Method and device for purifying catering oil smoke by utilizing synergistic effect of low temperature plasma and catalysts

A low-temperature plasma and synergistic technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of unseen volatile organic compounds and unlimited purification efficiency, and achieve the function of increasing condensation and growth , Reduce investment and operating costs, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

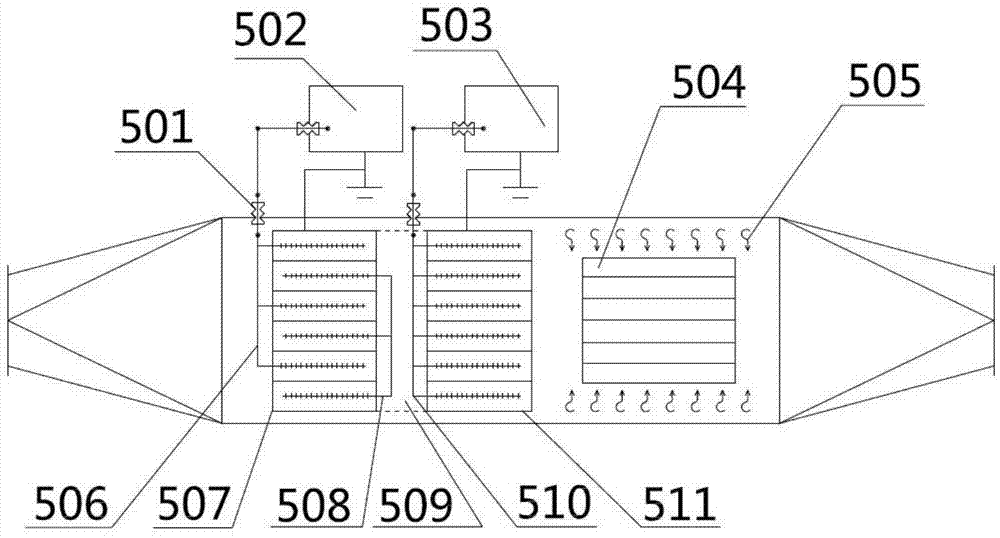

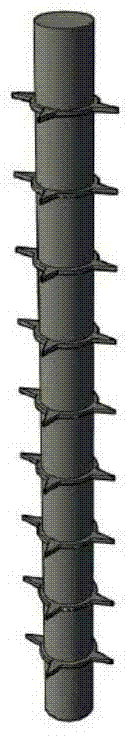

[0038] The first discharge electrode 506, the second discharge electrode 508, and the third discharge electrode 510 in the low-temperature plasma reaction zone are all in a zigzag shape. The first discharge electrode 506 is connected to the first high-voltage power supply 502, which is a negative DC high-voltage power supply. The discharge voltage -12kV; the second discharge electrode 508 and the third discharge electrode 510 are connected to the second high-voltage power supply 503, which is a positive DC high-voltage power supply, and the discharge voltage is +11kV; the first ground electrode 507 and the second ground electrode 511 are plate shape. The catalyst support is TiO 2 ; doped SiC and La 2 o 3 As a co-catalyst, the doping amount is 8wt.% and 6wt.% (mass percentage); the active component is manganese oxide, and the element manganese accounts for 5wt.% of the catalyst 504; the catalyst is regenerated by microwave heating . Use the catering oil fume purifier based ...

Embodiment 2

[0040] The first discharge electrode 506 in the low-temperature plasma reaction zone is needle-shaped, and the first discharge electrode 506 is connected to the first high-voltage power supply 502, which is a positive DC high-voltage power supply, and the discharge voltage is +6kV; the second discharge electrode 508 and the third discharge electrode 510 are all prickly, connected to the second high voltage power supply 503, which is a negative DC high voltage power supply, and the discharge voltage is -6kV; the first ground electrode 507 and the second ground electrode 511 are both plate-shaped. The catalyst support is Al 2 o 3 ; doped ZrO 2 and SiO 2 As a co-catalyst, the doping amount is 5wt.% and 5wt.% respectively; the active component is copper oxide, and the mass percentage of copper in the catalyst 504 is 8wt.%. The catalyst 504 is regenerated by infrared heating. Use the catering oil fume purifier based on this configuration to treat the catering oil fume in a unive...

Embodiment 3

[0042] The first discharge electrode 506 in the low-temperature plasma reaction zone is star-shaped, and the first discharge electrode 506 is connected to the first high-voltage power supply 502, which is a negative polarity DC power supply, and the discharge voltage is -18kV; the second discharge electrode 508 and the third discharge electrode 510 are both The gear shape is connected in series (six teeth are evenly distributed on each gear), connected to the second high-voltage power supply 503, which is a positive polarity DC superimposed high-frequency AC power supply, wherein the positive polarity DC working voltage is +15kV; the first grounding electrode 507 and The second ground electrodes 511 are all hexagonal honeycomb bodies. The catalyst support is Al 2 o 3 ; doped SiO 2 As a cocatalyst, the doping amount is 20wt.% by mass; the active components are manganese oxide and copper oxide, and the mass percent of manganese in catalyst 504 is 3%, and the mass percent of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com