Patents

Literature

68results about How to "Complete chemical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

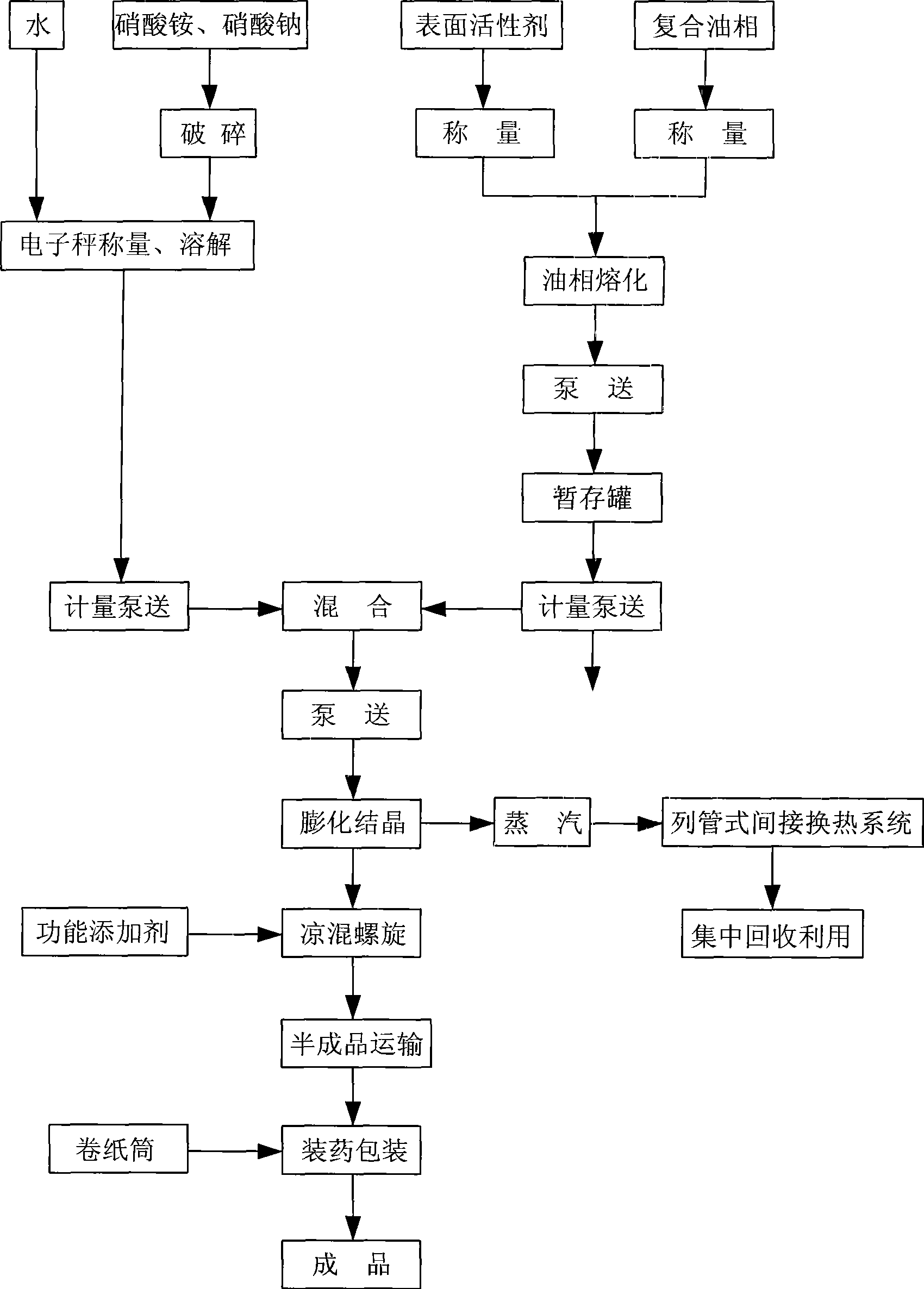

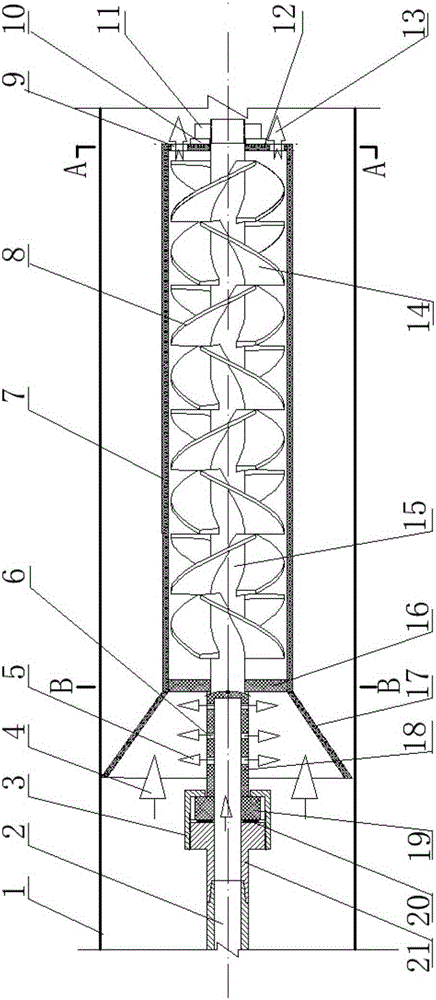

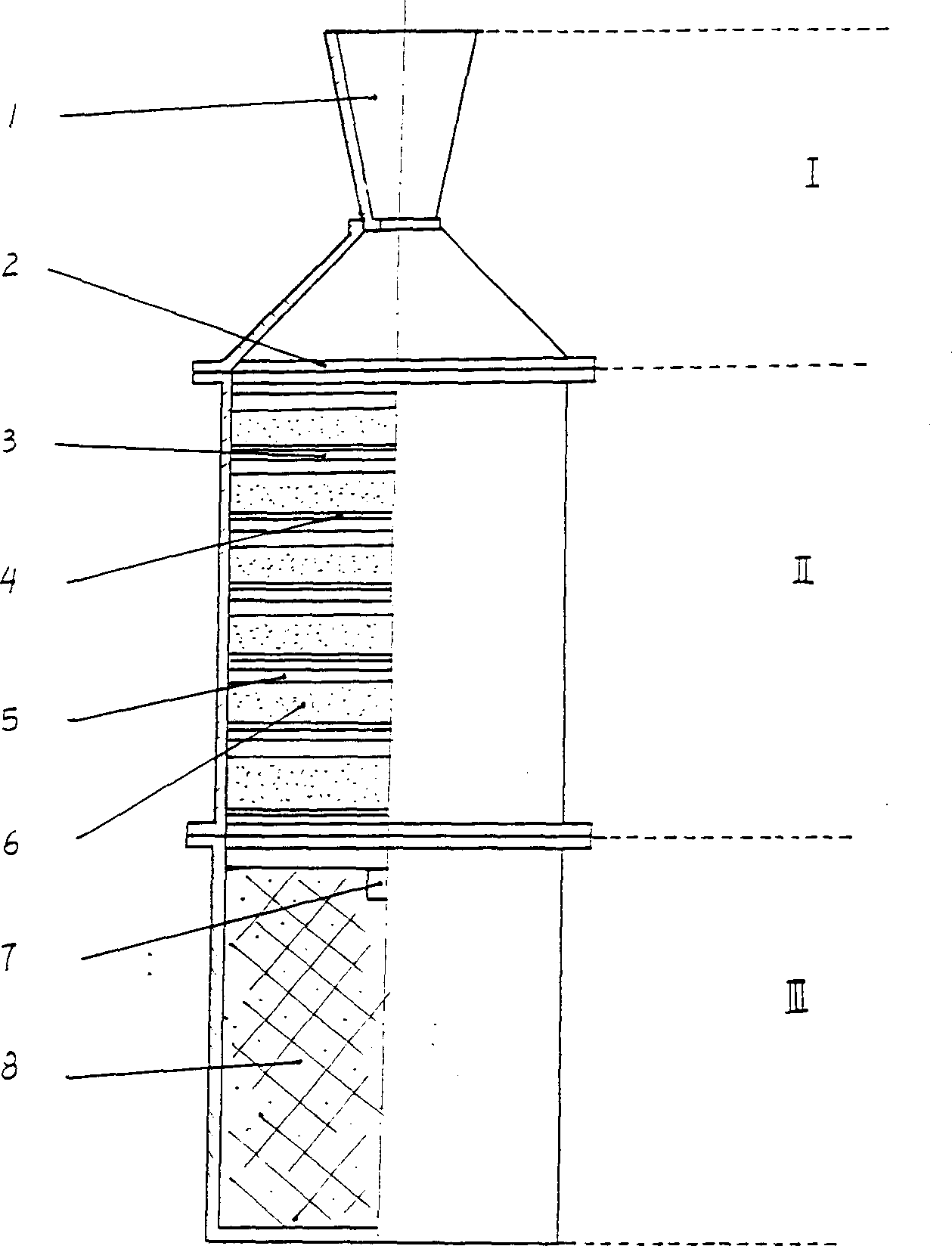

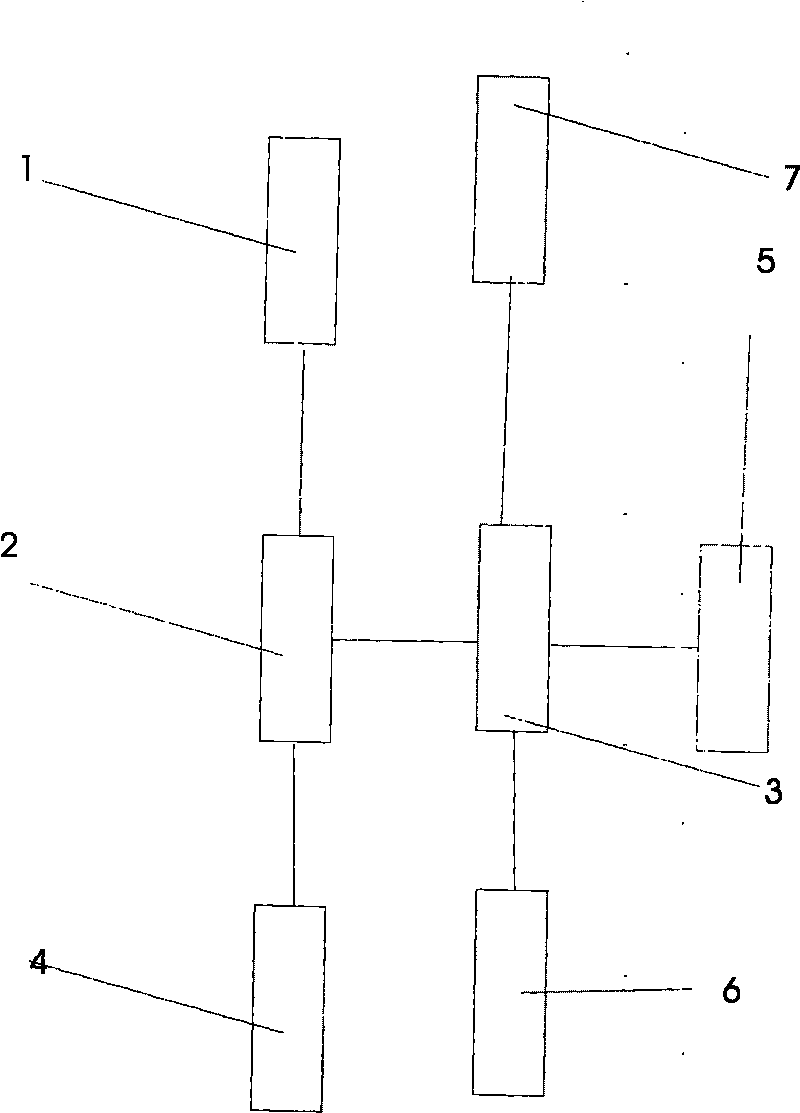

Process for producing novel puffing nitramon

ActiveCN101429081AZero emissionOnline storage is lowExplosive working-up apparatusAutomatic controlWork in process

The invention relates to a process for preparing novel expanded ammonium nitrate explosive, which comprises the following steps: water-phase dissolving and oil-phase melting; mixing two phases; expanding crystallization; realizing uninterrupted discharging through alternately converting vacuum cavities; mixing expanded explosive with a functional additive which is subjected to measurement after a product is dropped into a cool mixed spiral through a feeding bin; dropping a prepared semifinished product of the expanded explosive into a suspension conveyer through a spiral conveying device; and conveying the semifinished product to a filling package workshop by the suspension conveyer for explosive filling to obtain a finished product of the expanded ammonium nitrate explosive through package. The invention is the process for preparing the expanded ammonium nitrate explosive with safety and environmental protection, zero discharge of pollutant, small online explosive amount, high operating safety and high automatic control.

Owner:GUANGDONG HONGDA SHAOHUA IND EXPLOSIVES CO LTD

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

