Patents

Literature

34 results about "Inflow velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The inflow velocity setting will act as the 'pump' that pushes fluid through the pipe and fills up the tank. Important Note: That gap between the inflow and the back of the 'pipe' is necessary for fluid to flow.

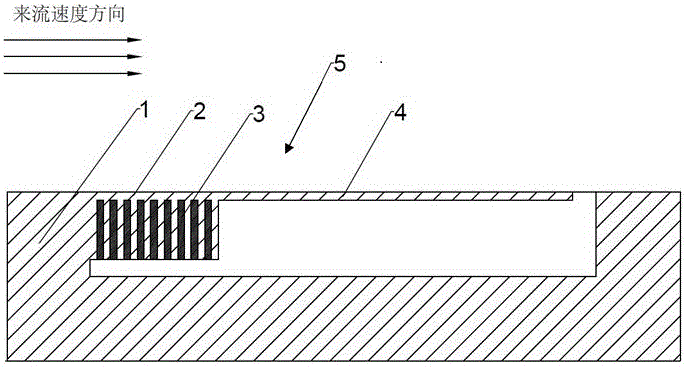

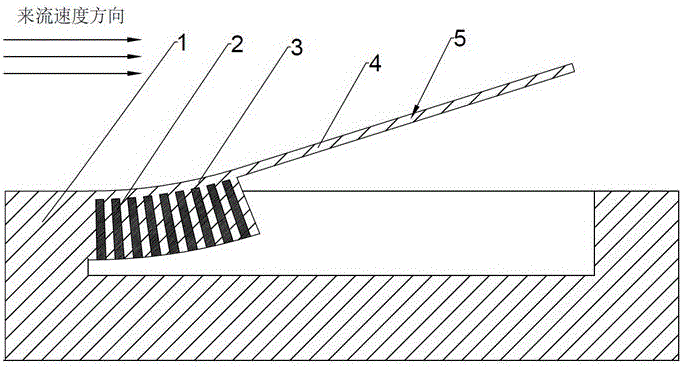

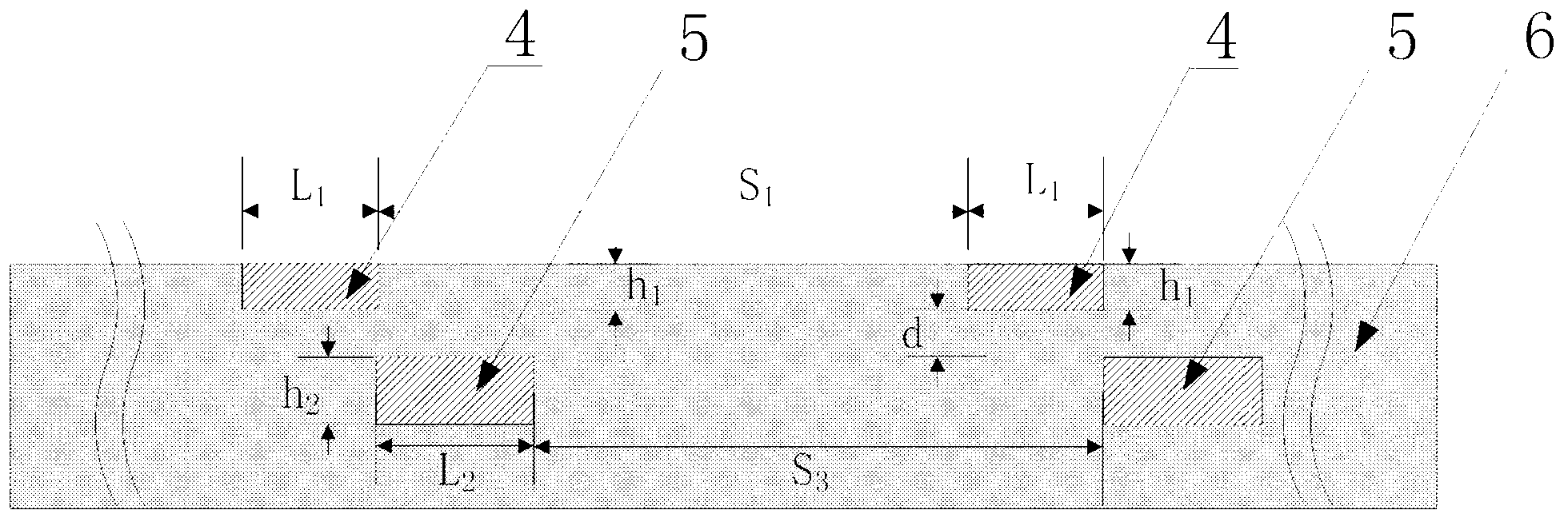

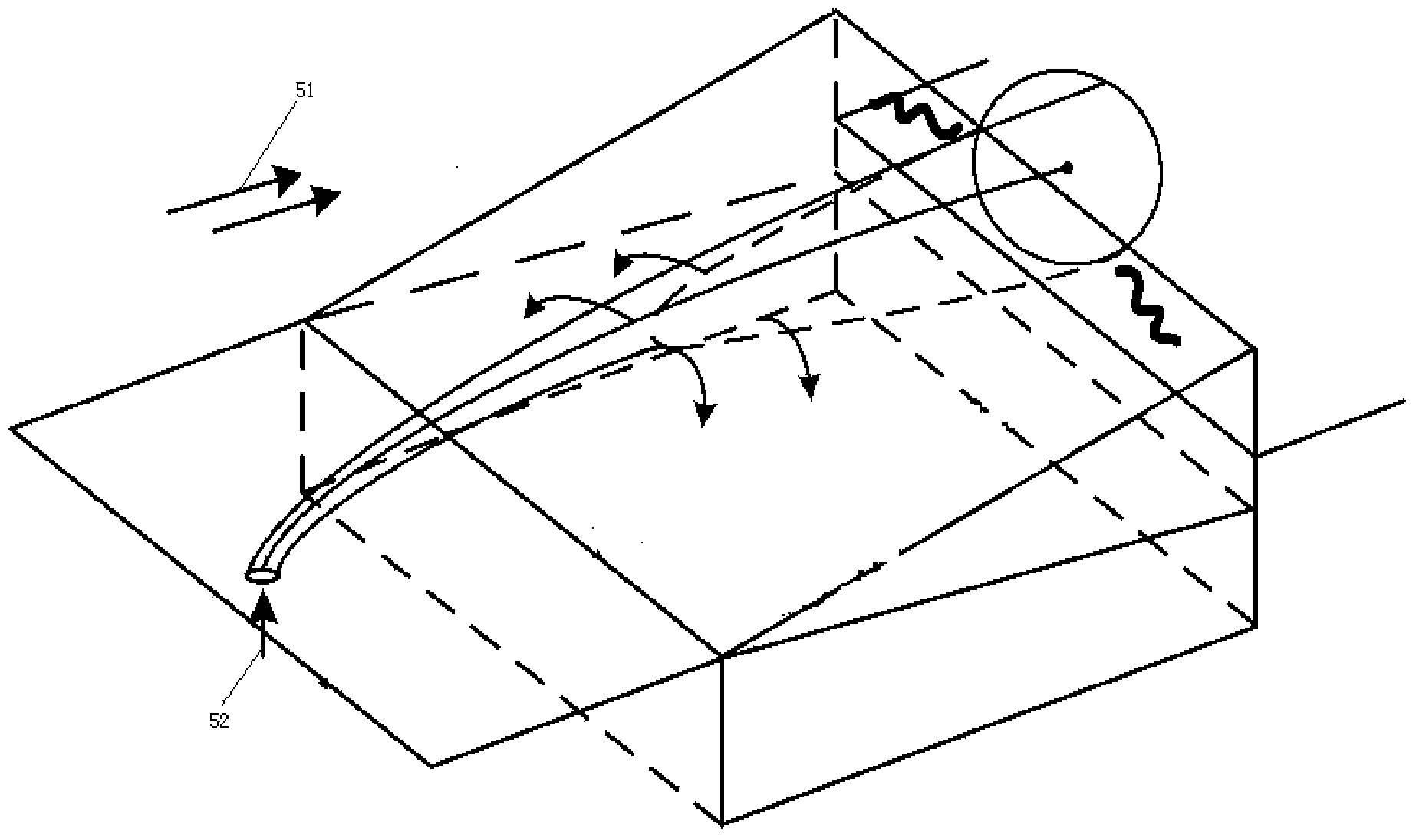

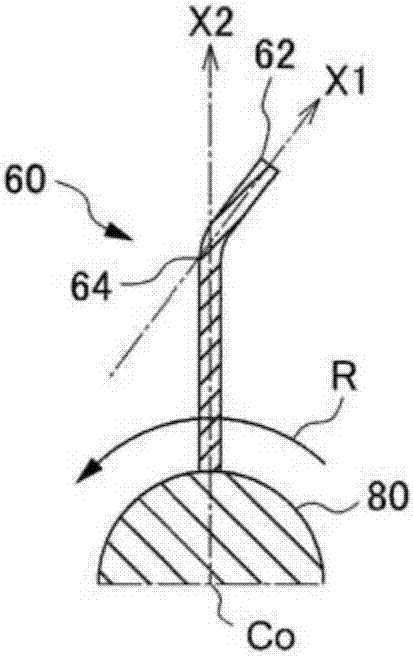

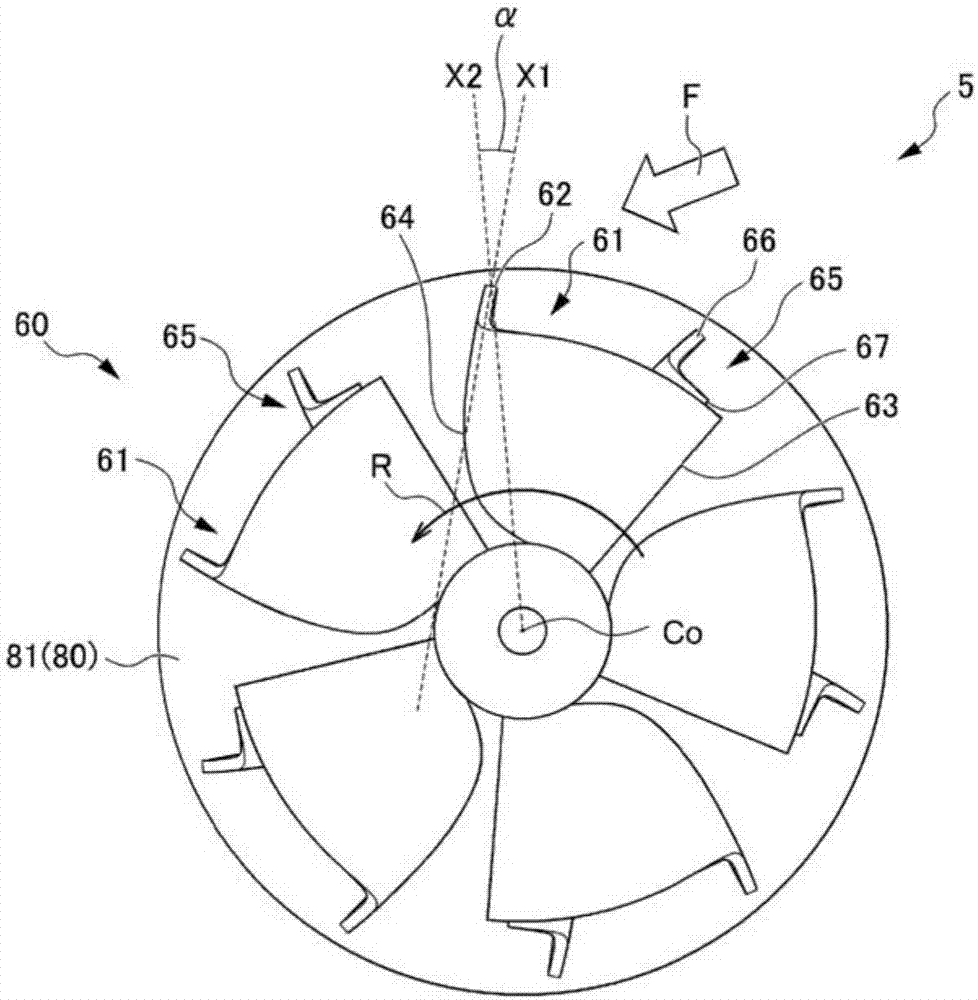

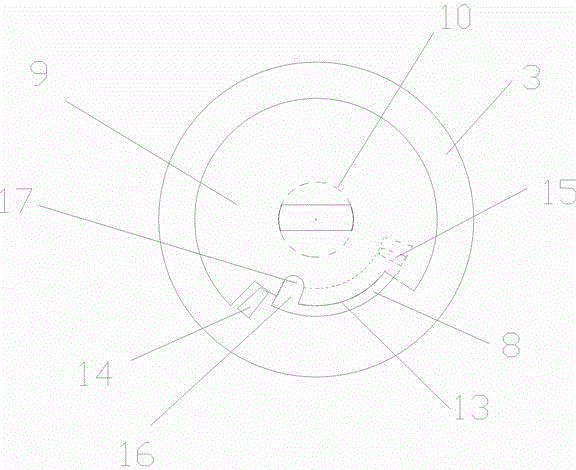

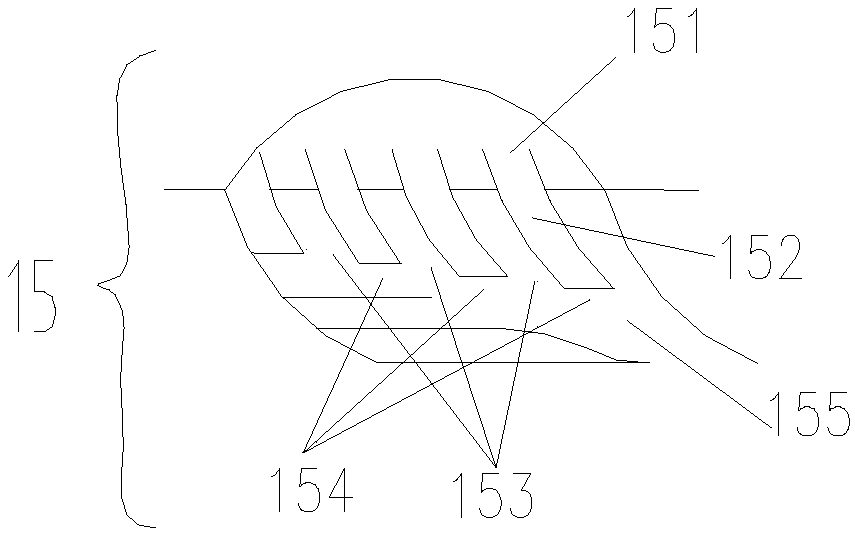

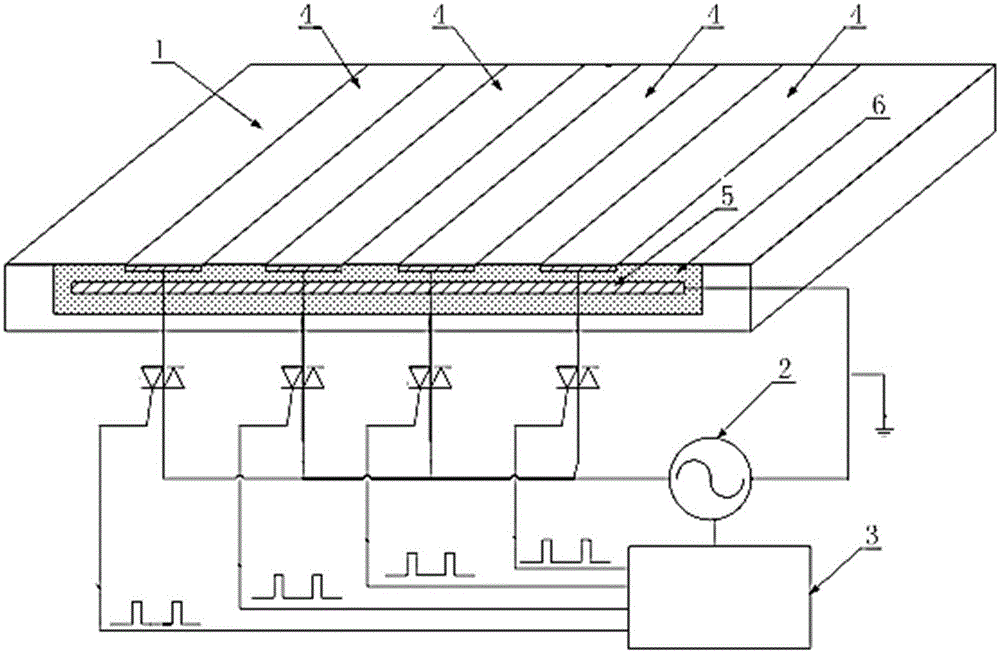

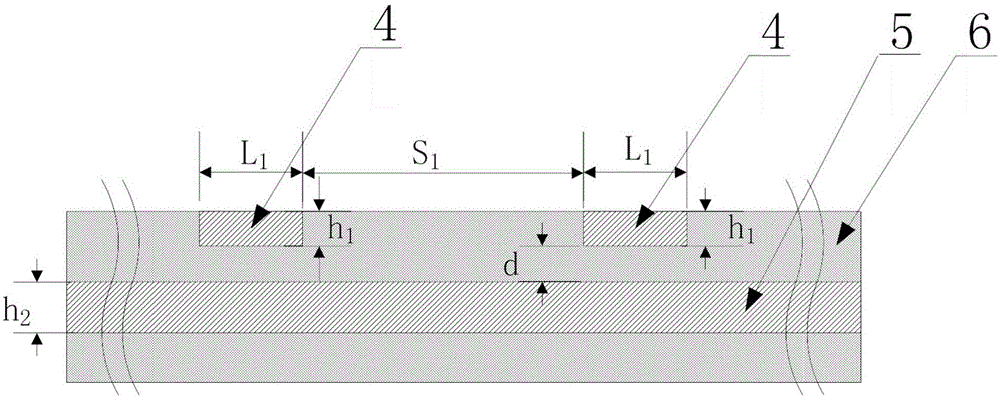

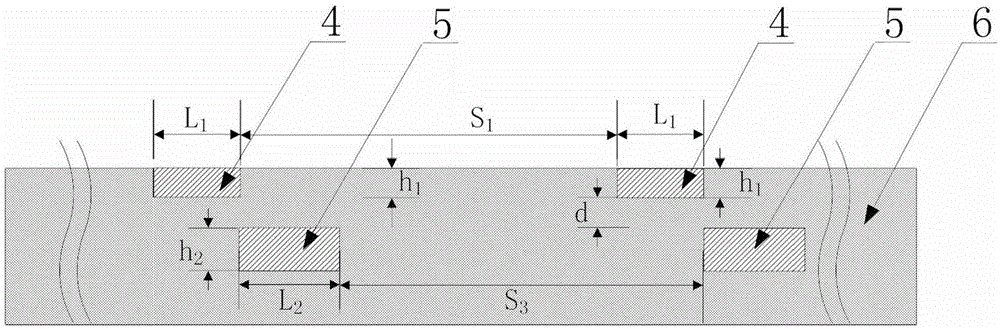

Passive type MEMS flow-induced vibration strengthened heat transfer apparatus and heat transfer method

ActiveCN106206490AEffective destructionSimple structureSemiconductor/solid-state device detailsSolid-state devicesCantilevered beamExternal energy

The invention discloses a passive type MEMS flow-induced vibration strengthened heat transfer apparatus and heat transfer method. Through reasonable structural design, a cantilever beam structure fixed on a heat sink can generate a deflection movement far from the heat sink when the temperature of the heat sink increases, and the deflection angle is enlarged along with the increasing of the heat sink temperature. When the deflection angle of the cantilever beam structure is enlarged, an included angle between the length direction and an inflow velocity direction is correspondingly enlarged, so that the vibration of the cantilever beam vibration part is more fierce; therefore, higher disturbance is brought to a flow field close to the cantilever beam, formation of a heat boundary layer is damaged, and strengthened heat transfer is realized finally; the strengthened heat transfer apparatus does not require manual control and external energy input; and instead, the heat dissipation intensity can be adjusted automatically according to the heat sink temperature, so that a new approach is provided to solve a high heat flux problem of modern electronic devices.

