Passive type MEMS flow-induced vibration strengthened heat transfer apparatus and heat transfer method

An enhanced heat transfer and passive technology, applied in microstructure devices, microstructure devices composed of deformable elements, piezoelectric devices/electrostrictive devices, etc. Heat dissipation performance, complex overall structure and other issues, to achieve the effect of simple structure, avoiding material separation, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

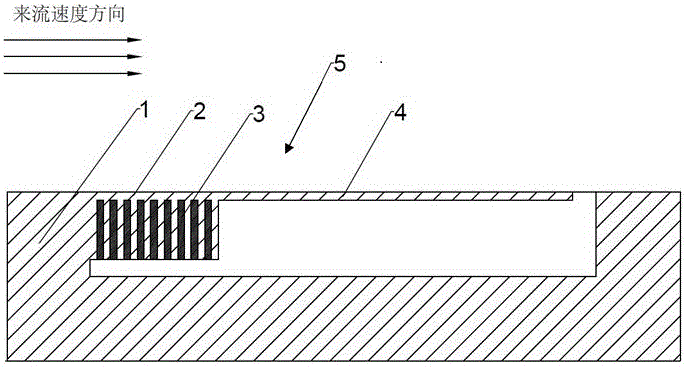

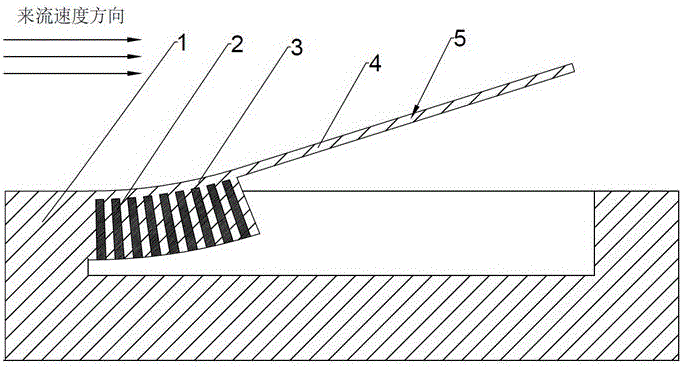

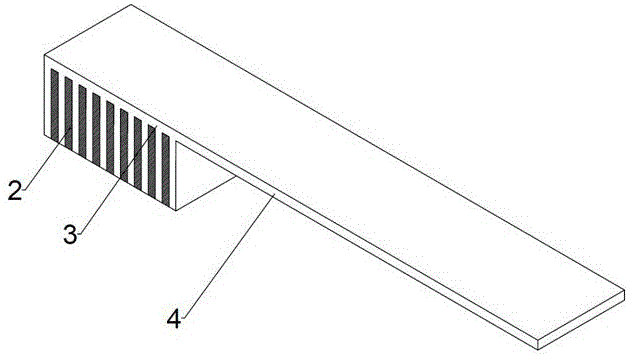

[0016] Such as figure 1 As shown, a passive temperature-controlled MEMS flow-induced vibration-enhanced heat transfer device includes a heat sink base 1, a filling material 2, a comb-shaped structure 3, and a vibration part 4; the heat sink base 1 and the heating of electronic devices Part of it is connected by a heat pipe, which can absorb the heat emitted by the electronic device and increase its temperature; the driving part is composed of a comb-like structure 3 and a filling material 2 filled between the teeth (usually a thermal expansion coefficient greater than 1x10 -5 / K The comb-tooth structure 3 is connected to the heat sink base 1; the vibrating part 4 is an extension of the top thin layer of the comb-tooth structure 3, which forms the MEMS flow together with the comb-tooth structure 3 and the filling material 2. The cantilever beam structure 5 of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com