Technology for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide and used incinerator

ActiveCN103395750AReduce lossesFull responseChemical industrySulfur compoundsHeat lossesHigh pressure

The invention relates to a technology for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide, and a used incinerator. The technology comprises the following steps: (1) atomizing the waste sulfuric acid, with concentration of greater than or equal to 75%, as a by-product in an oil refinery to form acid mist by combining high pressure pump conveying mechanical atomization with compressed air auxiliary atomization, wherein the grain diameter is smaller than or equal to 80 microns; (2) completely mixing hydrogen sulfide gas, with concentration of 0 to 50%, as the by-product in the oil refinery with hot air in a cyclone air inlet to product mixed gas; and (3) spraying the acid mist into the incinerator by using a waste acid spray gun, meanwhile spraying the mixed gas of hydrogen sulfide gas and hot air into the incinerator by a hydrogen sulfide spray gun and carrying out incineration, pyrolysis and reduction reaction to generate SO2 burner gas, wherein the SO2 burner gas enters an acid making system after the heat is recycled through a heat recovery boiler. During the reaction, the grain diameter of the acid mist is smaller than or equal to 80 microns, and the acid mist is introduced into the incinerator at the same time, so that various reactions can be performed completely and heat loss is reduced furthest at the same time, and produced products meet the requirement of the subsequent acid making technology.