Owner:ZHEJIANG UNIV

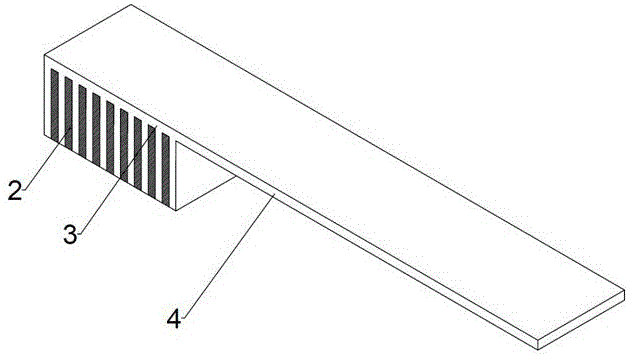

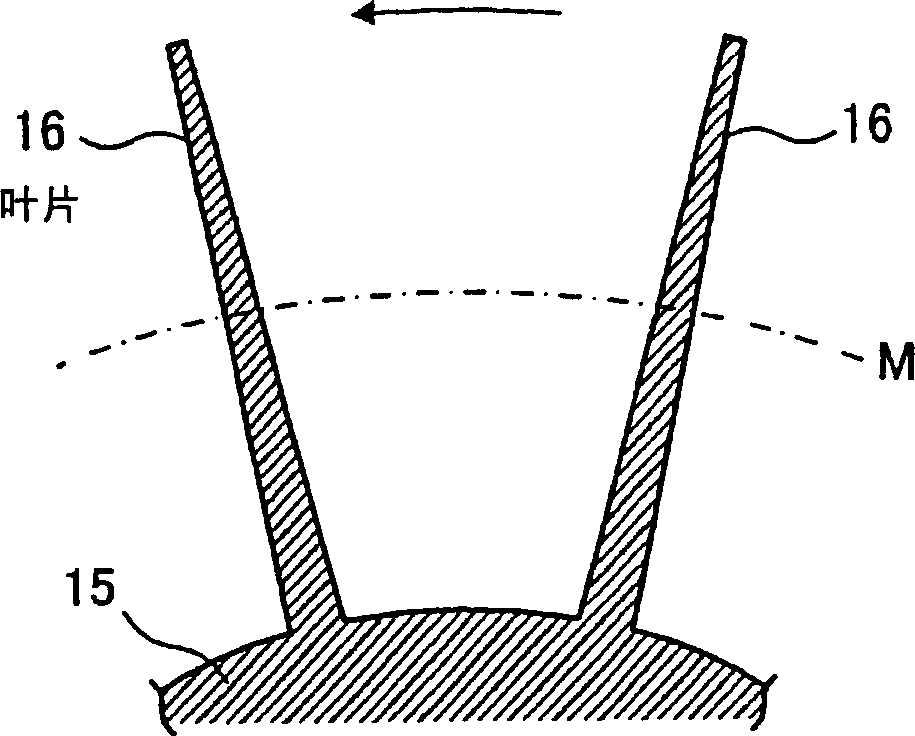

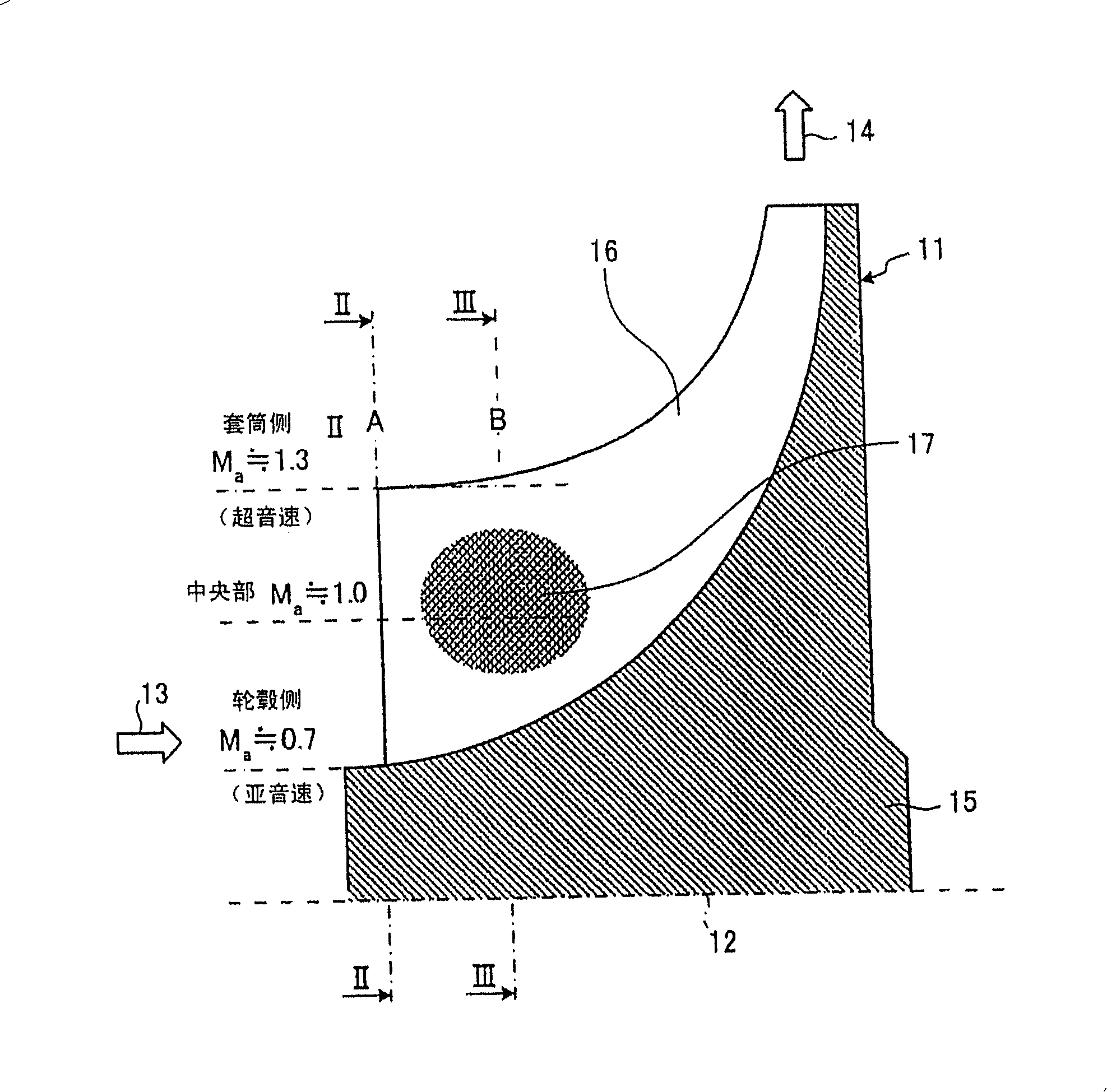

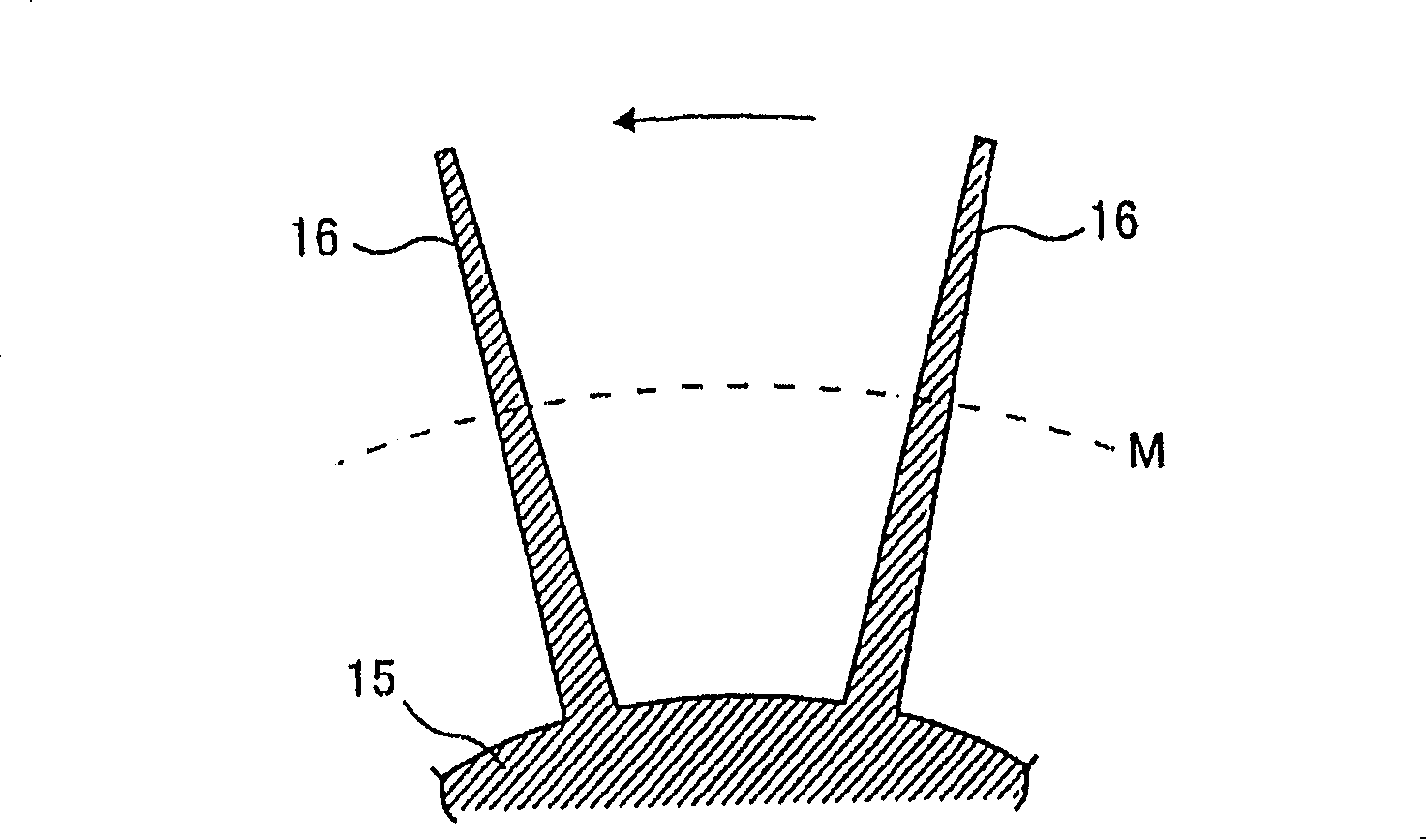

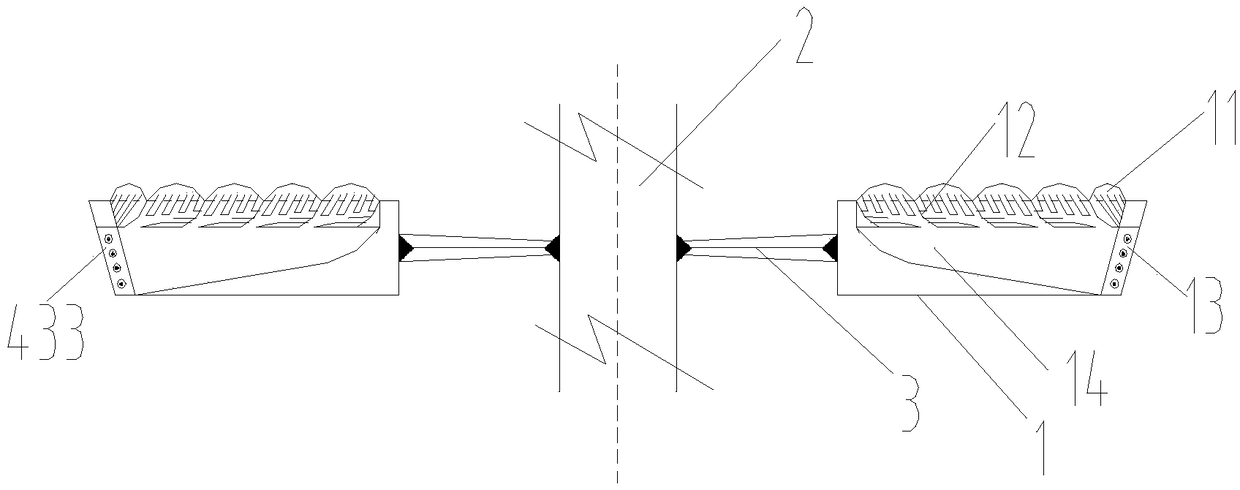

Centrifugal compressor and manufacturing method for impeller

The invention provides a manufacturing method of a centrifugal compressor and an impeller. On the side of the negative pressure surface of the vane (16) of the impeller (11), a convex portion (17) is formed in a curved line from the front edge portion (A) to the slit portion (B) at approximately the central portion in the radial direction, and the convex portion ( 17) By forming it so as to form a curve from the slit portion (B) to the rear edge portion, it will be formed at the position where the relative inflow velocity of the fluid flowing to the impeller (11) reaches the Mach number Ma≒1 The convex part (17) can improve the operation efficiency and expand the adaptable flow range, and further realize the improvement of performance.

Owner:MITSUBISHI HEAVY IND LTD

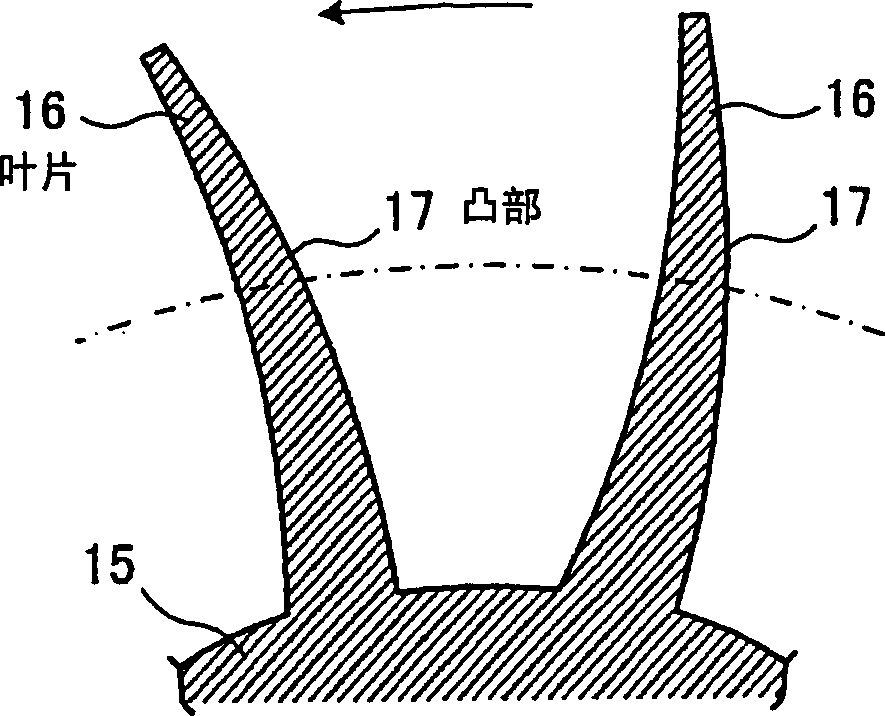

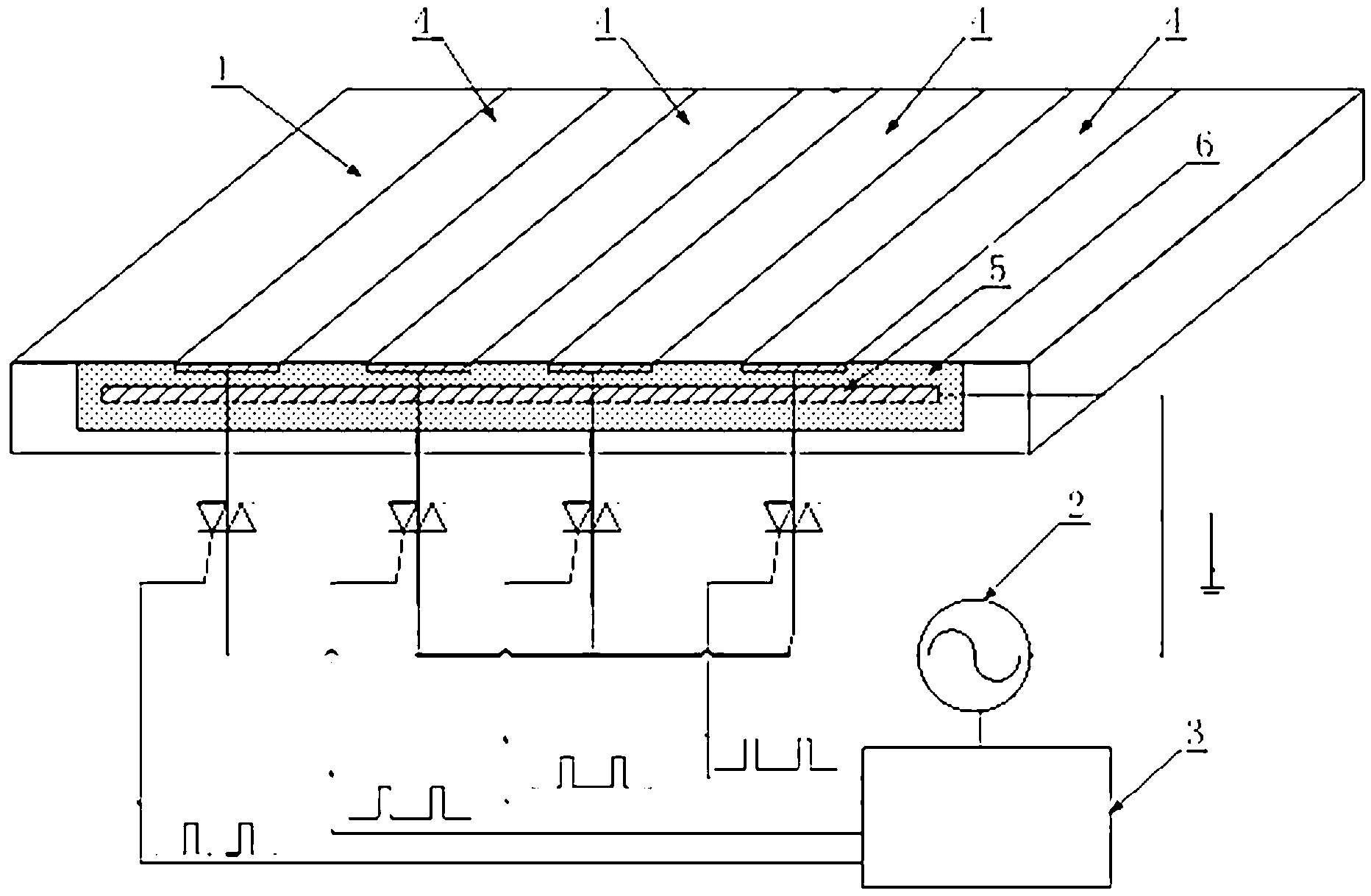

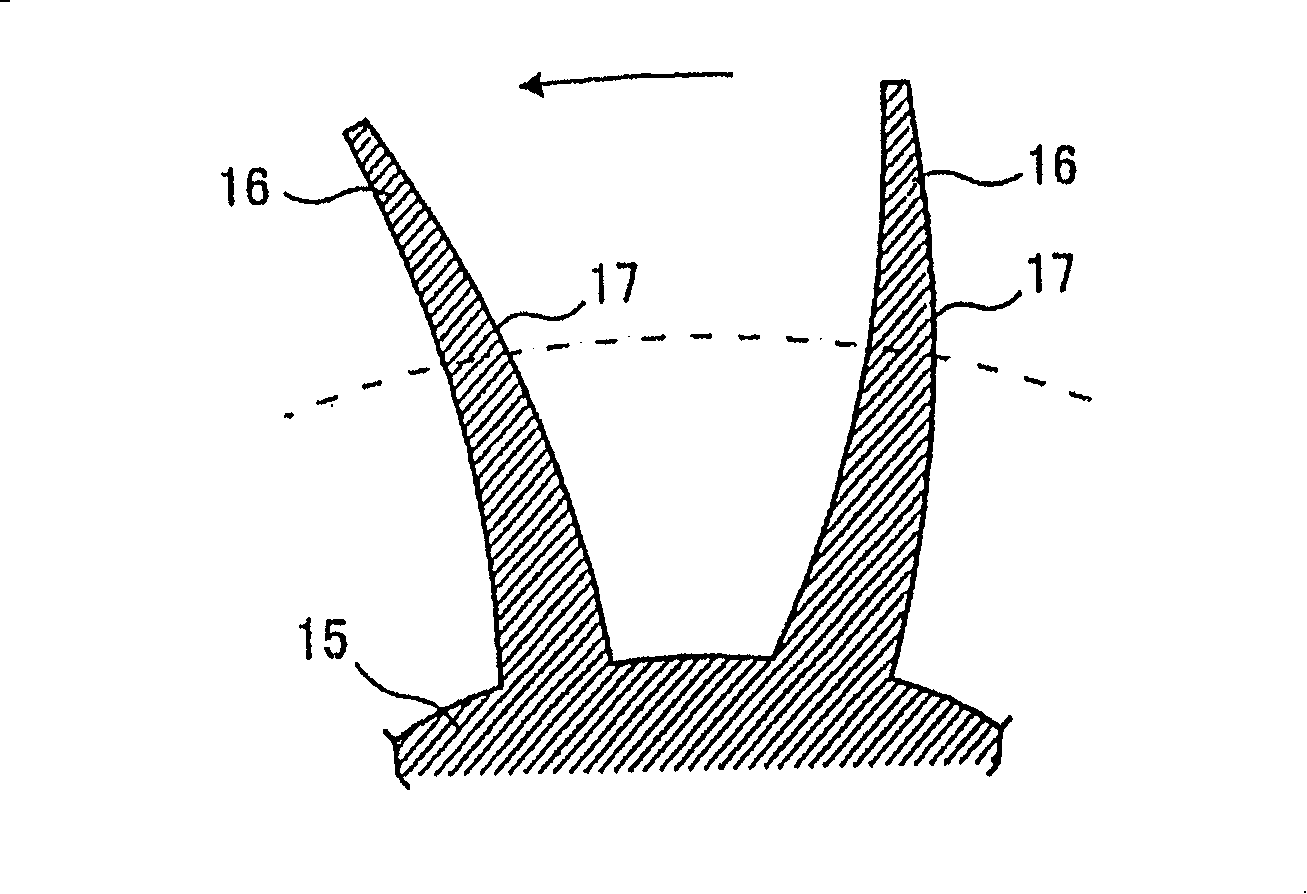

Method for reducing surface resistance based on plasma exciting device

InactiveCN103287575AReduce frictional resistanceInhibitionVehicle body stabilisationAxle-box lubricationLow speedInflow velocity

The invention discloses a method for reducing the surface resistance based on a plasma exciting device in the technical field of power of aircraft or ground transportation. Through an electrode array arranged on a target plane, a power supply and a controller used for regulating a parameter of the power supply, and different working states of the controller, a period controllable induced fluid is generated on the inner layer of a turbulent boundary layer on the surface of a solid, a bursting process and a downward-sweeping process of the inner layer of the turbulent boundary layer are interfered, the generation and the propagation of a coherent structure and a low-speed streak of the inner layer of the turbulent boundary layer are inhibited, and the effect of reducing the turbulent friction resistance on the surface of the solid is achieved. The plasma exciting device is capable of effectively inhibiting the turbulent friction resistance under a high reynolds number, has the characteristics of simple structure, low energy consumption, stable performance and no additional load, is capable of being actively regulated, and is suitable for a larger inflow velocity without additional parasite drag.

Owner:SHANGHAI JIAO TONG UNIV

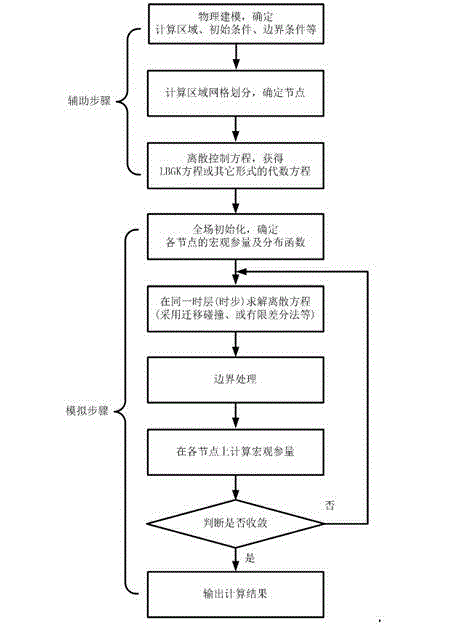

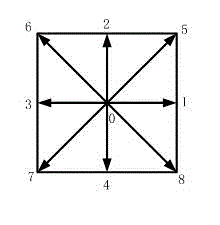

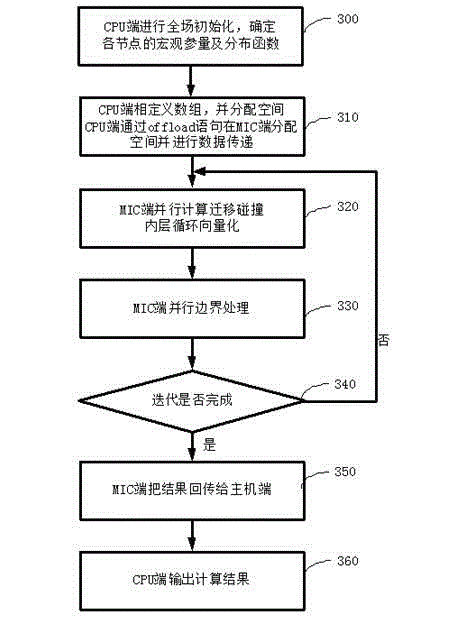

Method for utilizing microwave integrated circuit (MIC) to rapidly achieve lattice Boltzmann parallel acceleration

InactiveCN103064819AMeet the needs of simulationImprove performanceMultiple digital computer combinationsMicrowaveInflow velocity

The invention provides a method for utilizing a microwave integrated circuit (MIC) to rapidly achieve lattice Boltzmann parallel acceleration. The method comprises the steps of enabling a central processing unit (CPU) to set parameters such as a computational domain, a reference length, an inflow velocity, density and Reynolds numbers according to physical problems and design thread counts of an inner core according to nuclear numbers of an MIC card; enabling an MIC end to calculate equilibrium state distribution functions of all lattice points in various directions through the macroscopic parameters (the density, the speed, the Reynolds numbers and a coefficient of viscosity and the like) so as to enable the equilibrium state distribution functions to serve as a computational initial field, performing parallel solving of a discrete equation and a processing edge, and enabling results obtained by final iteration to be passed back to a CPU end. The characteristic of rapid calculation of an MICMIC end is utilized to participate in calculation of migration and collision in lattice-Boltzmann, and the iterative process of the lattice-Boltzmann is accelerated by coordinated operation of the CPUCPU end and the MICMIC end.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

