Fume purification system and working method thereof

A technology for oil fume purification and working methods, which is applied to chemical instruments and methods, oil fume removal, cleaning methods and appliances, etc. It can solve the problems of low oil fume purification rate, collection electric field failure, time-consuming and labor-intensive costs, etc., to ensure the ionization effect and ensure Purification effect, time-saving, labor-saving and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

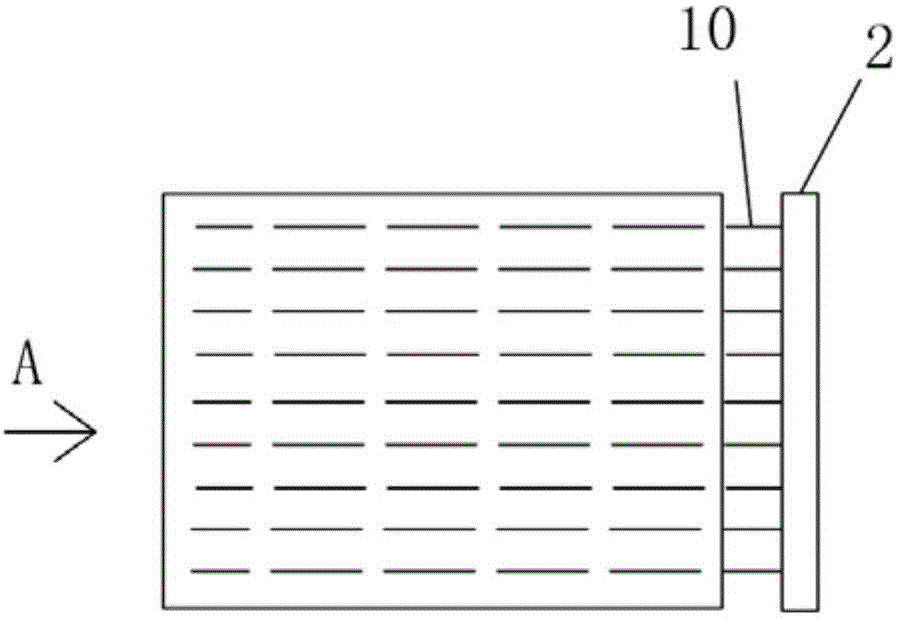

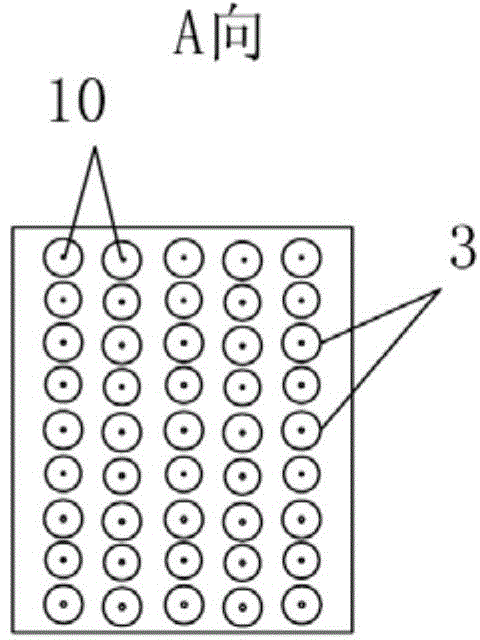

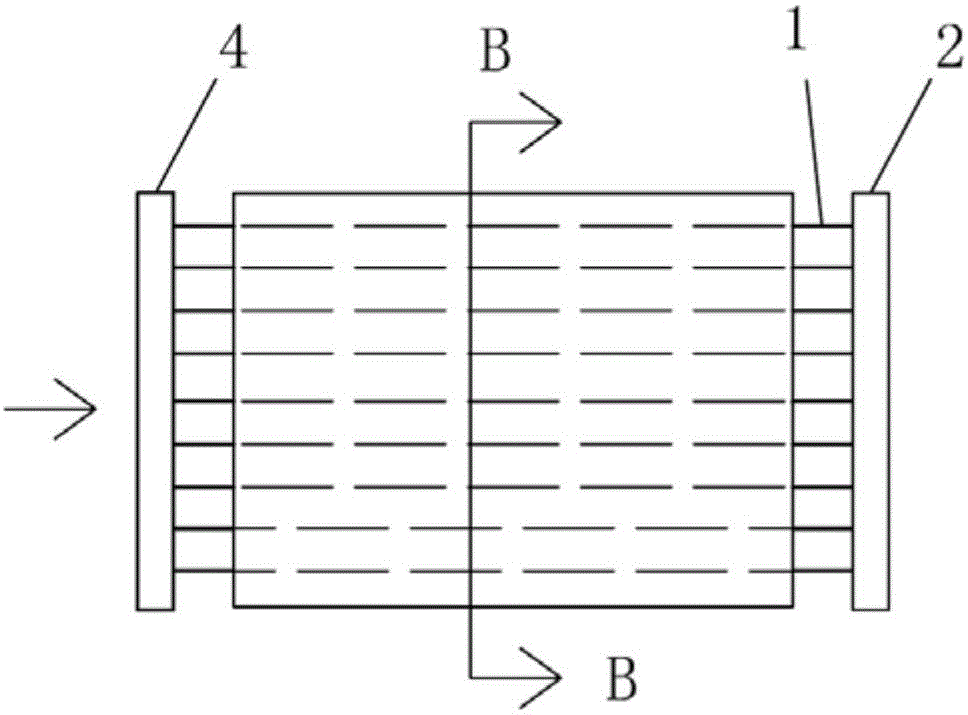

[0038] See Figures 5 to 8 , the oil fume purification system of this embodiment includes: a purification host, the purification host includes: a closed housing 5, the front and rear ends of the housing 5 are respectively provided with an air inlet 15 and an air outlet 16; the housing 5 is provided with a A partition 6, there is a gap between the top of the partition 6 and the inner wall of the housing 5, and the rest of the partition 6 is sealed and welded to the inner wall of the housing 5; inside the housing 5, on both sides of the partition 6 All are provided with a plurality of alternately arranged and vertically distributed metal tubes 13; metal ribs 1 are arranged on the central axis of each metal tube 13, between the middle and upper parts of each adjacent metal tube 13 or adjacent to the top, between the partition plate 6 and Between the upper middle part of adjacent metal pipes 13 or near the top, and the gap between the inner wall of the housing 5 and the middle upp...

Embodiment 2

[0056] (The upper and lower positions of the three buffer zones in this embodiment are opposite to those in Embodiment 1)

[0057] like Figure 9 , an oil fume purification system, including a purification main engine, the front end of the air inlet 15 of the housing 5 of the purification main engine is also provided with a filter system 17, a cooling system 18 and a buffer cavity 19 for successively filtering, cooling and buffering airflow. The purification host includes: a closed housing 5, the front and rear ends of the housing 5 are respectively provided with inlet and outlet ports 15, 16; There is a gap between the inner walls of the bottom of the partition plate 5, and the remaining part of the partition plate 6 is in sealing connection with the inner wall of the housing 5; inside the housing 5, on both sides of the partition board 6, there are a plurality of alternately arranged and vertically distributed metal Tube 13.

[0058] Metal bars 1 are arranged on the centra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com