Owner:JIANGSU YONGJI CHEM EQUIP

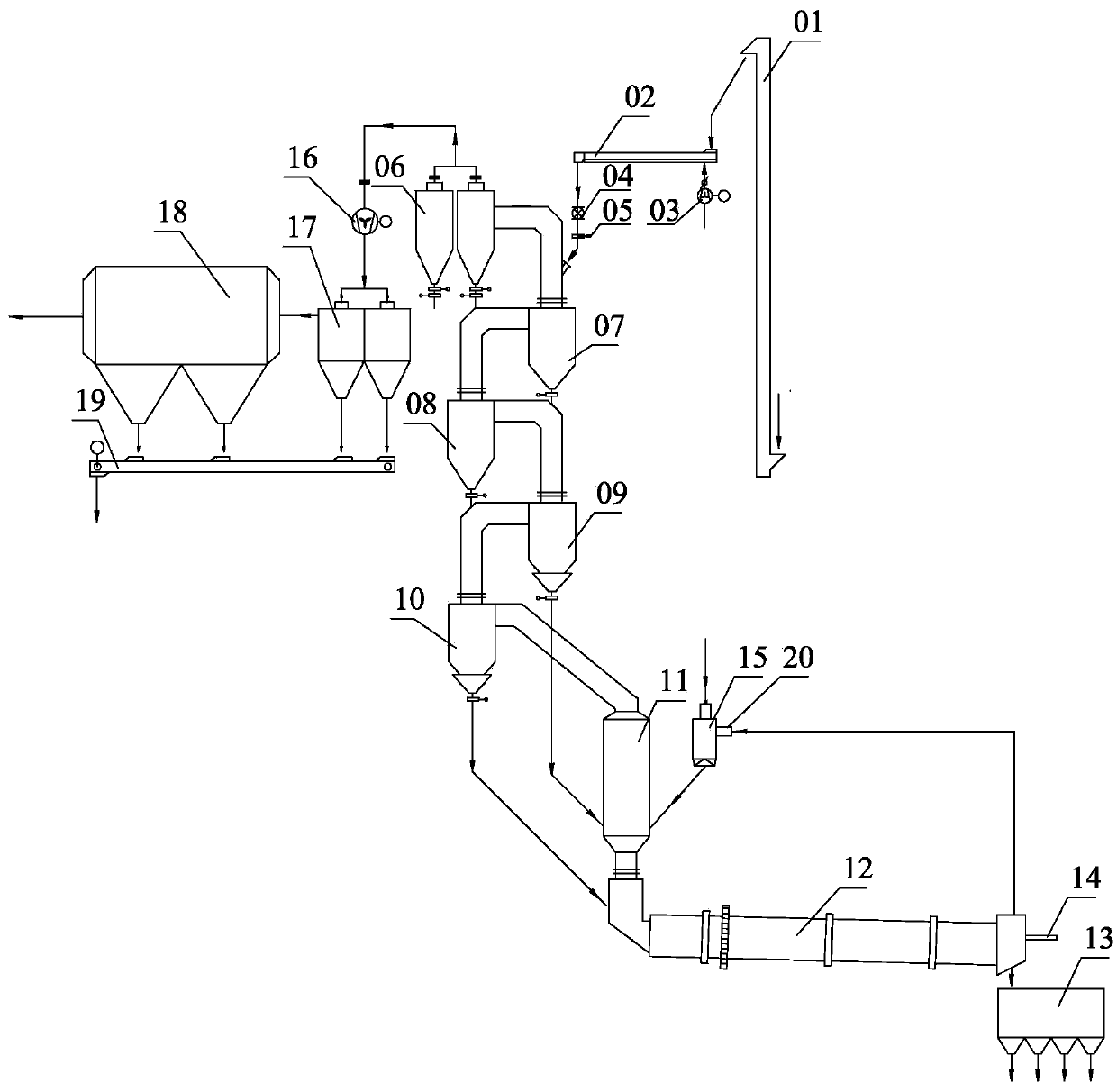

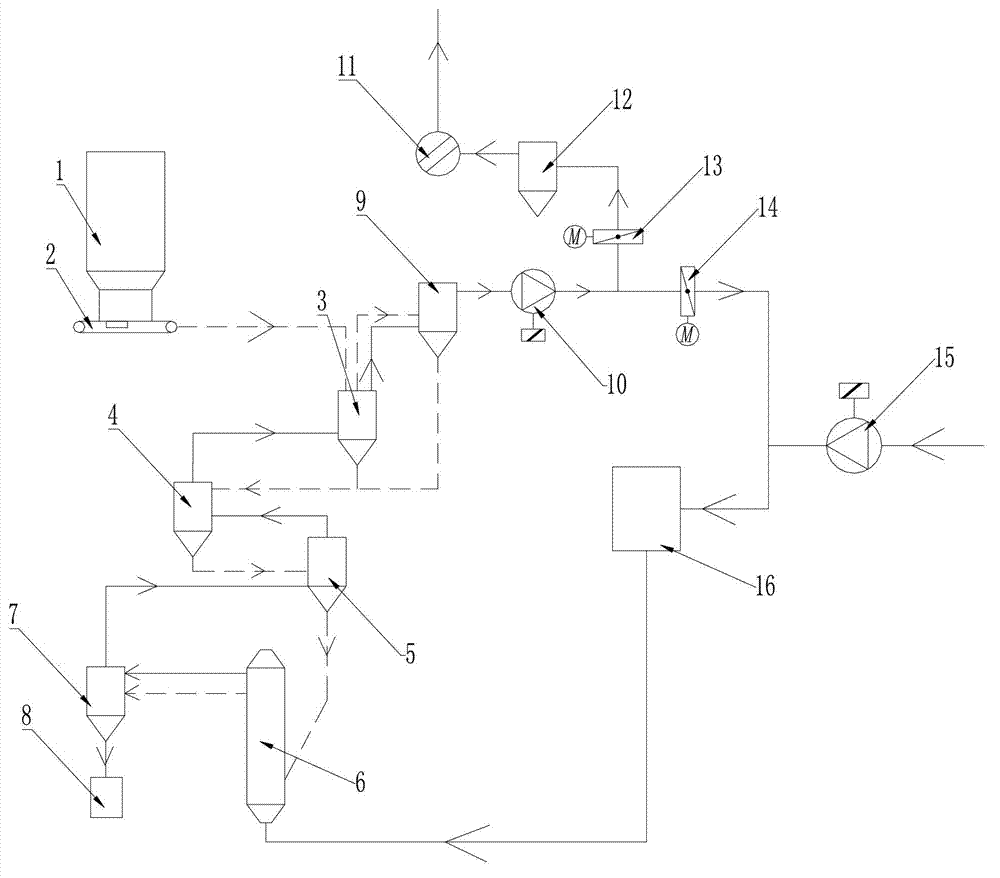

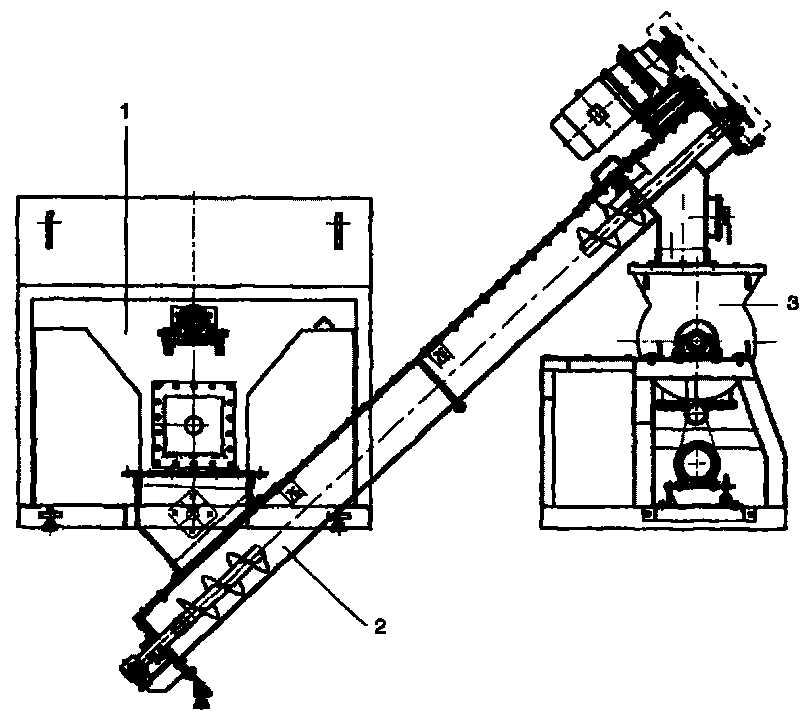

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

ActiveCN103468930AFast heat and mass transferShorten decrystallization wateChemical reactionLaterite