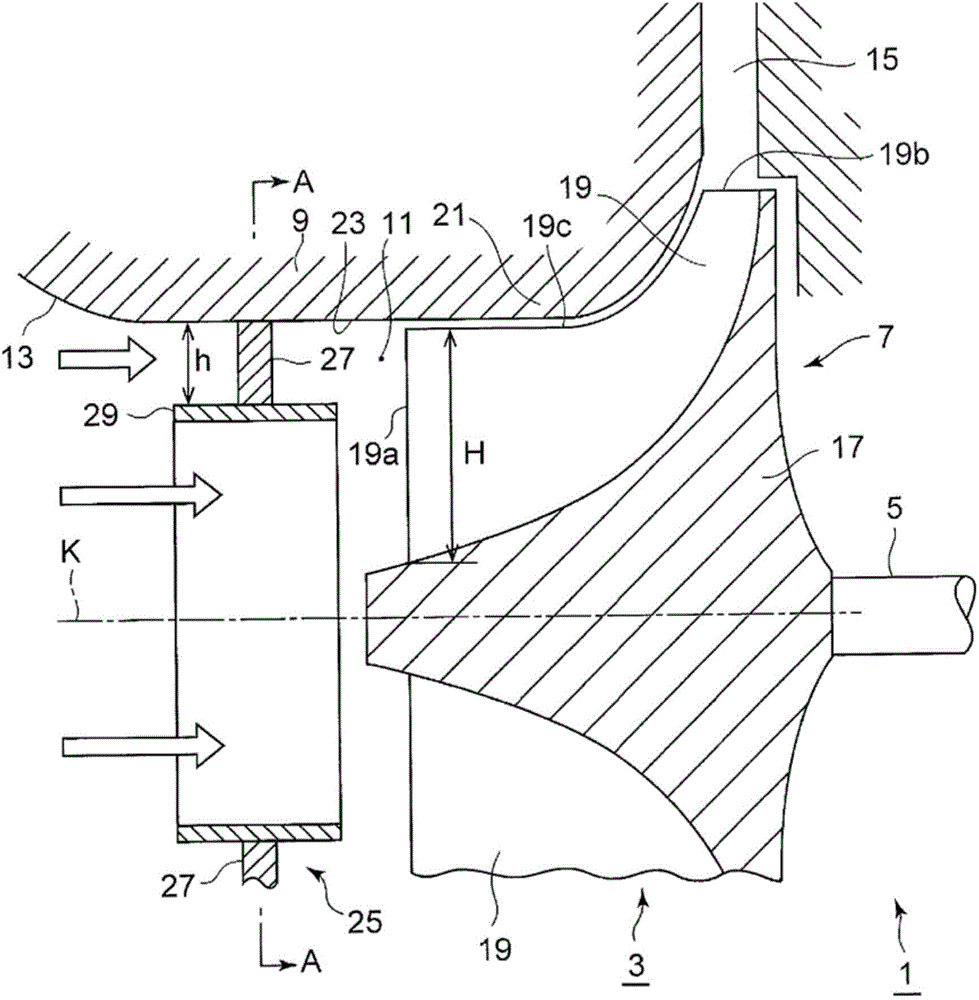

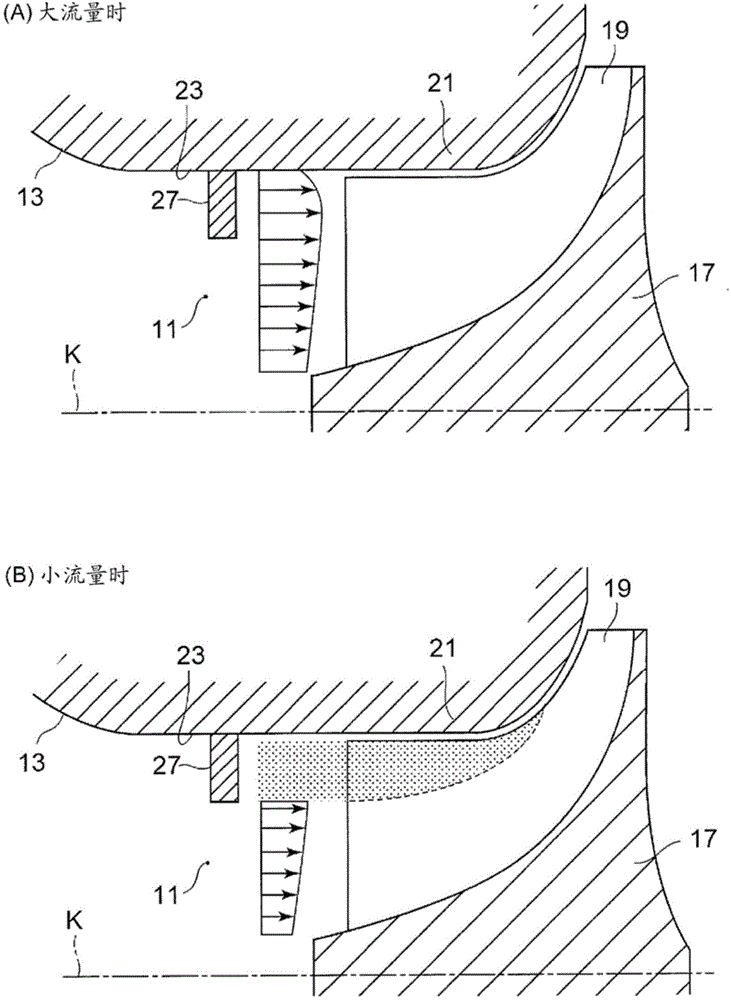

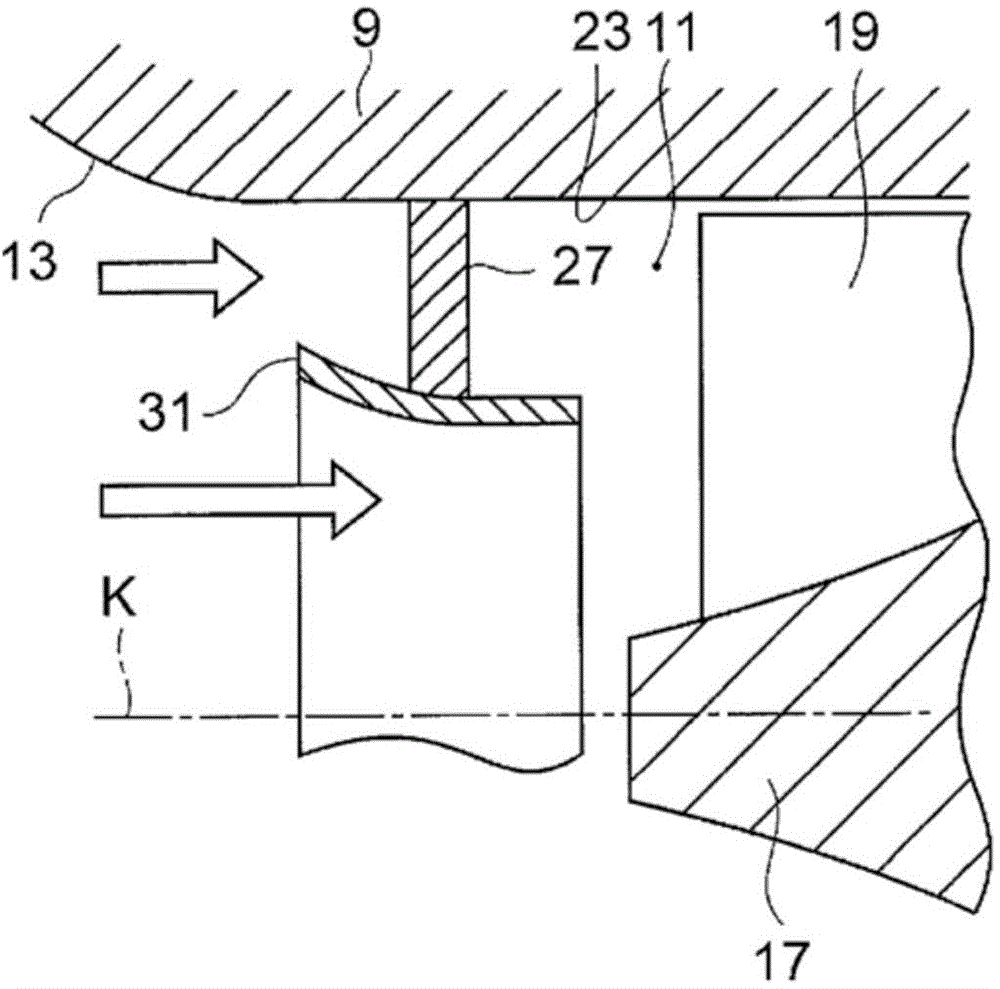

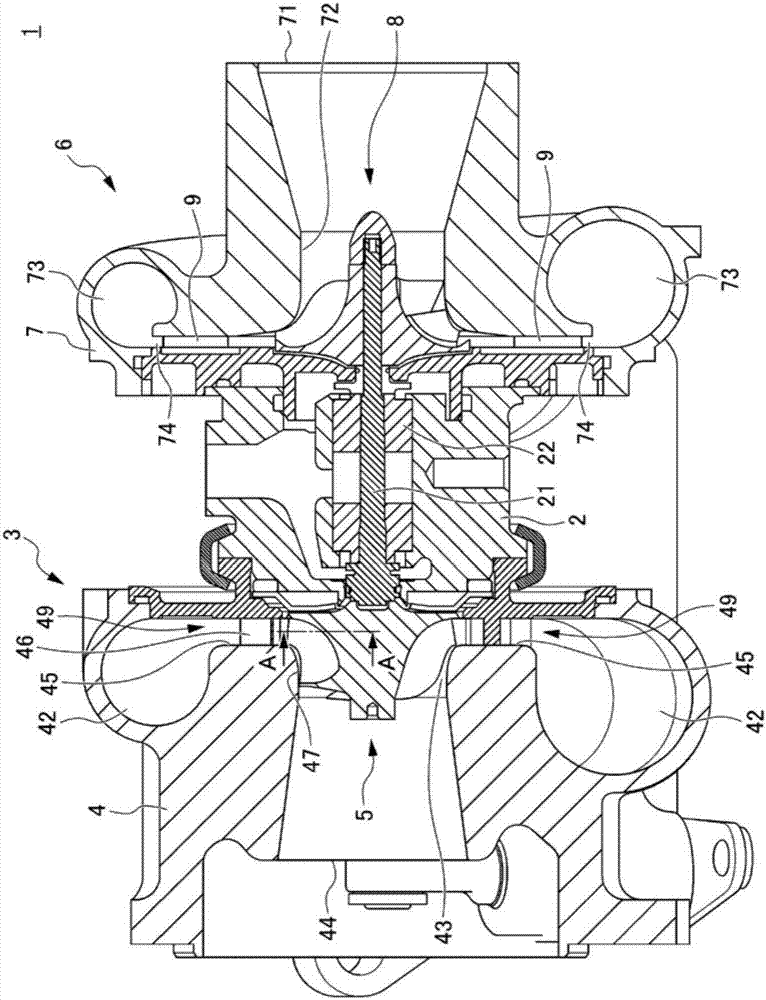

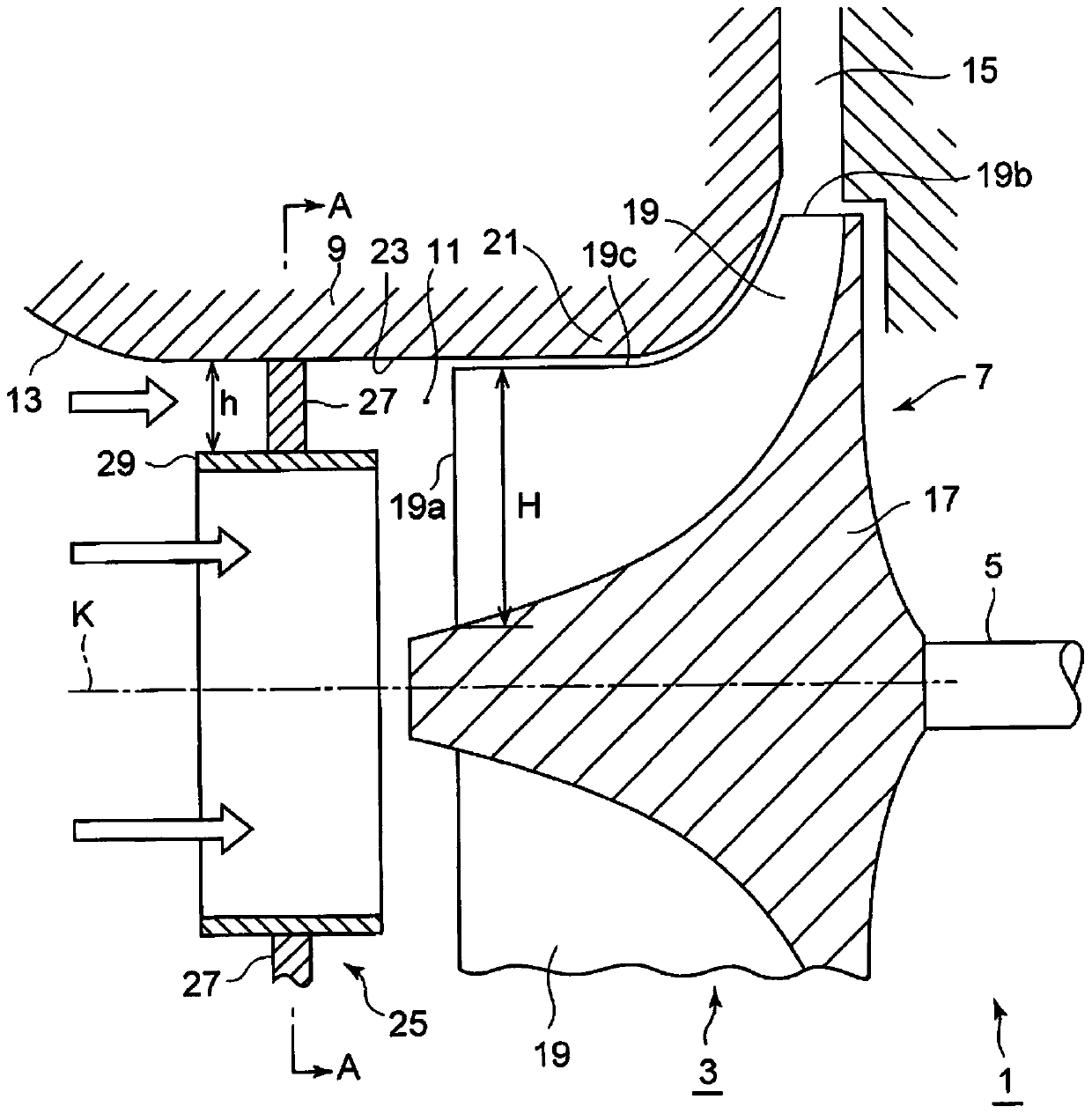

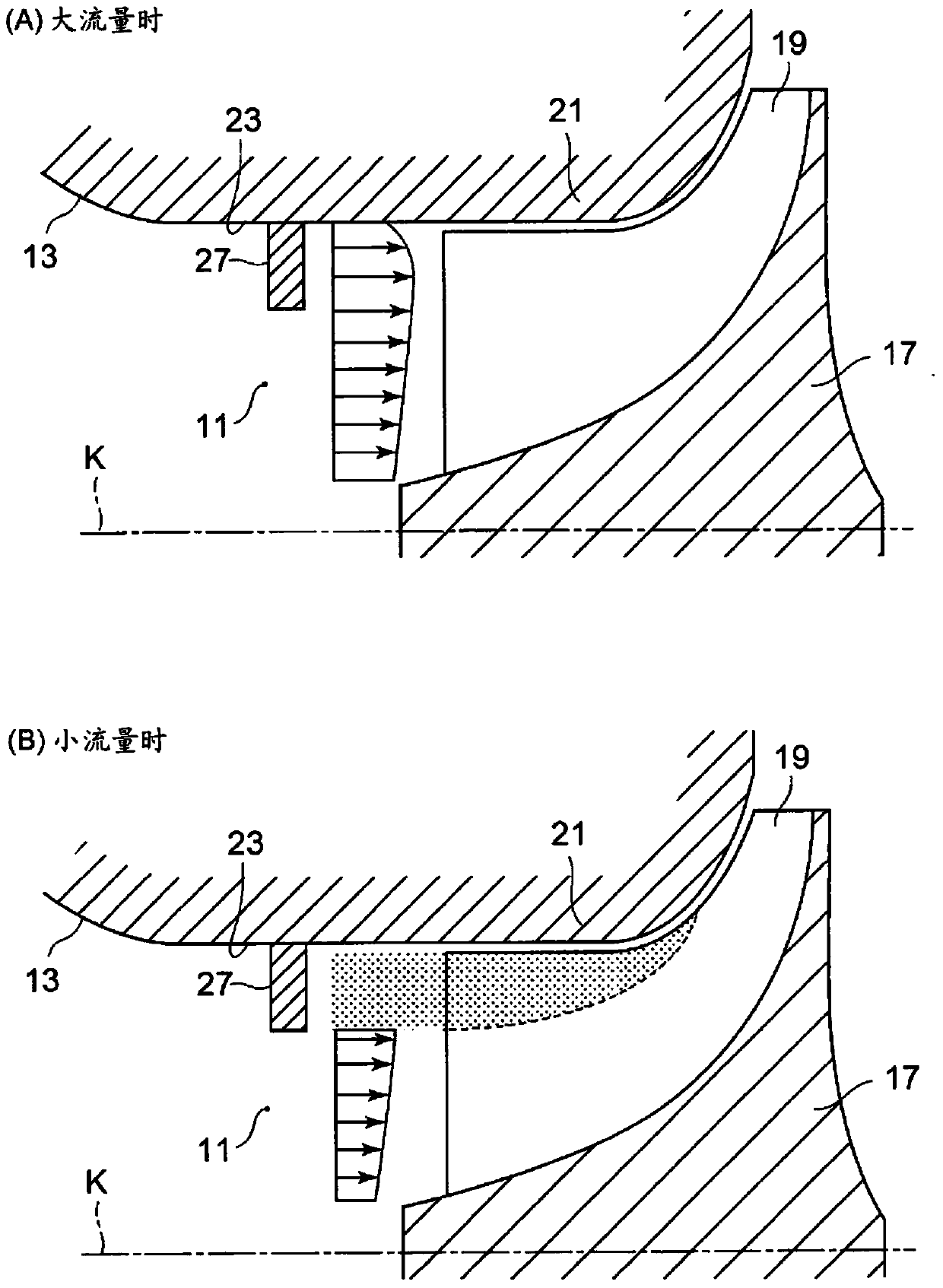

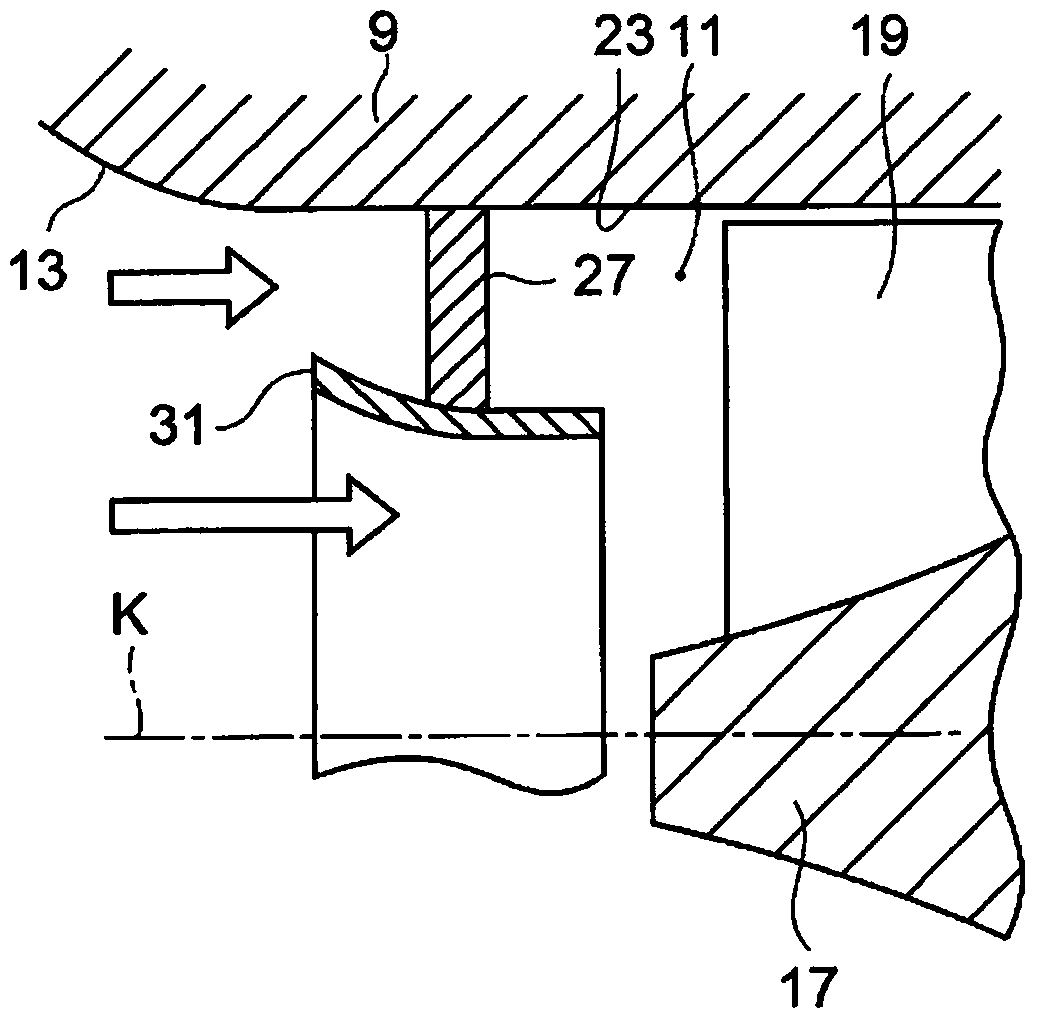

Centrifugal compressor

ActiveCN104968944AReduce surge limit flowEngine manufacturePump componentsInflow velocityCentrifugal compressor

[Problem] The purpose of the present invention is to provide a resistive element which radially narrows the passage cross-section of the intake passage that connects the rotary vane and the air inlet of this centrifugal compressor, thus increasing the inflow velocity to the blade of an impeller wheel and reducing the surging limit flow when the flow rate is low. [Solution] This centrifugal compressor is characterized by being providing with a compressor housing (9) which has an air inlet (13) opening in the rotation axis direction and an intake passage (11), and with an impeller wheel (7) which, inside of said housing, compresses air flowing in from the air inlet (13). A narrowing element (27, 43) is provided in the air intake flow in either the portion of the intake passage (11) on the inner peripheral wall (23) or the central portion of said intake passage (11) such that, when flow rate is low, by narrowing the cross-sectional area of the intake passage (11) by means of the resistive element (27, 43), the inflow velocity to the blade (19) of the impeller wheel is increased and the inflow is biased towards the hub side or the shroud side of the blade (19).

