Turbine impeller

A turbine impeller and turbine technology, which is applied to gas turbine devices, blade support elements, non-variable-capacity pumps, etc., can solve the problems of poor energy conversion efficiency and difficulty in ensuring the angle of attack, and achieve high energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings.

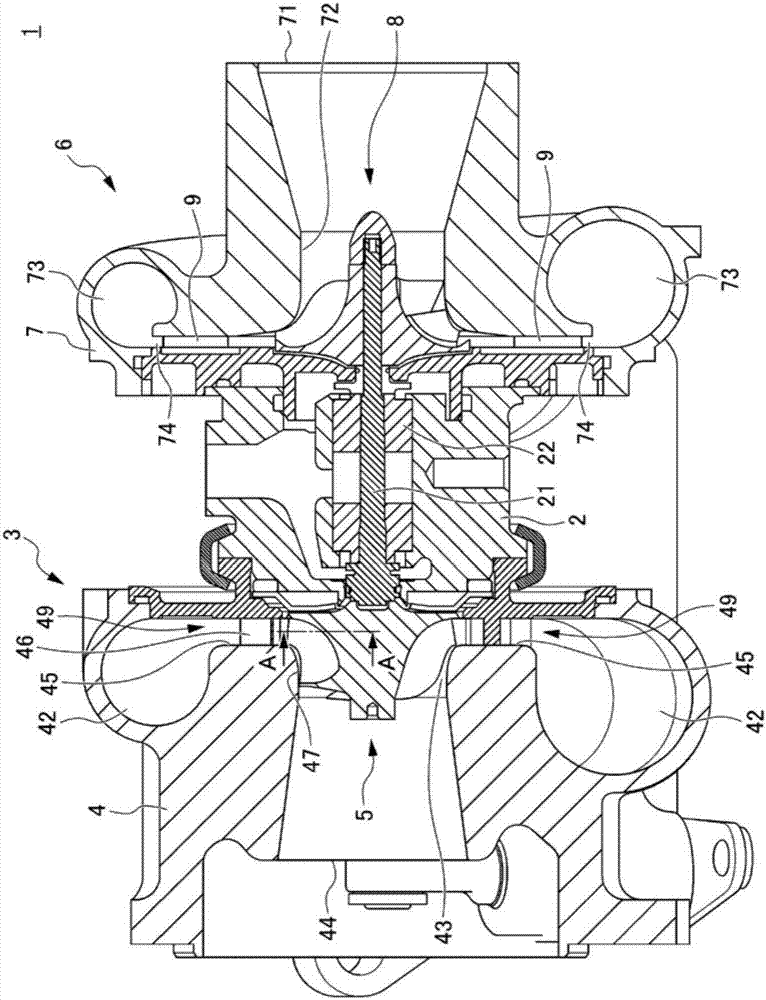

[0042] figure 1 It is a sectional view showing a supercharger 1 according to an embodiment.

[0043] A supercharger 1 according to the present invention includes a bearing housing 2 , a turbine 3 mounted on one end side of the bearing housing 2 , and a compressor 6 mounted on the other end side of the bearing housing 2 .

[0044] The bearing body 2 includes: a rod-shaped rotating shaft 21 extending between the turbine 3 and the compressor 6 ; and a bearing 22 rotatably supporting the rotating shaft 21 .

[0045] The compressor 6 includes a compressor housing 7 constituting a part of an intake passage of the internal combustion engine, a compressor impeller 8 and a diffuser 9 provided in the compressor housing 7 .

[0046] In the compressor housing 7, an annular compressor wheel chamber 72, an annular scroll flow path 73, and an annular intake flow path 74 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com