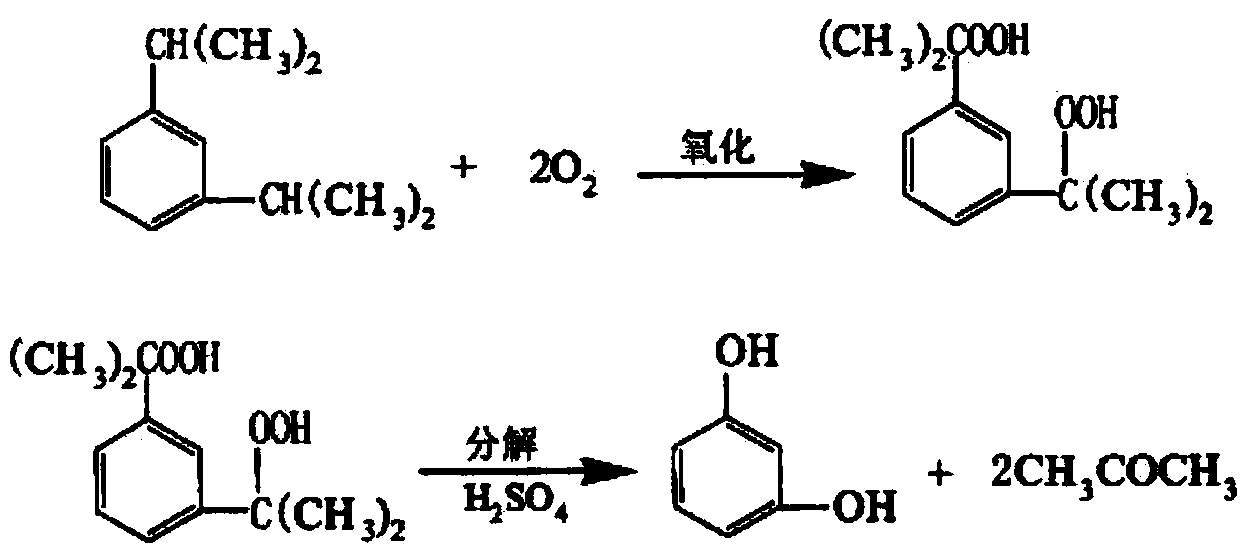

Process for preparing resorcinol

InactiveCN1830933ANo emissionsSolve pollutionOrganic chemistryOrganic compound preparationMeta-aminophenolResorcinol

Owner:HUIFENG CHEM PLANT WUJIANG CITY

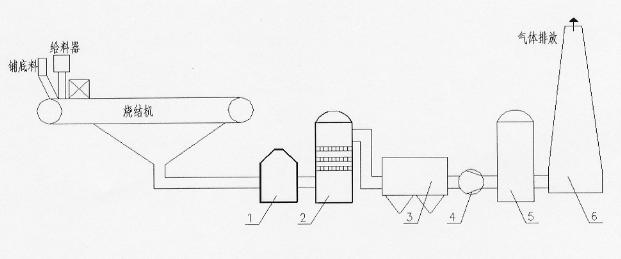

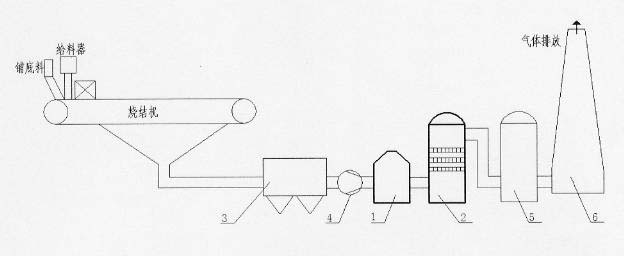

Denitration system and method for sintering flue gas without ammonia reducing agent

InactiveCN102188904ASimple processSimple process equipmentLighting and heating apparatusDispersed particle separationChemical equationProcess engineering

The invention relates to a denitration system and method for sintering flue gas without using ammonia as a reducing agent. The system comprises a sintering machine, and a heater, a denitration reactor, a deduster, a blower fan, a desulfurization tower and a chimney sequentially connected with the sintering machine. The denitration reactor is arranged before the deduster; that is, the deduster is arranged between the heater and the denitration reactor. A catalyst layer is provided in the denitration reactor. The method comprises the following steps that: sintering flue gas is heated by the heater to an appropriate temperature before the deduster and is sent to the denitration reactor; NOx is removed by a catalytic reduction in the denitration reactor under the influence of a catalyst, wherein the chemical equation for the removing of NOx is 2NO +2CO =N2 + 2CO2; the reacted sintering flue gas is emitted into the atmosphere after dedusting and desulphurization. According to the invention, the ammonia reducing agent needs not to be added, the catalyst is widely available and cheap, and investment and operation cost needed is low; the reducing agent used in the invention is CO reduction ingredients in the sintering flue gas instead of ammonia, thereby avoiding many problems resulting from the utilization of an ammonia reducing agent.

Owner:BAOSTEEL ENG & TECH GRP

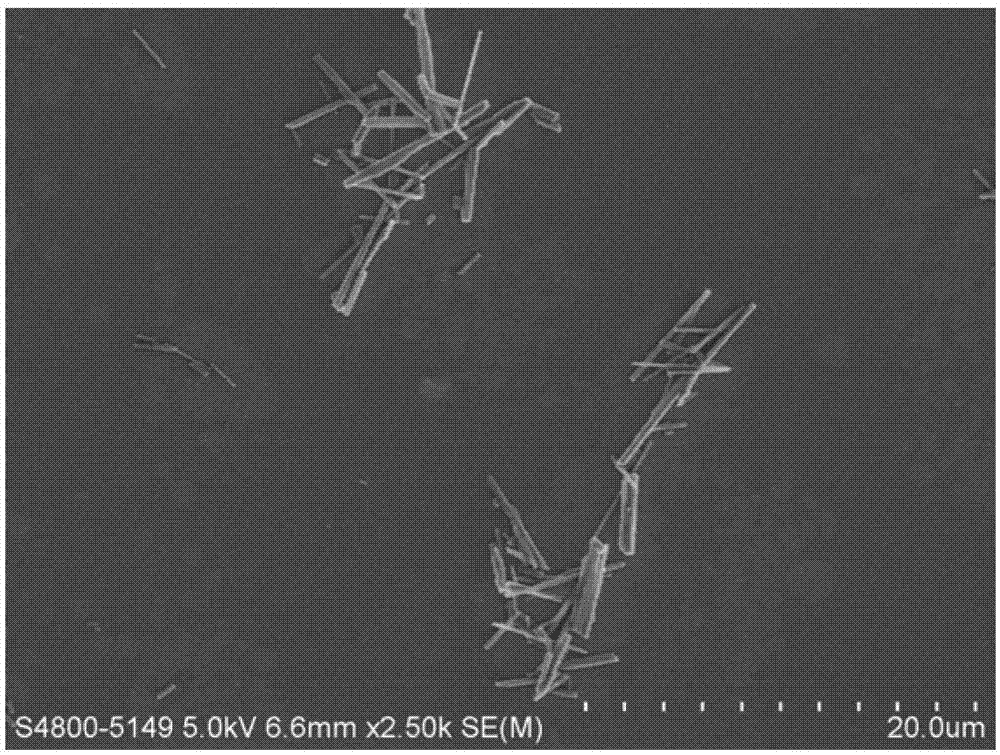

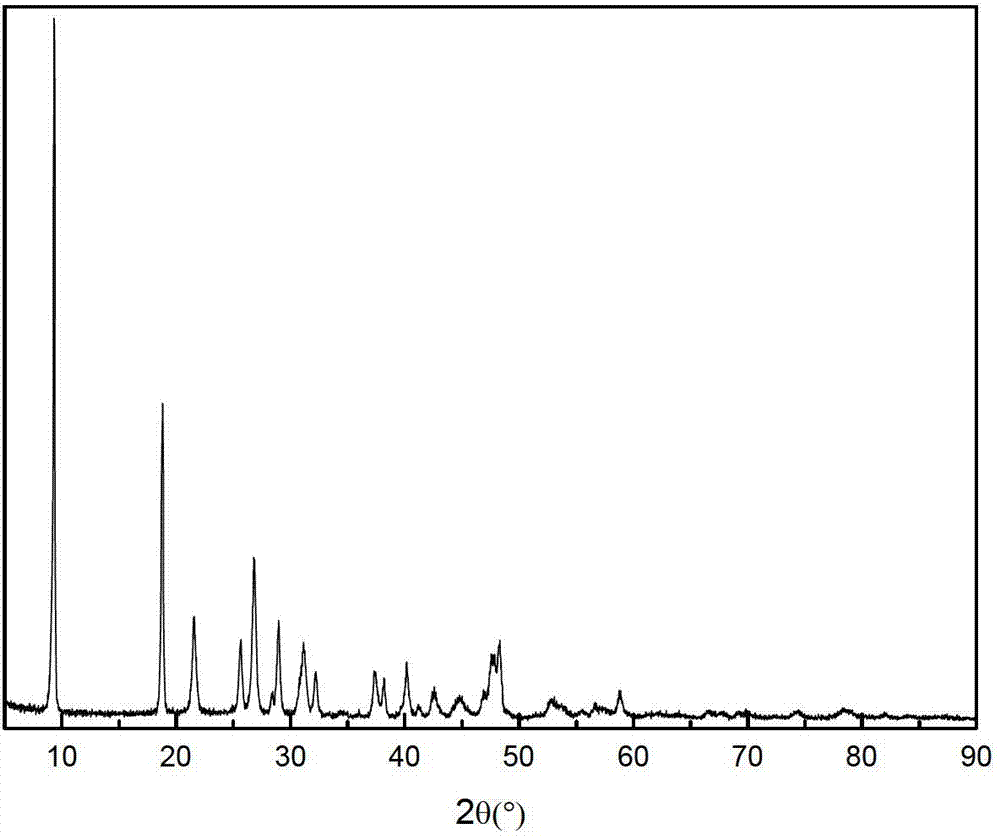

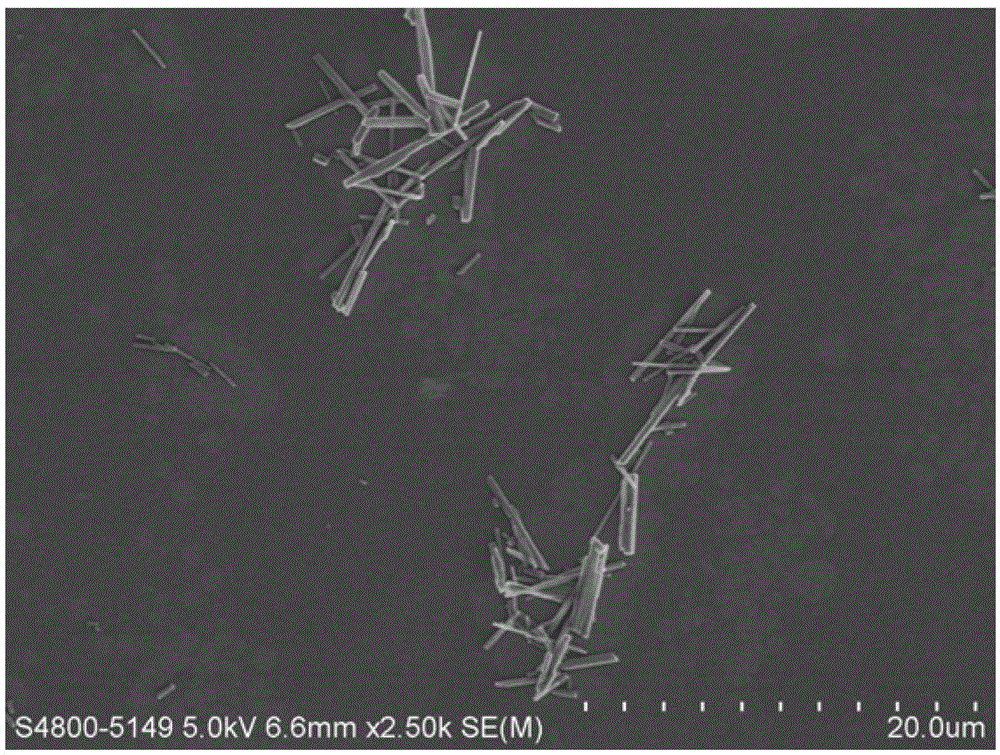

Production method and application of terephthalic metal slat whisker

ActiveCN103173845ASolve the vagariesSolve processingPolycrystalline material growthFrom normal temperature solutionsWastewaterWhiskers

The invention relates to a production method and application of a terephthalic metal slat whisker. The production method disclosed by the invention comprises the steps of: recycling crude terephthalic acid of which the purity is not smaller than 95% by an alkali peeling waste water treatment process; adding and dissolving crude terephthalic acid in a caustic soda solution as a raw material; adding a surface active agent after regulating the pH value; stirring the mixed solution uniformly, then adding a dissolvable calcium salt, stirring and ageing, thereby obtaining the terephthalic metal slat whisker. The terephthalic metal slat whisker can be used as an active filler of rubber, and the addition of the whisker can greatly improve the mechanical properties of a rubber plastic material.

Owner:常州市五洲环保科技有限公司

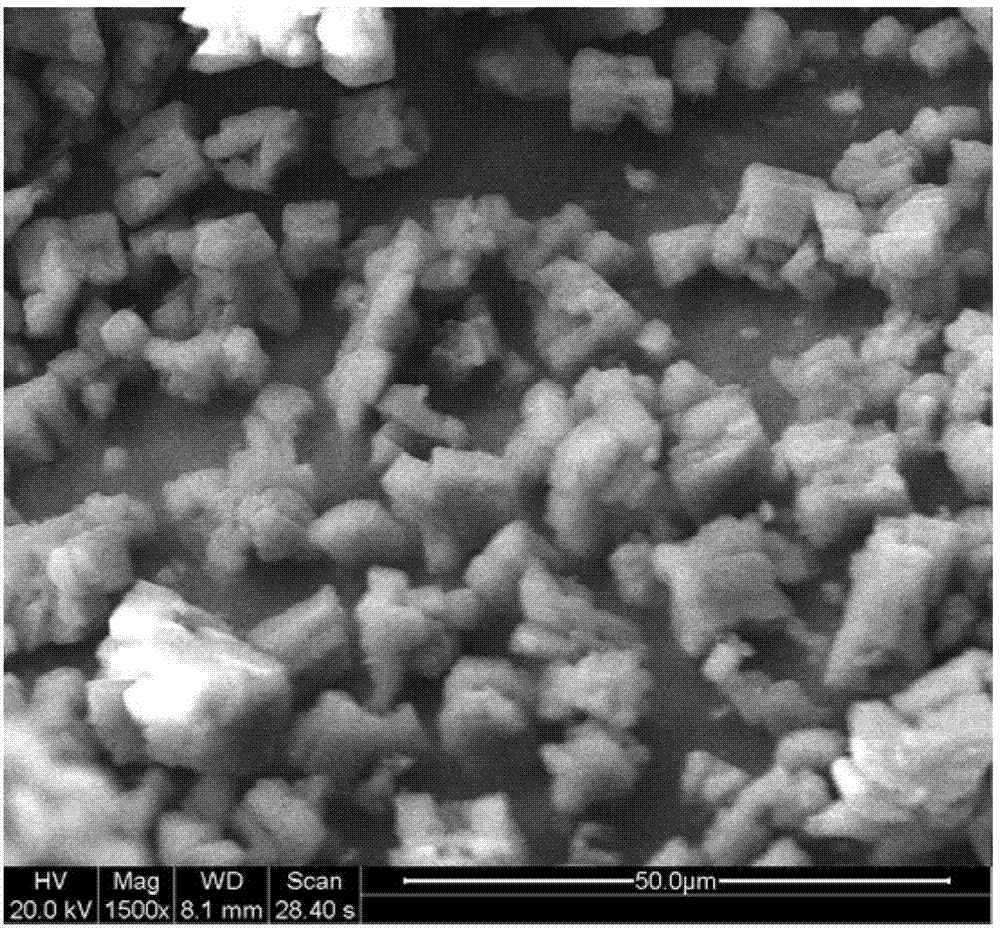

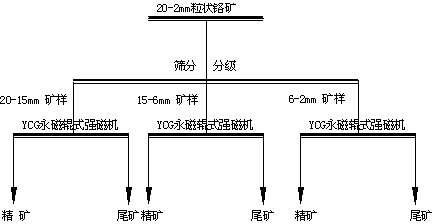

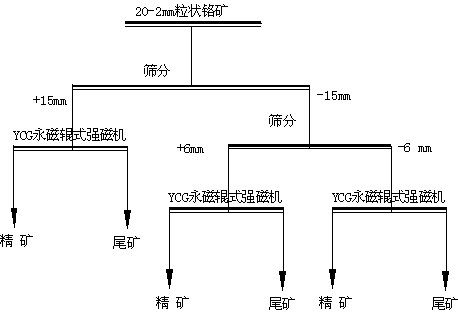

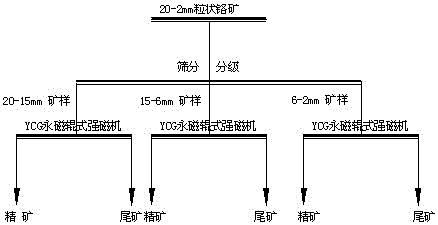

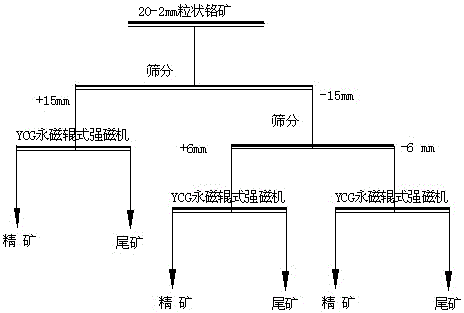

Beneficiation method for recovering chrome lump ore

ActiveCN103894287ARemarkable effect of energy saving and consumption reductionSuitable for deliveryHigh gradient magnetic separatorsManganeseSiderite