Owner:MITSUBISHI HEAVY IND LTD

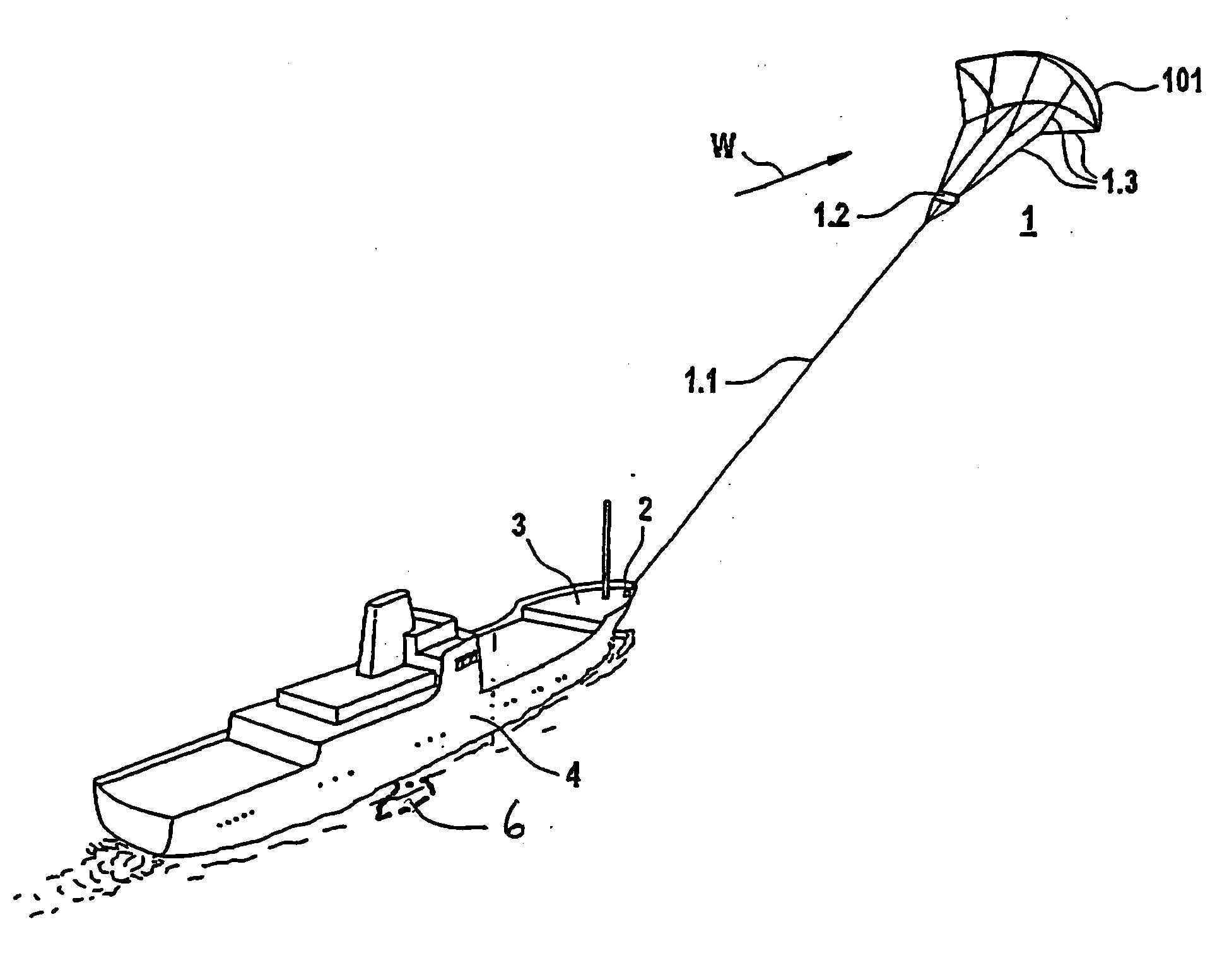

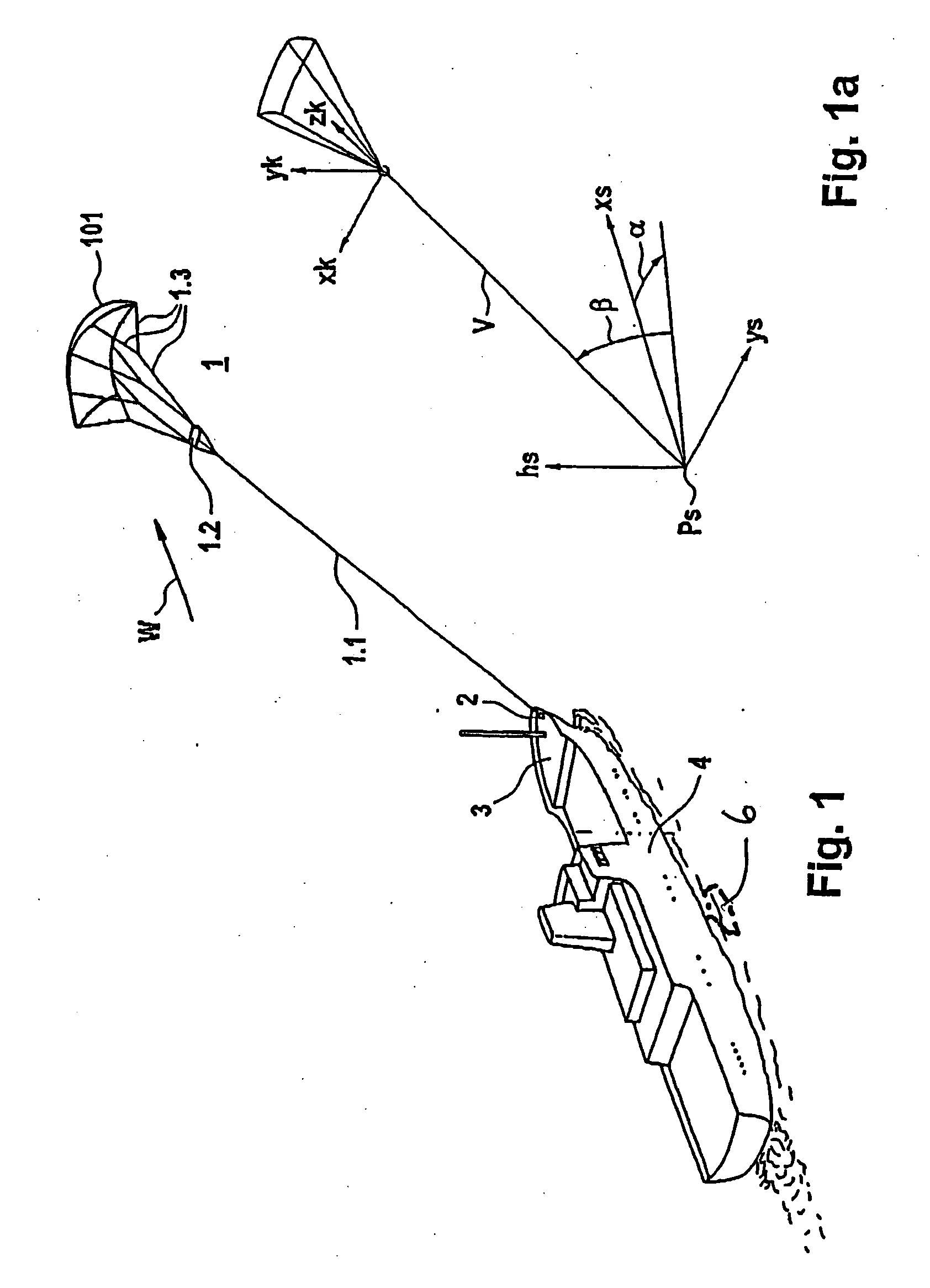

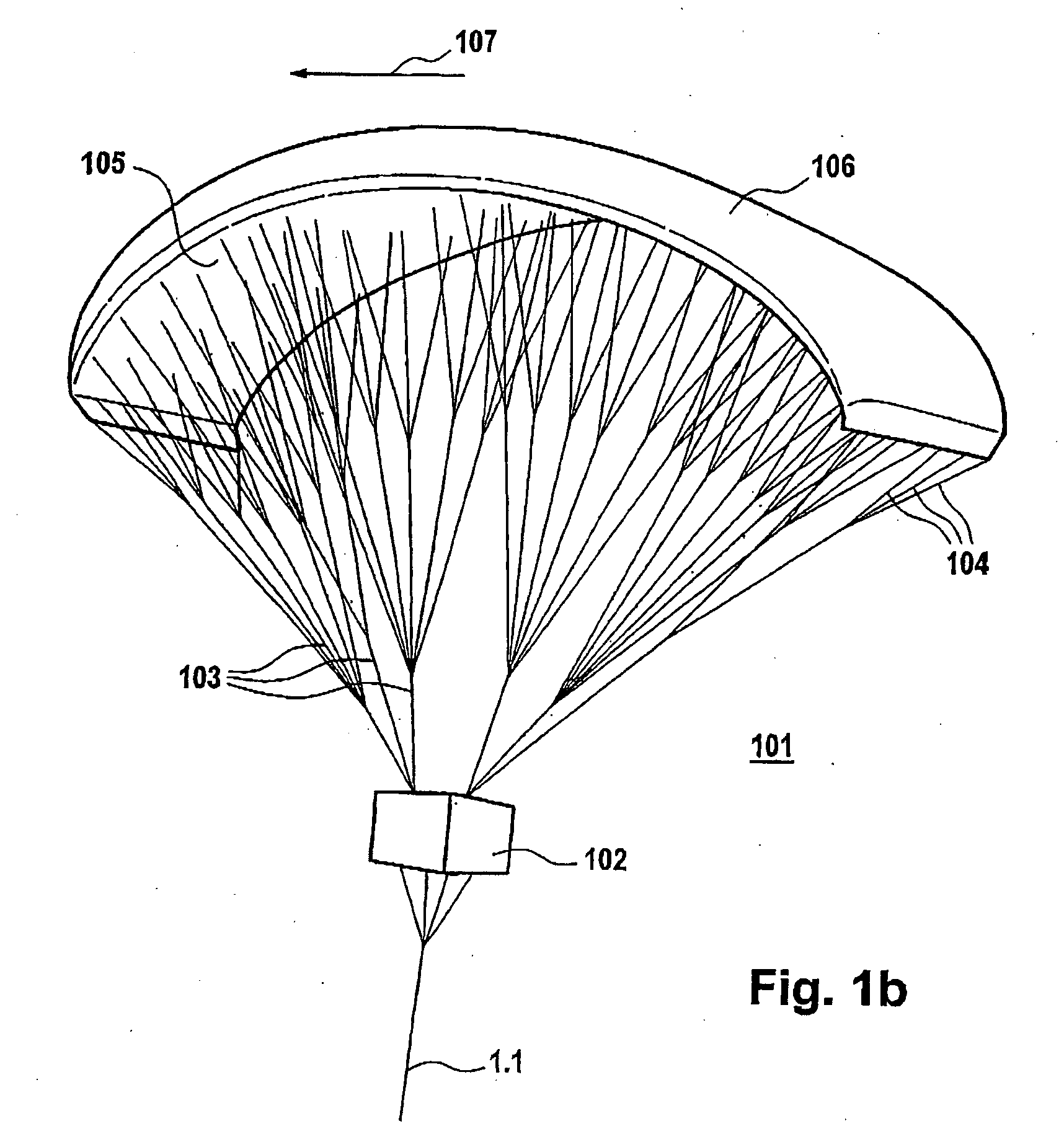

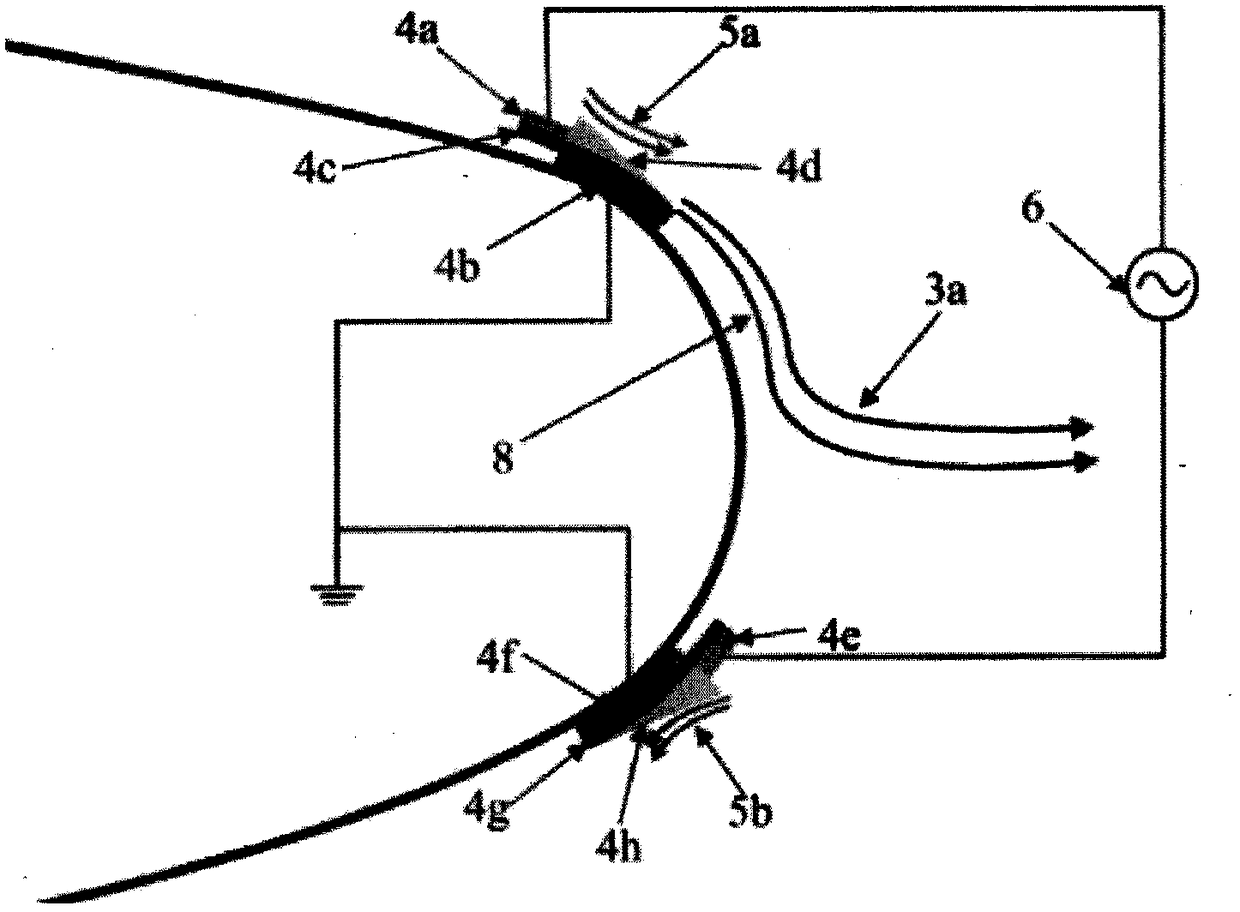

Positioning device for a free-flying kite-type wind-attacked element in a wind-powered watercraft

ActiveUS20090212574A1Stable operation without control oscillationsNone have achieved superiorPropulsion based emission reductionWind propelled vesselsInflow velocityEngineering

Disclosed is a positioning device for a free-flying kite-type wind-attacked element that comprises a profiled wing, is used as the exclusive, an auxiliary, or an emergency drive unit, and is connected to a watercraft via a traction rope. The positioning device is provided with a winch that encompasses means which cause the traction rope to be taken in when a given first tractive force is not attained and / or when the flow is about to stop or has stopped abruptly and / or cause the traction rope to be veered when given a second tractive force and / or a given inflow velocity are / is exceeded.

Owner:SKYSAILS GMBH & CO KG

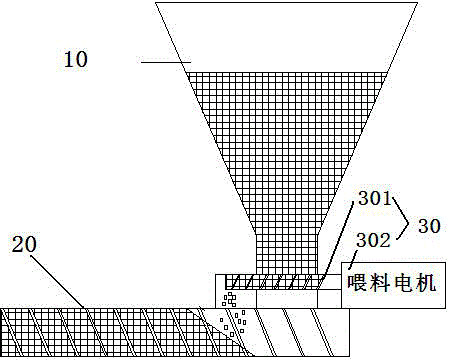

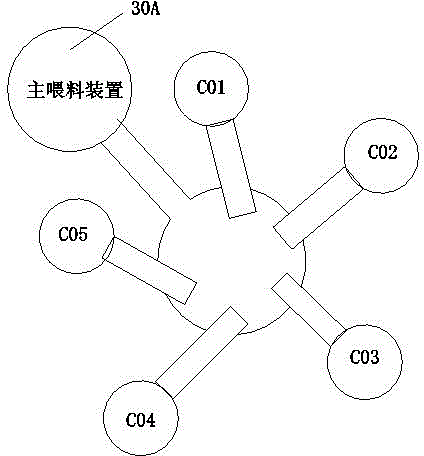

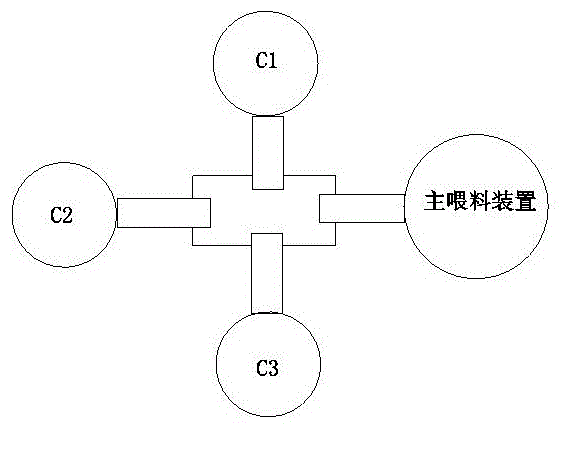

Processing technology and processing equipment of 3D printing wire

InactiveCN104552954AImprove quality observabilityPrevent lockAdditive manufacturing apparatusInflow velocityEngineering

The invention discloses a processing technology and processing equipment of a 3D printing wire. An underfeeding way is adopted to feed materials, wherein the underfeeding way is achieved by regulating the screw speed of granules falling into an extruder before feeding materials by virtue of a small-screw feeding device, and the feeding speed of the small-screw feeding device and the rotating speed of the screw of the extruder are kept at a certain speed ratio so as to achieve continuous running; raw materials are added from the blanking hole of a main extruder by regulating the ratio of the inflow velocity of main materials to the adding speed of different auxiliary materials, and discontinuous multi-color extrusion is achieved according to the ratio of the adding time ato the rotating speed of the different auxiliary materials. The processing equipment comprises a charging barrel and an extruder below the charging barrel. By virtue of the technology, a problem that the screw of the extruder is locked during extruding can be avoided, and a colorful 3D printer wire can be produced.

Owner:吴景阳

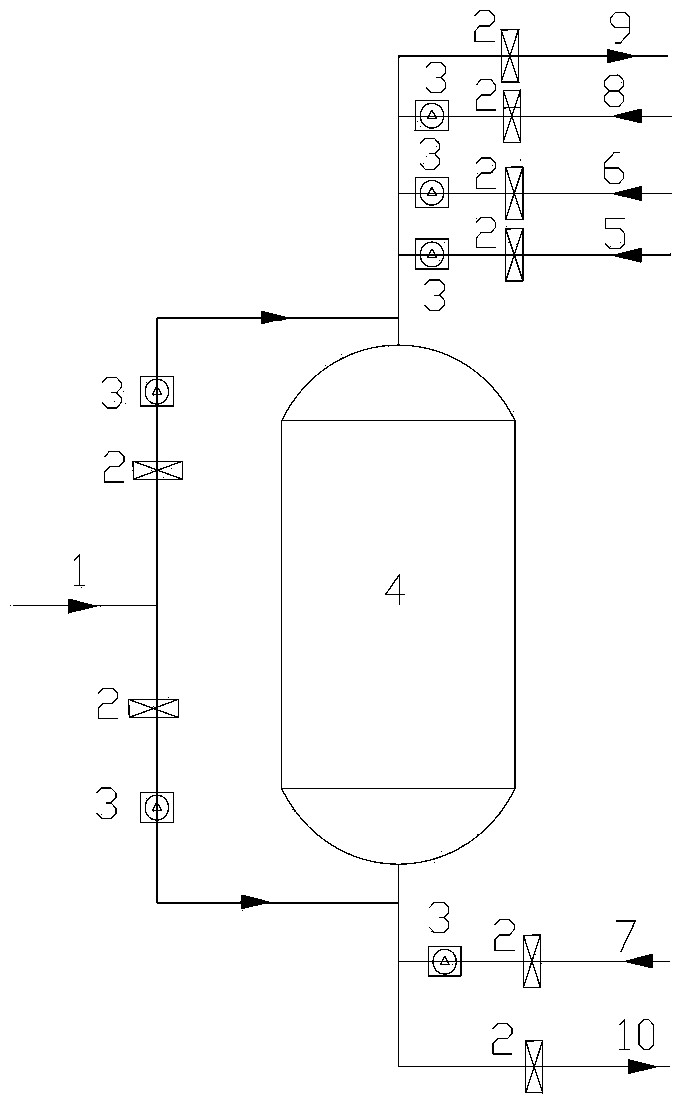

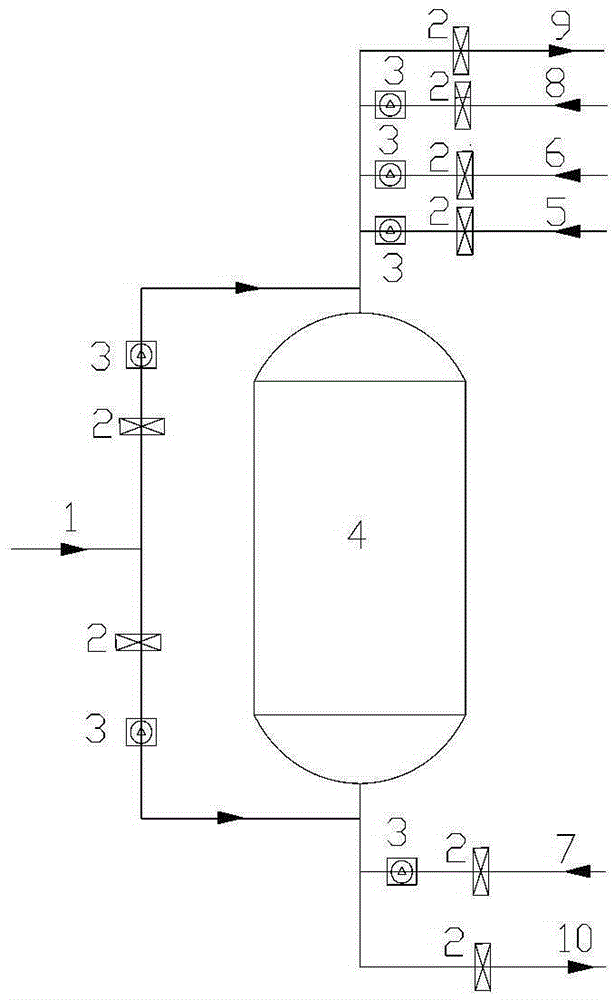

On-line recovery method for ion exchange resin

ActiveCN103638993AExtended use timeLower recovery costsIon exchange beds cleaning/rinsingRecovery methodIon exchange

An on-line recovery method for ion exchange resin is preformed in an ion exchange reactor and comprises the following steps: employing desalinized water to perform one-time washing on inactive ion exchange resin, wherein the one-time washing comprises alternative backwashing and forward washing and the water inflow velocity of backwashing is larger than the water inflow velocity of the forward washing; immersing ion exchange resin subjected to one-time washing with an acidic solution; immersing ion exchange resin with a mixed recovery solution composed of a Na2SO4 solution with a mass concentration of 10-12% and a NaOH solution with a mass concentration of 5-6%, and continuously introducing O3 into the ion exchange reactor when immersing; and performing regeneration on ion exchange resin by employing a NaOH solution or a KOH solution. By employing the on-line recovery method for ion exchange resin to perform on-line recovery on inactive resin, resin is used again after majority functions of the resin are recovered, so that the recovery cost is reduced, the service life of ion exchange resin is prolonged, and energy saving, emission reduction, cost reduction and effect improvement are facilitated.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Method for efficiently evaporating bittern and recovering fresh water

InactiveCN102464365AGood for evaporation and concentrationEasy extractionWater/sewage treatment by heatingHyperboloidEvaporation

The invention relates to a method for efficiently evaporating bittern and recovering fresh water. The method is especially suitable for high-efficiency evaporation of bittern for high-salinity salt pan or potash fertilizer production and recovery of fresh water. According to the method, transparent plastic foil is used to make a large-scale hyperboloid tower. The tower top forms a three-way connection with a horizontal condenser tube, which is slightly inclined downwards, through a vertical transparent plastic tube. The condenser tube collects fresh water and discharges the fresh water upward out from a far-end opening. There is enough gap between the tower bottom and a bittern pond so as to guarantee the air inflow velocity is less than the emptying velocity. The bittern passes through a center tube under the tower and is ejected sideways and downwards. It is not appropriate to splash the bittern on the plastic foil. In order to fully utilize the characteristic of large day-and-night temperature difference in the west of our country and raise the condensation efficiency, deposited crystals are removed out before the temperature is raised in the morning. According to the method, solar energy is fully utilized to heat the bittern, and the advantage of fast upper air-flow velocity is also utilized to raise the air flow velocity on the surface of the bittern so as to improve the evaporation speed. The fresh water is recovered by a condensation recovery device. The invention is beneficial to the salt pan production.

