Resistance reducing and energy saving type rudder blade

An energy-saving, rudder blade technology, which is applied in the direction of steering with rudder, can solve the problems of limited research on rudder energy saving and drag reduction, and achieve the effects of reducing rudder cavitation, reducing mutual interference, and reducing lateral force loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

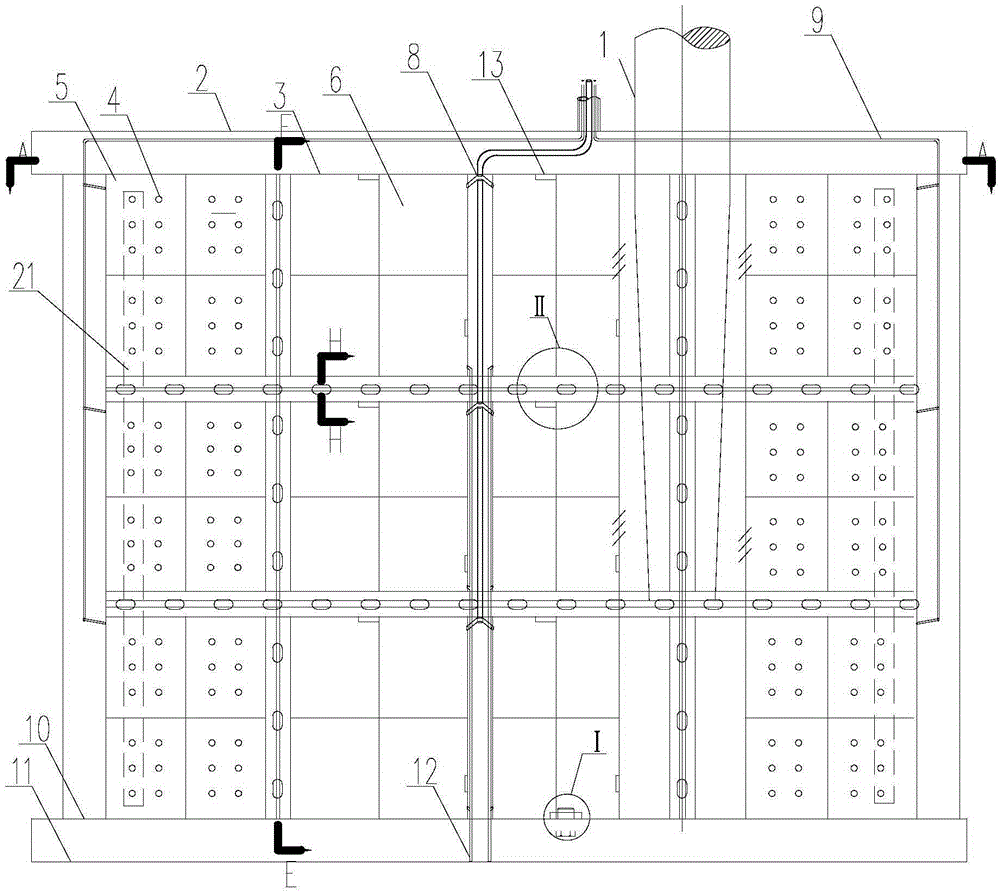

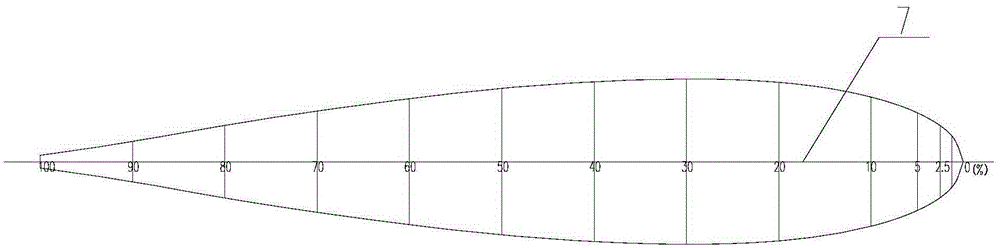

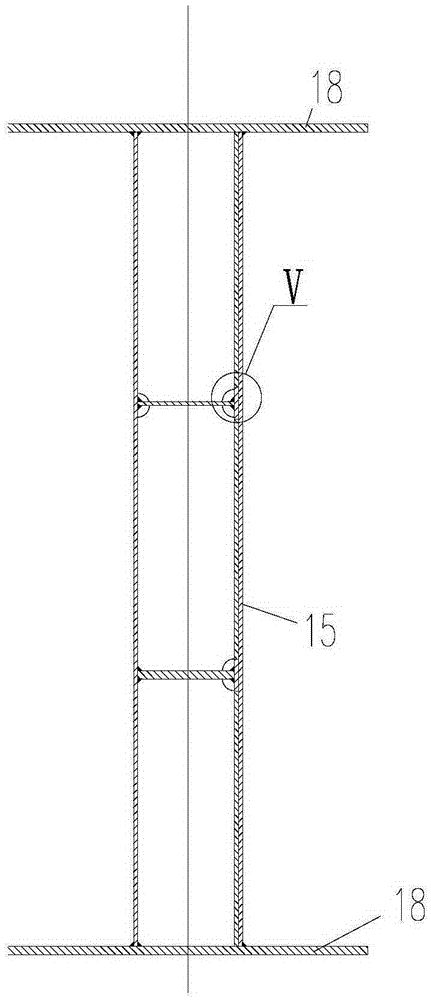

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 6 As shown, a drag-reducing and energy-saving rudder blade includes a hollow rudder blade main body. 6. The air chamber 5 is connected to the air intake pipe 9, and an exhaust hole 4 is provided on the outer surface of the air chamber 5, and the ballast water chamber 6 is connected to the air chamber 5 ballast water tank with the water inlet pipe 8 and the water outlet pipe 12 6 Ballast water tank 6 Water inlet pipe 8 Ballast water tank 6 Air tank 5 Air inlet pipe 9. The main body of the rudder blade is welded by flat steel 15, and a plurality of steel plates are welded on the main body of the rudder blade to divide it into an air chamber 5 and a ballast water tank 6. A pressure sensor is installed in the air chamber 5, and a pressure sensor is installed in the ballast water tank 6. pressure sensor 13.

[0027] In the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com