The invention discloses a beneficiation method for recovering chrome lump ore. The method comprises the following processing steps: crushing the chrome ore, and classifying three particle size grades including 20-15mm, 15-6mm and 6-2mm by narrow level screening; respectively carrying out dry-type strong magnetic separation on the three classified particle size grades obtained by screening by virtue of a permanent magnet roller type strong magnetic separator; adjusting the speed of a feeding belt of the permanent magnet roller type strong magnetic separator and the distance between the center of a barrel and a separating clapboard to obtain the best grading technical index, wherein the magnetic field intensity of the surface of the belt of the permanent magnet roller type strong magnetic separator is 0.9-1.3T. The method is simple in technological process, the high-quality Cr2O3 ore concentrate can be obtained by screening classification and narrow level screening, and the recovery rate of the Cr2O3 can be increased. The method is short in beneficiation process and is capable of obtaining the ore concentrate and removing tailings in advance; the beneficiation technology has the advantage of being lower in energy consumption compared with other technologies; the method not only can be used for screening the chrome ore, but also can be used for screening other weak magnetic iron minerals such as manganese ore, hematite, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

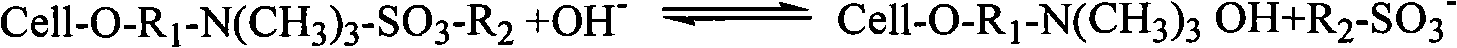

Method for processing negative ion surface active agent in wastewater

InactiveCN101628762AReduce consumptionReduce manufacturing costOther chemical processesWater contaminantsCelluloseProcess equipment

The invention discloses a method for processing negative ion surface active agent in wastewater, belonging to the field of chemical environmental protection and adopting the steps of wastewater acidification pretreatment, filtration, quaternary ammonium cationic cellulose composite adsorption column adsorption, and the like; and the process route of treatment is short, and the concentration of negative ion surface active agent in the treated water is greatly lower than the national wastewater discharge standard. The processing method of the invention has the advantages of simple process equipment, low energy consumption, high adsorption speed and large adsorption capacity, adsorbent can be used in the way of regeneration and circulation, the processing cost is low, and raw materials used for preparing the quaternary ammonium cationic cellulose has low production cost and wide range of acquisition, is non-toxic, can not cause secondary pollution to environment, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

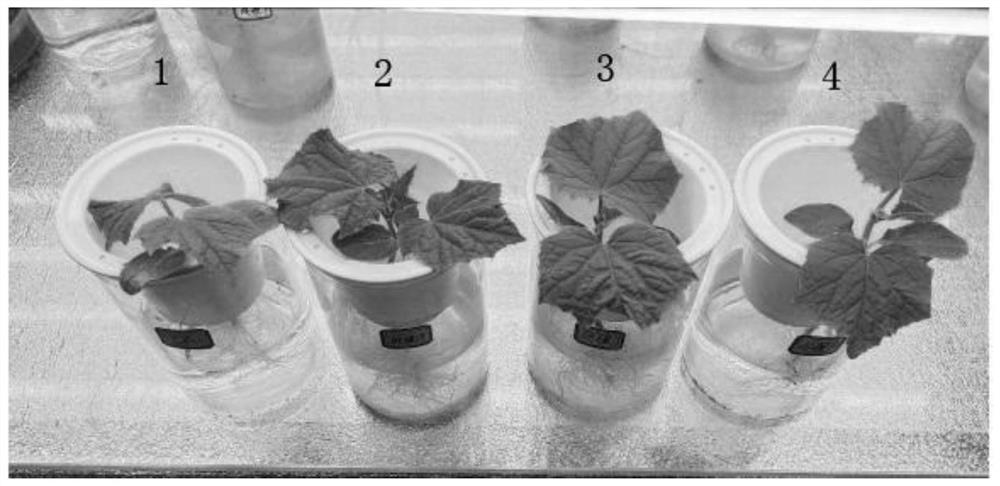

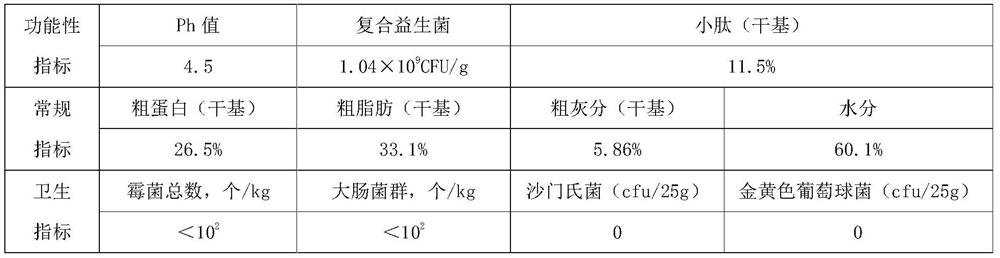

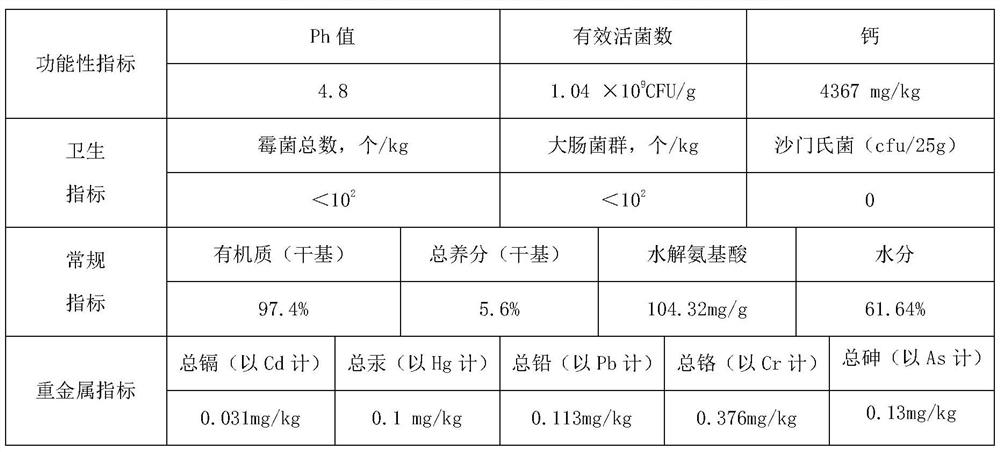

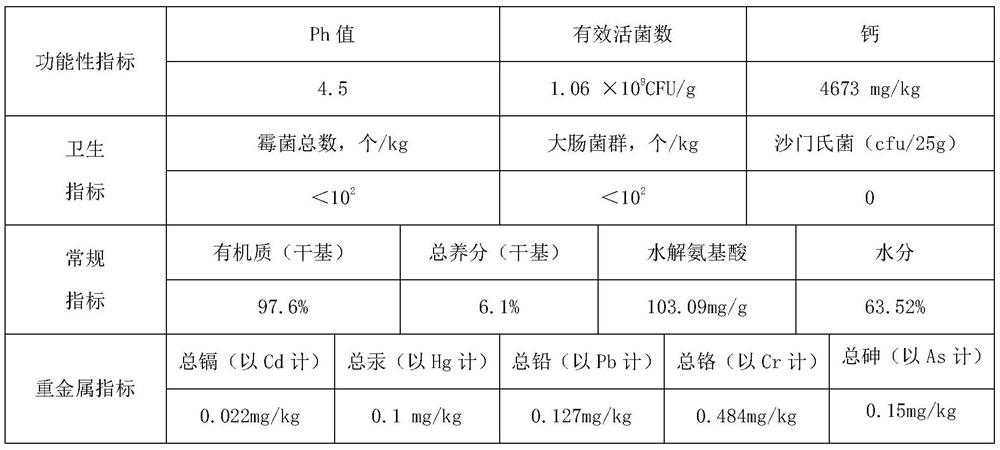

Functional amino acid enzyme and preparation method thereof

InactiveCN111838408AImprove immunityEnhance disease resistance functionBio-organic fraction processingFood processingBacillus licheniformisLactobacillus acidophilus

The invention discloses a preparation method of a functional amino acid enzyme. The method comprises the following steps: crushing an animal-derived protein raw material, and using acid protease and lipase for treatment; then carrying out aerobic fermentation by using bacillus subtilis, bacillus licheniformis and saccharomyces cerevisiae, carrying out anaerobic fermentation by using enterococcus faecalis, lactobacillus plantarum, lactobacillus acidophilus and streptococcus thermophilus after the aerobic fermentation is finished, and converting into a functional amino acid enzyme for feed or anagricultural functional amino acid enzyme fertilizer after microbial fermentation; the invention further discloses characteristics and application of the functional amino acid enzyme. According to the method, harmless treatment and resource utilization can be carried out on animals died of illness, the defects in the prior art are overcome, and the method has the advantages of being environmentally friendly, low in treatment cost, high in product additional value and wide in product application range and is a technology worthy of being popularized in the industry.