Owner:王辉

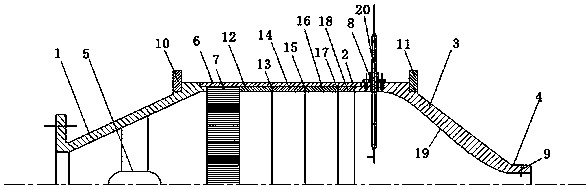

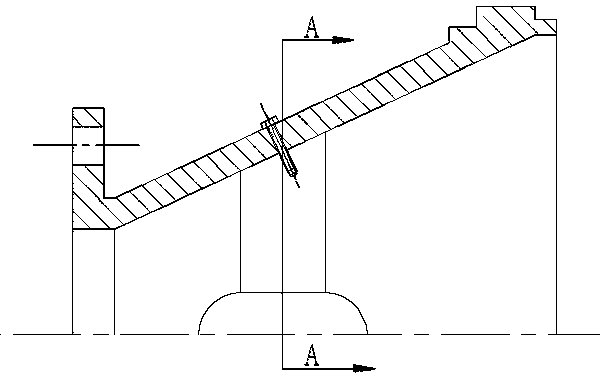

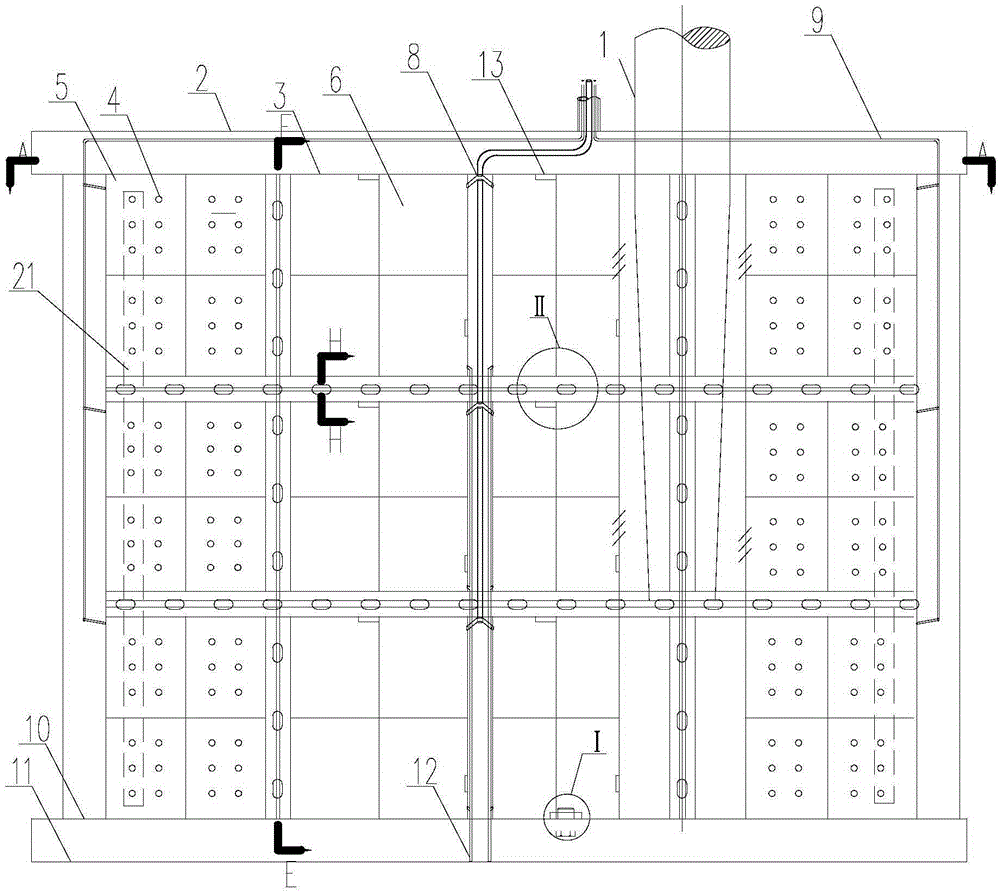

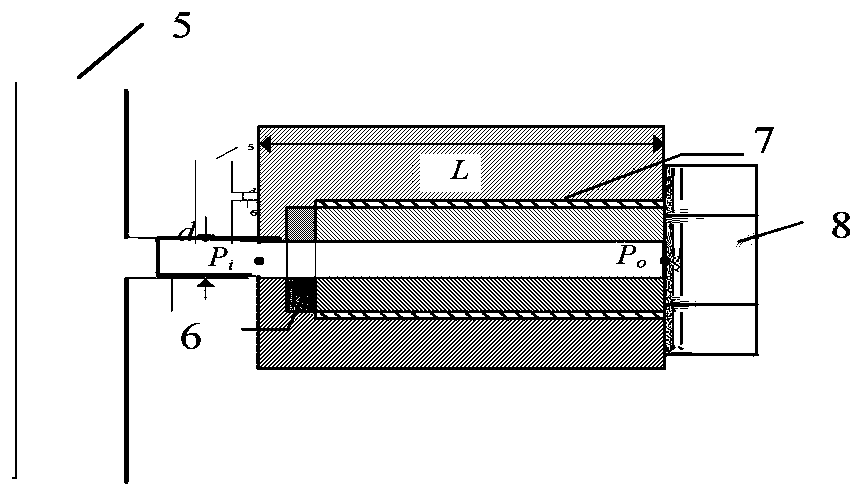

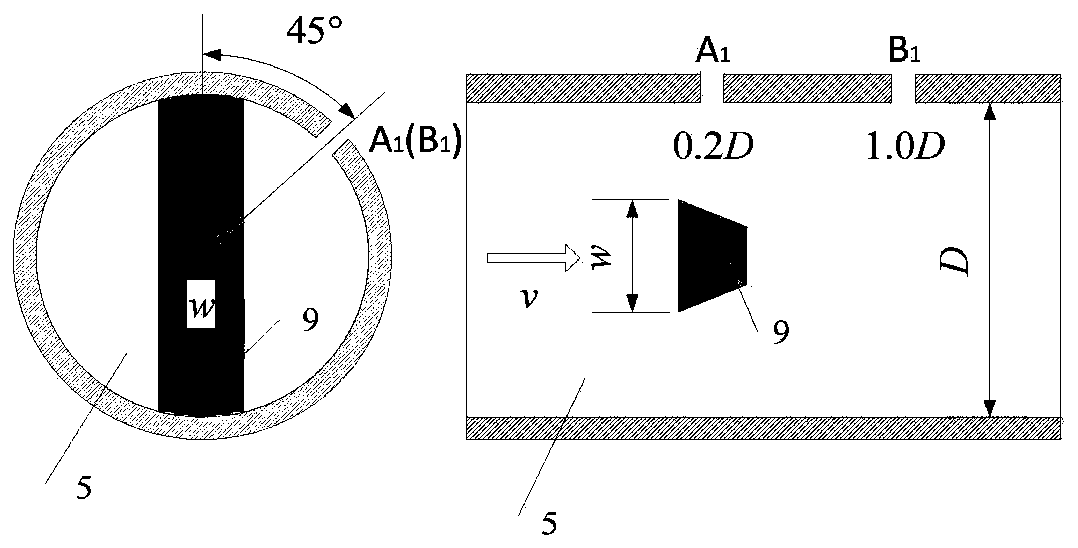

Subsonic-speed jet type pneumatic probe calibration wind tunnel

The invention belongs to the field of pneumatic probe calibration wind tunnels and particularly relates to a subsonic-speed jet type pneumatic probe calibration wind tunnel capable of increasing inflow velocity. The subsonic-speed jet type pneumatic probe calibration wind tunnel comprises an inlet expansion section, a flow stabilizing section, a contraction section and an experiment section whichare sequentially connected and is characterized in that the inlet expansion section gradually expands from the end to the flow stabilizing section, and the contraction section gradually contracts fromthe flow stabilizing section to the experiment section; the inlet expansion section is provided with an inlet sprue spreader, the flow stabilizing section comprises an outer annular sleeve, a cellular device, a plurality of inner annular sleeves and a vortex breaking net which are sequentially arranged, and the inner annular sleeves are arranged at intervals; the contraction section is provided with a total pressure probe mounting seat close to the flow stabilizing section, and the contraction section is provided with a static vent away from the flow stabilizing section. The subsonic-speed jet type pneumatic probe calibration wind tunnel has the advantages that the size and floor space of the wind tunnel are reduced, and the wind tunnel is easy in mounting and layout; after the contraction ratio of the wind tunnel and the size of each unit are reasonably designed, large inflow Mach number can be achieved under low motor power.

Owner:大连凌海华威科技服务有限责任公司

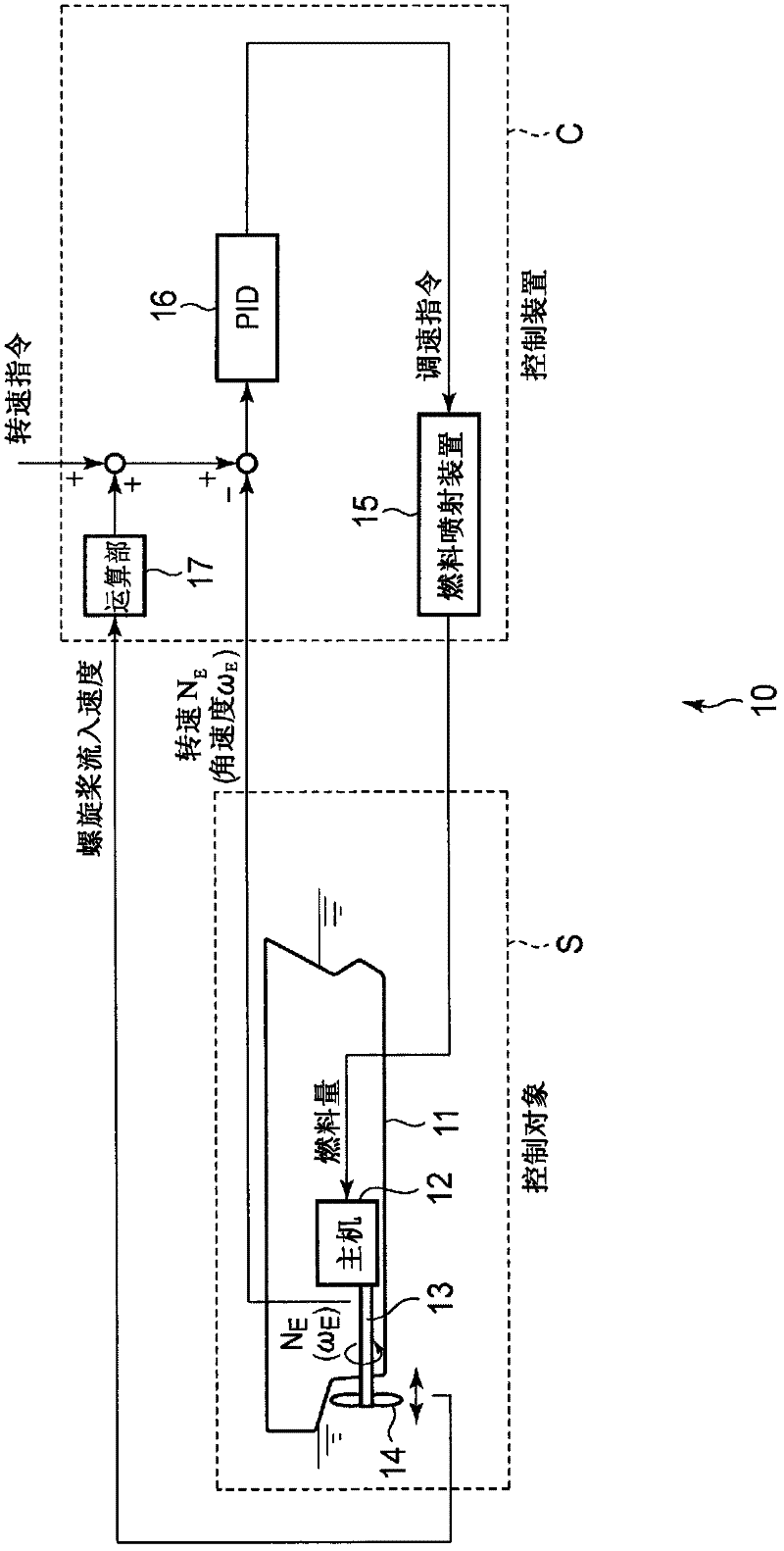

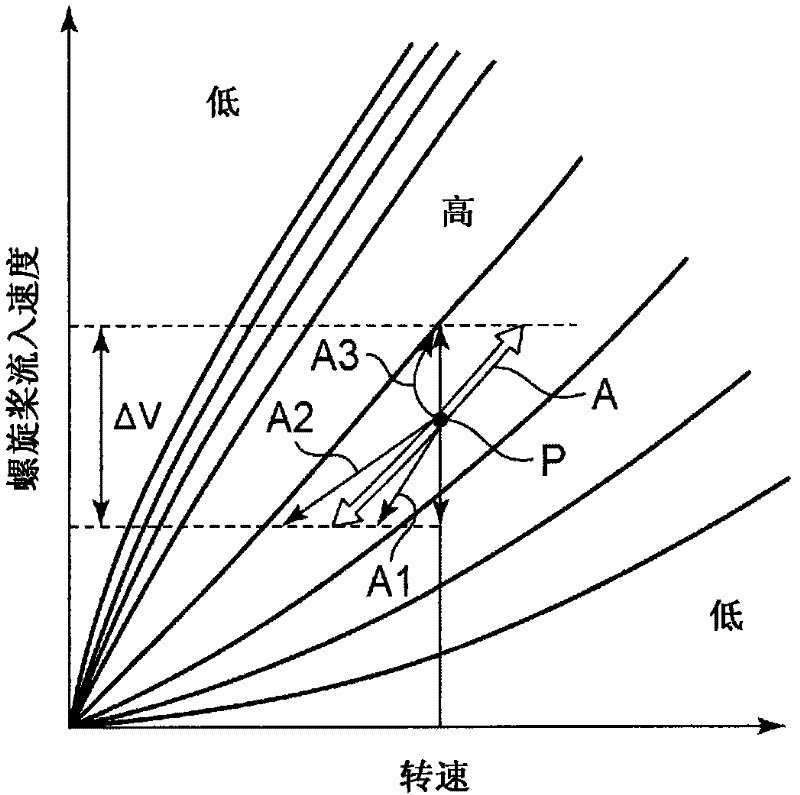

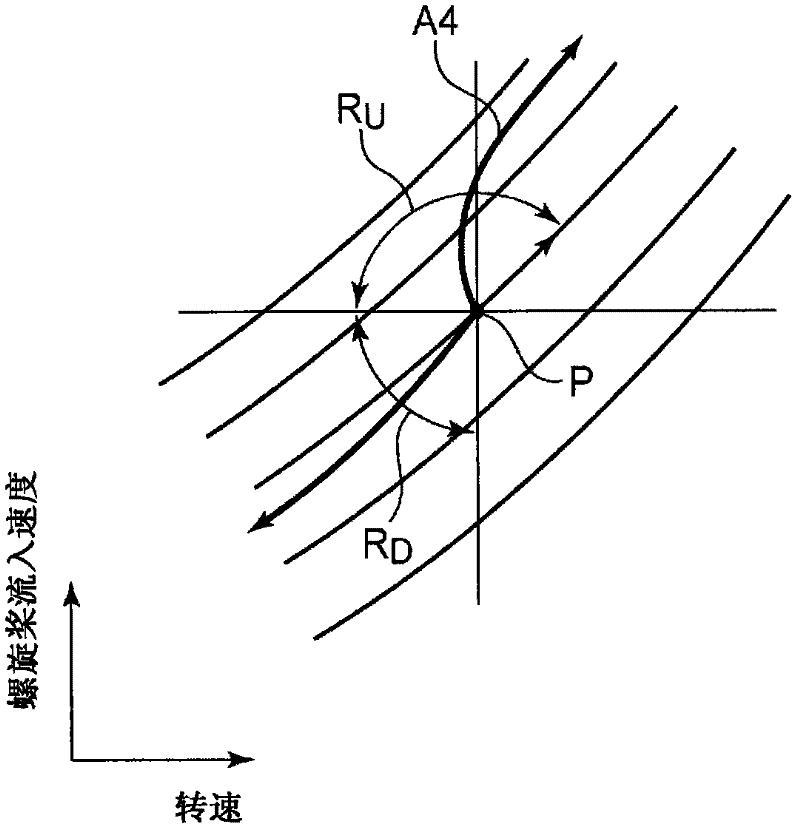

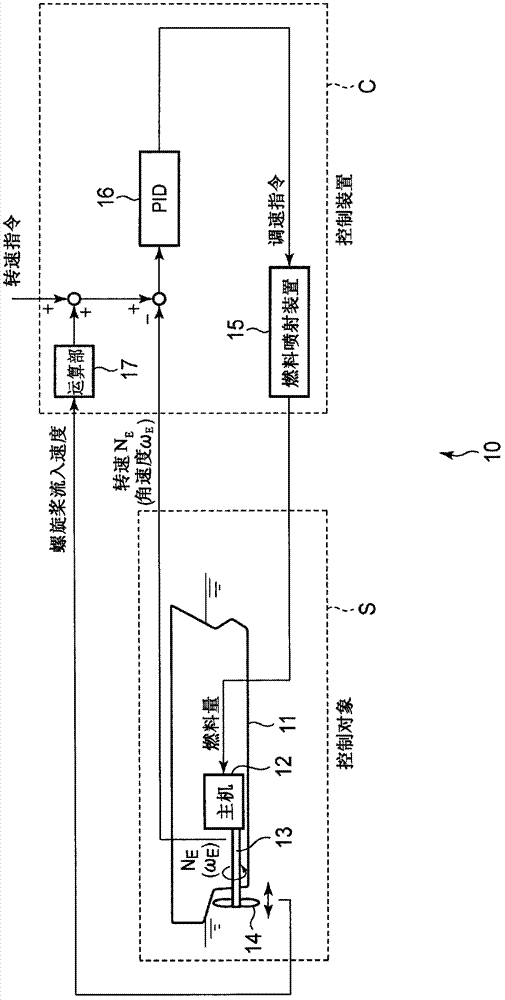

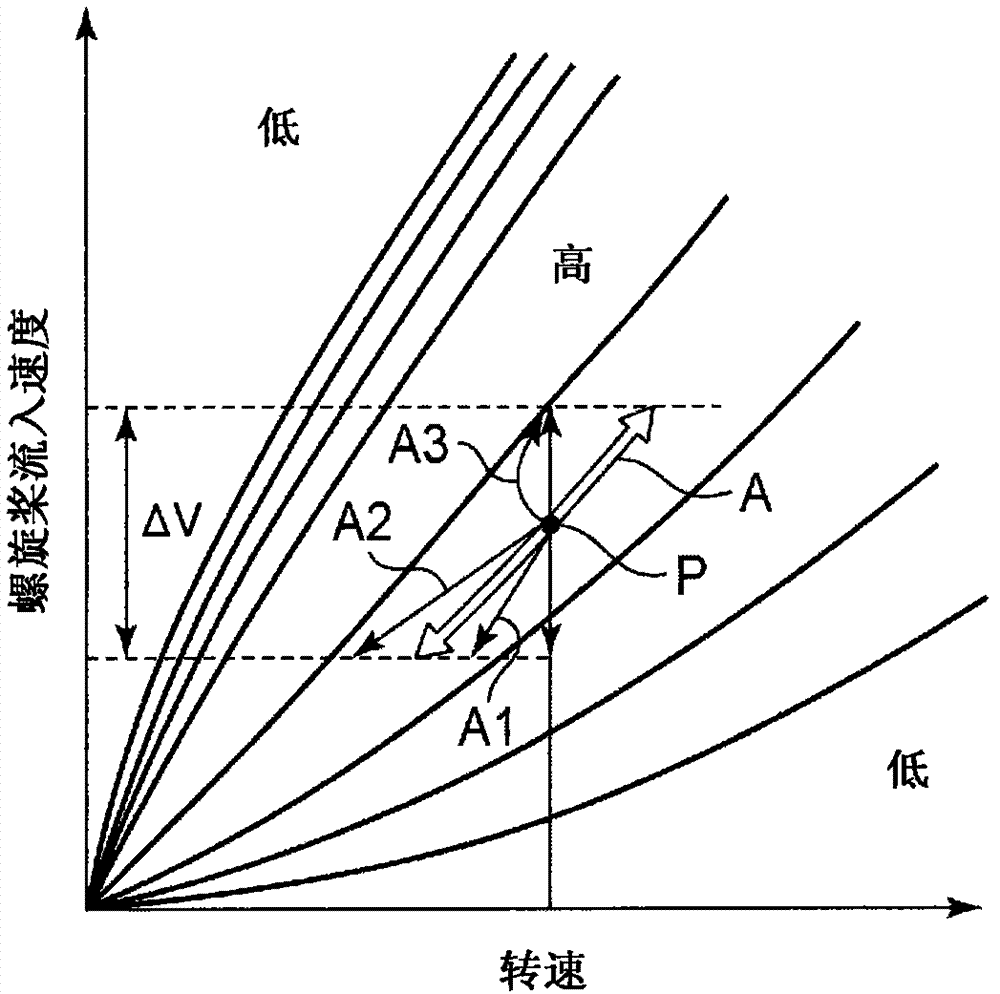

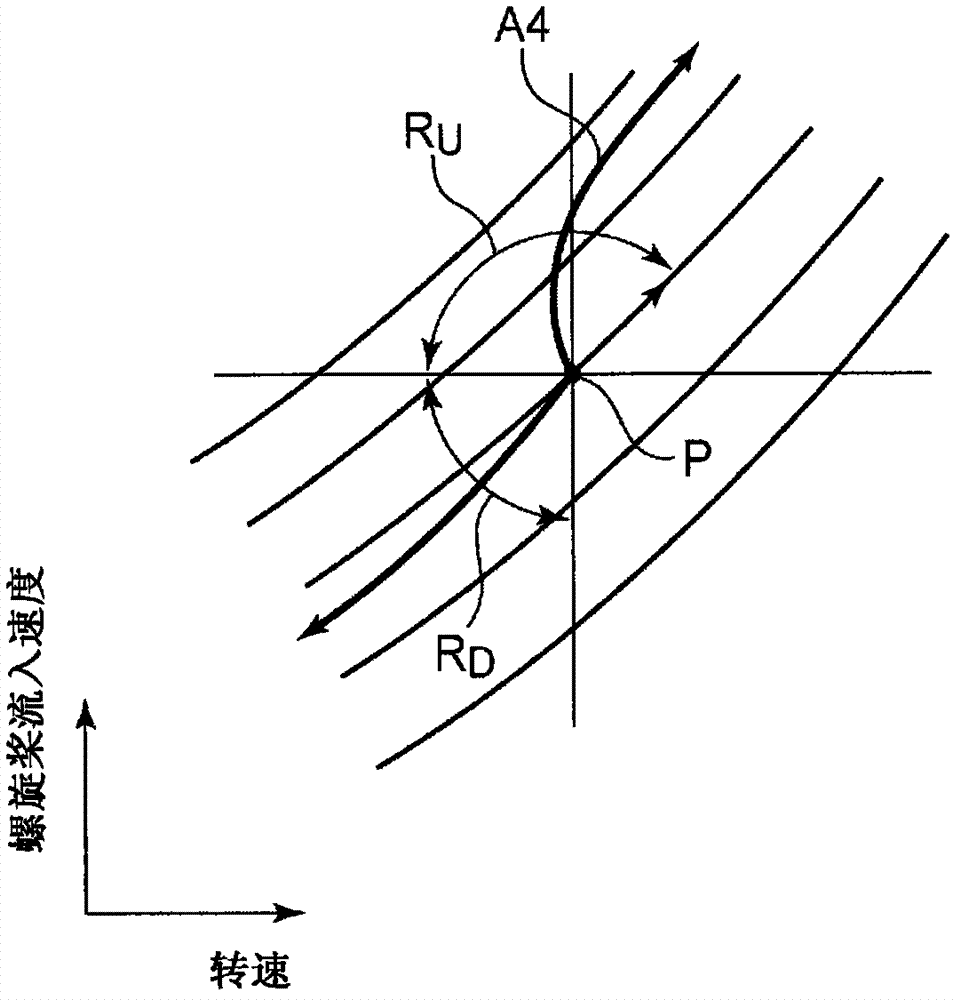

Ship engine control system

InactiveCN102365443AImprove fuel efficiencyPower plants being motor-drivenEngine controllersControl systemFuel efficiency

A main engine is operated at an efficient rotational frequency to match fluctuations in propeller inflow velocity, and fuel efficiency is increased. The divergence between a rotational frequency command and measured variations in rotational frequency (NE) of a main axle (13) or the main engine (12) is inputted into a proportional-integral-derivative (PID) computation unit (16), and feedback control is performed on the quantity of fuel supplied from a fuel injection device (15) to the main engine (12). The propeller inflow velocity of a propeller (14) is detected and inputted into a computation unit (17). The rotational frequency command is adjusted such that the control point moves along an efficiency curve in response to fluctuations in propeller inflow velocity.

