Green low-cost ternary precursor material, and preparation method and device thereof

A technology of ternary materials and precursors, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve problems such as investigations that do not involve the content of ternary elements, increased waste liquid treatment costs, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

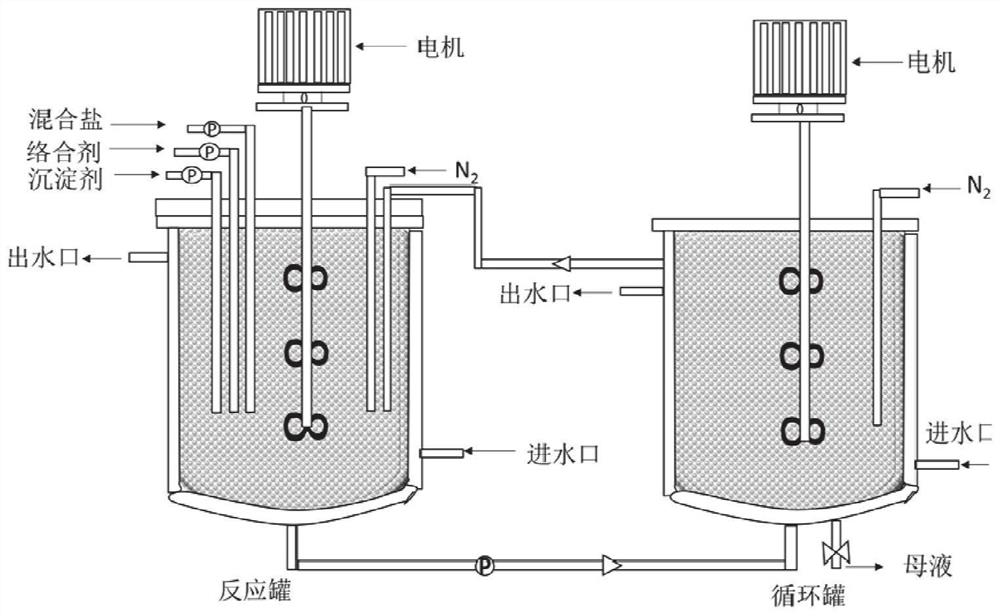

[0023] A green and low-cost ternary material precursor preparation method, the preparation method is as follows: nickel salt, manganese salt, and cobalt salt are formulated into a certain concentration of mixed salt solution according to a certain stoichiometric ratio, and a certain concentration of environmentally friendly The complexing agent and precipitating agent are fed into the N-filled 2 In the protected reaction tank, the hydrodynamic conditions such as concentration, reaction temperature, and stirring rate during the reaction process are strictly controlled, and the feed rate of the precipitant is controlled by a pH automatic dosing machine to maintain pH stability during the reaction; after a period of reaction , the product is pumped into the circulation tank through the bottom of the reaction tank. After the reaction liquid is filled with the circulation tank, it enters the reaction tank again from the overflow port, and the cycle is repeated several times; diamet...

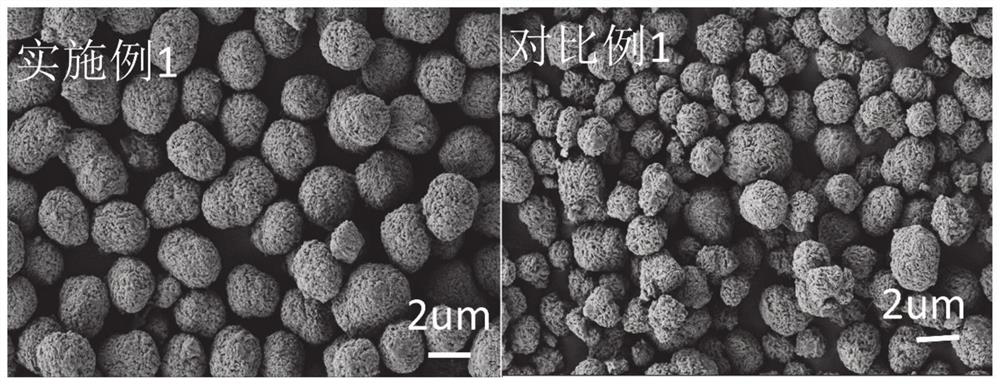

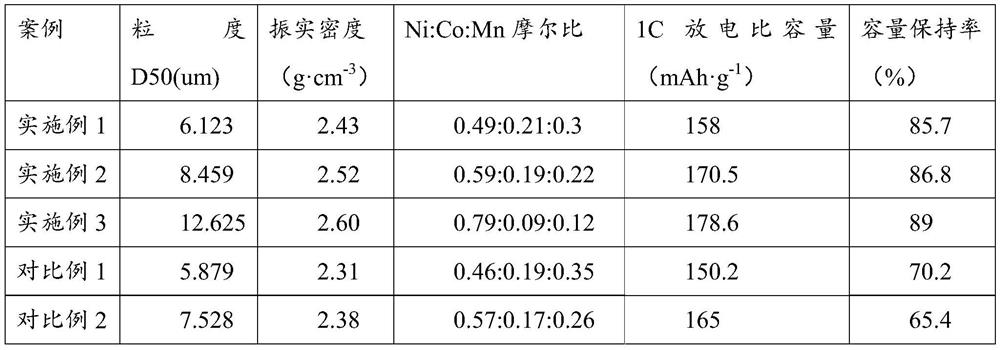

Embodiment 1

[0034] Weigh a certain amount of Ni (NO 3 ) 2 , Co(NO 3 ) 2 and Mn(NO 3 ) 2 Dissolve in deionized water to make a 0.1mol / L mixed salt solution, and flow it into a 1L reactor with 0.1mol / L sodium citrate solution, the reaction temperature is 30°C, the feed rate is controlled at 1ml / min, and the stirring intensity is 300r / min, the precipitating agent NaOH (0.2mol / L) adopts the pH automatic dosing machine to adjust and adjust the pH=10 in the reaction process. After the reaction solution stays in the reaction tank for 0.5 hours, the product is pumped into the circulation tank together with the reaction solution, and then overflows back to the reaction tank. After stirring for 5 hours, the final product was filtered, washed with water and dried to obtain Ni 0.5 co 0.2 mn 0.3 (OH) 2 precursor material.

Embodiment 2

[0036] Weigh a certain amount of NiC with Ni, Co, and Mn in a molar ratio of 0.6:0.2:0.2 2 o 4 、Co C 2 o 4 and MnC 2 o 4 Dissolve in deionized water to form a 10mol / L mixed salt solution, and flow it into the reactor with a 10mol / L polyacrylic acid solution. The reaction temperature is 50°C, the feed rate is controlled at 10ml / min, and the stirring intensity is 500r / min. Agent Na 2 CO 3 (10mol / L) pH=10.5 during the reaction process is regulated and adjusted by a pH automatic liquid dosing machine. After the reaction liquid stays in the reaction tank for 1 hour, the product is pumped into the circulation tank through the bottom of the reaction tank, and the reaction liquid naturally overflows into the reaction tank when it is filled with the circulation tank. After stirring and reacting for 20 hours, the final product is filtered and washed with water. and after drying to obtain Ni 0.6 co 0.2 mn 0.2 CO 3 precursor material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com