Owner:SHANDONG BAIDE BIOLOGICAL TECH

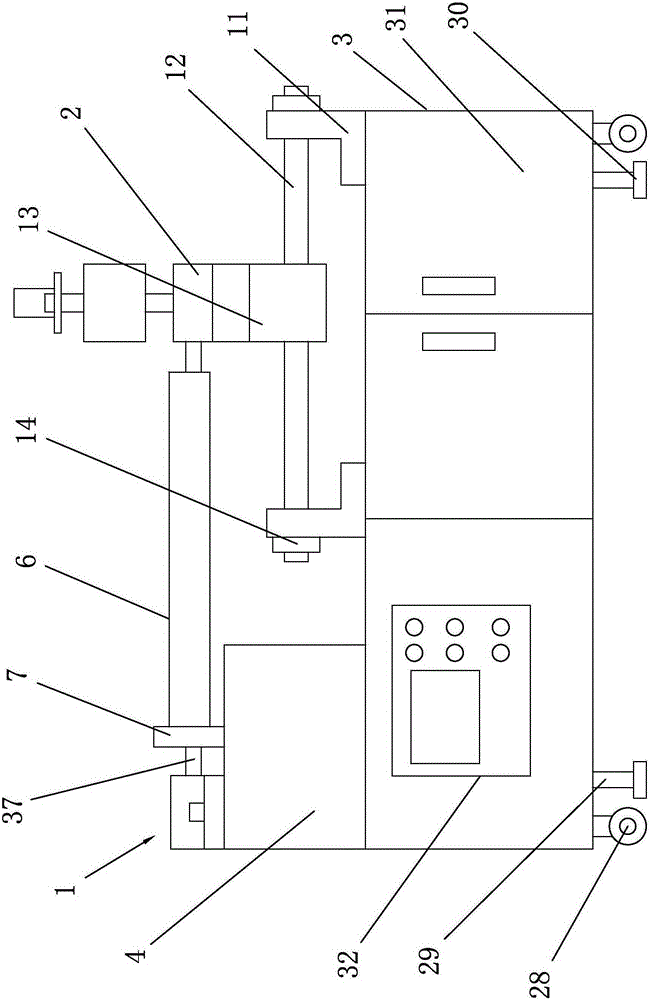

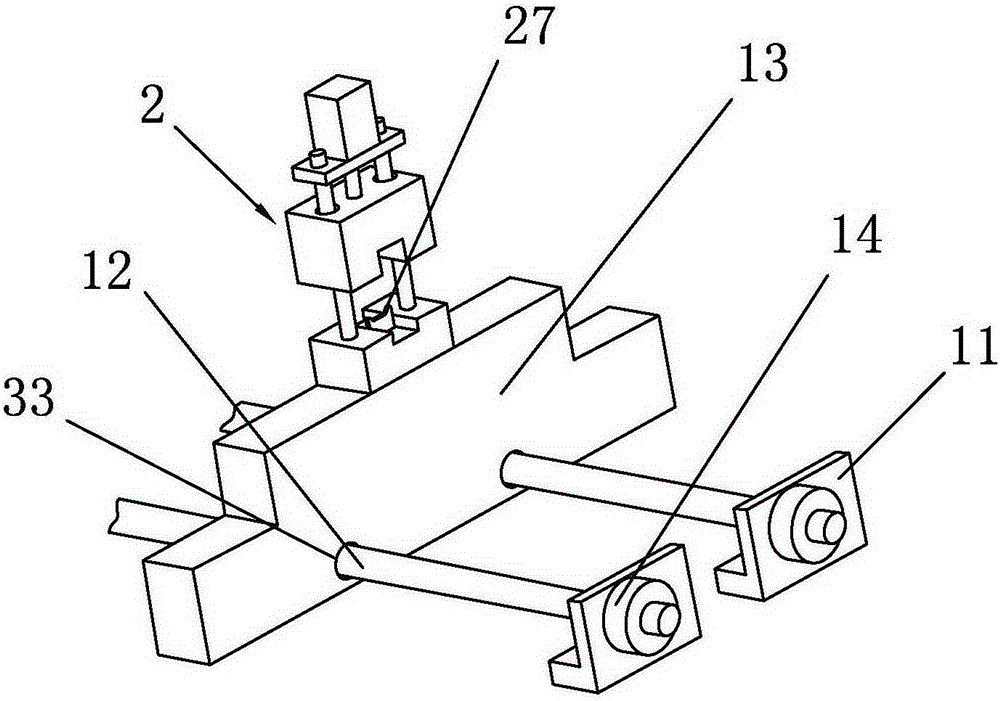

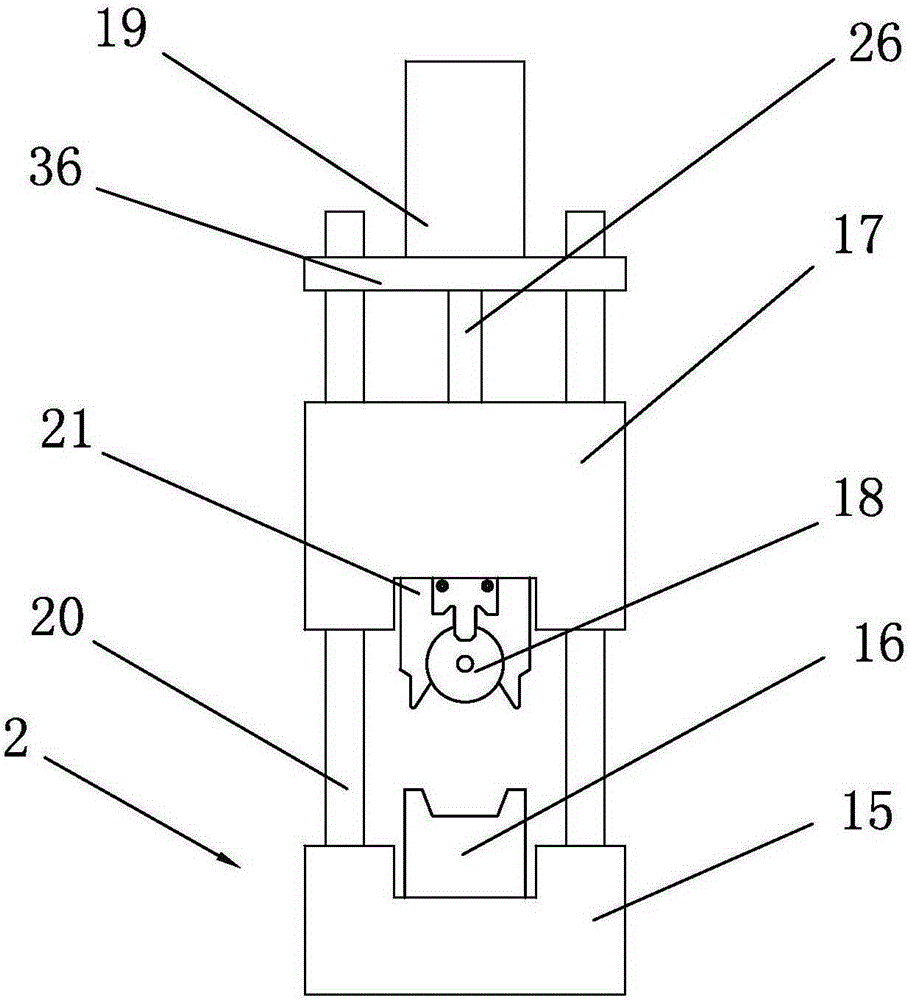

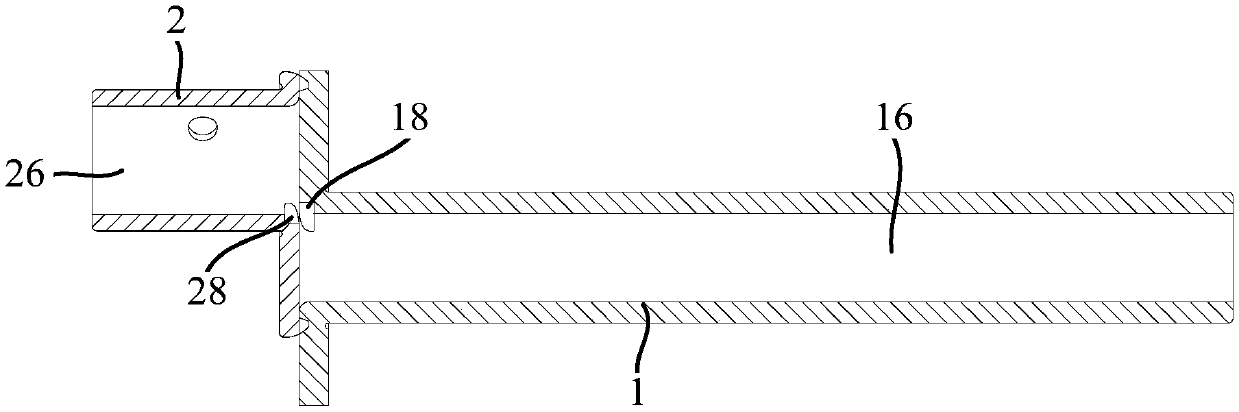

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

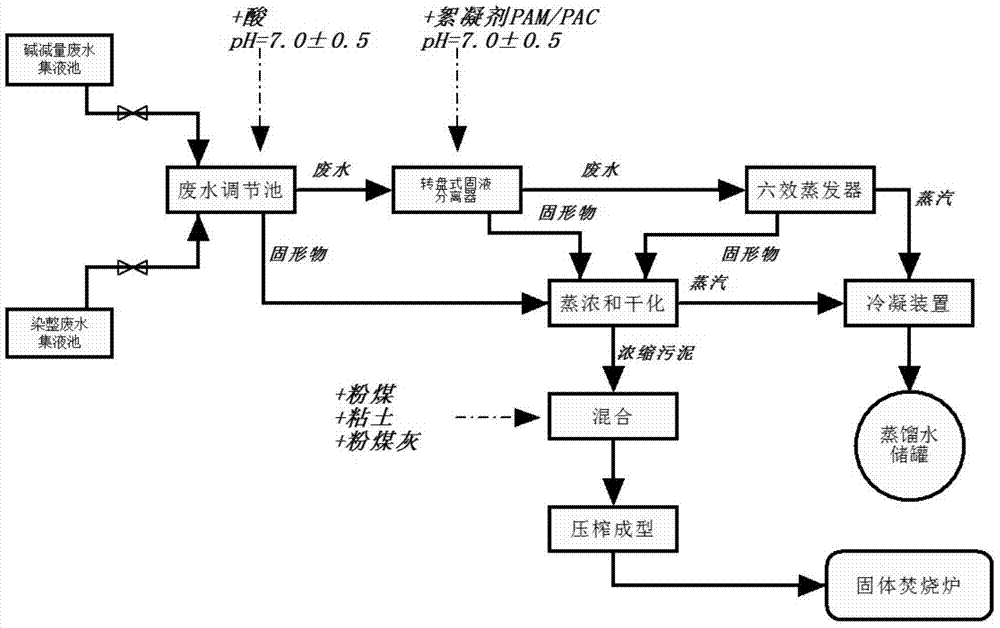

Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

InactiveCN103693792ASolve the technical bottleneck of zero emissionQuality improvementSludge treatment by de-watering/drying/thickeningBiofuelsFiberAluminium chlorohydrate

The invention discloses a wastewater zero discharge method in a manufacturing process of island superfine fiber synthetic leather. The method comprises the following steps: merging an alkali-minimization wastewater and a dyeing wastewater into a wastewater regulating reservoir, or merging the alkali-minimization wastewater into the wastewater regulating reservoir; adding acid to the wastewater regulating reservoir to form a solid matter; transferring the wastewater after the solid matter is cleaned into a turntable solid-liquid separator; adding a polyacrylamide flocculant and a polyaluminium chloride flocculant; evaporating the solid matter and the sludge obtained by solid-liquid separation in an evaporation tank, and simultaneously collecting distilled water in a condensation manner; transferring the wastewater from solid-liquid separation into a multi-effect evaporator to evaporate, and collecting distilled water by condensation; merging the residual residue in the evaporator into a sludge concentrating tank to continue to process. The production of the island superfine fiber synthetic leather is taken as a basic system, and is combined with collection, treatment and comprehensive utilization technologies of the production wastewater and the solid matter, the technical bottlenecks of wastewater zero discharge in the production process is solved, and the island superfine fiber synthetic leather which is friendly to environment and high in quality can be produced.

Owner:FUJIAN KELISHENG SUPERFINE FIBER

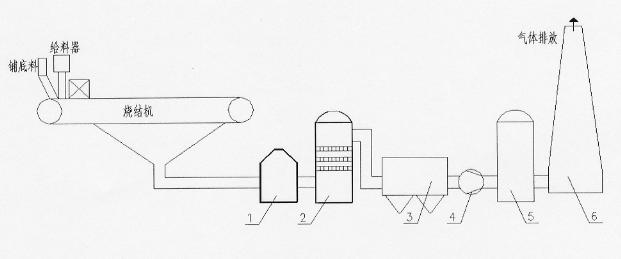

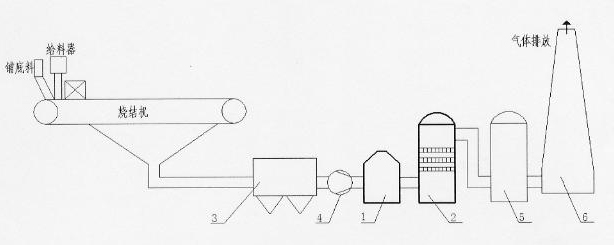

Denitrification system and method for sintering gas without ammonia reductant

InactiveCN102188906ASimple processSimplify equipment processLighting and heating apparatusDispersed particle separationTowerAmmonia

The invention relates to a denitrification system and a method for sintering gas without an ammonia reductant. The system comprises a sintering machine, a heater, a denitrification reactor, a deduster, a fan, a desulfurization tower and a chimney, wherein the deduster, the fan, the heater, the denitrification reactor, the desulfurization tower, and the chimney are sequentially connected with the sintering machine. The denitrification reactor is connected to the sintering machine behind the deduster, i.e., the deduster, the fan, and the heater are sequentially connected between the sintering machine and the denitrification reactor. The denitration reactor is provided with a catalyst layer. The method comprises the following steps that: after being processed through the deduster, the sintering gas is heated to a appropriate temperature through the heater, and is send to the denitration reactor; the sintering gas is subjected to a catalytic reduction in the presence of a catalyst in the denitration reactor to remove NOx; after being dedusted and desulfurized, the reacted sintering gas is discharged in atmospheric environment. With the present invention, the ammonia reductant does not require; sources of the catalyst are extensive; price of the catalyst is low; investment and operation cost of the system are relative low. In the present invention, the ammonia reductant does not be adopted, a reduction component CO in the sintering gas is adopted as the reductant, such that a plurality of problems due to adopting the ammonia reductant are avoided.

Owner:BAOSTEEL ENG & TECH GRP

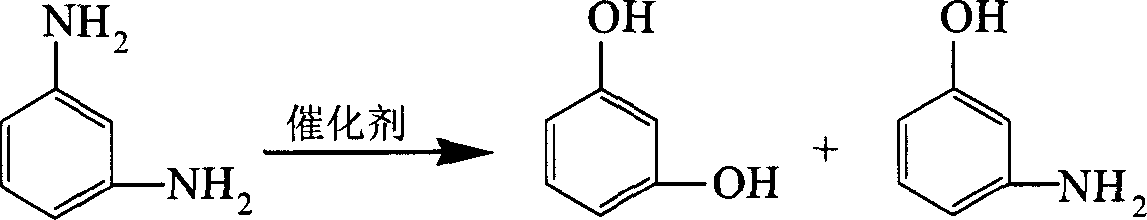

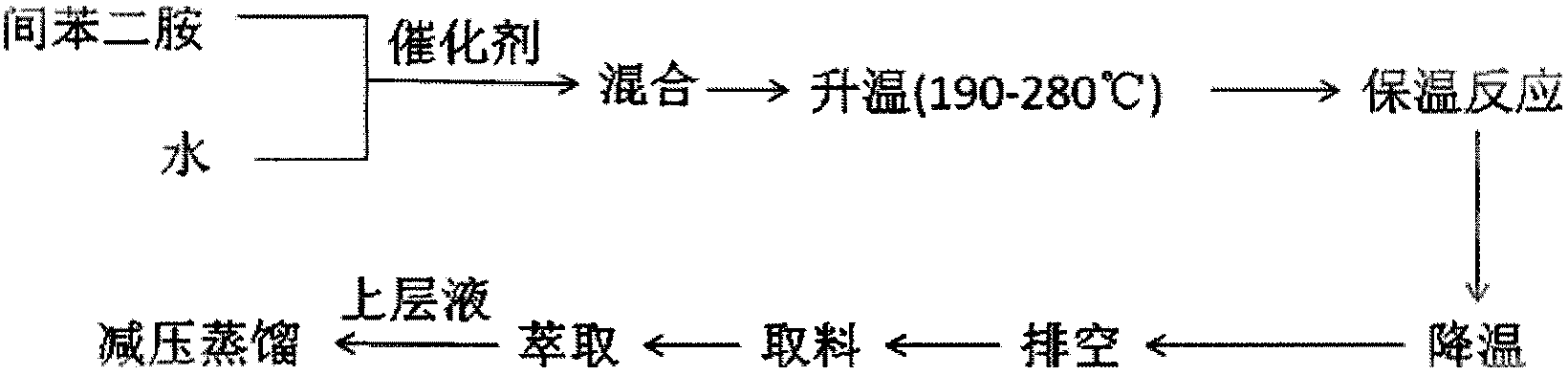

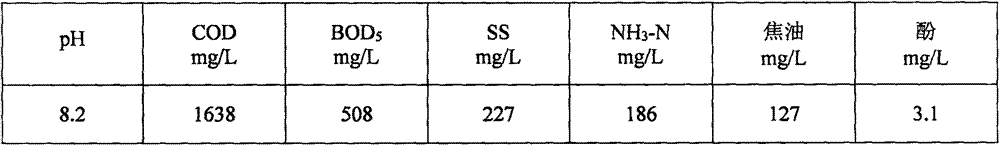

Process of producing resorcinol by hydrolyzing m-phenylenediamine

ActiveCN103848724AReduce pollutionReduce waste water dischargeOrganic chemistryOrganic compound preparationSolventChemistry

The invention relates to a process of producing resorcinol by hydrolyzing m-phenylenediamine. The process comprises the following steps: 1) adding m-phenylenediamine, an acid catalyst, a solid superacid catalyst and water in proportion into a high pressure hydrolysis reaction kettle, and uniformly mixing to obtain a mixed reaction liquid; 2) heating the reactor to hydrolyze m-phenylenediamine to obtain a resorcinol hydrolyzing reaction liquid; 3) carrying out filtration and solvent extraction on the hydrolyzing reaction liquid to obtain a resorcinol coarse product; and 4) carrying out reduced pressure distillation on the resorcinol coarse product to obtain a resorcinol finished product. The process provided by the invention is less in pollution, less in wastewater discharge, easy to control process condition and high in product yield.

Owner:NANJING UNIV OF TECH

Method of simultaneously dephosphorus desulfur of chromium containing molten iron using barium carbonate slag material

InactiveCN1948514AReduce processing costsLess investmentProcess efficiency improvementAir atmospherePhosphate

The invention offers a method to desulfurate and dephosphorize simultaneously for chromate liquid steel with slag charges of barium carbonate, which belongs to the field of preprocessing for liquid steel of metallurgical industry. In this method, deoxidated and chromate pig irons are heated in high temperature furnace or medium-frequency induction furnace under normal atmosphere and air atmosphere. Quantity of additional slag charges of barium carbonate is 10% of chromate pig irons. The slag charges of barium carbonate is prepared with BaCO3-FeO-Cr2O3. The proportion of various components can be adjusted according to phosphate sulfur requirement of different steel grades. This method can desulfurate and dephosphorize simultaneously. Phosphate can be deaminated stably under 0.02%, and sulfur can be deaminated stably under 0.008% with a small burning loss of chromium.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for treating biomass gasified gas washing wastewater and for resource utilization of wastewater treatment product

InactiveCN107381879AIncrease pore volumeLarge specific surface areaWater/sewage treatment by centrifugal separationLiquid carbonaceous fuelsCoal waterActivated carbon

The invention discloses a method for treating biomass gasified gas washing wastewater and for resource utilization of the wastewater treatment product. The method can effectively remove COD in the wastewater and reduce the concentration of organisms; the treated wastewater can be recycled or discharged up to standard; the wastewater treatment product serves as one of the raw materials to prepare coal water slurry. The method mainly comprises the following steps: (a) feeding the biomass gasified gas washing wastewater into a cyclone separator to remove the substances of which the densities are higher than that of water; (b) feeding the wastewater into an intermediate water tank, buffering the water quality, and reducing the water temperature to remove large-particle substances, and regulating the pH value of the wastewater; (c) feeding the wastewater into a coagulation sedimentation tank to remove fine-particle substances, colloidal substances and some of ammonia nitrogen; (d) feeding the wastewater into an activated carbon adsorption tower to remove most of the soluble organic substances; (e) feeding the wastewater into a clear water tank for recycling or discharging up to standard; (f) preparing coal water slurry by taking the adsorbed waste activated carbon as a raw material.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

