Membrane emulsification assembly for producing micron-sized micro-spheres and application of membrane emulsification assembly for producing micron-sized micro-spheres

A technology of microparticle and membrane emulsification, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc. It can solve the problem of uneven particle size of emulsions and microspheres, difficulty in preparing 100-micron emulsion droplets, and uneven shear force. and other problems, to achieve the effect of uniform particle size, meeting sterility requirements, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The membrane emulsification component for preparing micron-sized microspheres can be used to prepare drug-loaded or non-drug-loaded micron-sized microspheres, and the preparation method is as follows:

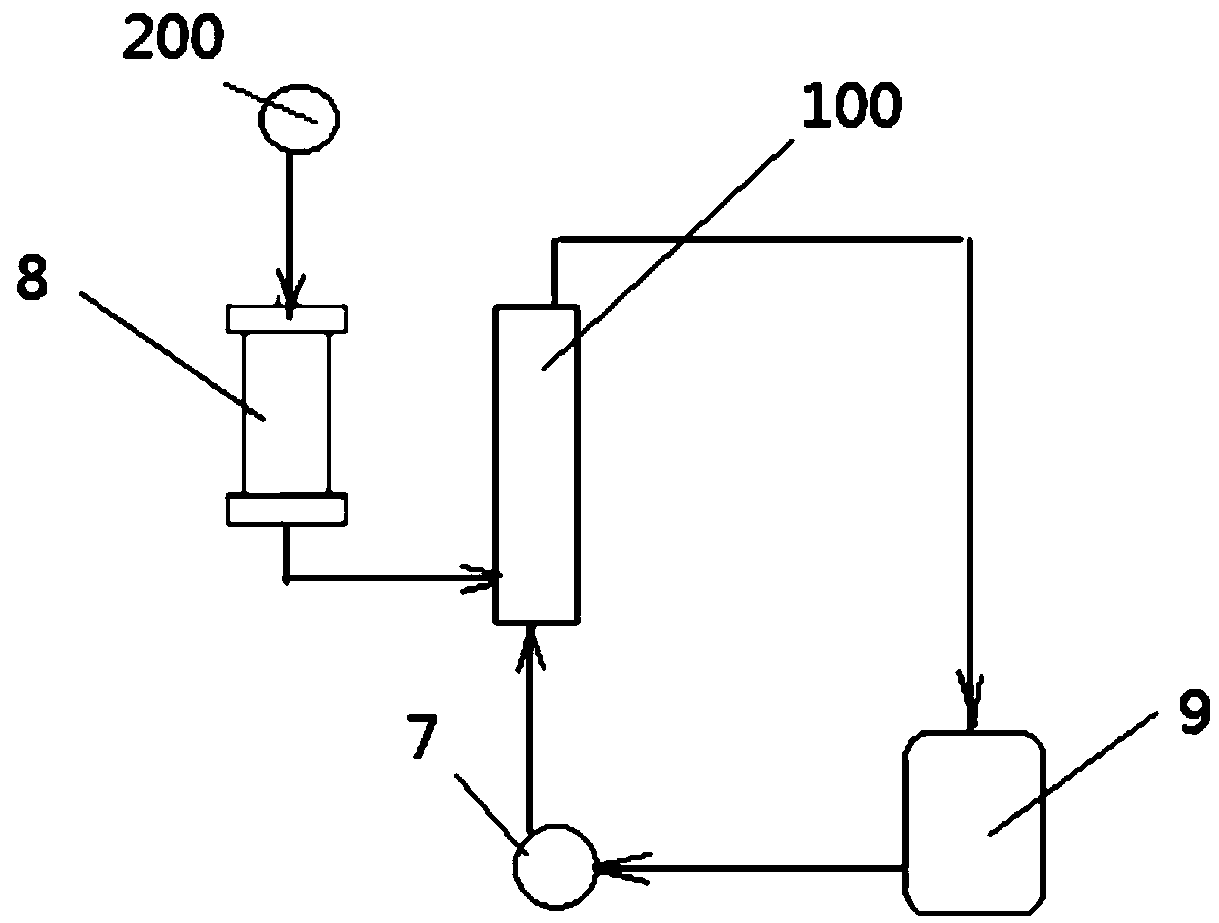

[0033] see figure 2 :

[0034] (1) The polymer material is dissolved in an organic solvent as a dispersed phase;

[0035] The polymer material is selected from polylactide glycolide (PLGA), polycaprolactone (PCL), polylactic acid (PLA) or polyamide.

[0036] The organic solvent is an organic solvent capable of dissolving the polymer material, such as dichloromethane, chloroform, tetrahydrofuran, ethyl acetate or benzyl alcohol.

[0037] In the dispersed phase, the content of polymer material is 10-20g / 100mL;

[0038] Preferably, the dispersed phase also contains active drugs such as risperidone at a content of 5-15g / 100mL;

[0039] (2) dissolving water-soluble substances such as PVA in water to obtain a continuous phase, wherein the content of the water-soluble subs...