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

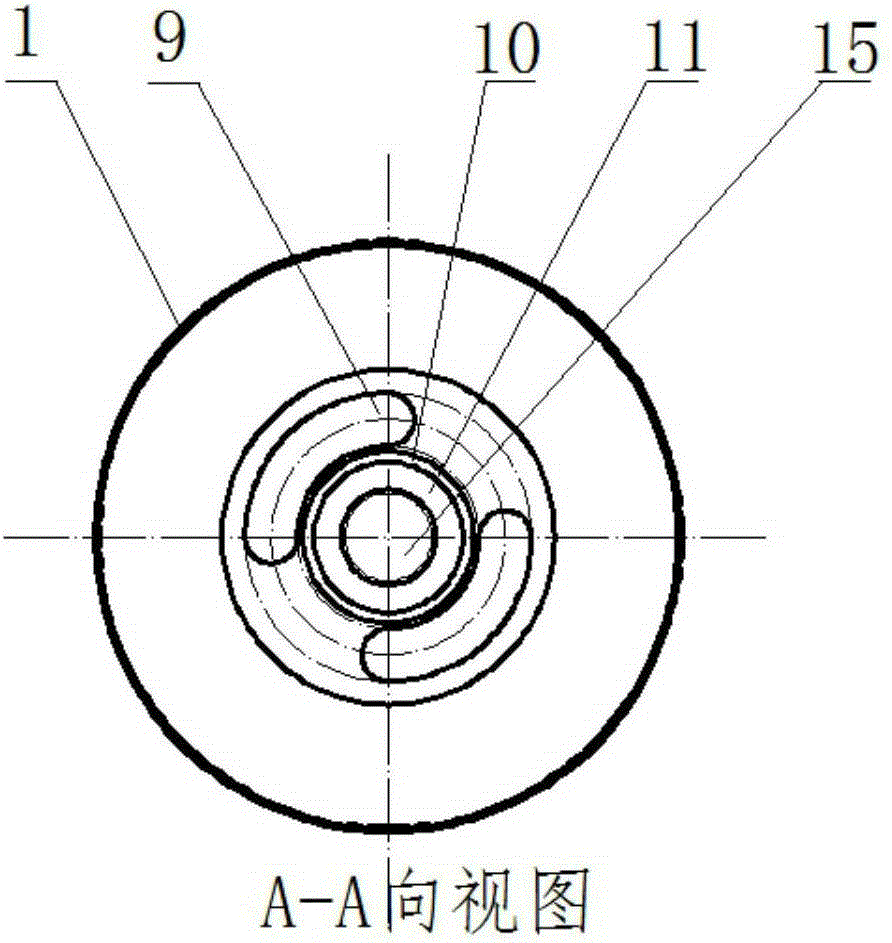

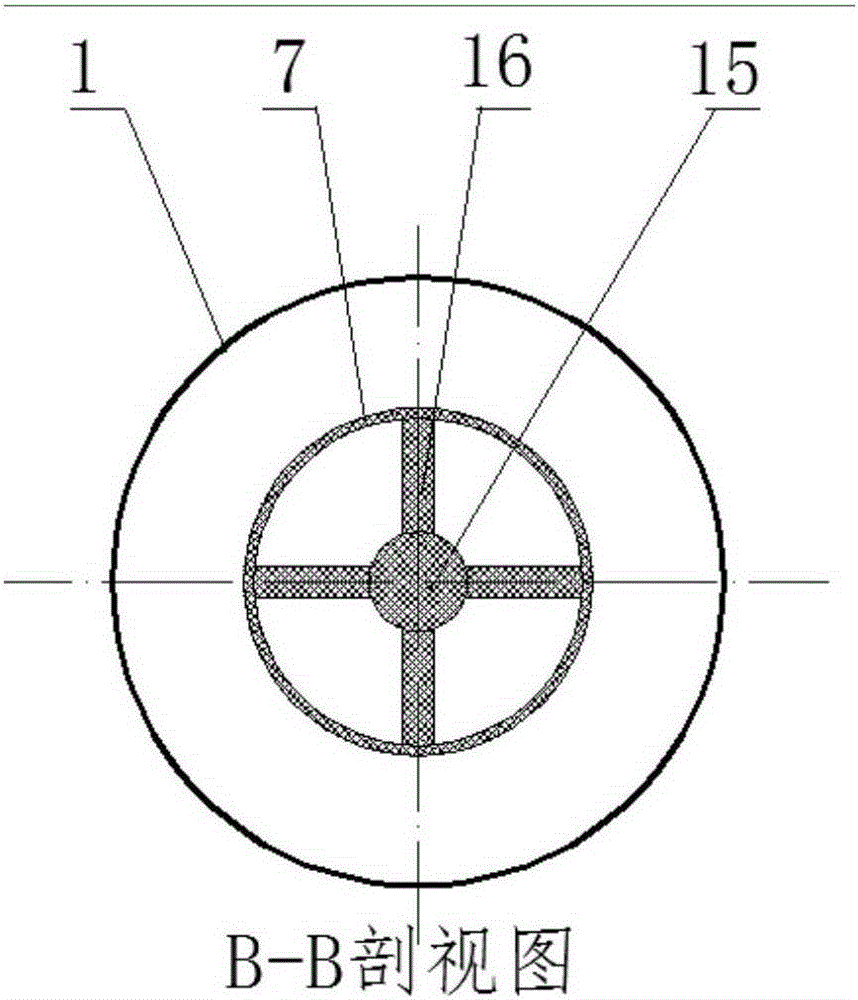

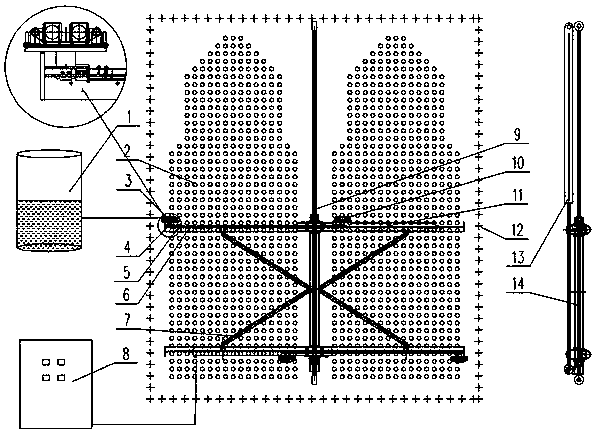

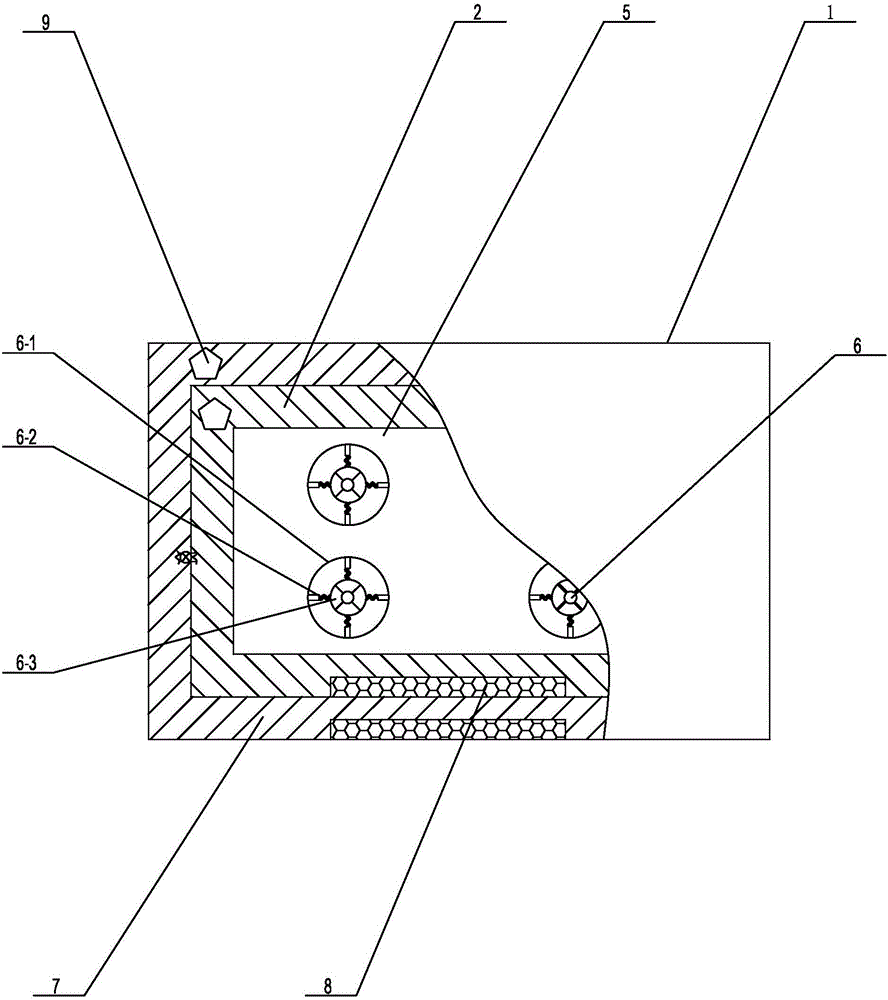

Mixing device for grout in inlet well at ground and application method thereof

ActiveCN105317396ASolve the technical problems of serious in-hole accidentsAvoid security risksSealing/packingChemical reactionEngineering

The invention discloses a mixing device for grout in an inlet well at the ground and an application method thereof. The mixing device comprises a mandril, a protecting bush and a grout collector, wherein the mandril is arranged in the protecting bush, and two ends of the mandril move through the protecting bush; the bottom end of the mandril is fixed to the protecting bush, and the upper end of the mandril is connected to a drilling rod through a short tube; the upper end of the protecting bush is connected to the grout collector; rightward rotating blades and leftward rotating blades are correspondingly arranged on the mandril in a staggering manner; the rightward rotating blade and the leftward rotating blade are arranged from the middle positions of the corresponding previous blades. The mixing device has the beneficial effects that the three purposes of injection mixing, swirling and agitating mixing, and slitting mixing can be essentially achieved in theory; the grout of two types can be fully mixed and completely chemically reacted, and the grouting effect is obvious.

Owner:SHANDONG UNIV

Treatment chemical for lead-zinc flotation tailing wastewater

InactiveCN102502934AQuick decalcificationReduce contentWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationHigh concentrationPhosphate