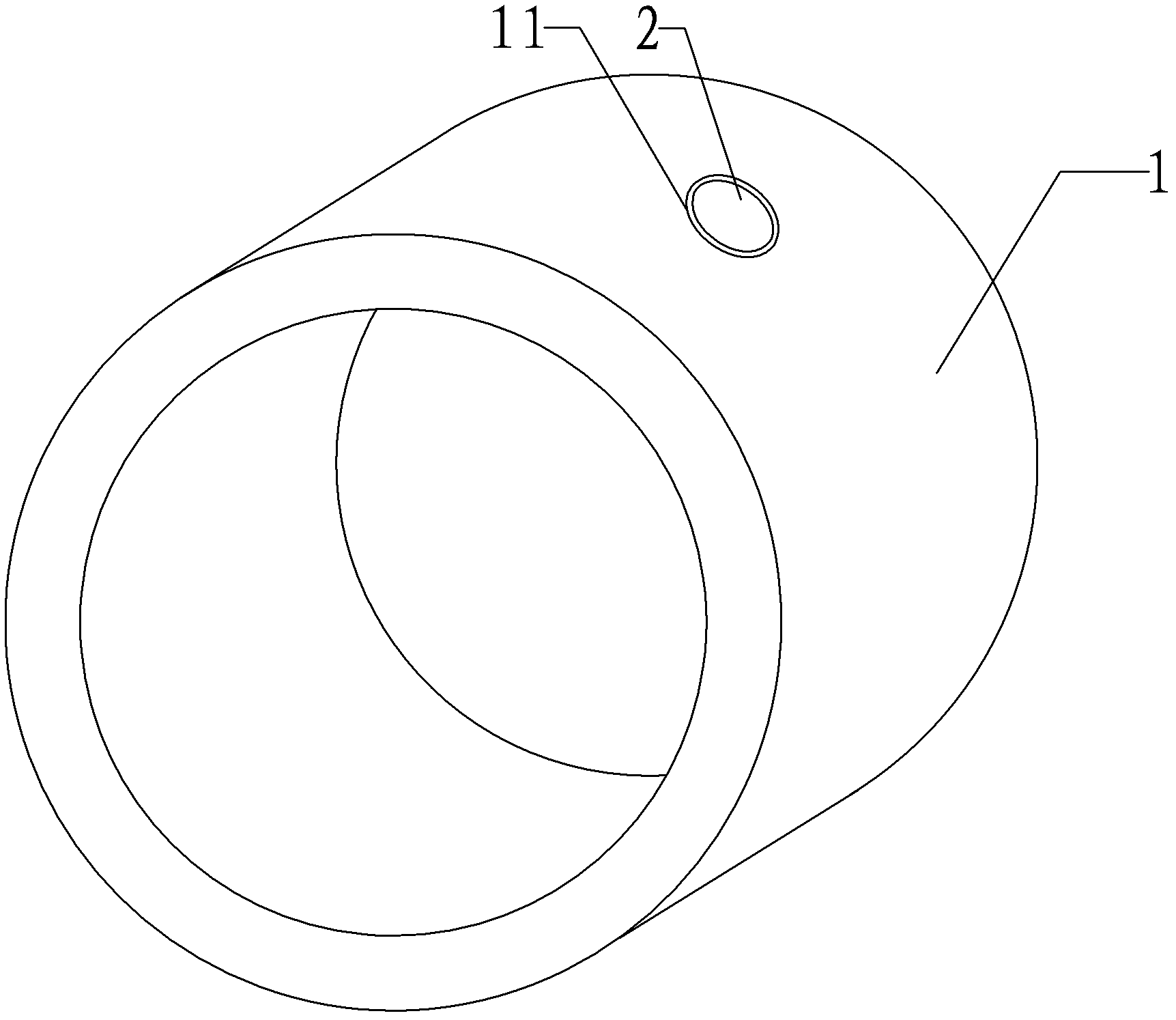

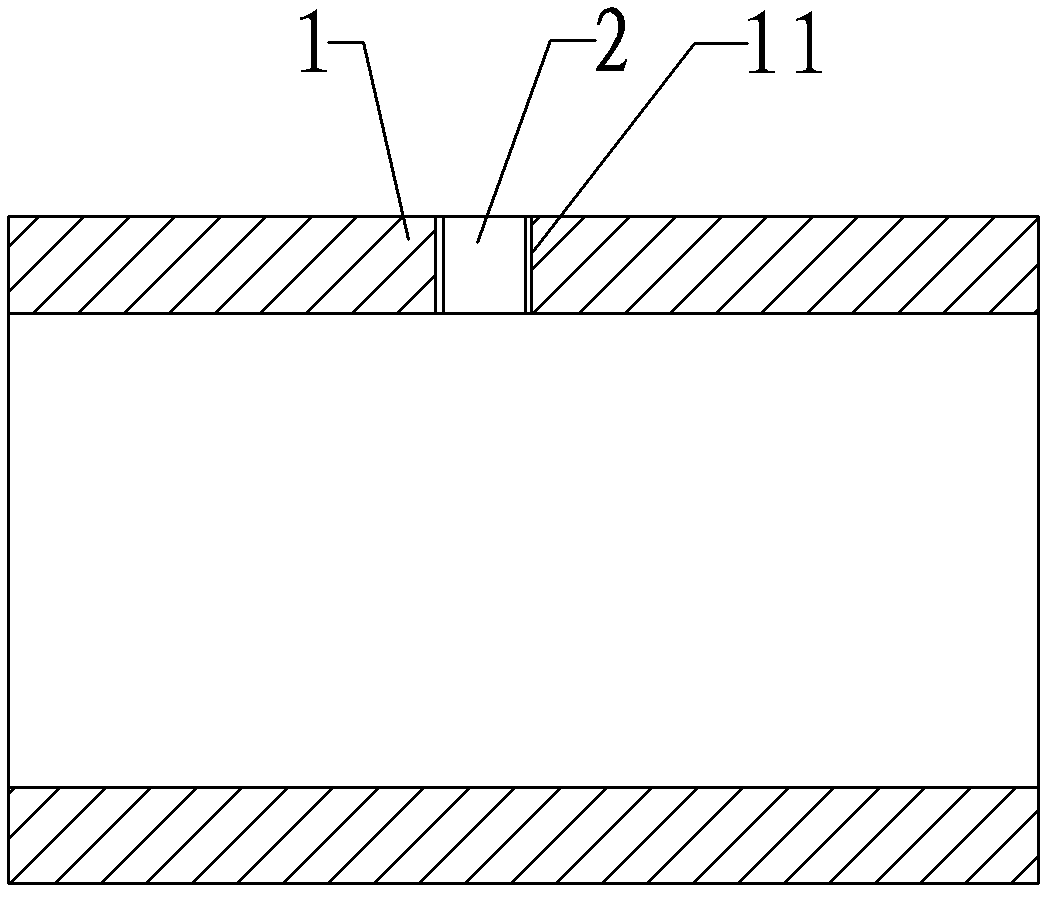

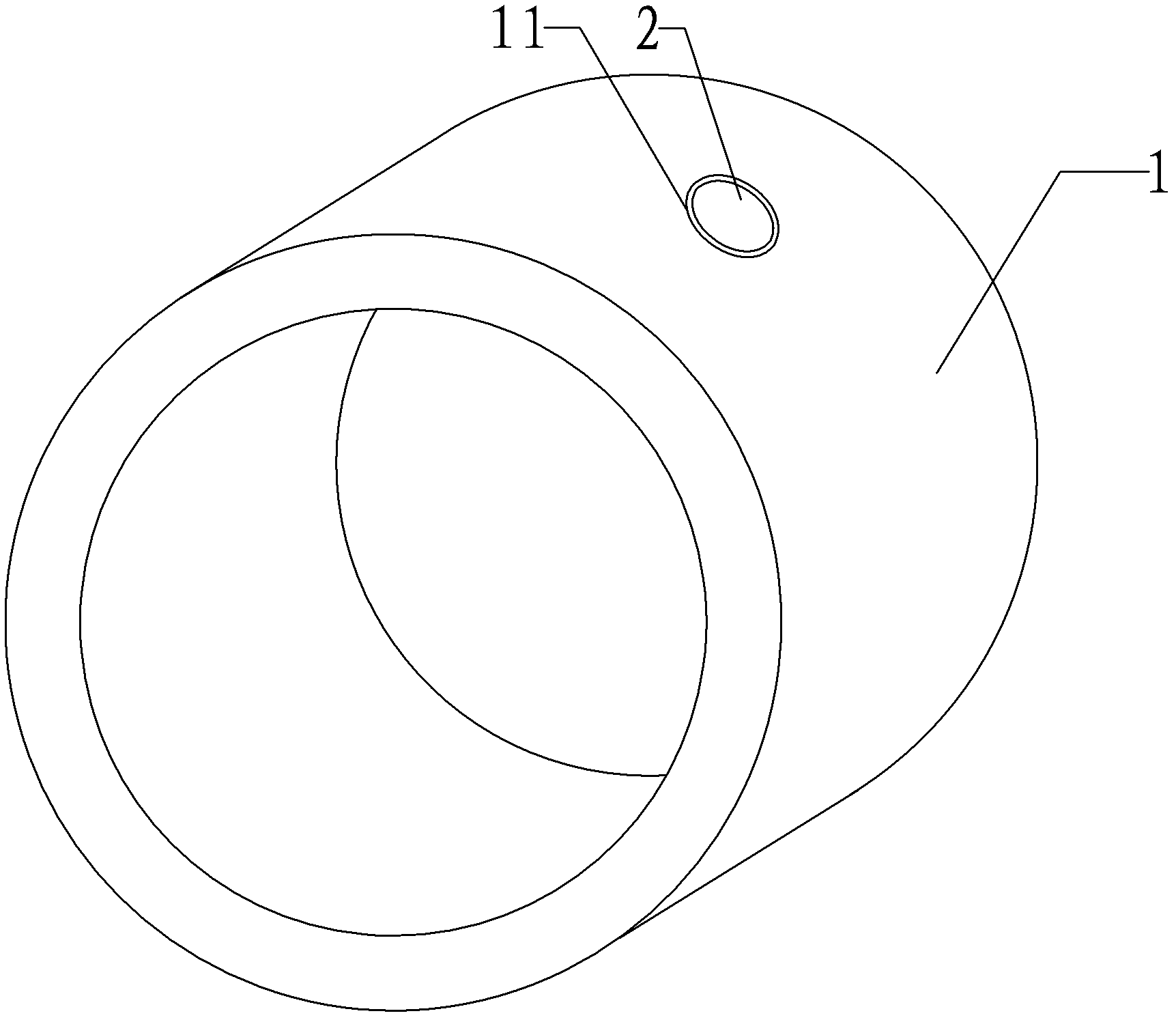

Cable pipeline capable of being detected conveniently

ActiveCN102545128AAvoid replacementHigh processing costsCable installations in underground tubesElectricityElectrical conductor

The invention provides a cable pipeline capable of being detected conveniently, which comprises a conductor and a pipe body used for installing a cable. The pipe body comprises an outer wall and an inner wall. Through holes are arranged abreast on the pipe body in the axial direction and penetrate through the outer wall and the inner wall, the conductor is arranged in the through holes. Therefore, when a section of the cable is damaged and has electricity leakage, the conductor at the position can be detected, and charge at the position can be detected to determine the specific position of damage and electricity leakage. The cable pipeline is convenient to operate, novel in structure, capable of avoiding construction cost increase caused by replacing the cable in a large scale and high in flexibility due to the fact that the distance between two through holes can be set.

Owner:福建恒杰塑业新材料有限公司

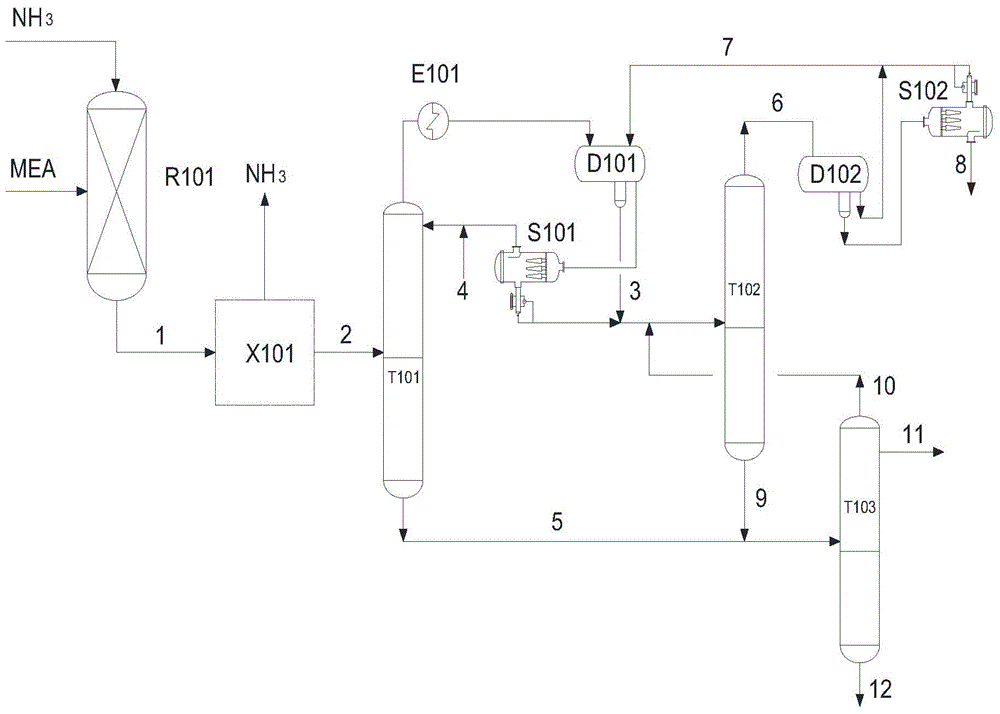

Ethylenediamine waste water recovery technology

ActiveCN105523943AImprove oil-water separation efficiencyLow costAmino compound purification/separationMultistage water/sewage treatmentWater recoveryEthylenediamine

The invention relates to an ethylenediamine (EDA) waste water recovery technology. The technology mainly solves the problem that the prior art has a low EDA recovery rate and a high amine-containing waste water treatment cost. The technology comprises carrying out pressurized distillation treatment on waste water containing a small amount of an entrainer and EDA from a dehydrating tower through an EDA recovery tower, transferring the entrainer and water from the tower top into a phase separation tank, carrying out phase separation, circulating the organic phase as an entrainer (mainly comprising the entrainer) to the dehydrating tower, feeding the waste water phase (mainly containing water) into a high efficiency coalescing separator, separating the residual entrainer, circulating the residual entrainer to the dehydrating tower, feeding the separated waste water to an aftertreatment section, mixing and feeding a dehydrating tower bottom liquid and an EDA recovery tower bottom liquid into an EDA product tower, collecting the entrainer and a small amount of EDA at the tower top, feeding the collected materials to the EDA recovery tower and collecting an EDA product at the side line below the top of the EDA product tower. The technology can effectively recover EDA and an entrainer in waste water, reduce a waste water treatment cost, well solves the above problem and can be used in EDA production.