Owner:MITSUI ENG & SHIPBUILD CO LTD

Resistance reducing and energy saving type rudder blade

The invention discloses a resistance reducing and energy saving type rudder blade which comprises a hollow rudder blade body. The two ends of the rubber blade body are connected with a top plate and a bottom plate respectively to form a sealing cavity. An air cabin and a water ballast tank are arranged in the sealing cavity, water enters the water ballast tank through a water inlet pipe, and the air cabin is inflated through an air inlet pipe. Air is exhausted outwards through the air cabin, and after microbubbles are formed on the surface of a rudder, the viscidity of mixed fluid containing the microbubbles is greatly lower than that of fluid free of microbubbles, and frictional resistance is remarkably reduced. Meanwhile, the speed distribution of the fluid in a boundary layer is also influenced by the microbubbles, the thickness of the boundary layer is increased at inflow velocity, the frictional resistance is reduced, and the resistance reducing effect is obvious.

Owner:CHONGQING JIAOTONG UNIVERSITY

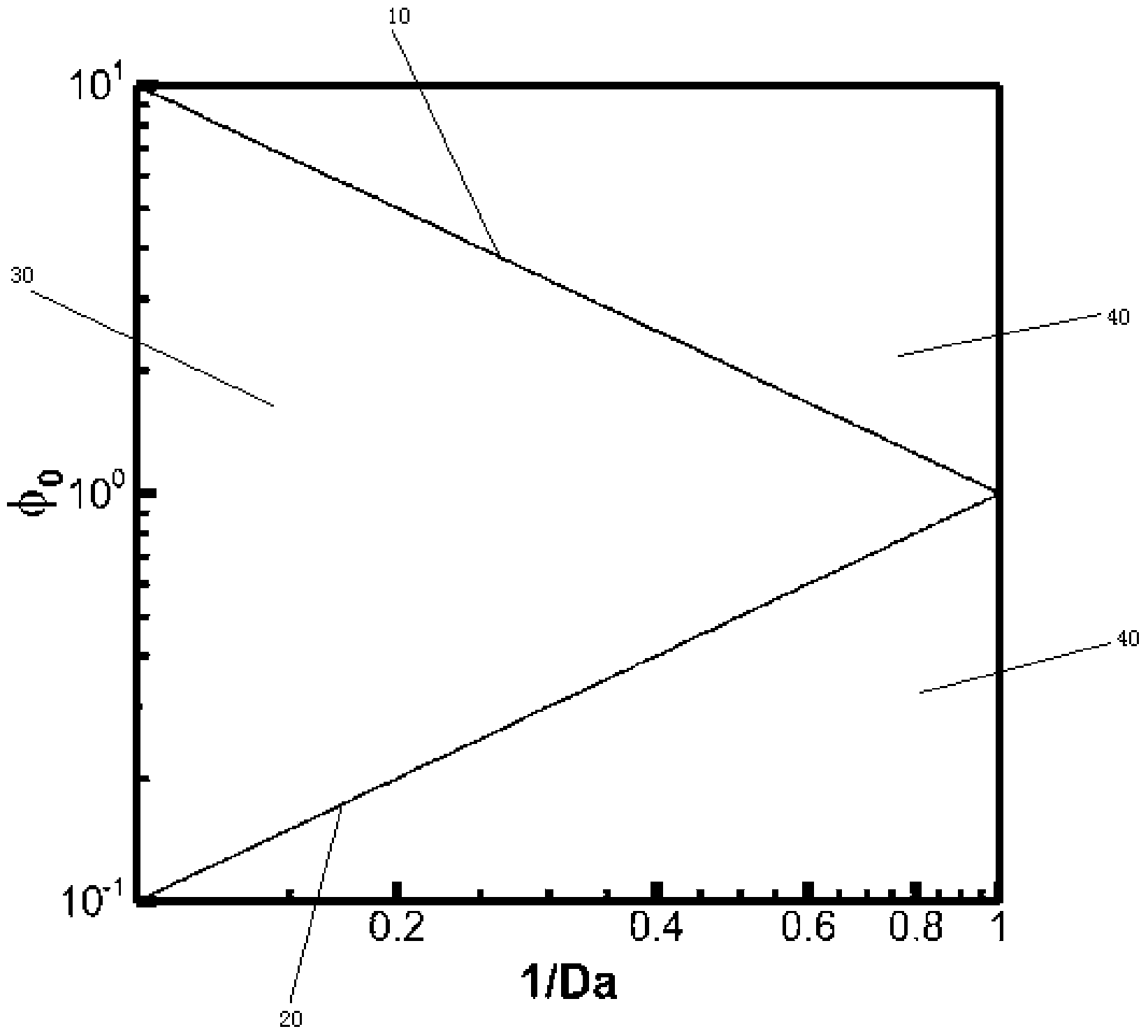

Engine, flameholder and concave cavity design method of flameholder

ActiveCN104019464ASimple methodShort design cycleContinuous combustion chamberState of artDesign cycle

The invention provides an engine, a flameholder and a concave cavity design method of the flameholder. The method includes the steps that the length value L of the concave cavity is set, and the valid equivalent ratio phi0 of fuel is determined; when the valid equivalent ratio phi0 is larger than 1, the flame time scale tau(f,r) in the rich fuel process is determined, and otherwise the flame time scale tau(f,l) in the lean burn process is determined; the Da value of the burn flow field of the concave cavity is determined according to the length value L, the air inflow velocity U , and the flame time scale tau(f,r) in the rich fuel process or the flame time scale tau(f,l) in the lean burn process, wherein the formula is that or , whether the state point (Da, phi0) is located in the flame stable region is determined according to the flame blowoff criterion, when the point (Da, phi0) is located in the flame stable region, the depth D of the concave cavity is determined according to the length depth ratio of the concave cavity, and otherwise the length value L of the concave cavity is reset. The method is simple and easy to implement, the design cycle is short, the universality is good, and the problems that the a method that the concave cavity is designed based on an even stirring reactor model in narrow in practical range and poor in physical basis in the prior art are effectively solved.

Owner:NAT UNIV OF DEFENSE TECH

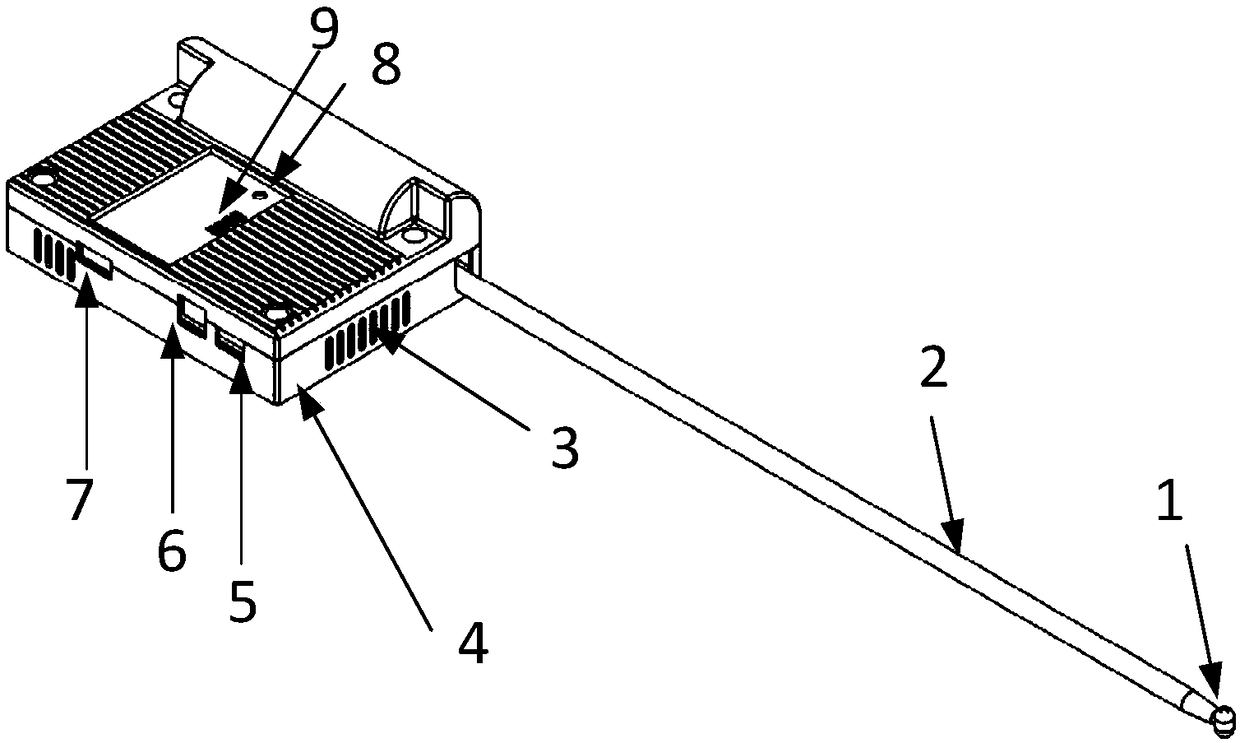

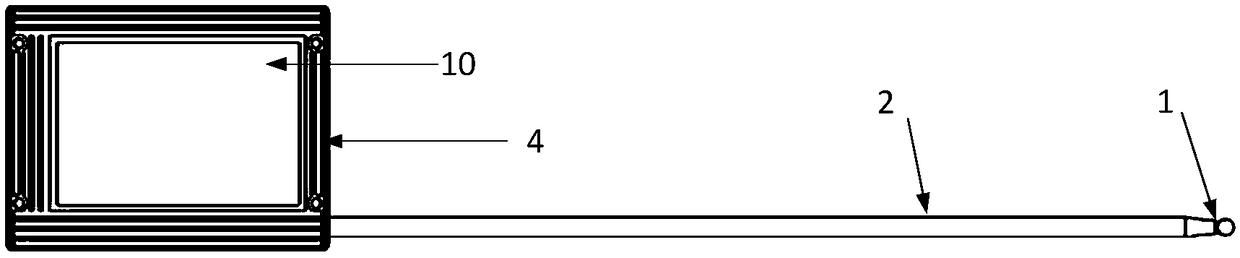

Five-hole probe measurement system integrating calibration data

PendingCN109445362AReduce computing loadImprove reliabilityProgramme controlComputer controlData displayFlight computer

The invention relates to the technical field of pressure testing, in particular to a five-hole probe measurement system integrating calibration data for a wind tunnel test or collection of inflow velocity and angle data during flight of an aircraft. The system is characterized by comprising a five-hole probe and an equipment box, the five-hole probe is in rigid fixed connection with the equipmentbox through a support rod, the equipment box is provided with a system rest button and a working state indicator light, a control circuit board is arranged in the equipment box, and a heat-dissipationvent hole, a stand-by power port, a USB communication serial port and a digital output interface are formed in the side face of the equipment box; a data display screen is arranged on the back face of the equipment box; the control circuit board comprises a minimum system circuit which comprises a micro-processor and a power supply circuit, and an external communication display circuit and a sensor data sampling circuit are arranged on the periphery of the micro-processor. Accordingly, the system reliability is improved, and development and maintenance time cost is lowered; the expandabilityis high, and a flight computer calculated load is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

