Denitrification system and method for sintering gas without ammonia reductant

A technology of sintering flue gas and reducing agent, which is applied in the field of sintering flue gas denitrification system without ammonia reducing agent, can solve the problems of low removal efficiency, large amount of flue gas from sintering machine, and high removal cost, so as to simplify the process flow, The effect of reducing floor space and simplifying process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

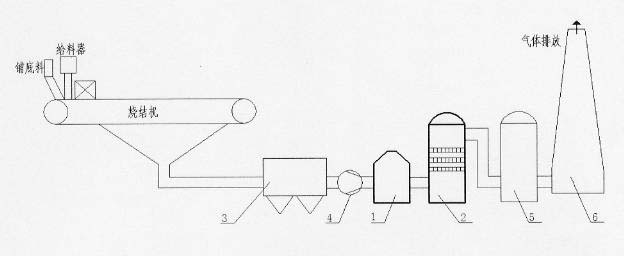

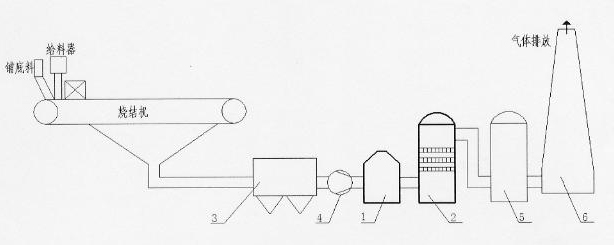

[0033] After the dust remover, the sintering flue gas is heated to a suitable temperature by a heater and then sent to the denitrification reactor. Since the denitrification reactor is equipped with a catalyst layer, the catalytic reduction reaction is carried out to remove NOx under the action of the catalyst, and the removal efficiency can reach 80 % to 90% or even higher, the sintering flue gas after the reaction is discharged into the atmosphere after dust removal and desulfurization.

[0034] In this embodiment, since the denitrification reactor is arranged behind the dust collector, the energy consumed by the heater is slightly larger during operation, but the consumption of this iron ore catalyst can be reduced; the denitrification reactor can also be designed as a fluidized bed , in order to replace the catalyst online.

[0035] Through research, it is found that CO in the sintering flue gas itself can reduce NOx by 10% to 15% by raising the temperature without a catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com