Owner:CHINA PETROLEUM & CHEM CORP +1

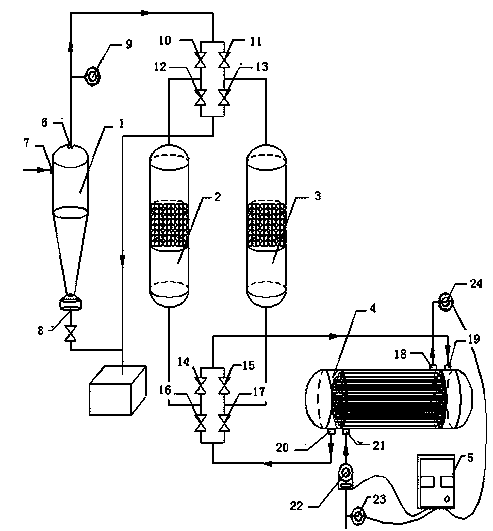

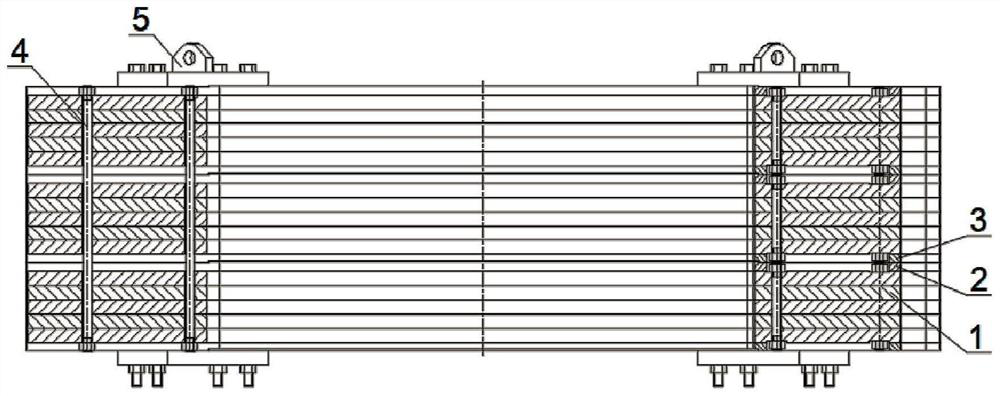

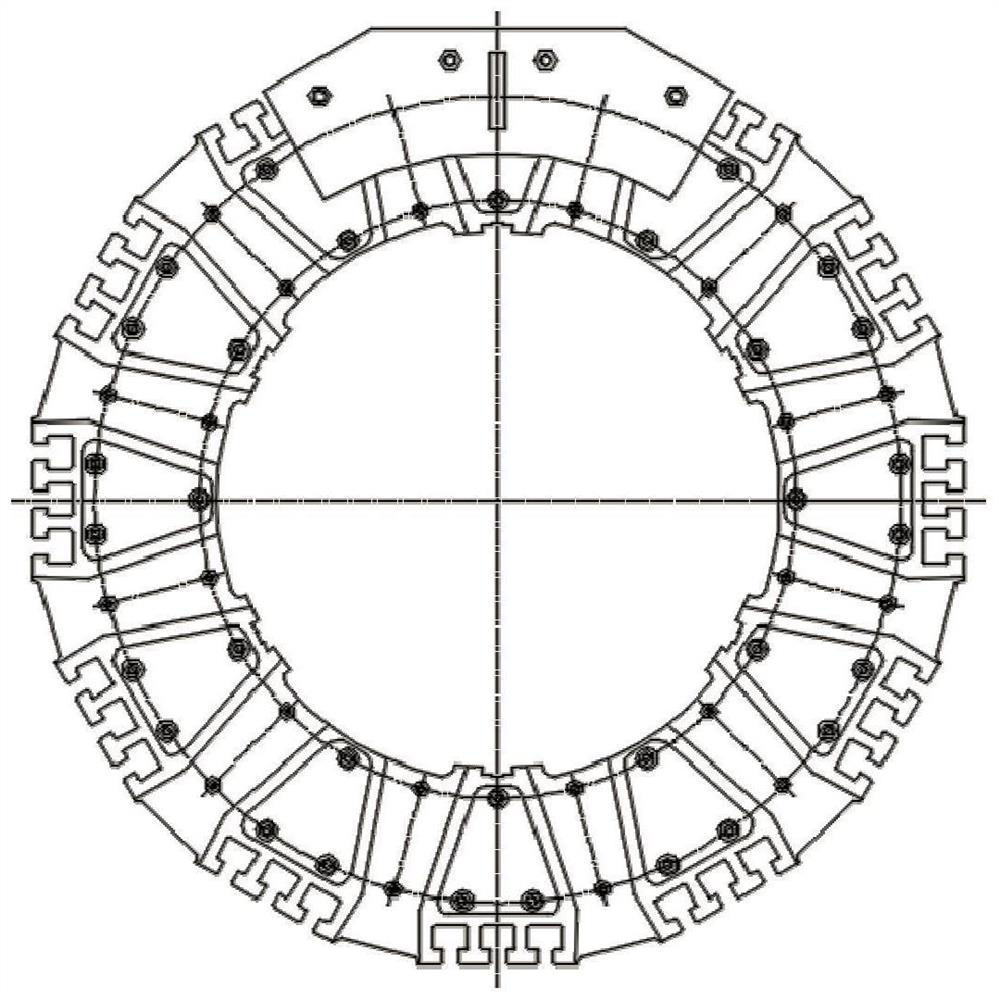

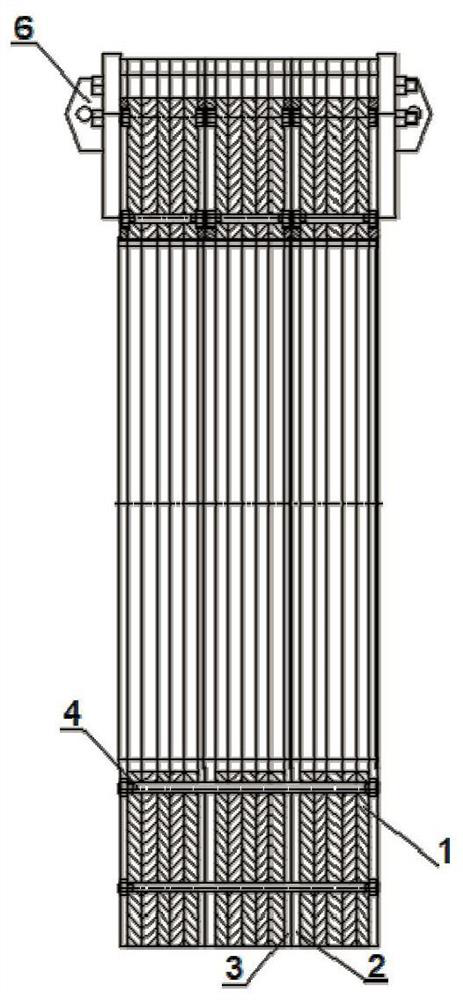

Waste water heat energy recycling equipment

InactiveCN103851934AReduce processing costsHigh processing costsEnergy industryStationary tubular conduit assembliesWater useWastewater

The invention discloses a waste water heat energy recycling equipment and particularly relates to the energy saving technology of recycling and reusing heat energy. The waste water heat energy recycling equipment comprises a centrifugal filtering device, a particle filtering device A, a particle filtering device B, a heat exchange unit and a cumulative heat meter. The problems about waste heat recycling, waste water filtering, filter backflushing water and saving amount display and confirmation and the like are taken into consideration, heat exchange between cold water and hot waste water discharged from factories and buildings is realized by the centrifugal filter, the particle filters, the heat exchangers and the advanced fuel saving amount device, and heat energy in the hot waste water can heat the cold water, therefore, energy is saved and environment is protected.

Owner:AI CAN SEIK MACHINERY EQUIP JIANGSU CO LTD

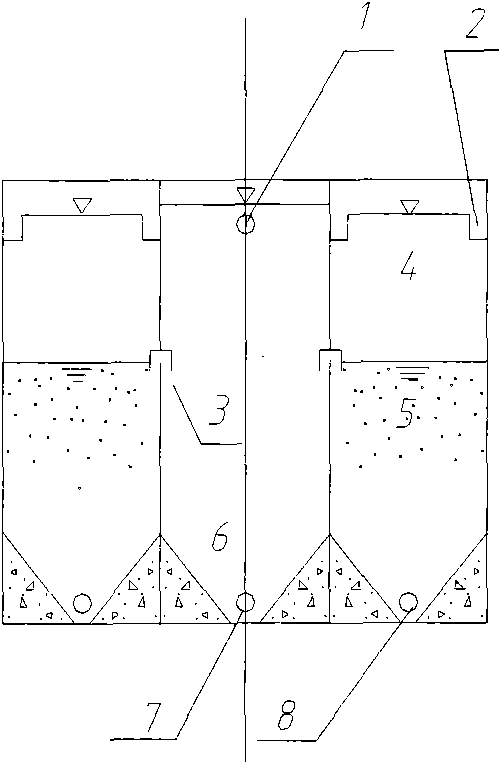

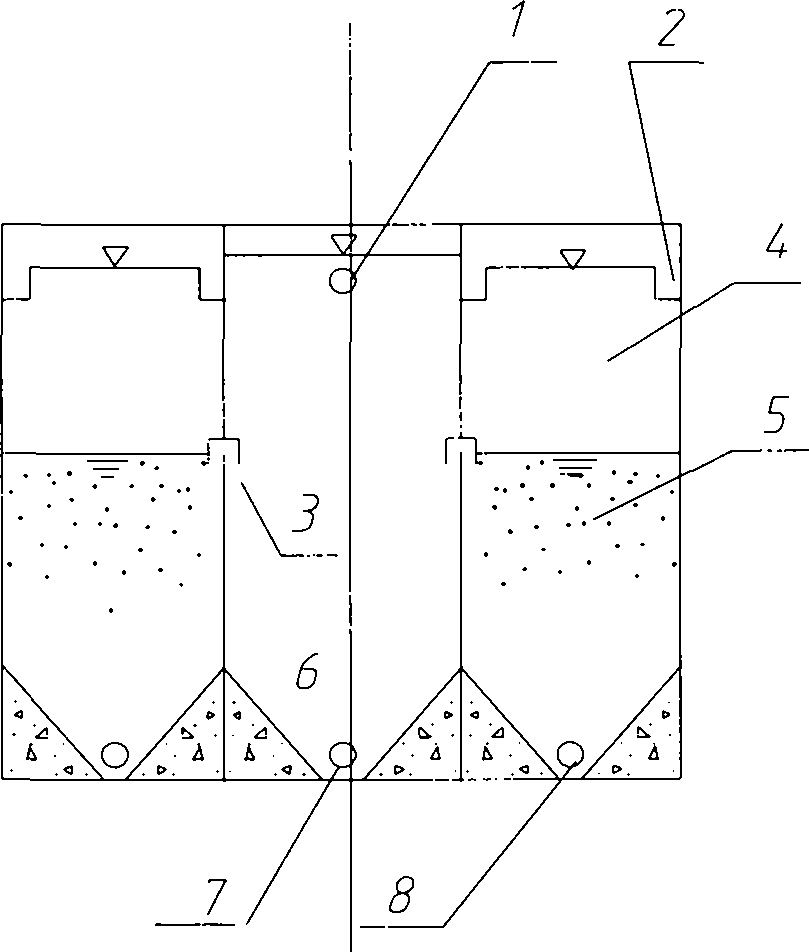

High-efficiency micro-suspension clarification pool

InactiveCN102335528AIncrease moisture contentEasy to handleSettling tanks feed/dischargeSedimentation settling tanksSludgeWater quality

The invention discloses a high-efficiency micro-suspension clarification pool, and belongs to the technical field of suspension deposition in water treatment. The high-efficiency micro-suspension clarification pool has usually a cylindrical structure. An inner cylinder is a reaction chamber. A middle cylinder is a diversion chamber. An outer cylinder is a clarification chamber. A micro-suspension device is arranged in the reaction chamber and comprises a stirrer capable of producing eddy flows and micro-suspension particles with a function of coagulation aid. Honeycomb-like inclined tubes are installed in the clarification chamber to improve clarification effects. Multiple sludge condensation funnels and a main sludge collecting pipe are installed at bottoms of the reaction chamber and the clarification chamber. Sludge in sludge collecting pipes are discharged periodically from the clarification chamber and simultaneously, clarified water flows out the high-efficiency micro-suspension clarification pool from a water-collecting groove of the clarification chamber, so that raw water clarification treatment is realized. The high-efficiency micro-suspension clarification pool has the advantages that 1, the high-efficiency micro-suspension clarification pool can adapt to water inflow velocity and suspended matter concentration and clarified yield water quality is stable; and 2, sludge water has high sludge content reaching 20 to 30%, and a scale of sludge water treatment equipment and a treatment cost of sludge water are reduced.

Owner:曹玉英

Production method and application of terephthalic metal slat whisker

ActiveCN103173845BSolve the role of "secondary pollution"Reduce pollutionPolycrystalline material growthFrom normal temperature solutionsPlastic materialsWastewater

The invention relates to a production method and application of a terephthalic metal slat whisker. The production method disclosed by the invention comprises the steps of: recycling crude terephthalic acid of which the purity is not smaller than 95% by an alkali peeling waste water treatment process; adding and dissolving crude terephthalic acid in a caustic soda solution as a raw material; adding a surface active agent after regulating the pH value; stirring the mixed solution uniformly, then adding a dissolvable calcium salt, stirring and ageing, thereby obtaining the terephthalic metal slat whisker. The terephthalic metal slat whisker can be used as an active filler of rubber, and the addition of the whisker can greatly improve the mechanical properties of a rubber plastic material.

Owner:常州市五洲环保科技有限公司

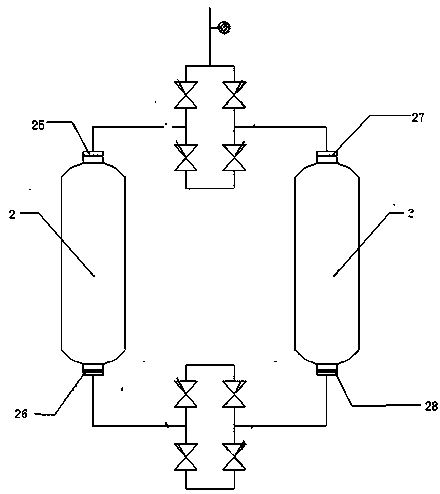

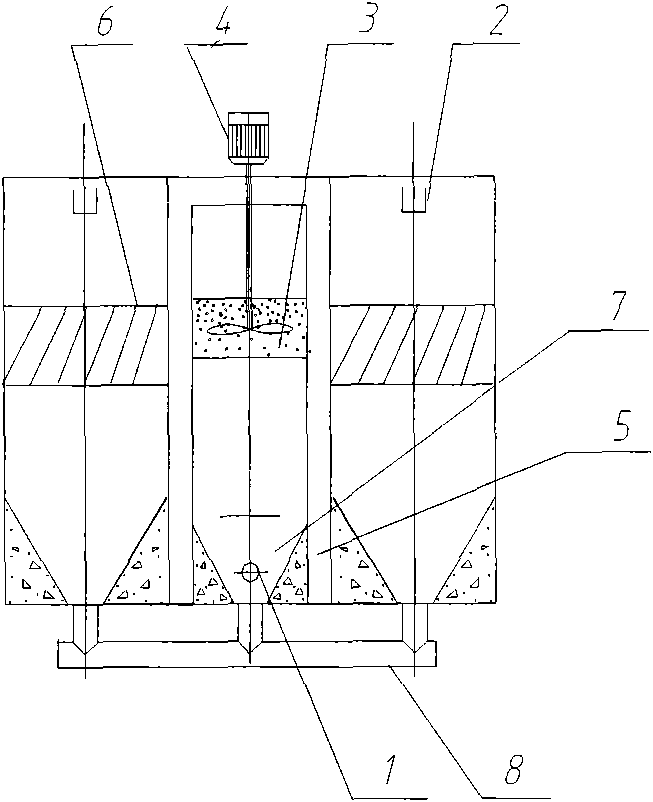

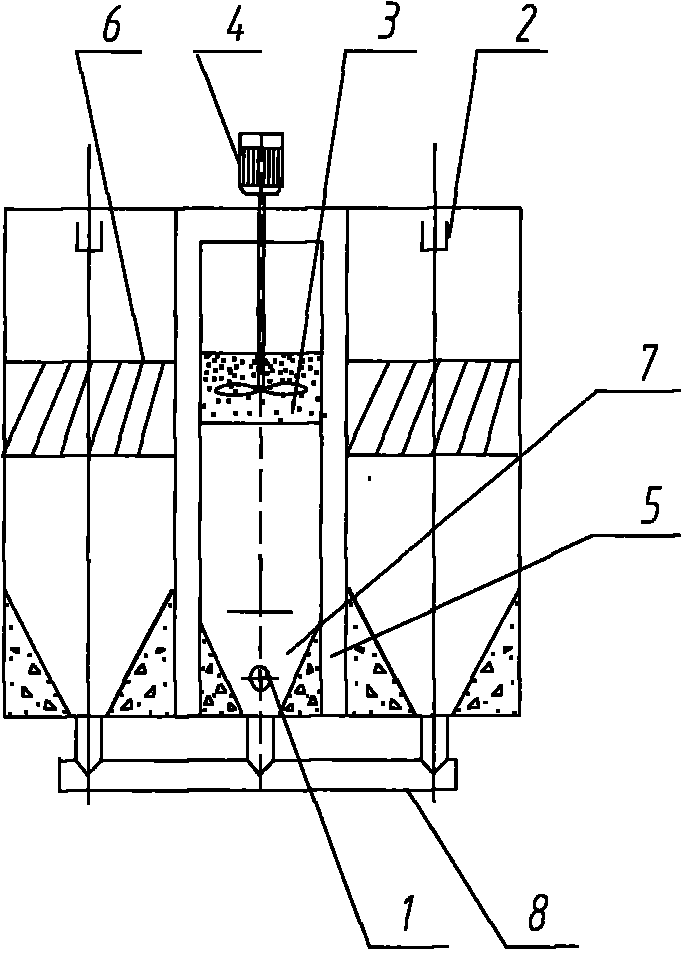

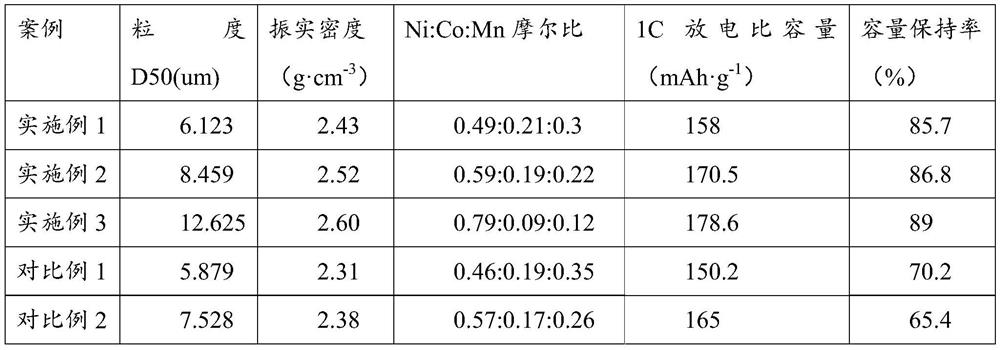

Green low-cost ternary precursor material, and preparation method and device thereof