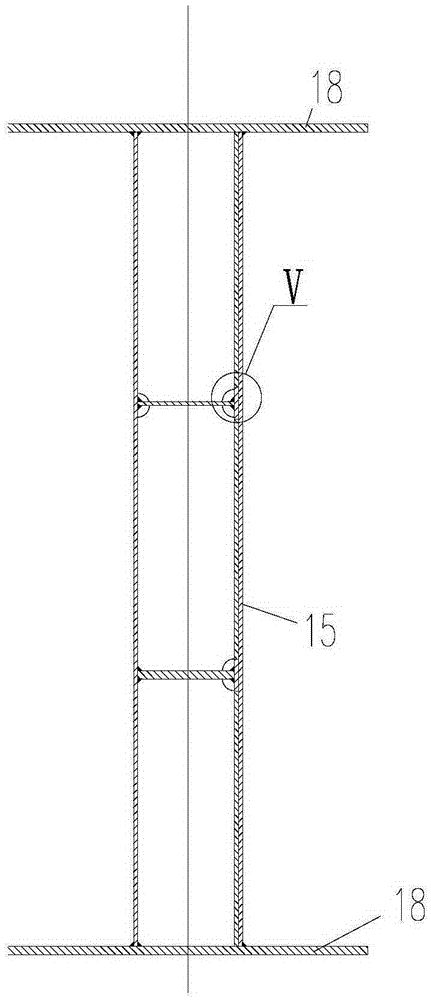

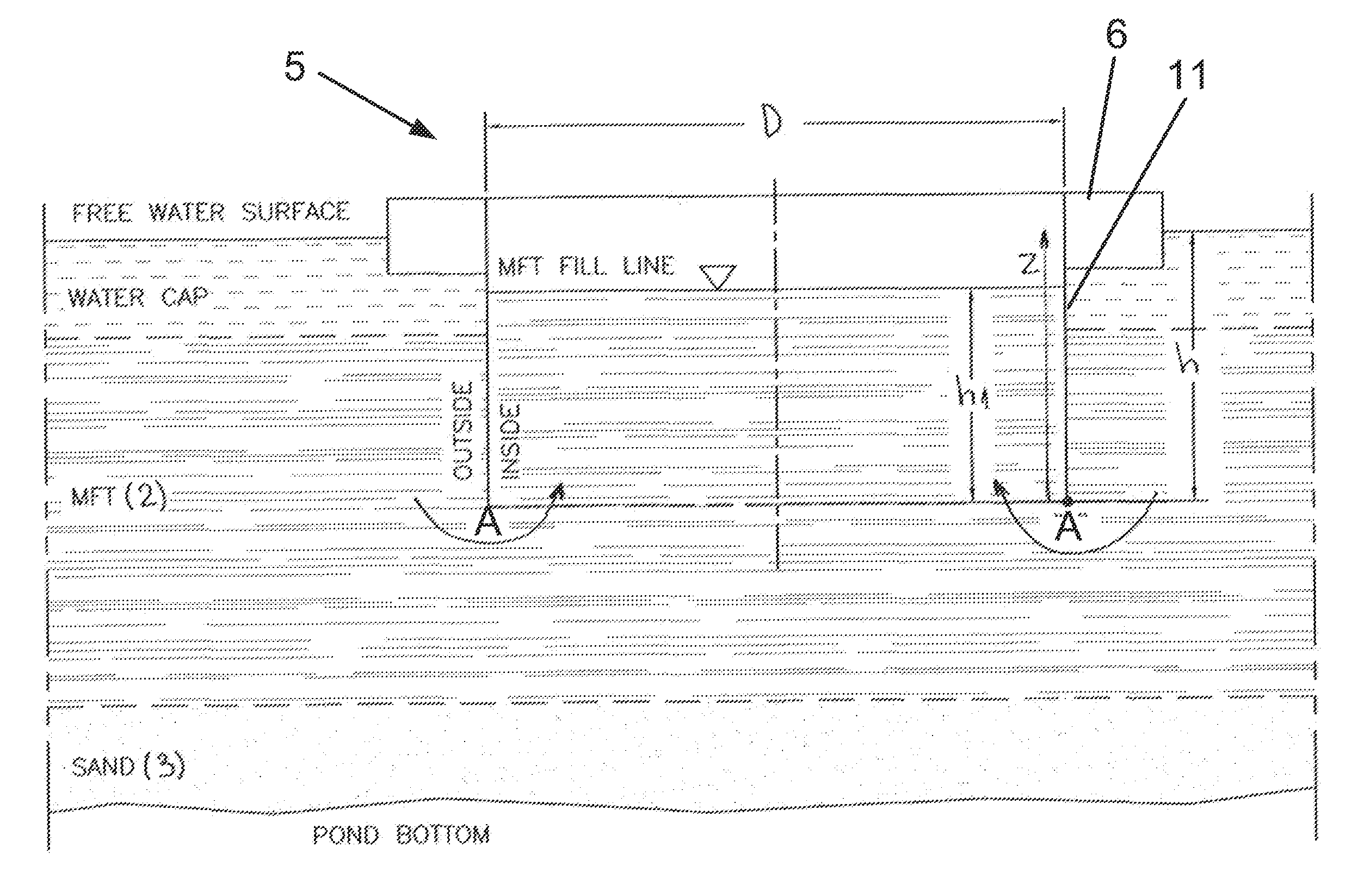

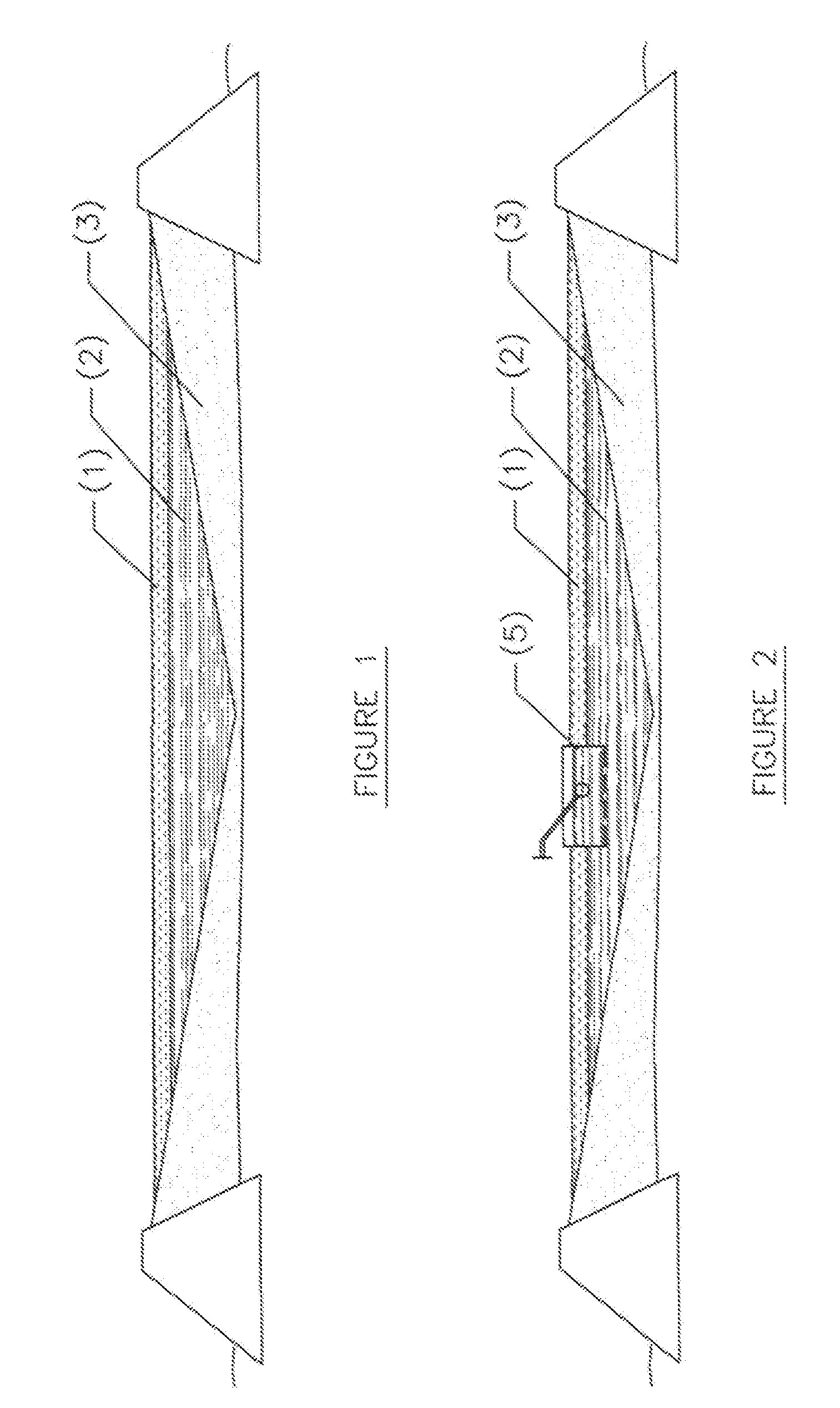

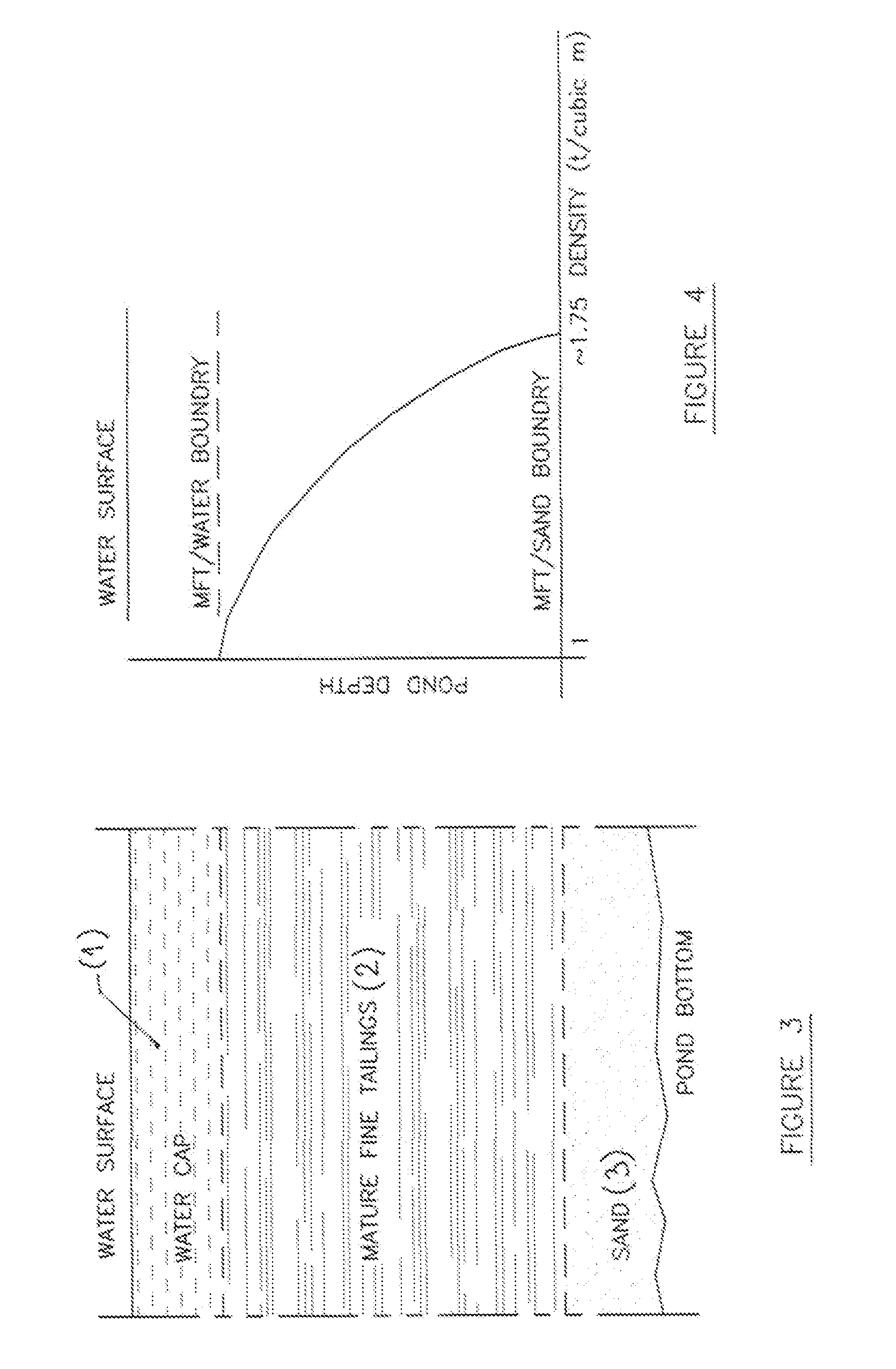

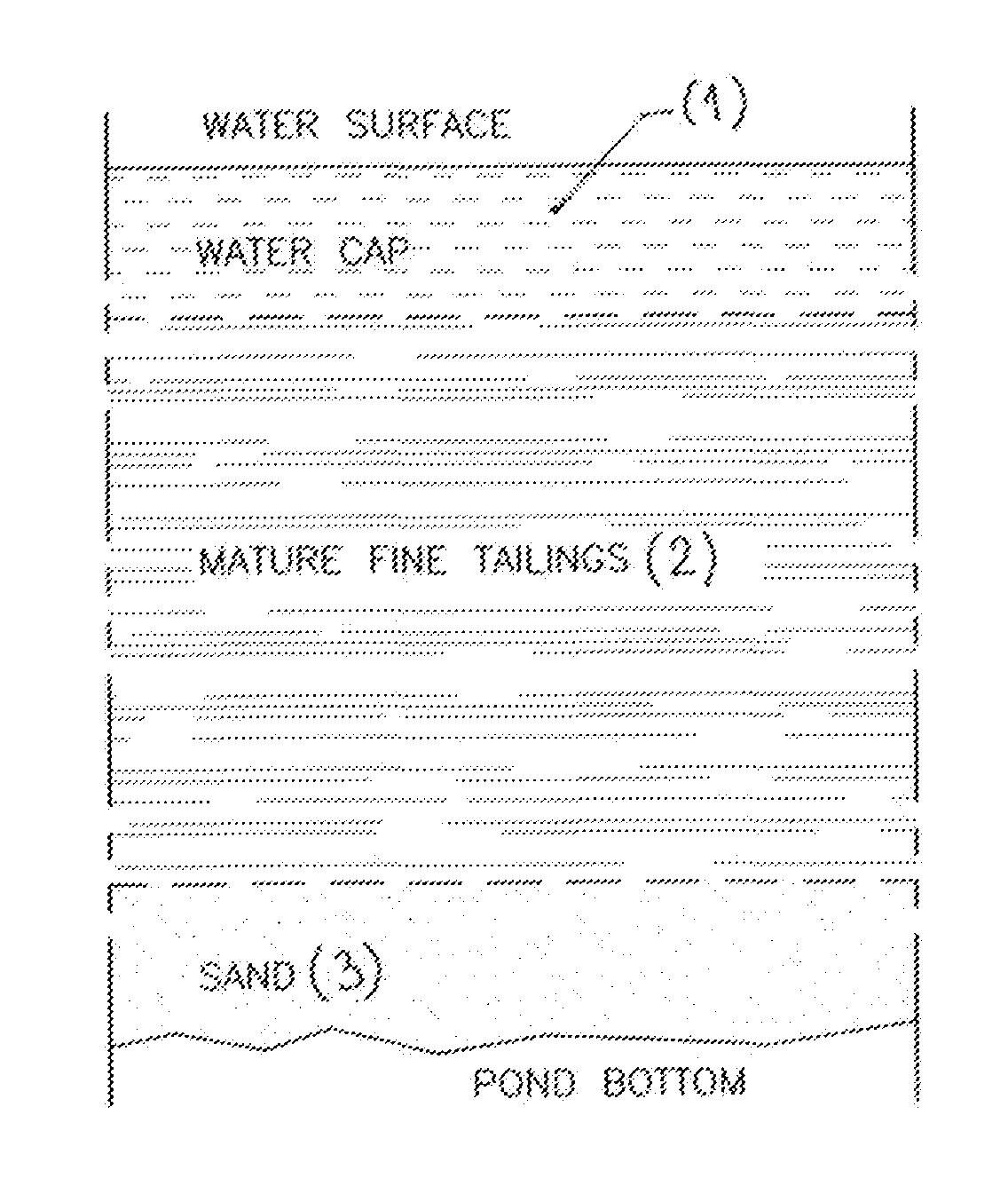

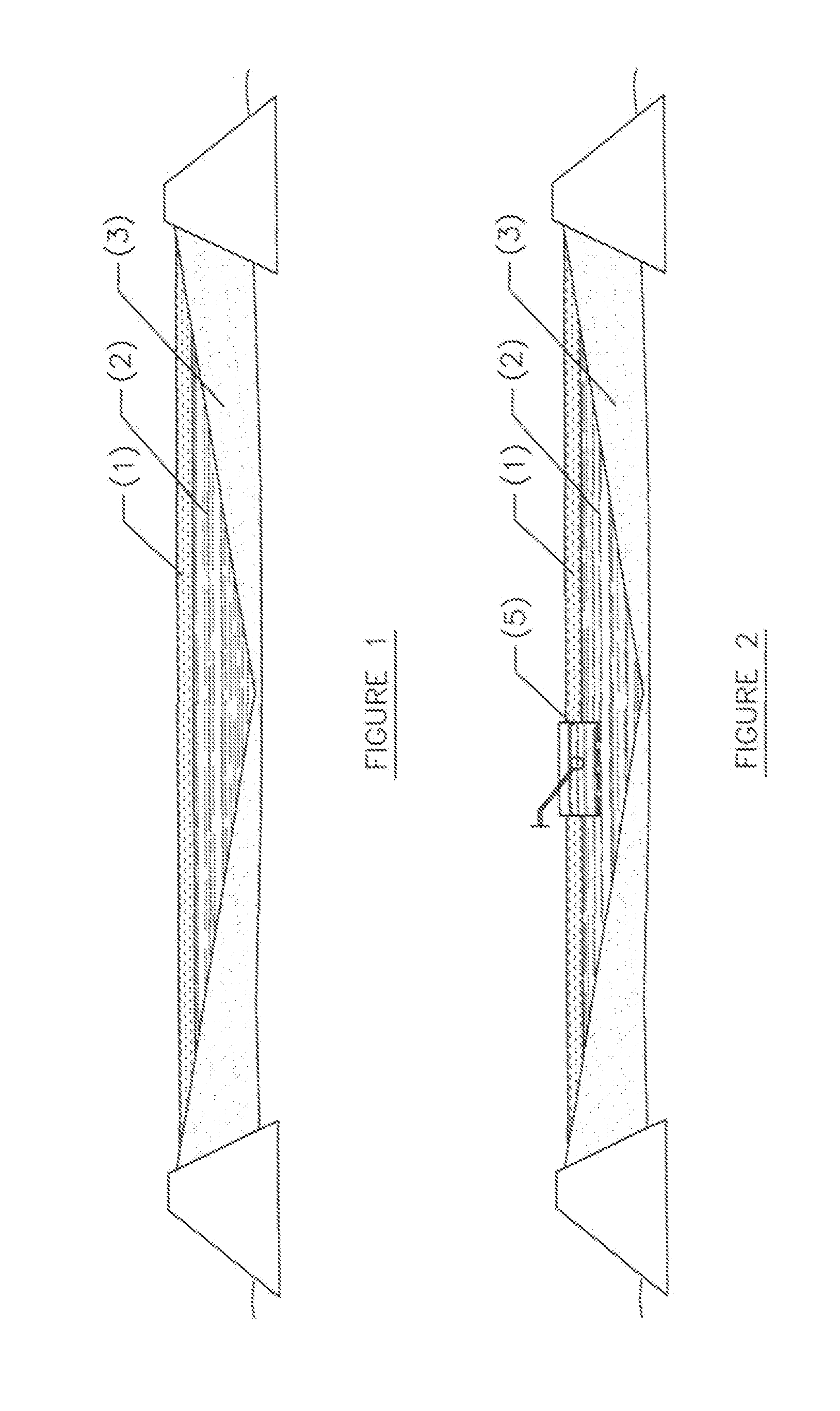

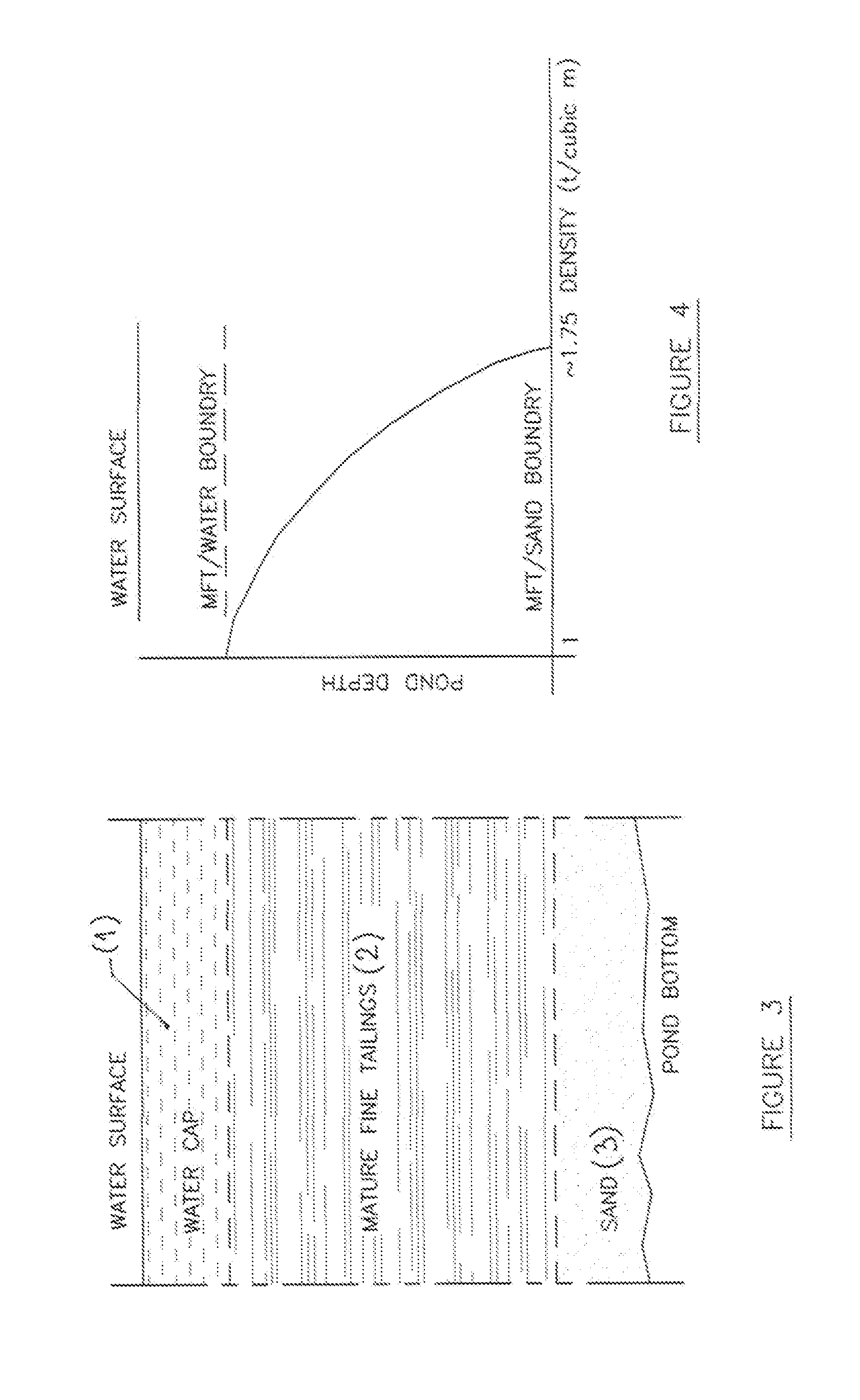

Recovering mature fine tailings from oil sands tailings ponds

ActiveUS9127427B1Waste water treatment from quariesDewatering/demulsification with mechanical meansSiphonOil sands tailings ponds

The present disclosure relates to systems and methods for recovering mature fine tailings (MFT) from oil sands tailings ponds. Some examples include a hollow, fully enclosed around its perimeter, ideally of cylindrical form, open bottom structure (a hollow conduit), of predetermined geometry, which is placed at the pond surface. The hollow conduit can penetrate MFT deposits to or below a level at which MFT of required density is located. A width or diameter of the hollow conduit can be determined with respect to the MFT inflow velocity and the corresponding shear rate, so as to enable MFT flow into the hollow conduit at a rate matching a rate at which the MFT is removed from the pond (e.g., a recovery rate). An MFT fill level inside the hollow conduit can be kept constant and equal to a required fill level throughout MFT recovery operations. MFT can enter the hollow conduit during MFT recovery operations solely under action of hydraulic head pressure. MFT can be transferred from within the hollow conduit utilizing a mechanical device such as a pump or a siphon, for transfer to shore based facilities and further processing.

Owner:TECHN ENG

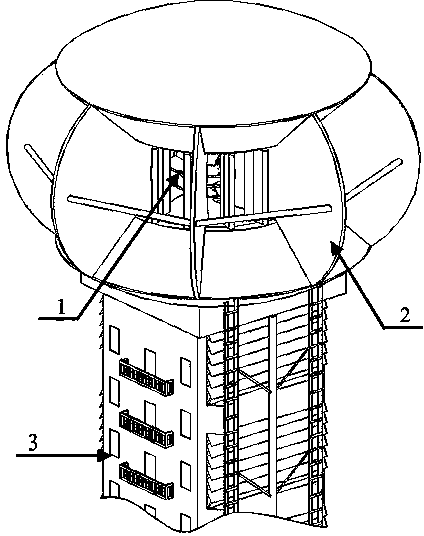

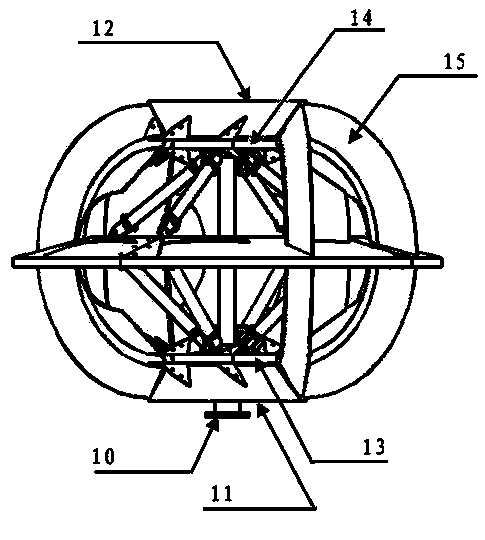

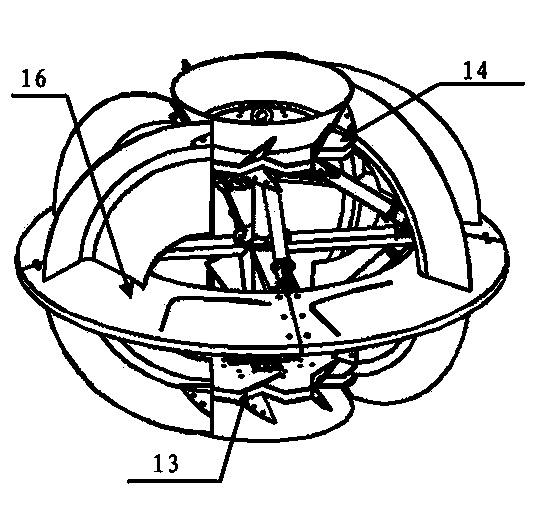

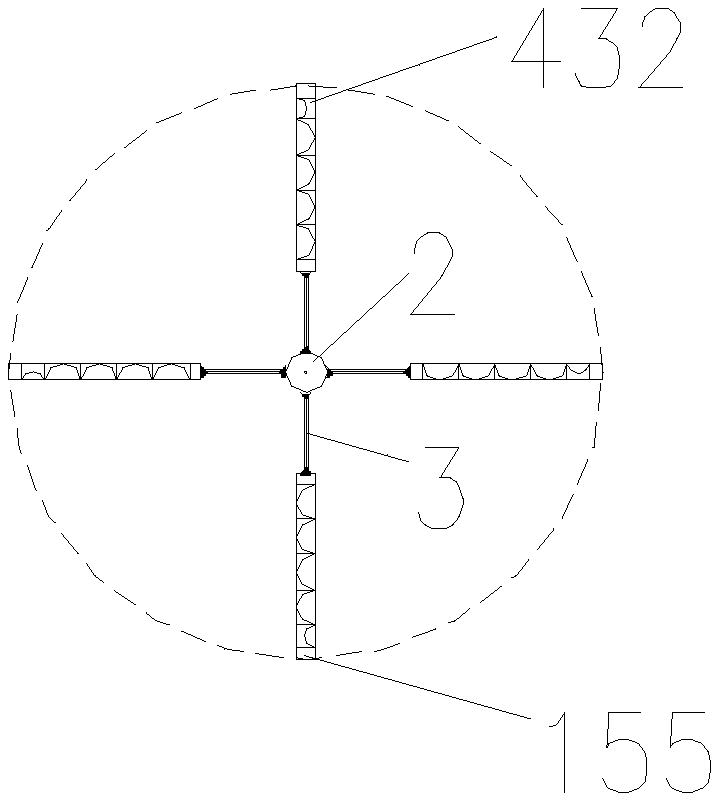

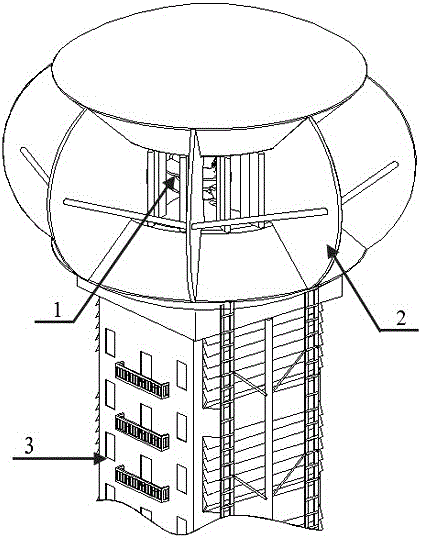

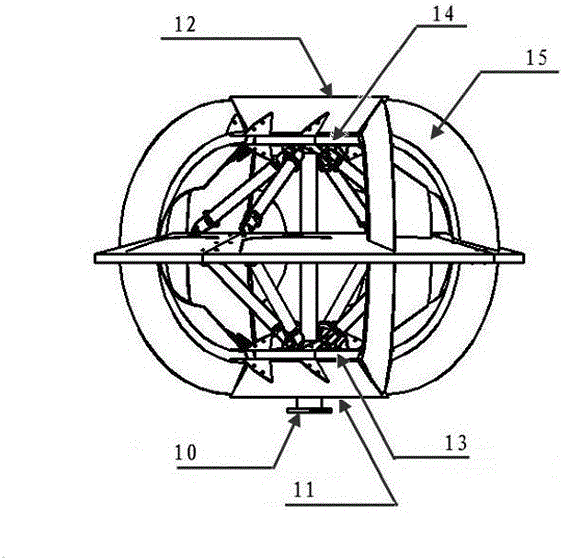

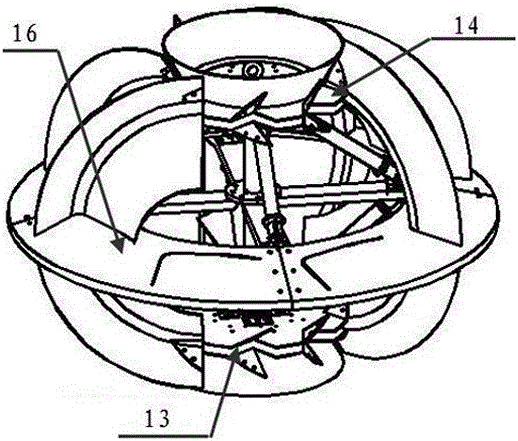

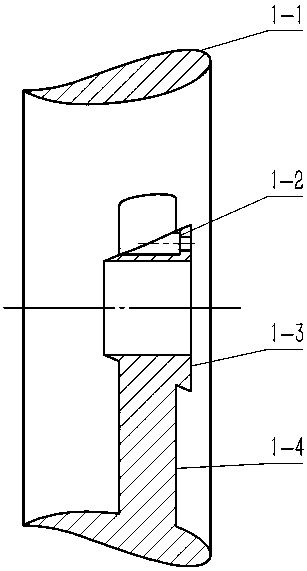

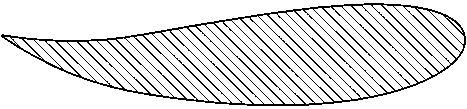

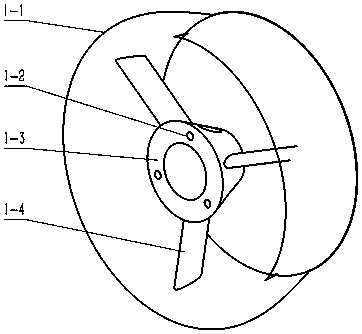

Novel perpendicular shaft distributed wind power unit

InactiveCN103711641AReduce resistanceNo noiseMachines/enginesRenewable energy generationWinding machineInflow velocity

According to the technology, the invention provides a perpendicular shaft low-wind-speed distributed wind power unit. The perpendicular shaft low-wind-speed distributed wind power unit is a practical and wind-range wind energy utilization device, can be integrated with a building and is safe in operation. The perpendicular shaft distributed wind power unit is characterized in that a structure assembly comprises a perpendicular shaft wind ball wind machine device, a ball-type potential flow cover device and a supporting device at the axial bottom of the ball-type potential flow cover device, wherein the perpendicular shaft wind ball wind machine device is arranged in the center of the ball-type potential flow cover device, the perpendicular shaft wind ball wind machine device and the ball-type potential flow cover device share the same ball center and the same perpendicular main shaft, and the external ball-type potential flow cover device is fixed. According to the main technical feature, the inner arc curved surface concave face of a blade included angle is in the head-on inflow velocity direction, and the outer arc curved surface convex face is in the backflow velocity direction to form rotating torque; meanwhile, the outer arc curved surface convex face forms the flow line curved surface in the main shaft rotating direction, the incident flow surface resistance of a blade in the wind ball rotating direction is reduced, noise is not generated, and the higher pushing resistance ratio is obtained.

Owner:邬海燕

Centrifugal compressor and manufacturing method for impeller

A centrifugal compressor and a method of manufacturing an impeller, the method wherein a projected part (17) is formed at the approximately radial center part of the impeller (11) on the negative pressure surface side of its a blade (16) so as to form a curve from the leading edge part (A) to the throat part (B) thereof. The projected part (17) is formed to be curved and then to be flat from the throat part (B) to the trailing edge part thereof. The projected part (17) is formed at a position where the relative inflow velocity of the fluid into the impeller (11) is nearly 1 in Mach number Ma. Thus, since an operating efficiency can be increased and an applicable flow range can be increased, the performance of the impeller can be increased.

Owner:MITSUBISHI HEAVY IND LTD

Aircraft lift force optimizing system

InactiveCN108069020AImprove stabilityHigh cost-effectiveHeat reducing structuresCost effectivenessInflow velocity

The invention discloses an aircraft lift force optimizing system which comprises a blunt trailing edge wing, a set of dielectric barrier discharge plasma exciters and a power supply. The circulation control cost-effectiveness of the system can reach 108 which is far higher than the maximum value 80 of traditional circulation control, energy consumption is low, an optimized key parameter combination can increase the effective inflow velocity to 35 m / s, the generated Coanda effect is more obvious, the circulation and lift force change is more obvious, and the system is suitable for popularization.

Owner:AIR FORCE UNIV PLA

Turbine impeller

InactiveCN107304682AImprove energy conversion efficiencyAppropriate Angle of AttackBlade accessoriesGas turbine plantsImpellerRotational axis

A turbine impeller supplies a high-pressure fluid through a scroll flow route and / or a exhaust supply port of a fixed nozzle and includes: blade components converting the fluid into a rotational force; and a rotor, configured with the blade components and can rotate around a specified rotational axis, wherein a direction, relative to a gas relative inflow velocity of the rotor, specified by using the fluid supply port as a starting point and subtracting a rotational velocity component of the rotor from a supply velocity component of the fluid is set to not intersect with the rotational axis of the rotor; and a shape, from a halfway portion to a front edge portion, of the blade component inclines, relative to a direction from a center of the rotor to an upstream portion of the blade component, toward front side of a rotating direction of the rotor by a specified angle.

