Multi-stage ejecting speed-increasing dust-collecting device

A collection port and wind flow technology, which is applied in the swirl device, the device whose axial direction can be reversed, etc., can solve the problems of slow sedimentation collection speed, high dust content in the air outlet, and small processing air volume, so as to improve Dust removal efficiency and dust removal effect, improvement of dust removal effect, and accelerated discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Attached below Figure 1-3 and specific embodiments to further describe the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

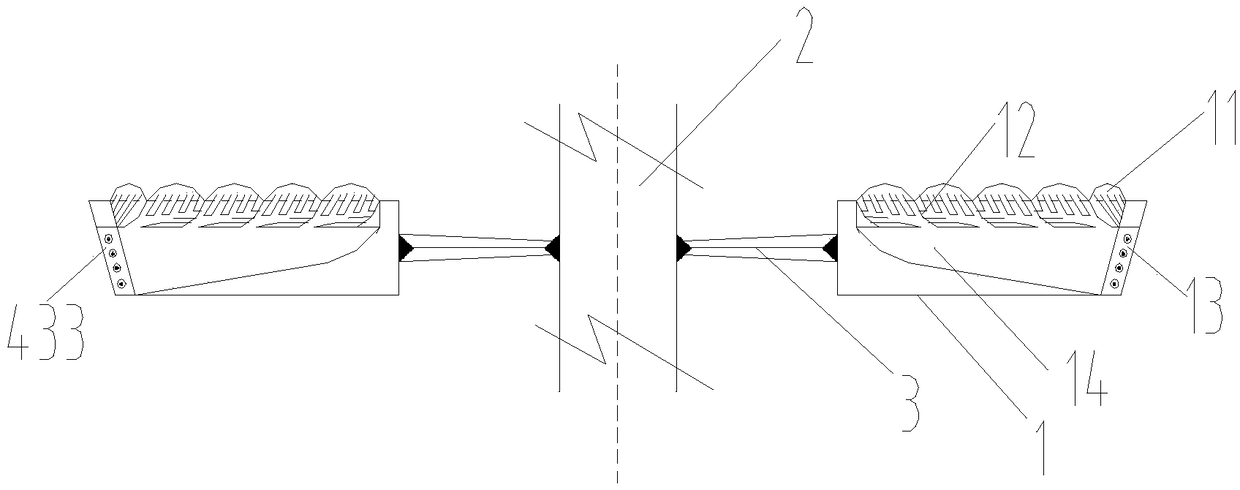

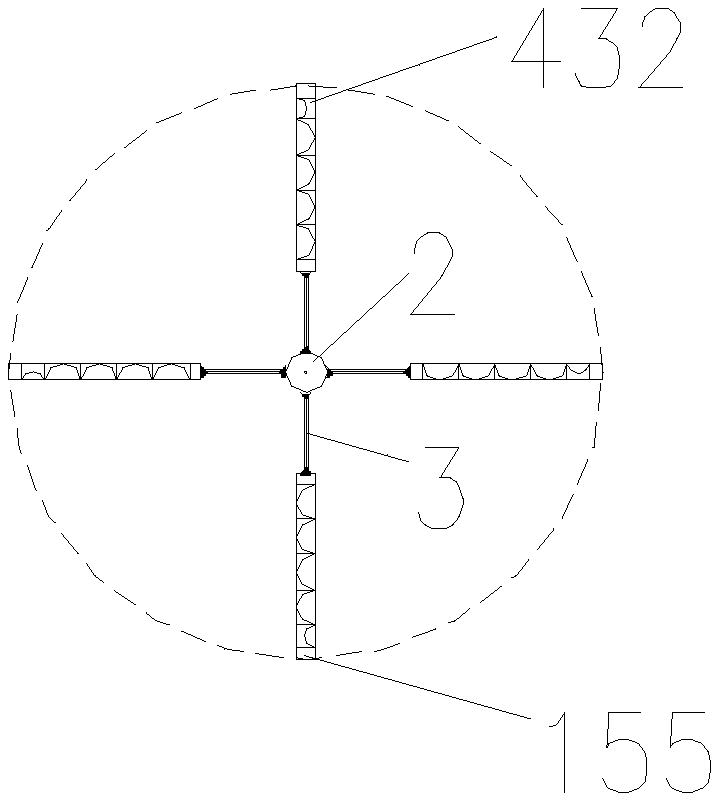

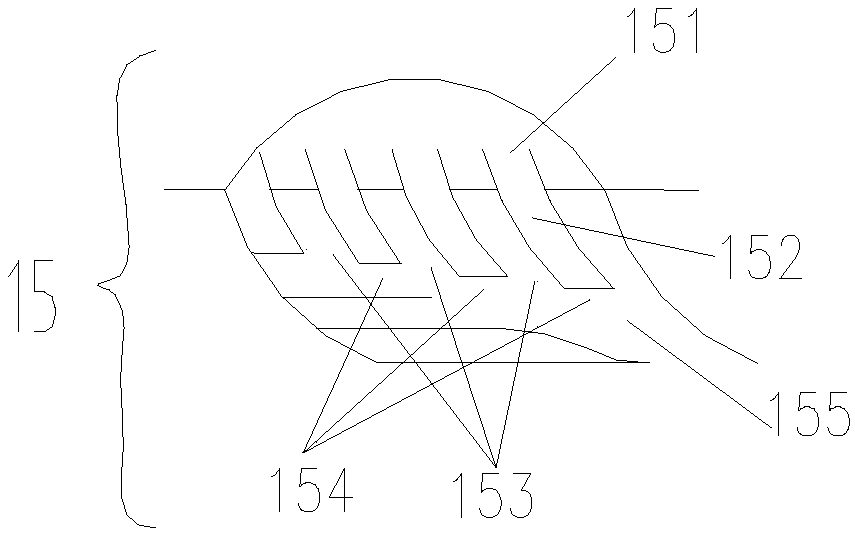

[0016] Figure 1-3 As shown, a multi-stage injection speed-increasing dust collection device includes: a circulating cyclone uniform distribution mechanism 1, a rotating shaft 2, and a supporting shaft 3. The circulation cyclone uniform distribution mechanism 1 passes through and the support shaft 3 stirs and evenly distributes on the rotating shaft 3 . The circulating cyclone uniform distribution mechanism 1 is provided with a wind flow collection port 11, a wind flow diversion channel 12, a secondary air flow outlet 13, a wind flow mixed flow area 14, and a multi-stage ejection speed-up mechanism 15; the wind flow collection port 11 is located at The upper end of the wind flow diversion channel 12 corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com