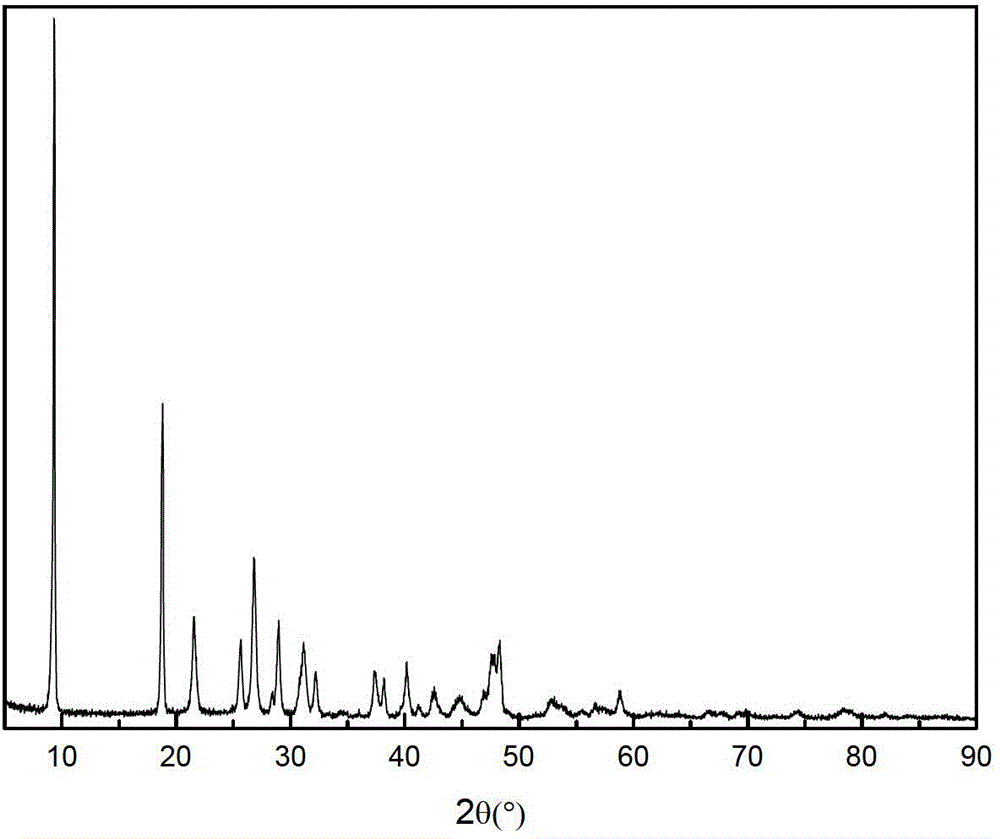

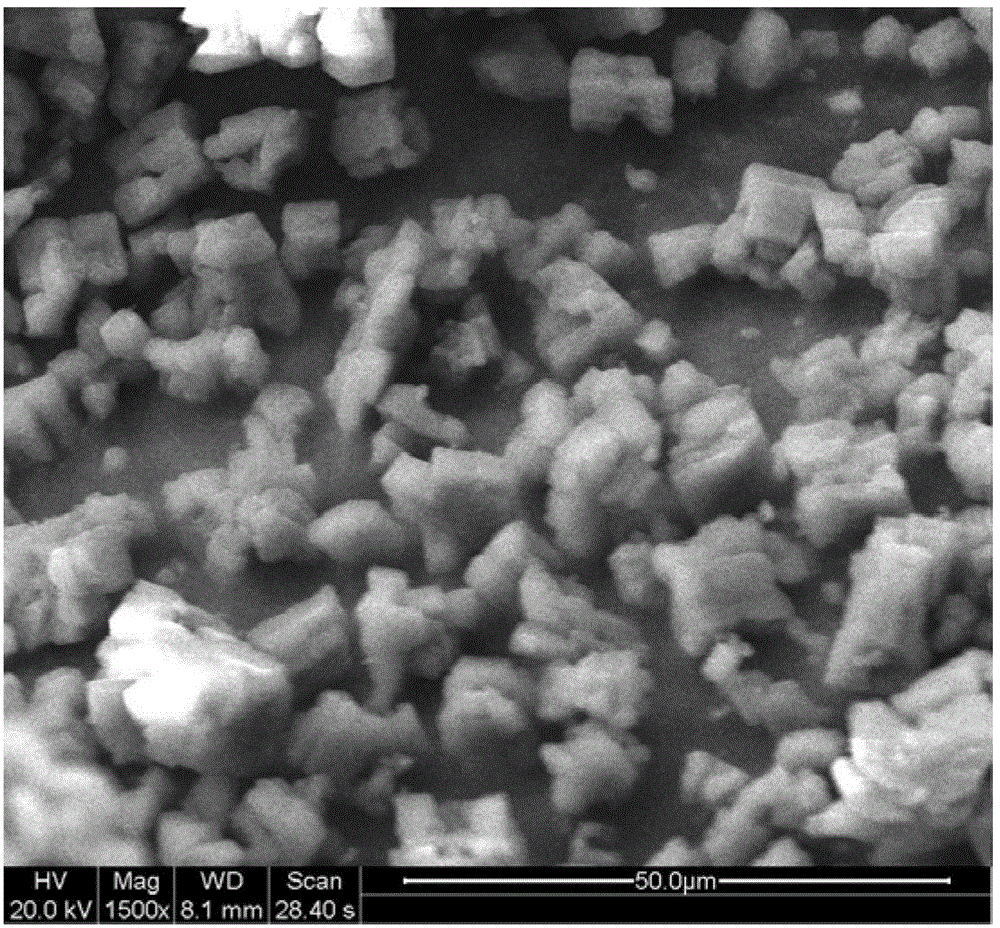

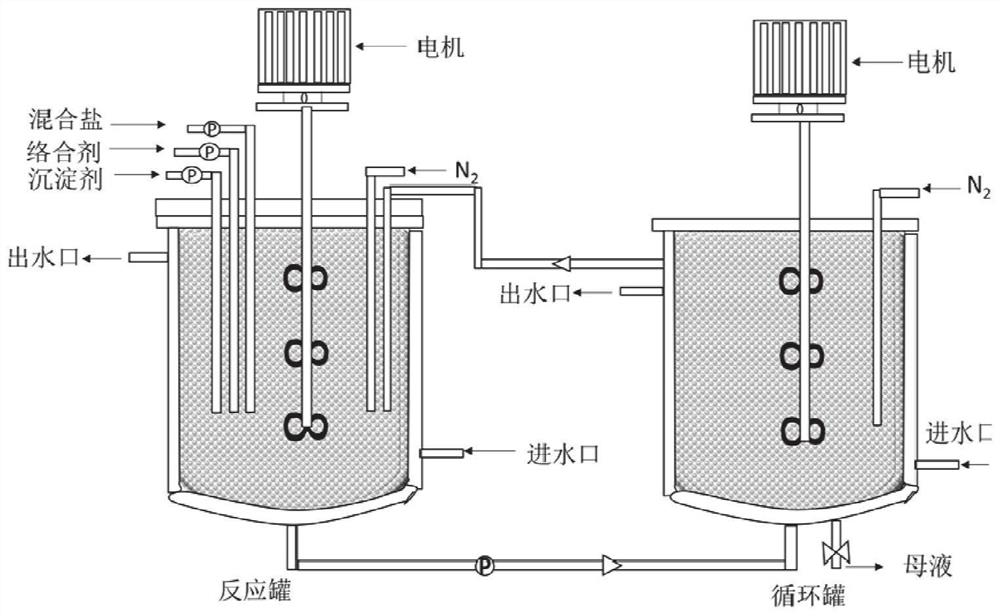

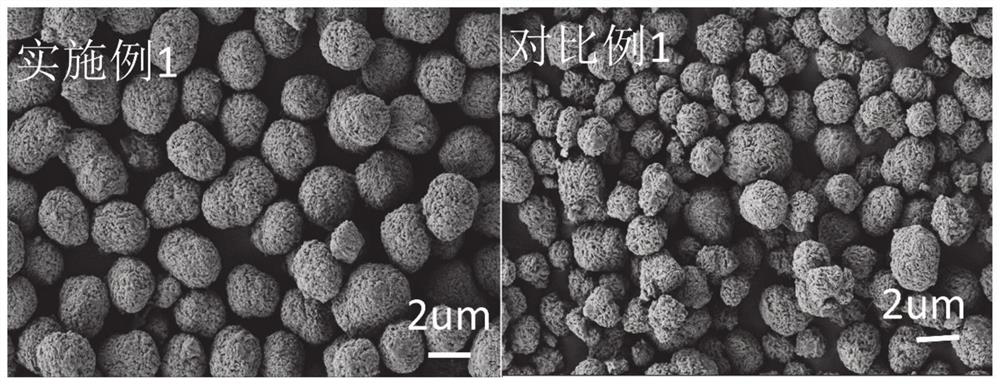

InactiveCN111792679AOvercome the defect of wide particle size distributionHigh processing costsCell electrodesNickel compoundsPower batteryNickel salt

The invention relates to a green low-cost ternary precursor material, and a preparation method and device thereof, belonging to the field of new energy power batteries. The method comprises the following steps: a mixed salt solution with a certain concentration is prepared from a nickel salt, a manganese salt and a cobalt salt; the mixed salt solution, an environment-friendly complexing agent witha certain concentration and a precipitant are simultaneously fed into a reaction tank filled with N2, reaction conditions are strictly controlled, and the feeding rate of the precipitant is controlled by an automatic pH liquid feeder; a formed product is pumped into a circulating tank from the bottom of the reaction tank and enters the reaction tank again from an overflow port after the circulating tank is filled with reaction liquid, and such a cycle is repeated multiple times; a reaction is stopped after the particle size of precursor particles meet a requirement; and filtering, washing anddrying are conducted to obtain the ternary precursor material. The method adopted by the invention overcomes the defect of wide particle size distribution in a traditional process; a precursor prepared by the invention has the advantages of qualified content of each metal, reasonable particle size distribution and high sphericity degree; and the method is simple in process, friendly to environment, low in energy consumption and suitable for industrial popularization.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

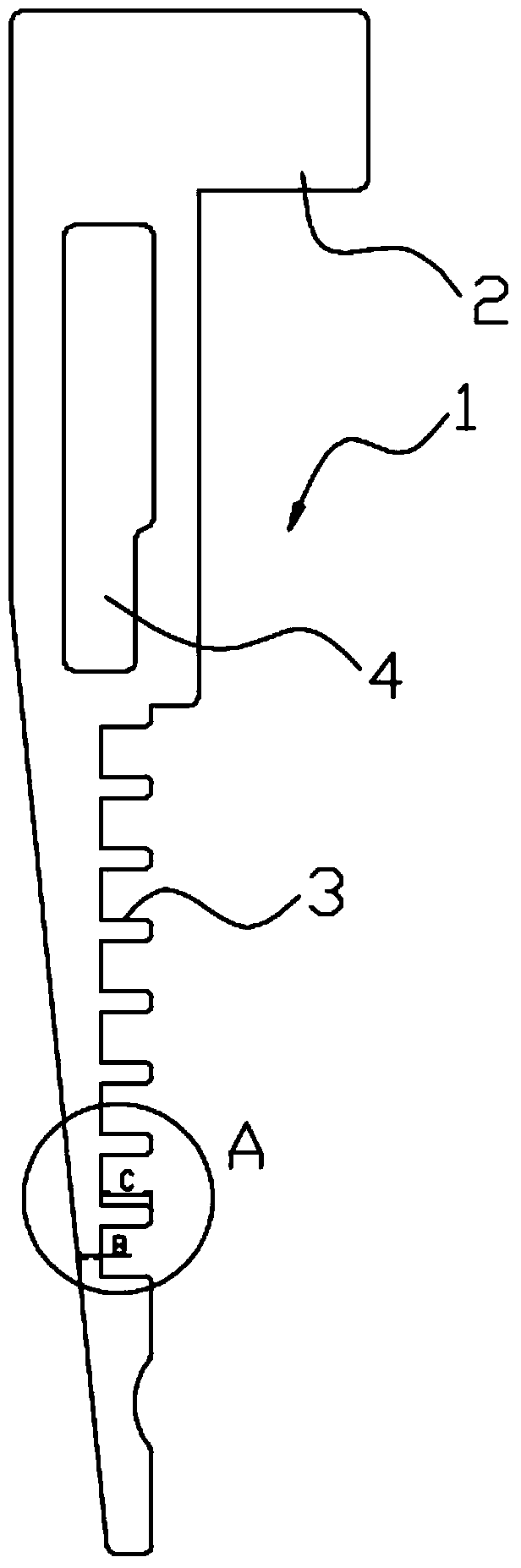

Yarn guide plate for patternbars of warp knitting machine

The invention discloses a yarn guide plate for the patternbars of a warp knitting machine and a magnesium alloy section forming process thereof. The yarn guide plate of the patterbars of the warp knitting machine comprises a yarn guide plate base body and rails arranged on the yarn guide plate body; the yarn guide plate base body and the rails are in an integrated structure; the non-bearing part of the yarn guide plate base body is provided with a hollow cavity; the surface of the yarn guide plate is provided with a nickel layer or a Teflon layer. The weight is lowered due to the adopted light magnesium alloy section. The yarn guide plate is formed integrally, and secondary machining of the trails is not needed, so that the buckling or deformation of the yarn guide plate caused by the secondary machining is avoided, and the stability is better. The yarn guide plate is subjected to surface treatment through Teflon spraying or chemical nickel-plating, so that the surface hardness of the yarn guide plate, especially the surface hardness of the inner sides of the rails is further enhanced, and the service life of the yarn guide plate is prolonged. According to the invention, the novel magnesium alloy section of the yarn guide plate for the patternbars of the warp knitting machine, which is stable in dimension and high in precision, is obtained by adjusting and combining a forming process and strictly controlling the contents of some alloying elements on the basis of the commercial AZ80 magnesium alloy.