Owner:HONDA MOTOR CO LTD

centrifugal compressor

InactiveCN104968944BReduce surge limit flowEngine manufacturePump componentsInflow velocityEngineering

Owner:MITSUBISHI HEAVY IND LTD

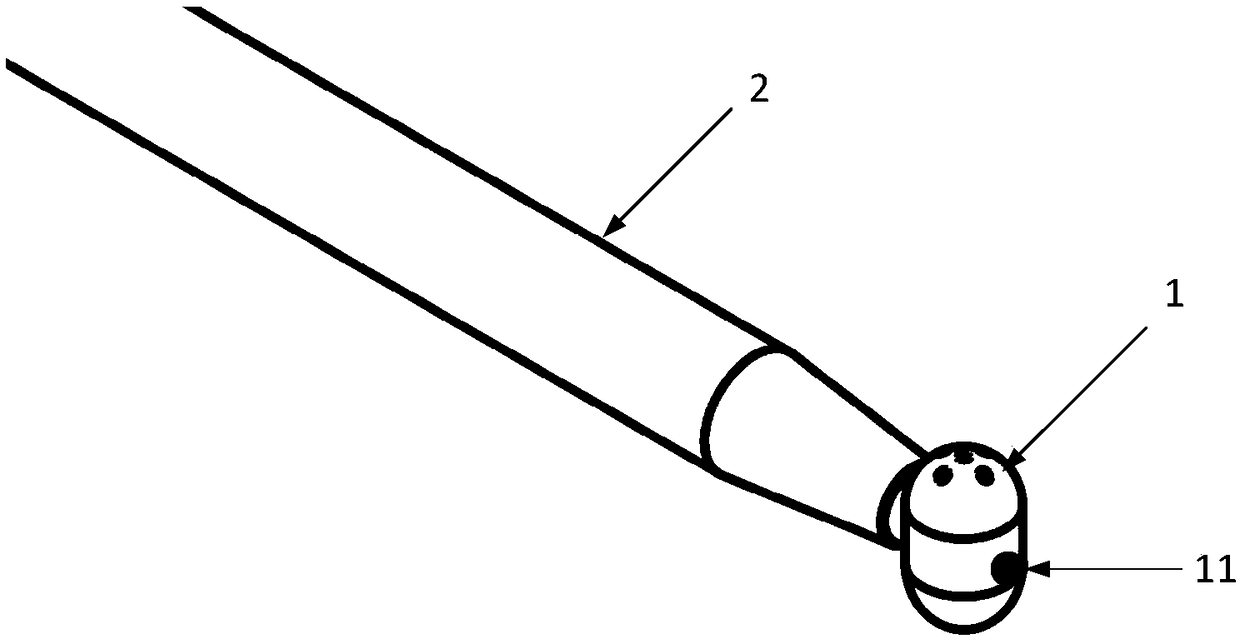

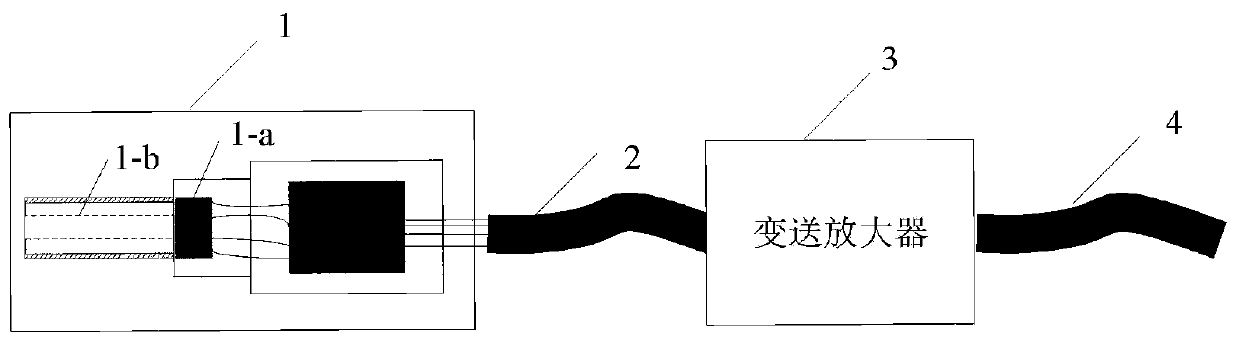

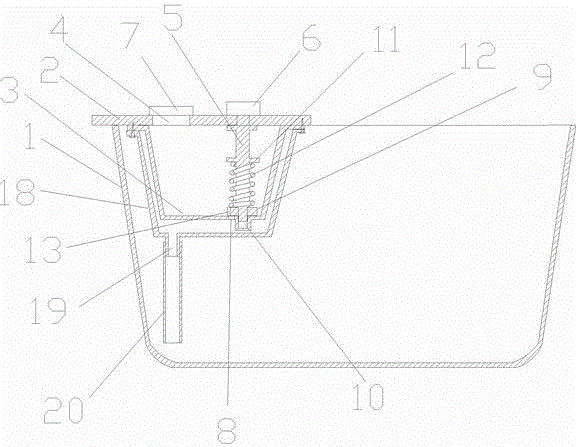

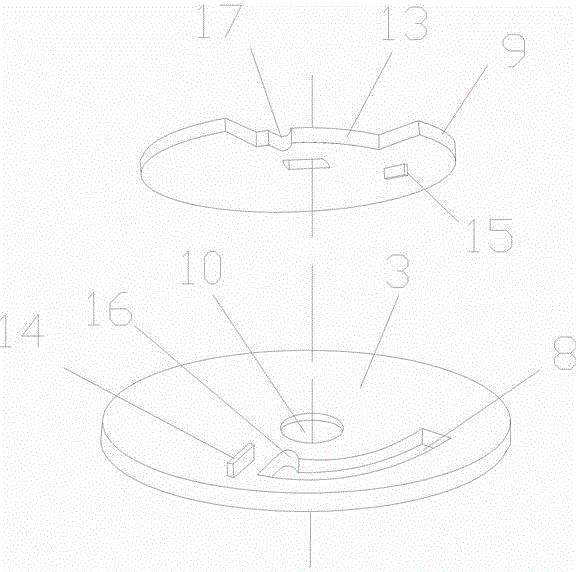

Vortex street cross-correlation flowmeter based on micro transient pressure sensors

ActiveCN110132364AReduce volumeGuarantee authenticityVolume/mass flow by dynamic fluid flow effectAudio power amplifierInflow velocity

The invention relates to a vortex street cross-correlation flowmeter based on micro transient pressure sensors. The micro transient pressure sensors are taken as measuring elements, each transient pressure sensor comprises a probe and a transmitting amplifier, each probe contains a sensitive element and a pressure guiding tube, each sensitive element is located at the tail end of the correspondingpressure guiding tube, and each pressure guiding tube is connected with a measuring pipeline; the length of each pressure guiding tube is not more than tube wall thickness and is as short as possible, and the diameter of each pressure guiding tube is consistent with the diameter of a pressure guiding hole of the corresponding probe, thereby guaranteeing that a cavity of each pressure guiding tubeis small enough; two transient pressure sensors which are the same are adopted for acquiring a vortex-induced fluctuating pressure signal, and distance l between the two sensors is less than wave length of one vortex street signal; and a vortex street signal acquired at the two transient pressure sensors is processed by utilizing a cross-correlation method, thus obtaining a vortex street convection velocity, calibrating and obtaining an inflow velocity as a convection velocity and the inflow velocity keep a linear relation, and then obtaining a measured value of the average flow rate.

Owner:TIANJIN UNIV

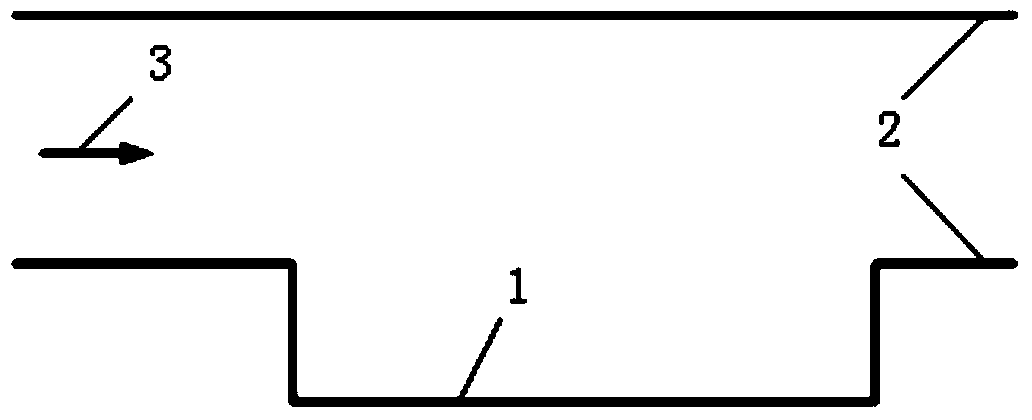

Non-electric constant temperature foot bath

The invention discloses a non-electrical constant-temperature foot tub, and the foot tub comprises a tub body and a thermal insulation cover plate, wherein a box body is fixed below the thermal insulation cover plate, a water filling nozzle capable of injecting water into the box body is arranged on the thermal insulation cover plate, a valve for releasing water is arranged at the bottom of the box body, and the valve rod top of the valve is extended out of the cover plate and fixedly connected with a rotary knob on the cover plate. In use, hot water appropriate for foot-soaking temperature is poured into the tub body, high-temperature water is injected into the box body through the water filling nozzle on the thermal insulation cover plate, the rotary knob on the cover plate is rotated to open the valve at the bottom of the box body such that the high-temperature water in the box body can slowly flow into the tub body and mix with the hot water therein, when the dissipated heat of the hot water in the tub body and the supplementary heat from the high-temperature water reach a balance state, the hot water in the tub body can keep constant temperature, the water velocity of the valve is controlled by adjusting the rotating angle of the rotary knob, and the inflow velocity of the different high-temperature water can make the hot water in the tub body at different constant temperature.

Owner:杜志刚

Multi-stage ejecting speed-increasing dust-collecting device

InactiveCN109248795AImprove dust removal effectConvenient nestingReversed direction vortexCycloneAir velocity

Owner:ANHUI UNIV OF SCI & TECH

New Vertical Axis Distributed Wind Turbine

InactiveCN103711641BReduce resistanceNo noiseRenewable energy generationMachines/enginesWinding machineInflow velocity

According to the technology, the invention provides a perpendicular shaft low-wind-speed distributed wind power unit. The perpendicular shaft low-wind-speed distributed wind power unit is a practical and wind-range wind energy utilization device, can be integrated with a building and is safe in operation. The perpendicular shaft distributed wind power unit is characterized in that a structure assembly comprises a perpendicular shaft wind ball wind machine device, a ball-type potential flow cover device and a supporting device at the axial bottom of the ball-type potential flow cover device, wherein the perpendicular shaft wind ball wind machine device is arranged in the center of the ball-type potential flow cover device, the perpendicular shaft wind ball wind machine device and the ball-type potential flow cover device share the same ball center and the same perpendicular main shaft, and the external ball-type potential flow cover device is fixed. According to the main technical feature, the inner arc curved surface concave face of a blade included angle is in the head-on inflow velocity direction, and the outer arc curved surface convex face is in the backflow velocity direction to form rotating torque; meanwhile, the outer arc curved surface convex face forms the flow line curved surface in the main shaft rotating direction, the incident flow surface resistance of a blade in the wind ball rotating direction is reduced, noise is not generated, and the higher pushing resistance ratio is obtained.

Owner:邬海燕

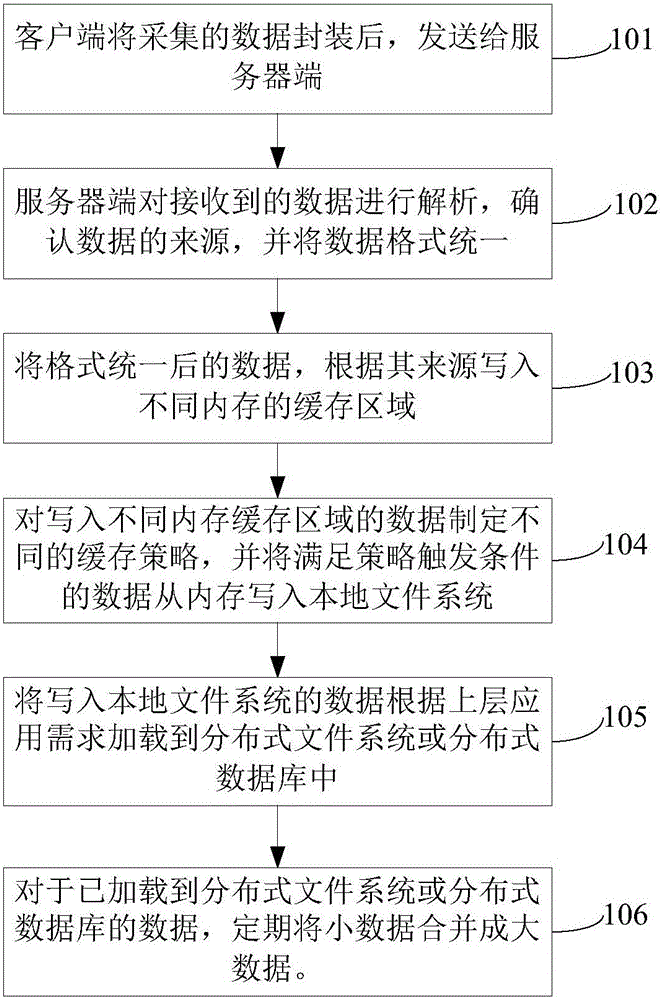

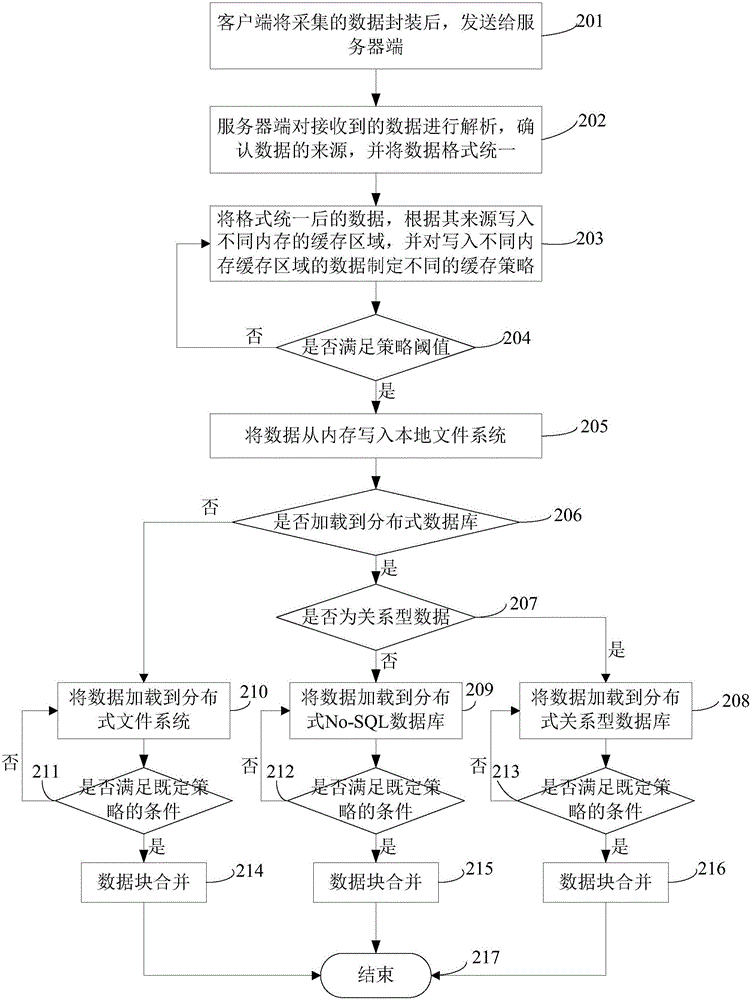

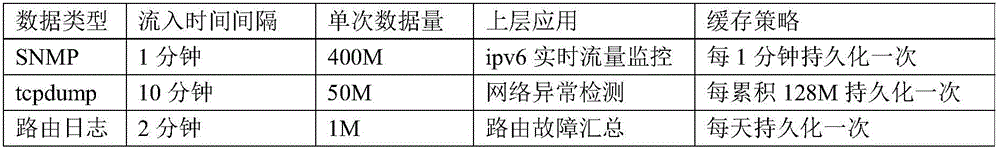

A Large-Scale Network Streaming Data Cache Writing Method

ActiveCN103699660BProcessing speedSave storage spaceSpecial data processing applicationsStreaming dataSmall data

The invention provides a large-scale network streaming data cache-write method including that a client side packages collected data and sent the same to a server side; the server side analyzes the received data to determine data resources and unifies data formats; the data with uniform formats are written into cache regions of different inner memories according the data resources; different cache strategies are made according to the data which are written into the cache regions of the different inner memories, and the data meeting strategy trigger conditions are written into a local file system from the inner memories; the data written into the local file system are loaded to a distributed file system or distributed database according to the upper application demand; and to the data which are loaded to the distributed file system or distributed database, small data blocks are combined into large data blocks at fixed time. The large-scale network streaming data cache-write method is applicable to write of large-scale network data that are of different resources and different inflow velocity by the aid of a multi-stage cache mechanism.

Owner:CERTUS NETWORK TECHNANJING

Method of Reducing Surface Resistance Based on Plasma Exciting Device

InactiveCN103287575BReduce frictional resistanceInhibitionVehicle body stabilisationAxle-box lubricationLow speedEngineering

The invention discloses a method for reducing the surface resistance based on a plasma exciting device in the technical field of power of aircraft or ground transportation. Through an electrode array arranged on a target plane, a power supply and a controller used for regulating a parameter of the power supply, and different working states of the controller, a period controllable induced fluid is generated on the inner layer of a turbulent boundary layer on the surface of a solid, a bursting process and a downward-sweeping process of the inner layer of the turbulent boundary layer are interfered, the generation and the propagation of a coherent structure and a low-speed streak of the inner layer of the turbulent boundary layer are inhibited, and the effect of reducing the turbulent friction resistance on the surface of the solid is achieved. The plasma exciting device is capable of effectively inhibiting the turbulent friction resistance under a high reynolds number, has the characteristics of simple structure, low energy consumption, stable performance and no additional load, is capable of being actively regulated, and is suitable for a larger inflow velocity without additional parasite drag.

Owner:SHANGHAI JIAO TONG UNIV

Recovering mature fine tailings from oil sands tailings ponds

ActiveUS20160228796A1Waste water treatment from quariesDewatering/demulsification with mechanical meansSiphonPipeflow

The present disclosure relates to systems and methods for recovering mature fine tailings (MFT) from oil sands tailings ponds. Some examples include a hollow, fully enclosed around its perimeter, ideally of cylindrical form, open bottom structure (a hollow conduit), of predetermined geometry, which is placed at the pond surface. The hollow conduit can penetrate MFT deposits to or below a level at which MFT of required density is located. A width or diameter of the hollow conduit can be determined with respect to the MFT inflow velocity and the corresponding shear rate, so as to enable MFT flow into the hollow conduit at a rate matching a rate at which the MFT is removed from the pond (e.g., a recovery rate). An MFT fill level inside the hollow conduit can be kept constant and equal to a required fill level throughout MFT recovery operations. MFT can enter the hollow conduit during MFT recovery operations solely under action of hydraulic head pressure. MFT can be transferred from within the hollow conduit utilizing a mechanical device such as a pump or a siphon, for transfer to shore based facilities and further processing.

Owner:TECHN ENG

A method for on-line recovery of ion exchange resin

ActiveCN103638993BExtended use timeLower recovery costsIon exchange beds cleaning/rinsingRecovery methodIon exchange

An on-line recovery method for ion exchange resin is preformed in an ion exchange reactor and comprises the following steps: employing desalinized water to perform one-time washing on inactive ion exchange resin, wherein the one-time washing comprises alternative backwashing and forward washing and the water inflow velocity of backwashing is larger than the water inflow velocity of the forward washing; immersing ion exchange resin subjected to one-time washing with an acidic solution; immersing ion exchange resin with a mixed recovery solution composed of a Na2SO4 solution with a mass concentration of 10-12% and a NaOH solution with a mass concentration of 5-6%, and continuously introducing O3 into the ion exchange reactor when immersing; and performing regeneration on ion exchange resin by employing a NaOH solution or a KOH solution. By employing the on-line recovery method for ion exchange resin to perform on-line recovery on inactive resin, resin is used again after majority functions of the resin are recovered, so that the recovery cost is reduced, the service life of ion exchange resin is prolonged, and energy saving, emission reduction, cost reduction and effect improvement are facilitated.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

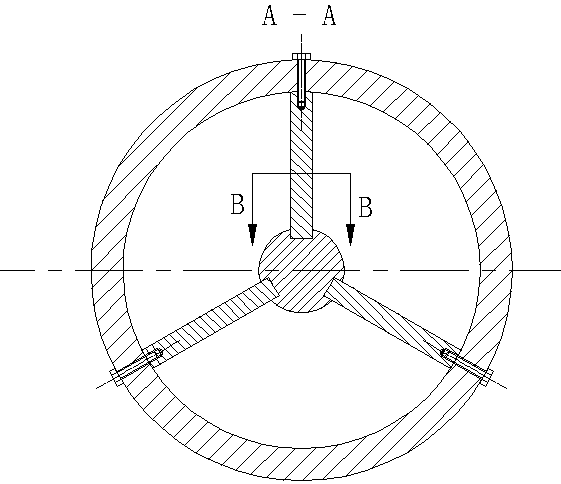

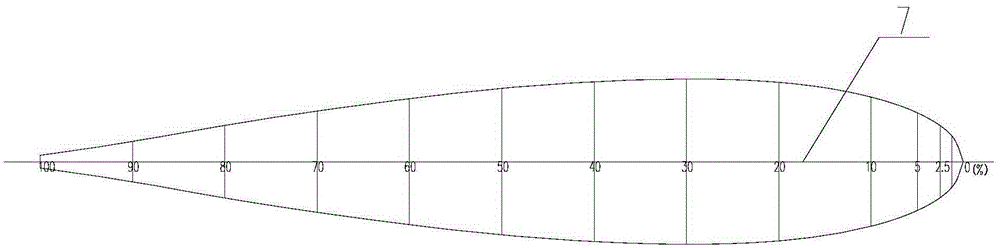

Flow guiding shield used for autonomous underwater vehicle

PendingCN108482629AImprove efficiencyPlay a protective effectPropulsive elementsMarine engineeringPropeller

The invention belongs to the field of autonomous underwater vehicle equipment, discloses a flow guiding shield used for an autonomous underwater vehicle and particularly relates to the flow guiding shield used in a propelling system of the autonomous underwater vehicle. A novel practical electrically-driven underwater thruster the application number of which is 200620055186.1 is disclosed in the prior art, and according to the underwater thruster, an axial section of the flow guiding shield is designed in a wing shape, so that the purposes of high efficiency and low power consumption are achieved, but which type of wings should be adopted is not specifically indicated in the prior art, and the defects of poor structural universality and a limited application range still exist. According tothe flow guiding shield, a wing type NACA6721 and a 3D printing technology are adopted for designing the flow guiding shield which is simple in structure and wide in application range, the inflow velocity is increased, the propelling force of propellers is enhanced, the efficiency of the propelling system is improved, vibration of the tail part of the propelling system is reduced, and a great protection function is achieved on the propellers. The flow guiding shield is structurally characterized in that the axial section of an outer shield body is the wing type NACA6721, the angle of attack is 10 degrees, and by adopting a spoke-type structure, not only is the intensity ensured, but also the flow guiding shield is convenient to disassemble and assemble.

Owner:CHINA JILIANG UNIV

Ship engine control system

InactiveCN102365443BImprove fuel efficiencyPower plants being motor-drivenEngine controllersControl systemFuel efficiency

Owner:MITSUI ENG & SHIPBUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com