The invention discloses a treatment chemical for lead-zinc flotation tailing wastewater, wherein the chemical comprises, in percentage by weight, 80-90% of carbonate, 9-19% of phosphate and 0.5-1% of non-ionic polyacrylamide; and the treatment chemical is suitable for treating lead-zinc flotation tailing wastewater with suspended solids, highly-free calcium oxide, high pH, high-concentration heavy metal ions, and over-standard COD (chemical oxygen demand) and BOD (biochemical oxygen demand). The new chemical has the multi-functions of rapidly removing calcium, removing suspended matters and precipitates, i.e., heavy metal ions and the like, as well as is large in the particle size of precipitate particles and complete in precipitation. Moreover, operation is simple and cost is low by using the chemical.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing zeolite 4A

ActiveCN102107880ASimple processRaw materials are easy to getAluminosilicate zeolite type-AKaolin clayBiological activation

The invention belongs to the zeolite field and discloses a method for preparing zeolite 4A by using kaolin as raw material. The method comprises the following steps: mixing kaolin and sodium hydroxide solution, placing the mixture in a reaction kettle to perform activation treatment and obtain the mixture containing active silica and active alumina, standing the obtained mixture for aging, crystallizing, filtering the crystallization product, washing and drying to obtain zeolite 4A. The method of the invention has the advantages that the process is simple, the energy consumption is low, the production cycle is short, the obtained product has high quality and low cost, etc.