Owner:WUXI FUMEI LIGHT ALLOY TECH

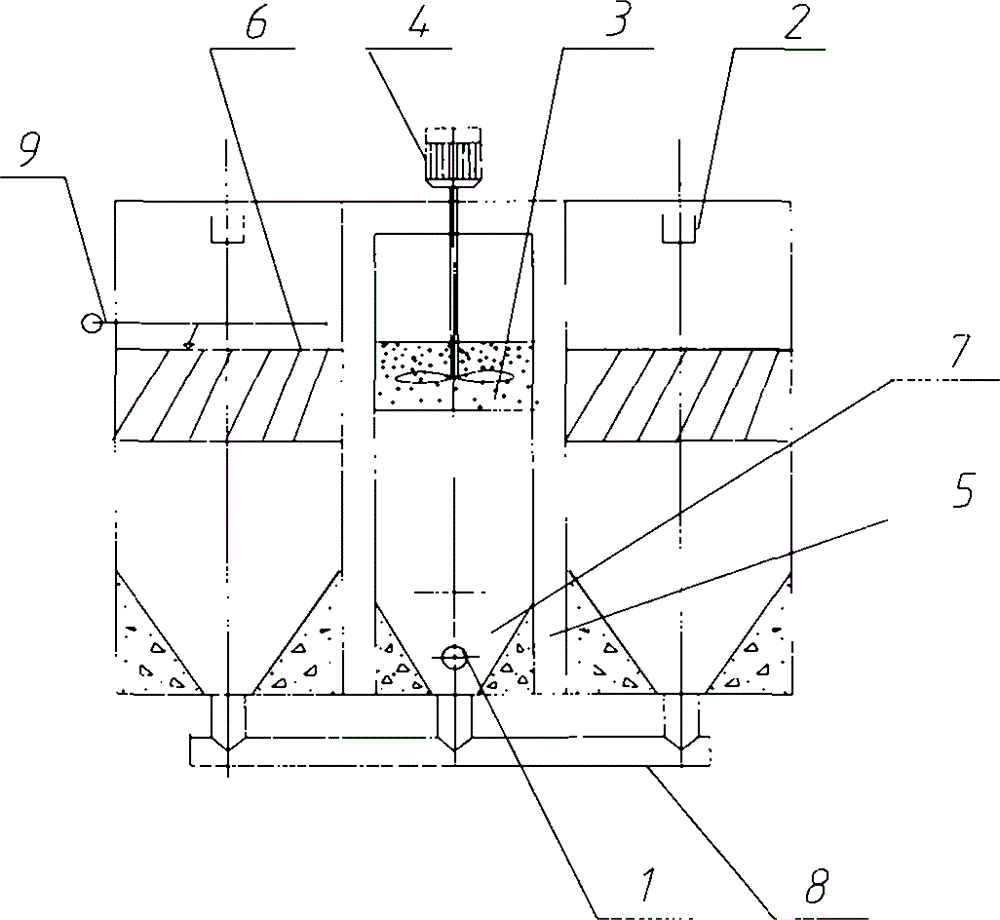

Efficient backwashing-free filtering clarification tank

InactiveCN104944622AGood adsorption and temperature resistanceConvenient operation control and production managementMultistage water/sewage treatmentContinuous modeHoneycomb

The invention discloses an efficient backwashing-free filtering clarification tank, and belongs to the technical field of water treatment suspended solid precipitation. According to the structure, the efficient backwashing-free filtering clarification tank is generally of a cylindrical structure, an inner cylinder is taken as a reaction chamber, a middle cylinder is taken as a guide chamber, an outer cylinder is taken as a clarification chamber, and suspended filtering devices which consist of non-metallic filtering materials with filtering functions and stirrers with filtering material stirring and washing functions are arranged inside the reaction chamber. The filtering materials consist of smooth flat granules, the stirrers are operated in a non-continuous mode, and the stirring time and the intermittent time can be set up after the water quality characteristics are tested and confirmed. Honeycomb-shaped inclined tubes are mounted inside the clarification chamber, so that the clarification effect can be improved; as compressed air washing devices are mounted at the upper ends of the inclined tubes, the inclined tubes can be periodically washed; compressed air nozzles are arranged in a single-row moveable manner, the inclined tubes can be washed row by row.

Owner:北京信力筑正新能源技术股份有限公司 +1

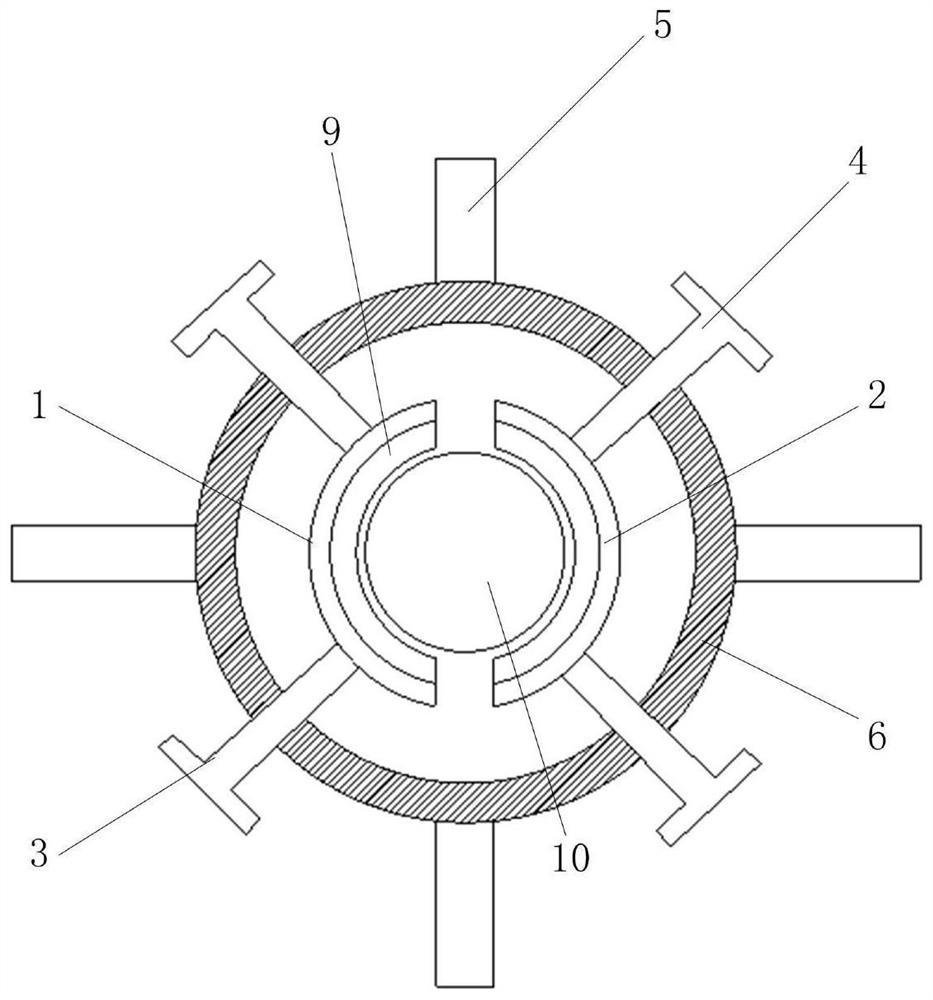

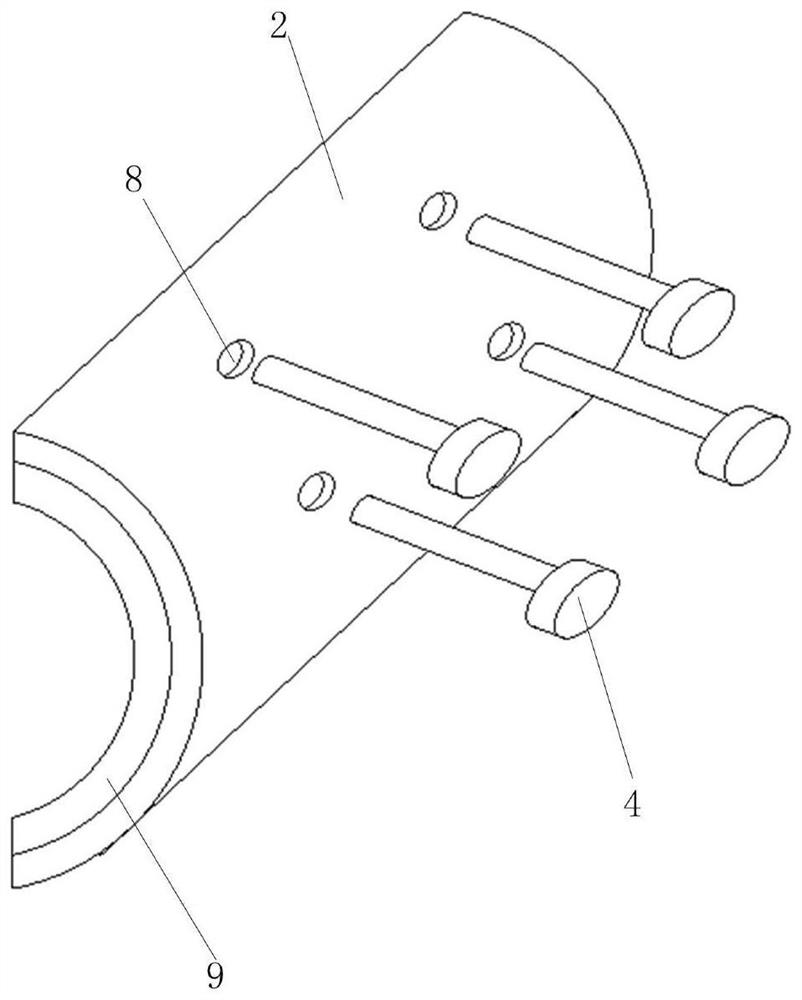

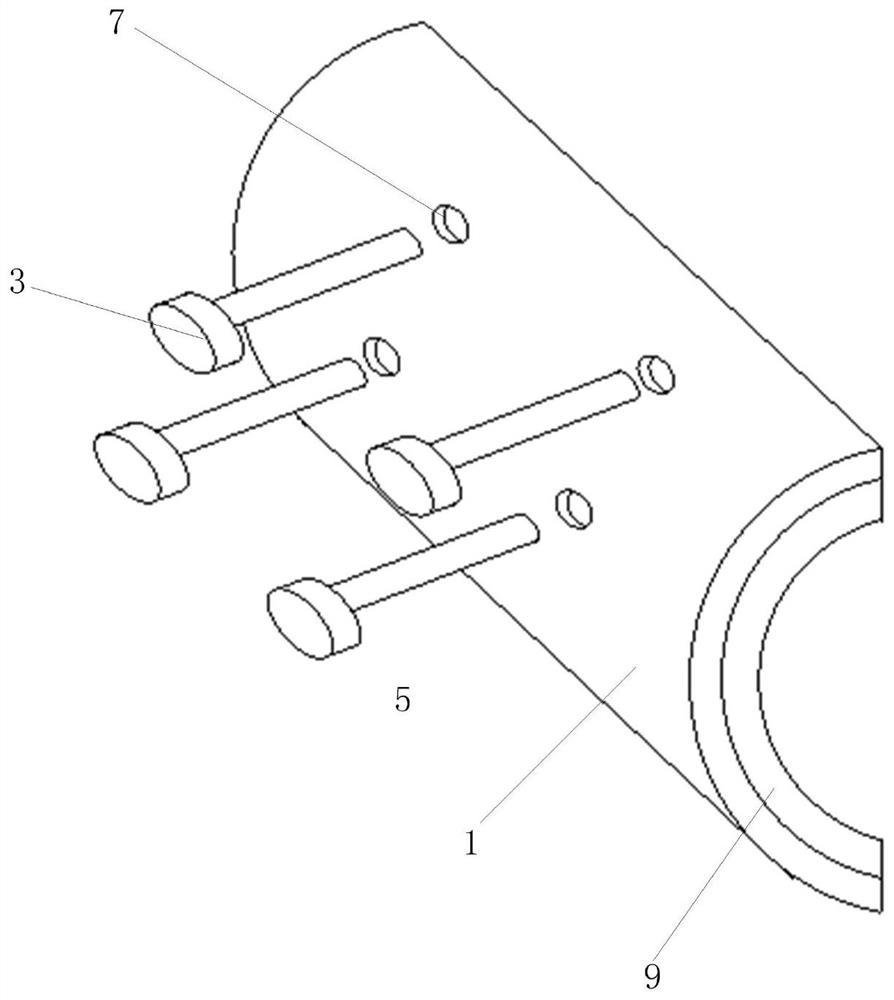

Turbine rotor small shaft disc grinding tool

PendingCN112643531AConvenience for high precision requirementsAccurate and high precision requirementsLapping toolsCircular discJackscrew

The embodiment of the invention provides a turbine rotor small shaft disc grinding tool. The grinding tool comprises a first arc-shaped grinding block, a second arc-shaped grinding block, a first jackscrew, a second jackscrew, a grip and a sleeve, the first arc-shaped grinding block and the second arc-shaped grinding block are combined to form a circle, a size of the circle is a preset size, a first groove matching the end of the first jackscrew is formed in the outer side wall of the first arc-shaped grinding block, the first jackscrew penetrates through the sleeve, the end of the first jackscrew abuts against the interior of the first groove, a second groove matching the end of the second jackscrew is formed in the outer side wall of the second arc-shaped grinding block, the second jackscrew penetrates through the sleeve, the end of the second jackscrew abuts against the interior of the second groove, and the grip is fixedly arranged on the outer side wall of the sleeve. According to the scheme, the concentricity and the parallelism are adjusted by means of a pressing plate designed in a matching mode, manual monitoring grinding is conducted, and the high-precision requirement for grinding the shaft head round face conveniently and accurately in a time-saving and labor-saving mode is met.

Owner:HUANENG YIMIN COAL POWER CO LTD

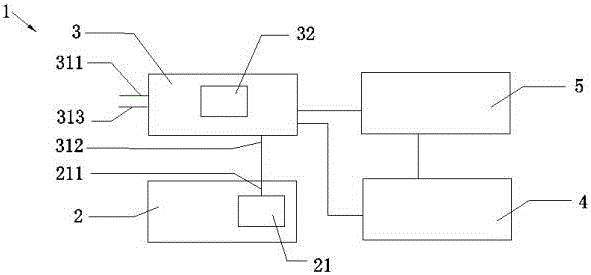

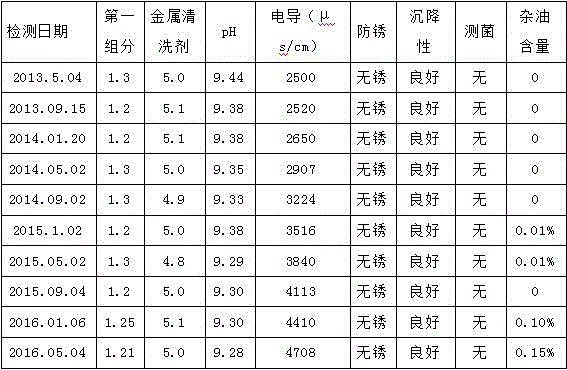

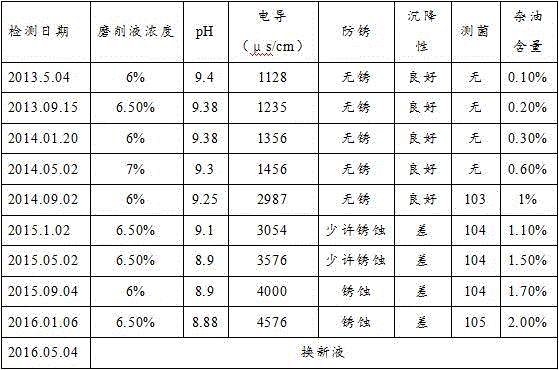

Metal cutting fluid, preparation method and use system thereof

InactiveCN106381203AWith cleaningHas a cleaning effectLubricant compositionIsoannonacinDiethylene glycol monobutyl ether

The invention relates to the field of metal cutting fluids and specifically discloses a metal cleaner, which comprises the following raw materials (by weight): 5-10% of potassium carbonate, 10-15% of triethanolamine, 4-8% of sebacic acid, 3-7% of isononanoic acid, 0.2-0.5% of methyl benzotriazole, 1-3% of iso-tridecanol polyoxyethylene ether, 4-8% of diethylene glycol monobutyl ether, 8-15% of 2-amino-2-methyl-1-propanol and water supplemented to 100%. Through mutual cooperation of the above raw materials according to the above ratio, the formed metal cleaner is used for cleaning during metal working and maintenance and has excellent cleaning and anti-rust effects. Meanwhile, no aftertreatment is required after use of the metal cleaner. The recovered metal cleaner can be directly mixed with a component with a lubricating effect to form a metal cutting fluid which is used for machining. Therefore, the aftertreatment process after use of the cleaner is omitted, and aftertreatment cost is saved.

