Metal cutting fluid, preparation method and use system thereof

A technology of metalworking fluid and metal cutting fluid, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of cost and achieve excellent cleaning and antirust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

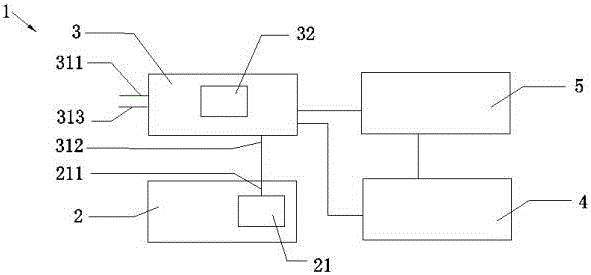

Image

Examples

Embodiment 1

[0109] Weigh 5 parts of potassium carbonate, 10 parts of triethanolamine, 4 parts of sebacic acid, 3 parts of isononanoic acid, 0.2 parts of methyl benzotriazole, 1 part of isomeric tridecyl alcohol polyoxyethylene ether 9EO, 4 parts of di Ethylene glycol monobutyl ether, 8 parts of AMP95, and 64.8 parts of water were mixed uniformly to obtain a colorless transparent liquid to obtain a metal cleaning agent.

[0110] The above-mentioned parts are all parts by mass. The total number of parts of each raw material in the metal cleaning agent is 100 parts, and the number of parts of a raw material is the mass percentage of the raw material in the metal cleaning agent.

Embodiment 2

[0112] Weigh 10 parts of potassium carbonate, 15 parts of triethanolamine, 8 parts of sebacic acid, 7 parts of isononanoic acid, 0.5 parts of methyl benzotriazole, 3 parts of isomeric tridecyl polyoxyethylene ether 9EO, 8 parts of di Ethylene glycol monobutyl ether, 15 parts of AMP95, and 33.5 parts of water were mixed uniformly to form a colorless transparent liquid to obtain a metal cleaning agent.

[0113] The above-mentioned parts are all parts by mass. The total number of parts of each raw material in the metal cleaning agent is 100 parts, and the number of parts of a raw material is the mass percentage of the raw material in the metal cleaning agent.

Embodiment 3

[0115] Weigh 20 parts of glycerin, 30 parts of BASF trans-block polyether 1720, 34 parts of BASF trans-block polyether 1740, 5 parts of AMP95 (2-amino-2-methyl-1-propanol), 11 part neodecanoic acid, after being stirred evenly, it was a colorless transparent liquid, and the first component was obtained.

[0116] The above-mentioned parts are all parts by mass. The total number of parts of each raw material in the first component is 100 parts, and the number of parts of a raw material is the mass percentage of the raw material in the first component.

[0117] The metal cleaning agent prepared in Example 1 was uniformly mixed with the first component prepared in this example at a mass ratio of 50:1 to obtain a metal cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com