Owner:何子豪 +1

Firework type extinguishant and extinguisher thereof

InactiveCN1333067AImprove ignitabilityIgnition lag period shortenedFire extinguisherOrganic acidOxidizing agent

The composition of fire-extinguishing agent is made of (wt%) 40-65% of oxidant, 10-20% of fuel, 20-40% of catalyst, 0-5% of additive and 3-7% of combustion speed regulator, in which the oxidant is ammonium nitrate, the fuel is a compound whose molecular formula is CnH2n-2On-1 (n=5-7), and the catalyst is one of nitrates or mixture of more than two kinds of them, and the combustion speed regulatoris chloride, inorganic acid salt and organic acid salt. Said invented fire extinguisher includes exhaust chamber, cooling chamber and charging chamber, said three portions are made into cylindrical form. Said exhaust chamber includes filtering screen and nozzle on the filtering screen, the cooling chamber includes includes at least 6 layers of sieve plates, on the plate the screen for holding cooling agent is laid, and the charging chamber also is equipped with a starter made of chemical initiating agent. Its combustion speed is high, it does not pollute environment, and is extensive in application.

Owner:松全才 +1

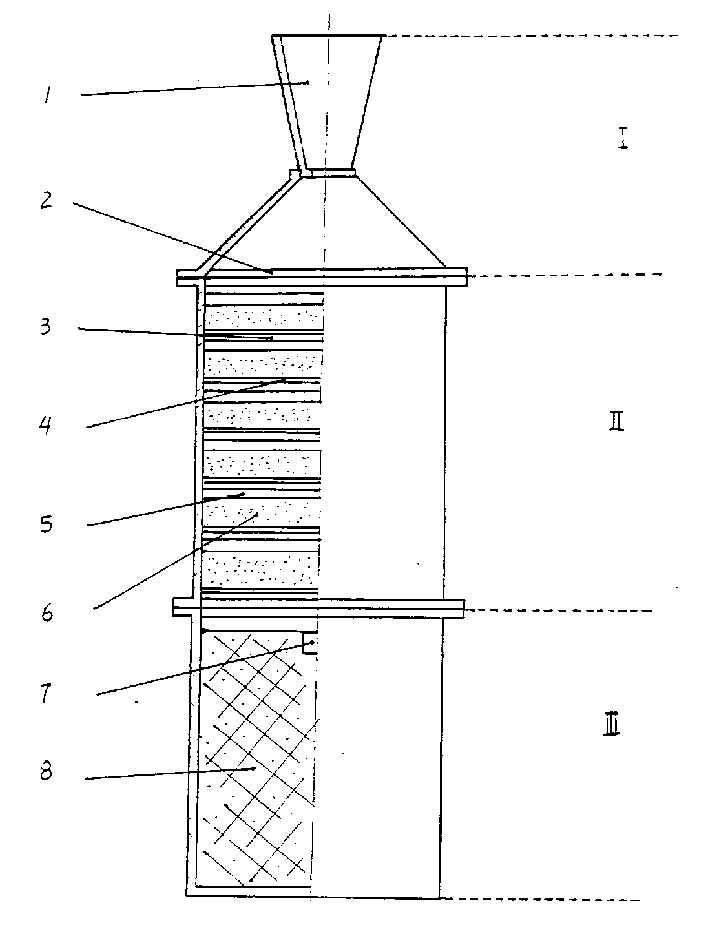

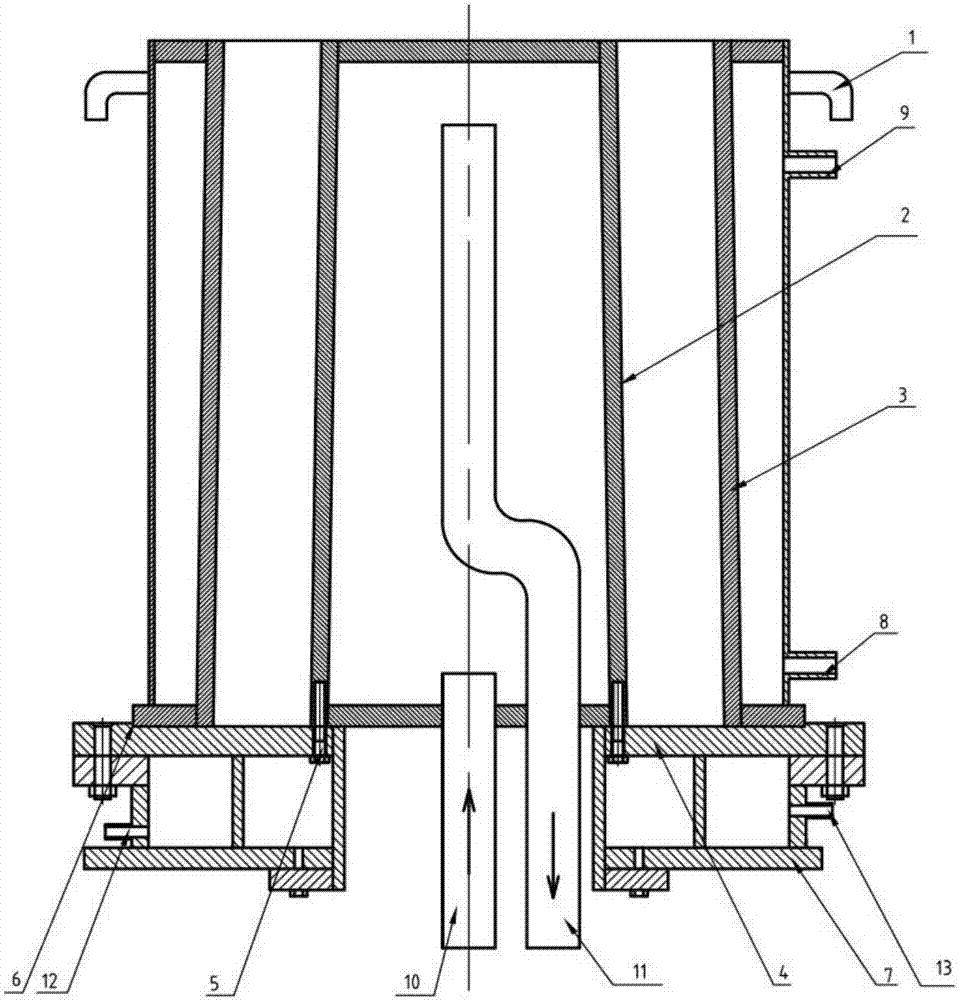

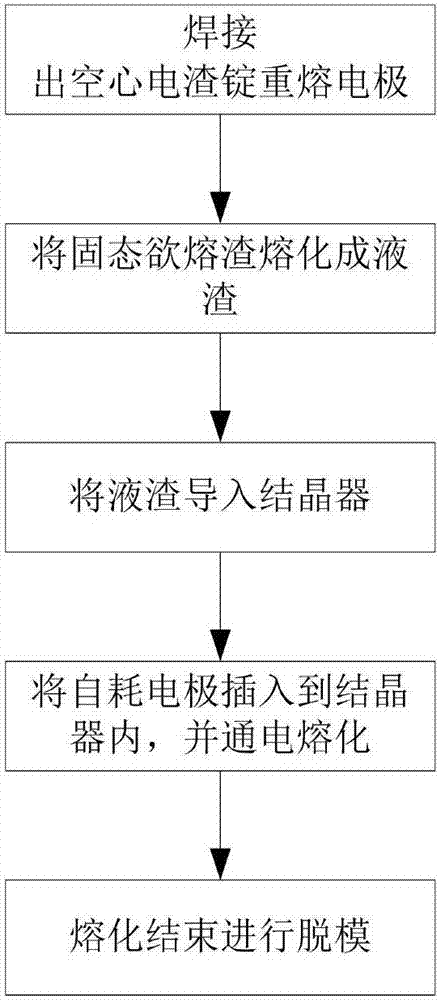

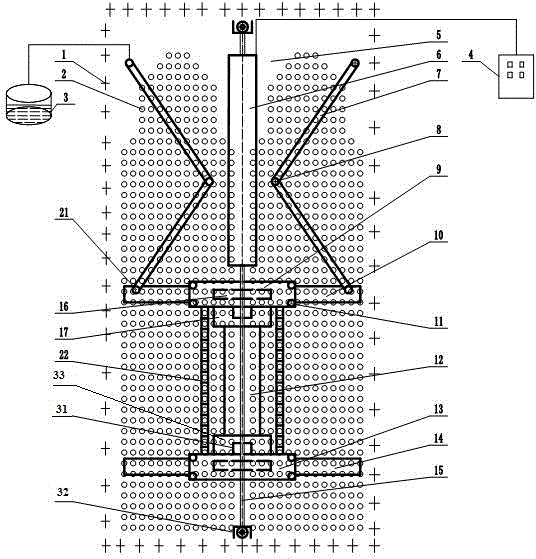

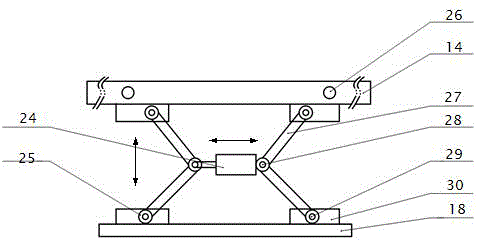

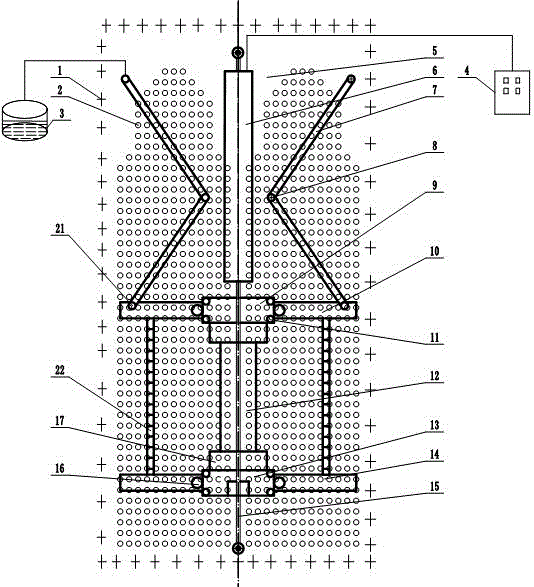

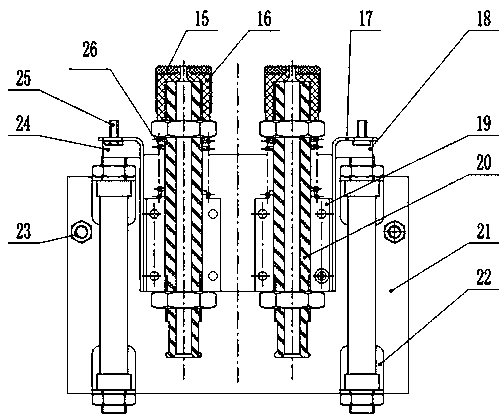

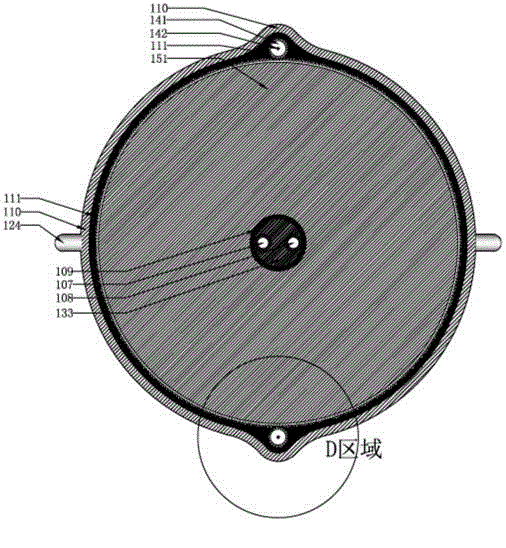

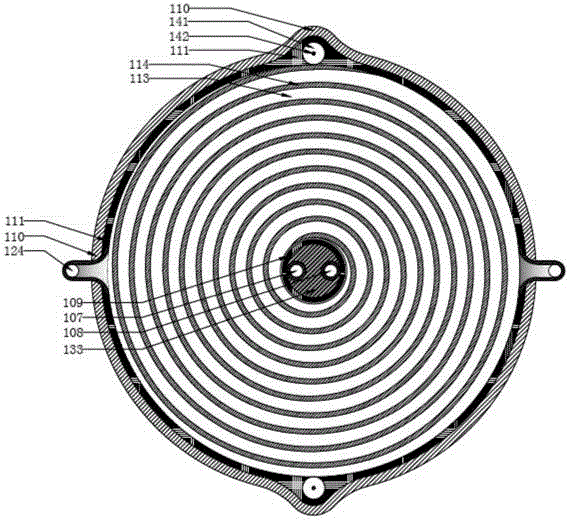

Device and method for producing small hollow electroslag ingot

The invention discloses a device and a method for producing a small hollow electroslag ingot, belongs to the technical field of hollow electroslag ingot melting, and solves the technical problems of incapacity of ensuring the concentricity of the hollow electroslag ingot, incapacity of ensuring a high filling ratio, complex