Owner:江苏富兰克环保技术服务有限公司

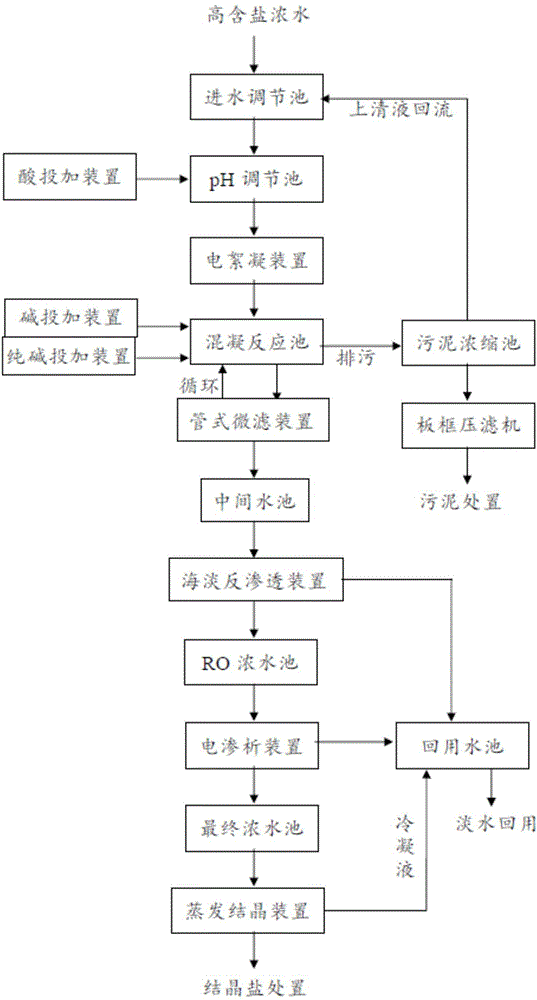

High-salt-content concentrated water zero-discharge treatment system and process method

PendingCN106746130AReduce business operating costsReduce environmental pollutionWater/sewage treatment by centrifugal separationGeneral water supply conservationIonChemistry

The problem that COD (chemical oxygen demand) and scaling ions in high-salt-content concentrated water form scales and block a subsequent membrane device is effectively solved by adopting the technology of combining electric flocculation and a tube micro-filtration membrane. The high-salt-content concentrated water is concentrated by adopting an electrodialysis process, so that the salt content in the concentrated water can be concentrated to 12-15 times, and the volume of the concentrated water can be reduced to 5-10% of the original volume. With the adoption of an MVR (Mechanical Vapor Recompression) evaporator, only a minute quantity of vapor is needed, the operating cost of enterprises is greatly reduced, and the environmental pollution is reduced. Waste hot steam emission is avoided, and the energy-saving effect is very obvious. Because a heat source is provided by a compressor, compared with the traditional evaporator, the MVR evaporator has small temperature difference and can achieve moderate evaporation, the product quality is greatly improved, and scale formation is reduced. Moreover, a condenser is not needed, and the system is extremely simple in structure and process flow, is operated in a full-automatic manner, can be continuously operated and is safe and reliable.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

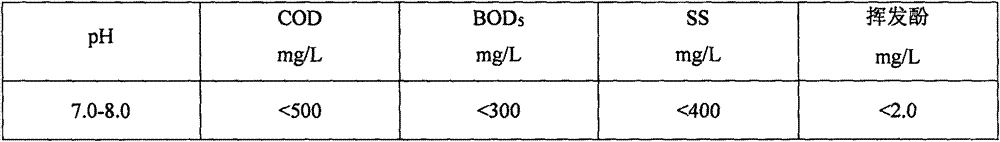

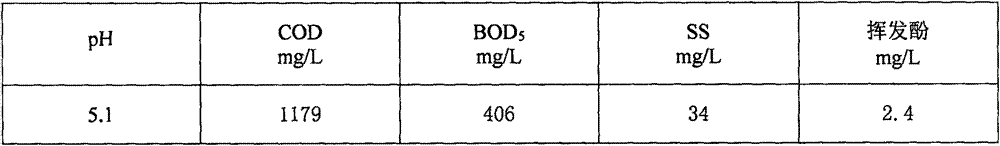

Pretreatment method of biodiesel wastewater

InactiveCN106746055AReduce CODReduce chromaWater treatment parameter controlTreatment involving filtrationActivated carbonHydrogen

The invention discloses a pretreatment method of biodiesel wastewater. The pretreatment method comprises the following steps of 1, microelectrolysis: adding an aluminum strip and activated carbon particles into the biodiesel wastewater, continuously filling air, reacting for 18 to 24h at the temperature of 35 to 45 DEG C, and filtering after reaction is finished, so as to obtain filtrate and the reacted aluminum strip and activated carbon particles; (2) flocculating and settling: adding an alkaline solution into the filtrate obtained in step (1), adjusting the pH (potential of hydrogen) value to 4.5 to 5.0, fully stirring, adding 1% polymeric aluminum water solution, and then adding 0.1% polyacrylamide, wherein the volume percentage of polymeric aluminum water solution accounts for 5 to 10% of the volume of the biodiesel wastewater, and the volume percentage of polyacrylamide accounts for 0.8 to 1.2% of the volume of the biodiesel wastewater; fully stirring to form a flocculating and settling substance, standing, and filtering, so as to obtain a colorless or light yellow transparent liquid. The pretreatment method has the advantages that the difficulty in biological treatment is greatly decreased, and the treatment efficiency of wastewater is improved.

Owner:SHAANXI UNIV OF SCI & TECH

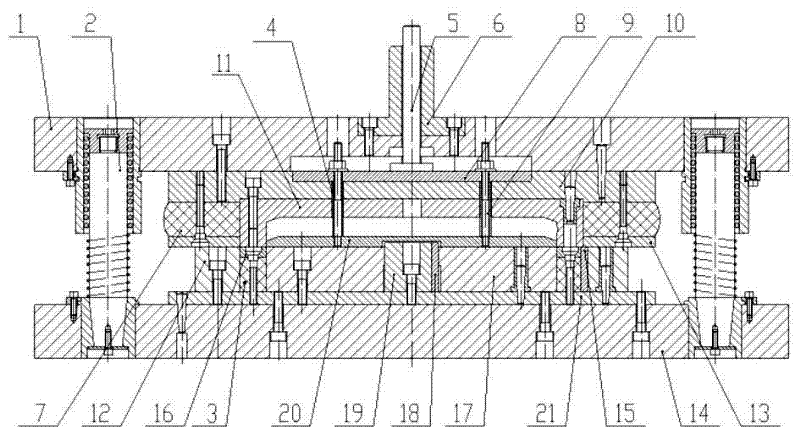

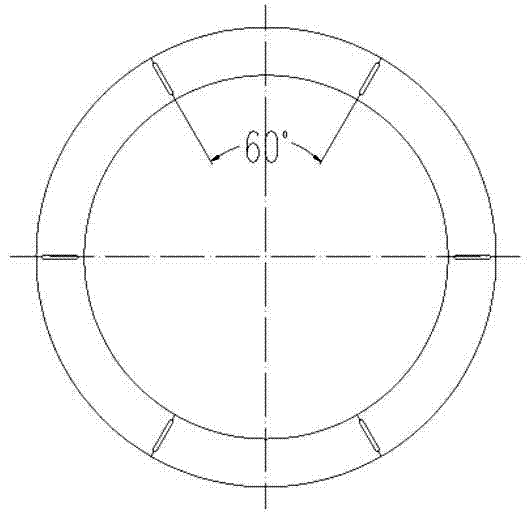

Stator or rotor punching mould of power generator

InactiveCN102403848AReduce distortionThe impact of reduced qualityManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a stator or rotor punching mould of a power generator, which comprises upper and lower mould seats, and rolling guide assemblies arranged uniformly and vertically between the upper and lower mould seats, as well as upper and lower mould assemblies fixedly connected to the lower surface of the upper mould seat and the upper surface of the lower mould seat. The stator or rotor punching mould of the power generator disclosed by the invention has the advantages that: the traditional opened annular convex-concave mould is changed into a downwardly opened structure with a sealed top, so that deformation of the convex-concave mould in processing and deformation caused by thermal treatment of parts are reduced so as to reduce the influence of the deformation of the parts on the quality of the mould; a knockout plate, a fixed plate and a convex-concave mould rotor material returning plate are connected together through six groups of uniformly arranged knockout rods to form a rigid material returning device for returning materials, so that the whole circumference in the rotor punching and material returning process is ensured to be stressed evenly; with respect to structures of six assembled fanning strips, the material cost is saved by about 40% in blank material forging process; and the processing expense and processing difficulty of parts are greatly lowered.

Owner:ZHENGZHOU JINYANG ELECTRIC

Vertical processing method for internal key grooves of rigid magnet yoke

The invention discloses a vertical processing method for internal key grooves of a rigid magnet yoke. Three magnet yoke sections are combined into a whole through a screw; firstly, an inner circle, anupper side air guide belt plane and a lower side air guide belt plane are processed on a vertical lathe; and then an external T-shaped tail groove plane and T-shaped tail grooves are processed in a boring machine. The inner circle, the upper side air guide belt plane, the lower side air guide belt plane and the external T-shaped tail groove are used for alignment and positioning, and the internalkey grooves are processed in the three magnet yoke sections together. The problem that processing equipment for the internal key grooves of the rigid magnet yoke is large in limitation is solved, theproblem of staggering in processing of the internal key grooves is solved, a powerful guarantee is provided for subsequent magnet yoke assembling, meanwhile, the vertical processing method has the advantages of being simple and convenient, high in processing precision and the like, and the processing period is shortened. The vertical processing method is suitable for manufacturing the rigid magnet yokes of all pumped-storage power generation motors, and has very high popularization and application value.

Owner:HARBIN ELECTRIC MASCH CO LTD +1

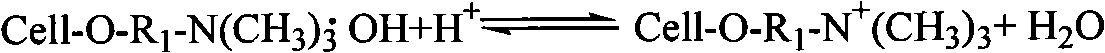

Animal enzyme for saline-alkali soil improvement and preparation method thereof

InactiveCN113046085AAvoid missingLower pHAgriculture tools and machinesOther chemical processesBiotechnologyAnimal science

The invention discloses an animal enzyme for saline-alkali soil improvement. The animal enzyme is prepared from the following components in parts by weight: 60 to 100 parts of an animal protein raw material, 0.1 to 0.5 part of a compound enzyme preparation, 0.1 to 0.5 part of a fermentation inoculant A, 0.1 to 1 part of a fermentation inoculant B and 1 to 2 parts of auxiliary materials. Meanwhile, the invention discloses a preparation method and application of the animal enzyme for saline-alkali soil improvement. The production process is simple and reasonable, the raw materials are easy to obtain, the produced product is remarkable in functionality and good in saline-alkali soil improvement effect, and the utilization field of breeding waste is widened.

Owner:SHANDONG BAIDE BIOLOGICAL TECH

A kind of beneficiation method of recovering chrome ore lump ore

ActiveCN103894287BRemarkable effect of energy saving and consumption reductionSuitable for deliveryHigh gradient magnetic separatorsManganeseSiderite

The invention discloses a beneficiation method for recovering chrome lump ore. The method comprises the following processing steps: crushing the chrome ore, and classifying three particle size grades including 20-15mm, 15-6mm and 6-2mm by narrow level screening; respectively carrying out dry-type strong magnetic separation on the three classified particle size grades obtained by screening by virtue of a permanent magnet roller type strong magnetic separator; adjusting the speed of a feeding belt of the permanent magnet roller type strong magnetic separator and the distance between the center of a barrel and a separating clapboard to obtain the best grading technical index, wherein the magnetic field intensity of the surface of the belt of the permanent magnet roller type strong magnetic separator is 0.9-1.3T. The method is simple in technological process, the high-quality Cr2O3 ore concentrate can be obtained by screening classification and narrow level screening, and the recovery rate of the Cr2O3 can be increased. The method is short in beneficiation process and is capable of obtaining the ore concentrate and removing tailings in advance; the beneficiation technology has the advantage of being lower in energy consumption compared with other technologies; the method not only can be used for screening the chrome ore, but also can be used for screening other weak magnetic iron minerals such as manganese ore, hematite, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

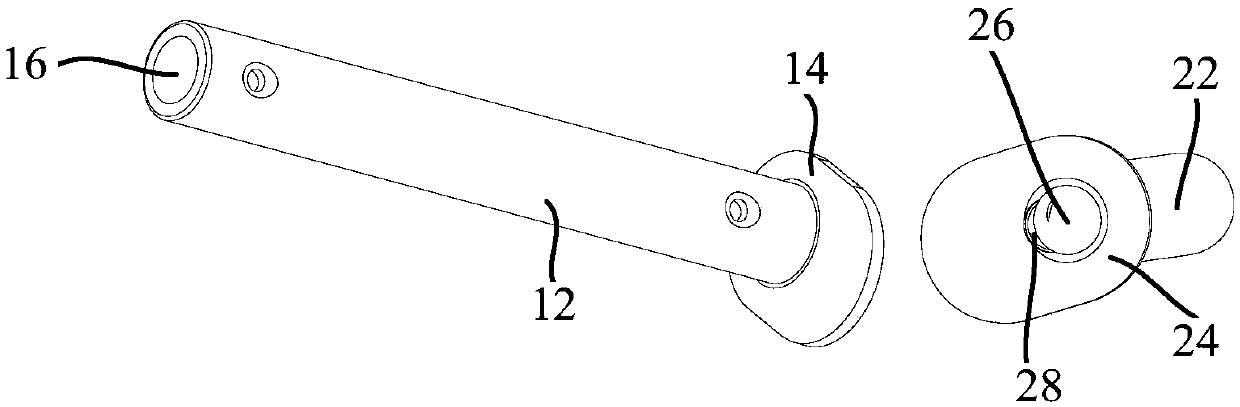

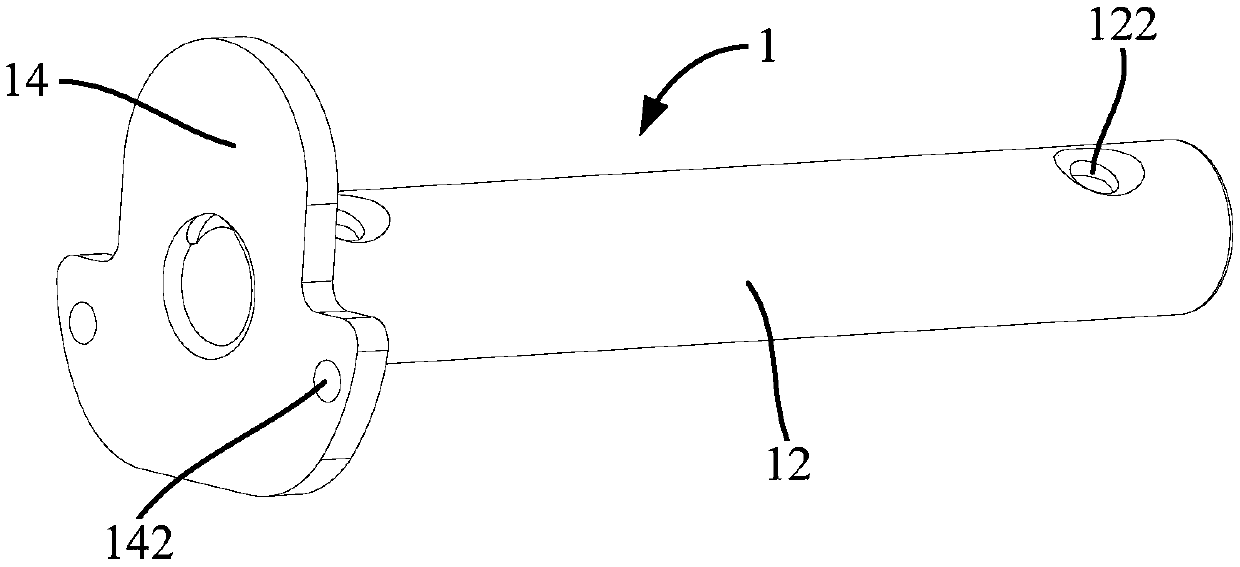

Crankshaft and compressor

ActiveCN111287941AImprove versatilityHigh degree of standardizationPositive displacement pump componentsPositive-displacement liquid enginesElectric resistance weldingMechanical engineering

The invention provides a crankshaft and a compressor. The crankshaft comprises a first shaft and a second shaft which are arranged in a split mode, wherein the second shaft is eccentrically arranged on the end face of the first shaft; the first shaft and / or the second shaft are / is formed through forging and pressing, and / or the second shaft is eccentrically welded to the end face of the first shaft in an electric resistance welding mode. According to the scheme, the crankshaft is arranged to be the two split shafts, and in this way, the eccentric distance of the crankshaft can be adjusted by changing the relative placement positions of the first shaft and the second shaft during arrangement so that the universality of the crankshaft can be better, the standardization degree of the crankshaft is higher, meanwhile, the machining cost of the crankshaft can be saved, and the product development progress can be promoted; meanwhile, the first shaft and / or the second shaft are / is formed through forging and pressing, so that the crankshaft is simple to form and easy to machine, and machining of the crankshaft is more energy-saving and environment-protecting; and the first shaft and the second shaft are arranged together in an electric resistance welding mode, so that the connection quality between the first shaft and the second shaft is better, the connection process is more convenient, and the efficiency is higher.

Owner:ANHUI MEIZHI COMPRESSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com