A method for on-line recovery of ion exchange resin

An ion exchange resin and exchange resin technology, applied in the direction of ion exchange, ion exchange regeneration, ion exchange bed cleaning/flushing, etc. Pollution failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail with reference to exemplary embodiments.

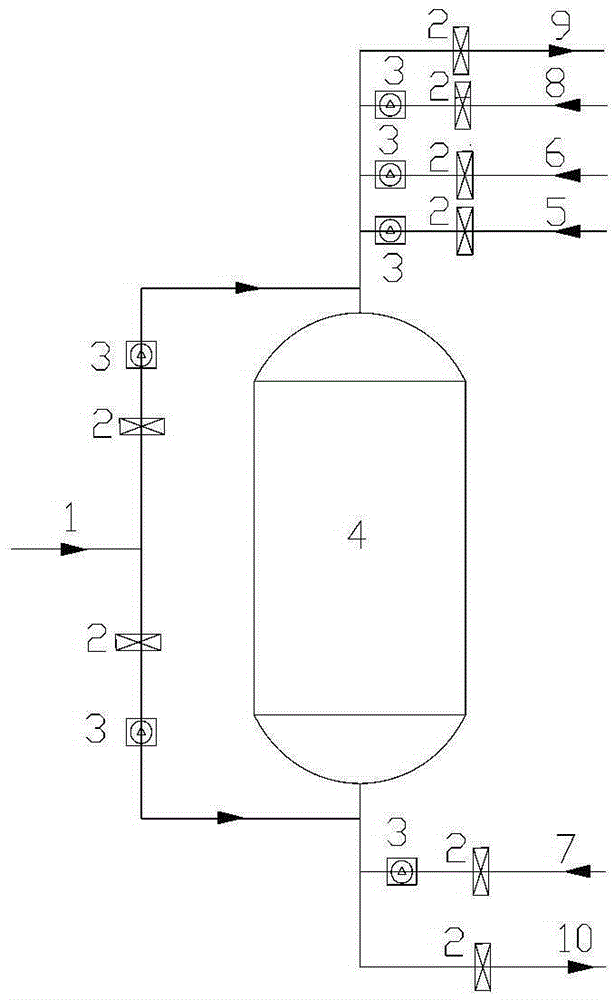

[0021] The method for on-line recovery of ion exchange resins according to an exemplary embodiment of the present invention is carried out in an ion exchange reactor, and the method includes the following steps:

[0022] (1) Rinse the expired ion exchange resin with desalinated water to remove dust, suspended solids and other substances in the ion exchange resin. Moreover, one flushing includes alternately performing backwashing and forward washing, and the flow rate of water inflow for backwashing is greater than the flow rate of water inflow for forward washing. Specifically, when using desalinated water to flush the expired ion exchange resin, backwashing is performed first, and the fast water inflow method is used for backwashing, the inflow flow rate is 45-50m / h and the backwashing time is 0.3-0.5h Under the action of high-speed water flow, the ion-exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com