Embodiment 1

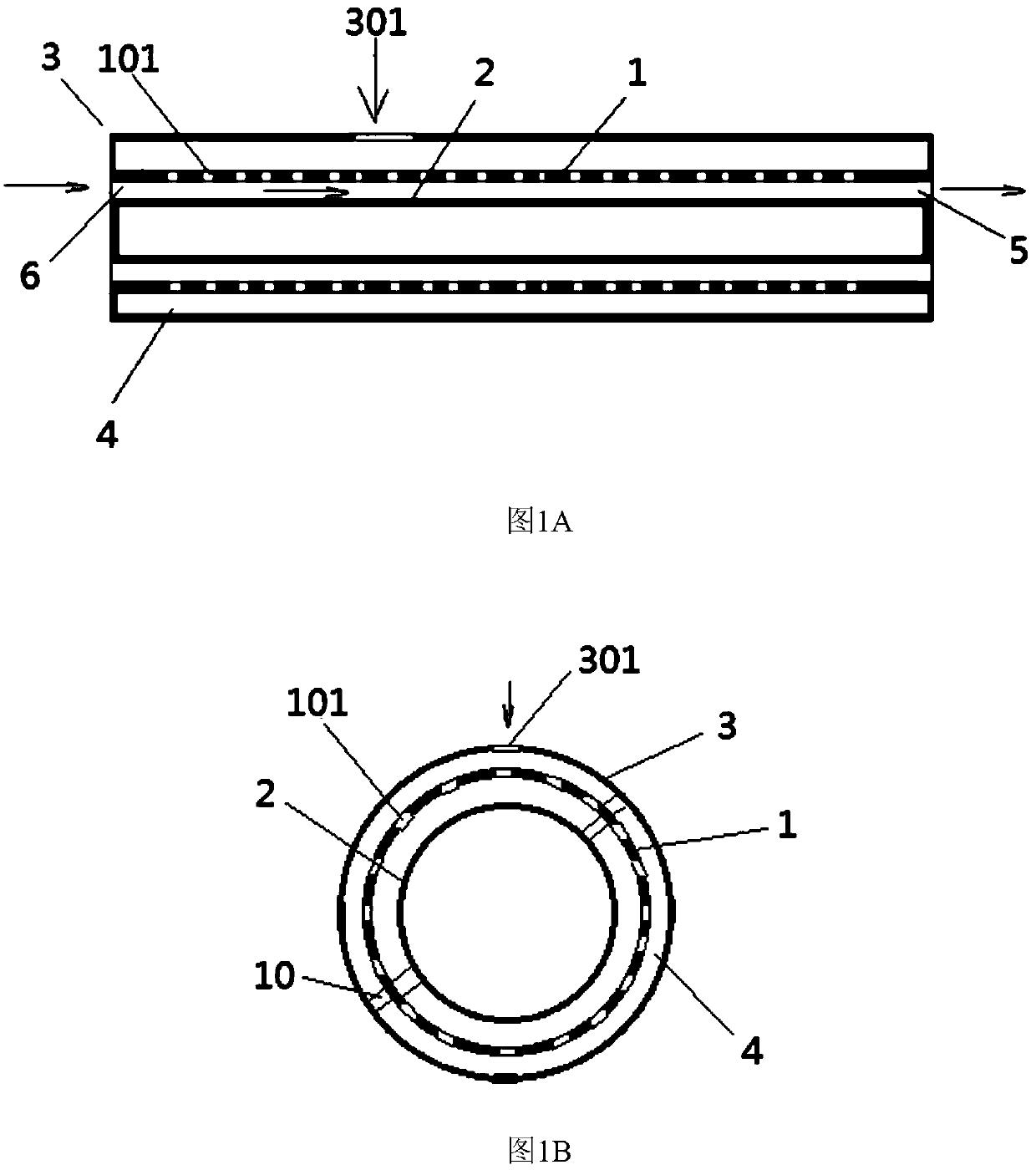

[0046] use figure 1 and figure 2 device for the preparation of risperidone microspheres.

[0047] The pitch of the membrane holes 101 is 1.5 mm, and the average pore diameter is 20 μm;

[0048] The distance between the embedded tube 2 and the membrane tube 1 is 1 mm;

[0049] Dissolve 15g of PLGA in 60mL of dichloromethane, add 7.5g of risperidone powder, dissolve and set the volume to 100mL, cool down to 10°C, as the dispersed phase.

[0050] Dissolve 240g of PVA in 12L of water and lower the temperature to 10°C as the continuous phase.

