Engine, flameholder and concave cavity design method of flameholder

A technology of flame stabilizer and design method, which is applied in the design field of engine, flame stabilizer and its concave cavity, and can solve problems such as narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

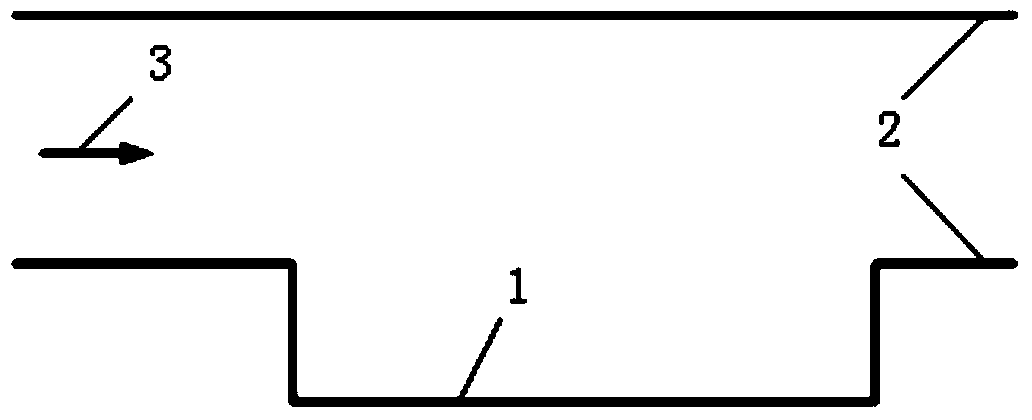

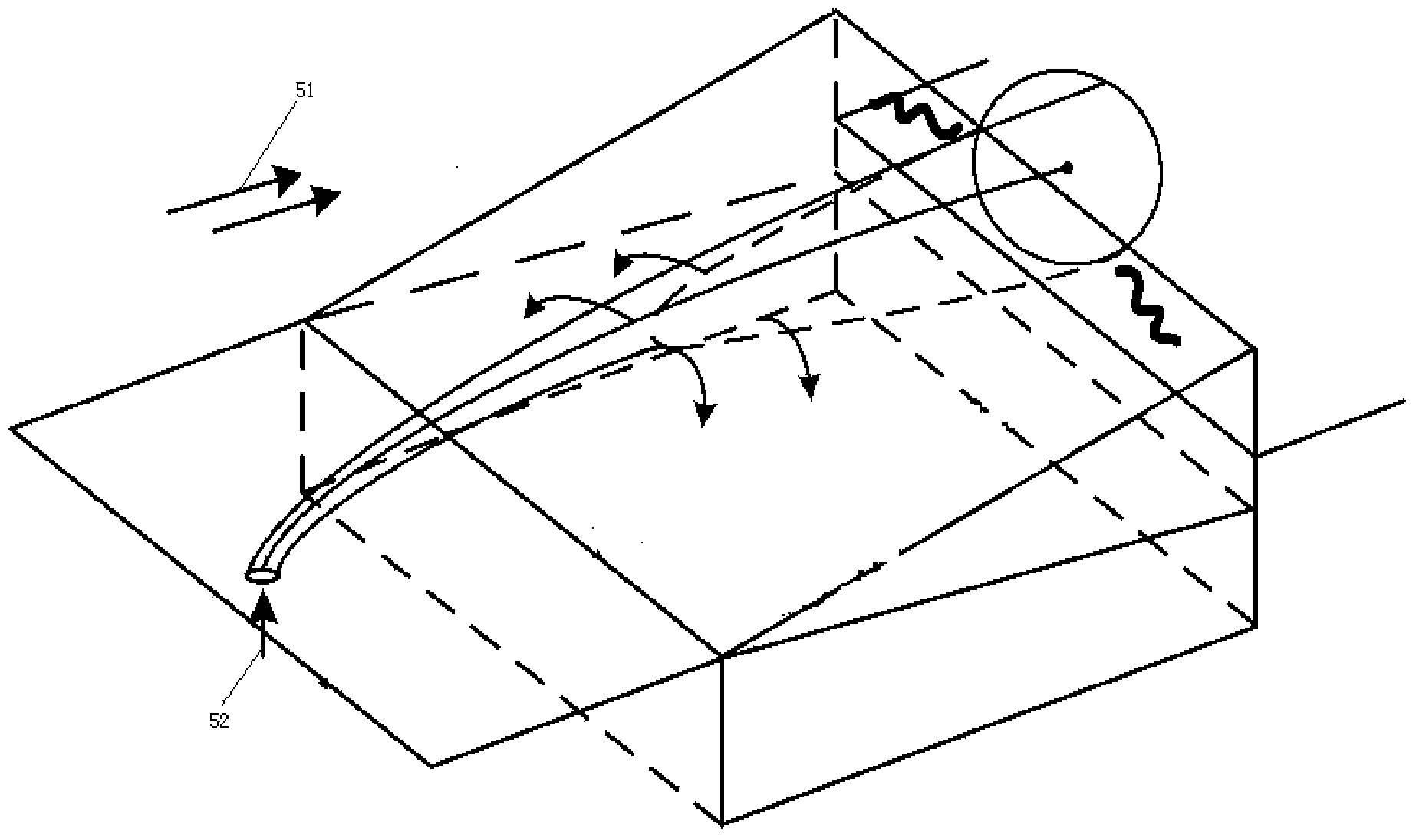

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

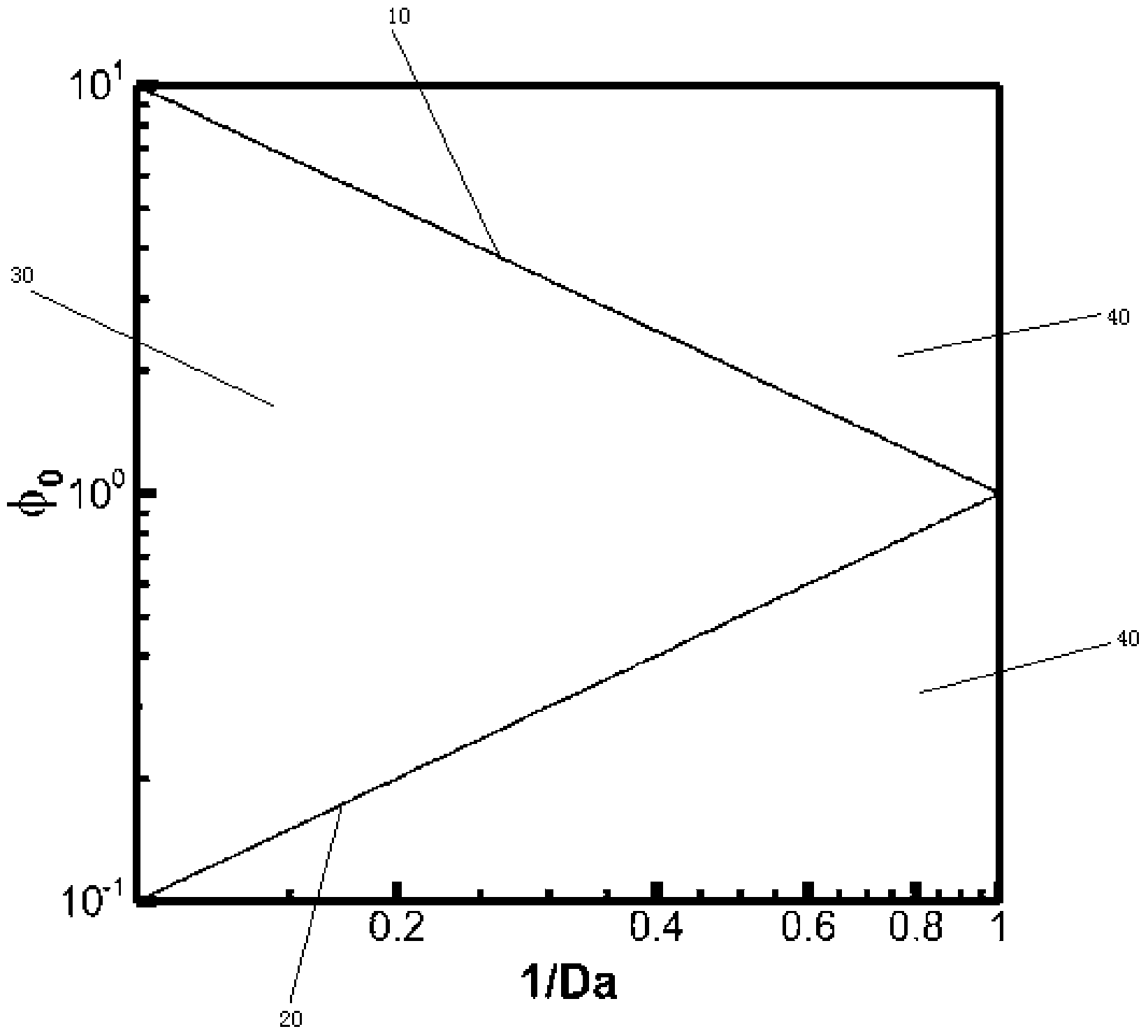

[0033] One aspect of the present invention provides a method for designing a cavity of a flame stabilizer, including: setting the length L of the cavity; determining the effective equivalence ratio φ of the fuel 0 ; When the effective equivalent ratio φ 0 When greater than 1, determine the flame time scale τ in rich combustion f,r , otherwise, determine the flame timescale τ at lean burn f,l ;According to the length value L, the incoming air velocity U and the flame time scale τ at the time of rich combustion f,r or the flame timescale τ at lean burn f,l Determine the Da number of the combustion flow field in the concave cavity, where, or Determined according to the flame blowout criterion (Da, φ 0 ) is located in the flame stable zone, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com