structure, high production cost and inapplicability to a small hollow electroslag ingot in the prior art. According to the device disclosed by the invention, an inner crystallizer is fixed to a bottom water tank, and an outer crystallizer is of a movable structure. The method disclosed by the invention comprises the following steps: welding a re-melting electrode of the hollow electroslag ingot; melting a solid pre-melting slag; pouring the liquid slag into the crystallizers in the invention, and carrying out electrifying melting; and carrying out die release after the melting is concluded. The device disclosed by the invention has the advantages of being simple in structure, easy to produce, simple to operate during a melting process, and low in production cost.

Owner:凌远科技股份有限公司

Method for synthesizing P zeolite molecular sieve from rice husk

InactiveCN106379913APromote pyrolysisDamage structureCrystalline aluminosilicate zeolitesHigh pressureMuffle furnace

The invention discloses a method for synthesizing a P zeolite molecular sieve from rice husk. The method includes: subjecting crushed rice husk to pretreatment with sulfuric acid, conducting washing and drying, then putting the dried rice husk into a muffle furnace for pyrolysis, collecting combusted rice husk ash, putting the combusted rice husk ash and a sodium hydroxide aqueous solution in a high pressure kettle to conduct hydrothermal activation for 2-4h under a temperature of 180-230DEG C, and performing cooling to obtain an activated alkali solution, adding an aluminum source into the activated alkali solution, then adding a P zeolite molecular sieve crystal, and carrying out aging, heating crystallization, filtering, washing and drying, thus obtaining a finished product. The method realizes waste recycling, and has the advantages of simple process, short production period, easy operation, and the obtained product has the characteristics of high quality and low cost, etc.