[0051] Add the dispersed phase to the dispersed phase tank 8, pressurize the dispersed phase to 12kPa through a nitrogen bottle, use a pump to circulate the continuous phase at an average flow rate of 0.38m / s in the membrane tube, and squeeze the dispersed phase through the membrane holes at a pressure of 12kPa , into the middle tank 9 of the continuous phase;

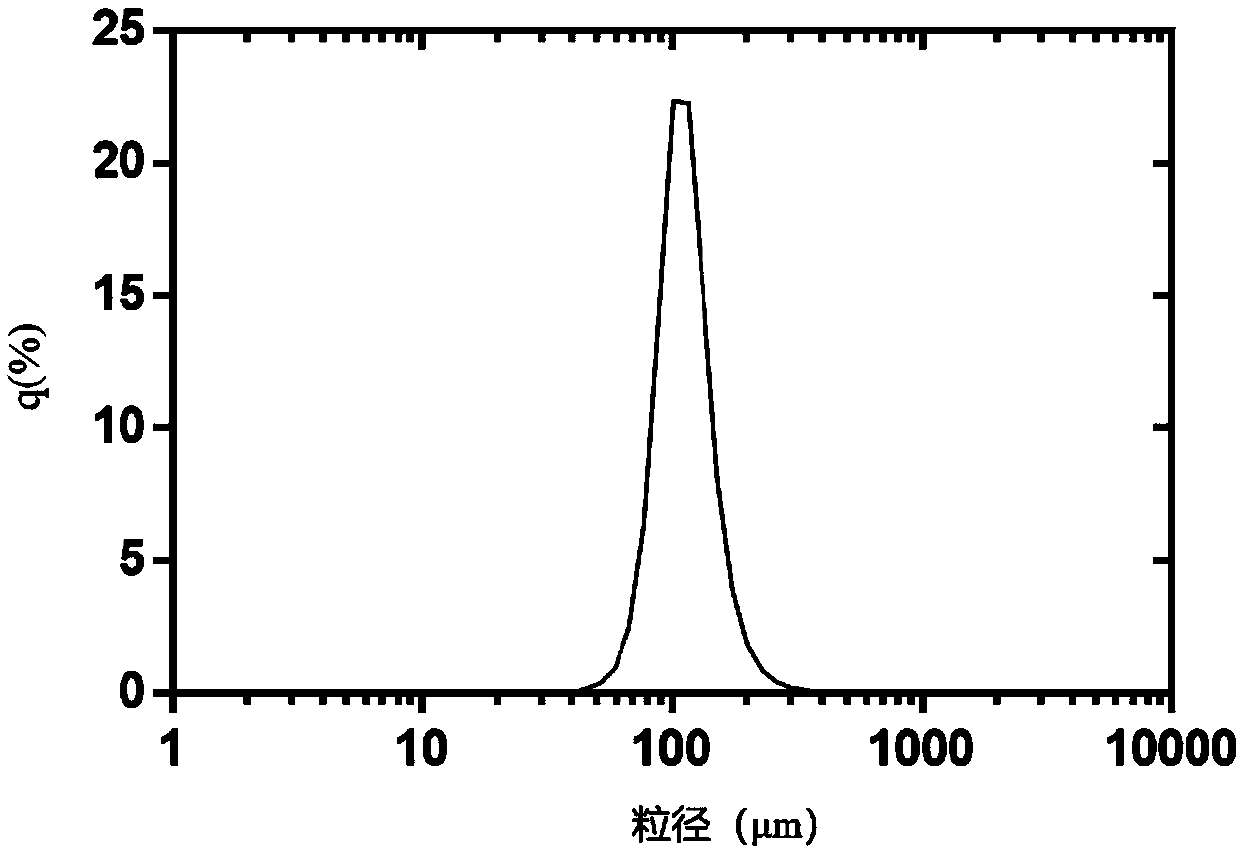

[0052] After collecting emulsion droplets and standing for 15 minutes, rep...

Embodiment 2

[0055] use figure 1 and figure 2 device to prepare non-drug-loaded PLGA microspheres.

[0056] The pitch of the membrane holes 101 is 1.5 mm, and the average pore diameter is 20 μm;

[0057] The distance between the embedded tube 2 and the membrane tube 1 is 1 mm;

[0058] Dissolve 18g of PLGA in 70mL of dichloromethane, dilute to 100mL after dissolving, and lower the temperature to 10°C as the dispersed phase.

[0059] Dissolve 300g of PVA in 15L of water and lower the temperature to 10°C as the continuous phase.

[0060] Add the dispersed phase to the dispersed phase tank 8, pressurize the dispersed phase to 25kPa through a nitrogen bottle, use a pump to circulate the continuous phase at an average flow rate of 0.20m / s in the membrane tube, and squeeze the dispersed phase through the membrane holes at a pressure of 25 , into the middle tank 9 of the continuous phase;

[0061] After collecting emulsion droplets and standing for 15 minutes, replace the continuous phase w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com