Beneficiation method for recovering chrome lump ore

A beneficiation method and chromium ore technology, applied in the field of chromite ore beneficiation and recovery, can solve the problems of high loss rate, difficulty in accurate sorting, low concentrate grade, etc., and achieve remarkable results in energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the present invention, a kind of beneficiation method of recovering chrome ore lump ore of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment.

[0025] The ore sample is DCM chrome ore of Sinosteel South Africa Chrome Industry Co., Ltd. The main valuable elements of the ore are chromium, Cr 2 o 3 The content is 34.49%; the main impurity components are SiO 2 , MgO and Al 2 o 3 , the contents of the three are 14.66%, 13.90% and 11.15% respectively.

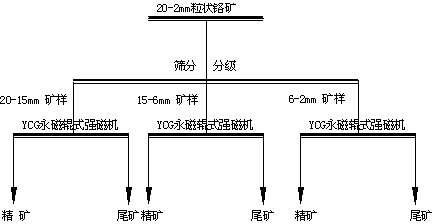

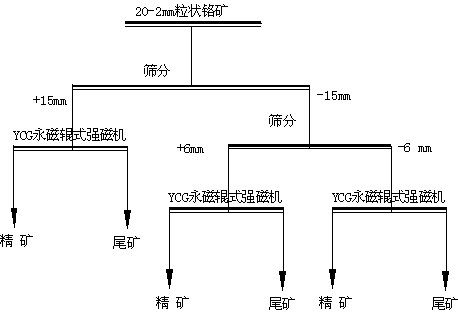

[0026] Depend on figure 2 The implementation process flow diagram of a kind of ore dressing method of the shown present invention reclaiming chrome ore lump ore and combining figure 1 Find out that a kind of mineral processing method of reclaiming chrome ore lump ore of the present invention comprises following technique, step:

[0027] (1) Screening and grading—one-stage dry strong magnetic separation.

[0028] The 20mm-2mm part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com