Owner:曹蕊

Method for preparing barium hydroxide by using barium carbonate

ActiveCN102923748AFast heat and mass transferShorten the timeCalcium/strontium/barium oxides/hydroxidesChemical reactionBarium peroxide

The invention discloses a method for preparing barium hydroxide by using barium carbonate. The method comprises the following steps of firstly grinding ores containing barium carbonate into ore powder, carrying out high-temperature roasting on the ore powder in a suspension fluidized state to obtain roasted ore containing barium hydroxide, soaking the roasted ore in water to react and generate a barium hydroxide solution, carrying out solid-liquid separation on the barium hydroxide solution, cooling and crystallizing to obtain barium hydroxide products. The method for preparing the barium hydroxide by using the barium carbonate, disclosed by the invention, has the advantages that the heat transfer area of the ore powder is large, each ore particle can uniformly and totally finish a chemical reaction, the reaction time is short, and the utilization rate of barium carbonate is high.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

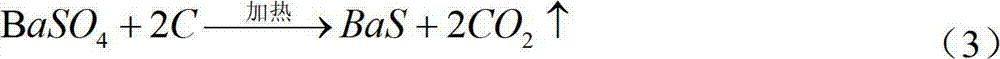

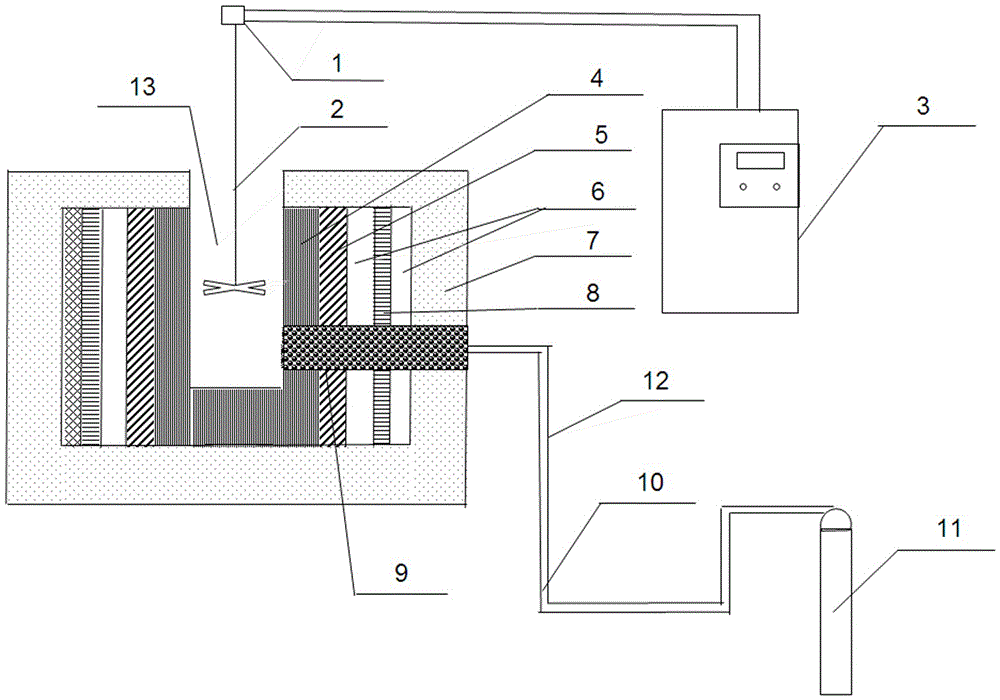

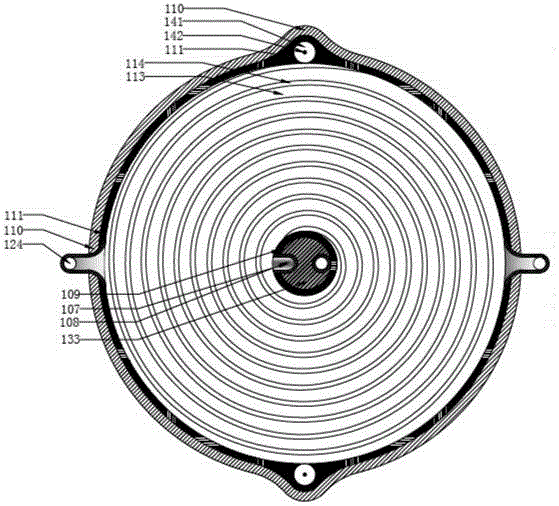

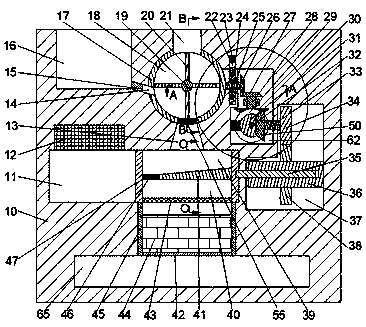

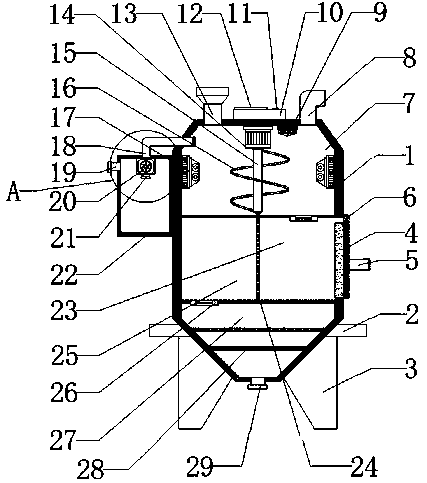

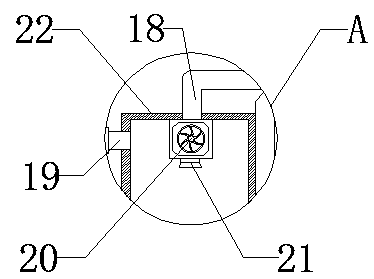

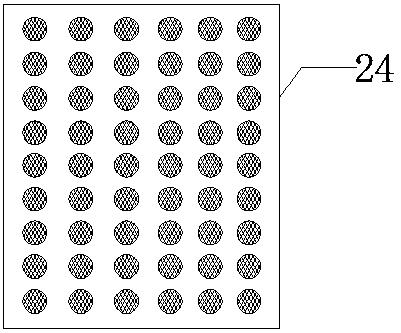

Blowing-type induction melting furnace

InactiveCN105603209AAvoid carbon pollutionGuaranteed uniformityProcess efficiency improvementPropellerInduction system

The invention provides a blowing-type induction melting furnace which comprises a furnace body, an air brick, a mechanical stirring system, a blowing system and an induction system, wherein the furnace body and a refractory crucible of the induction system form a molten pool; the inner wall of the furnace body and the induction system are partitioned and sealed through a thermal insulation material; the air brick is arranged at the bottom part or the side wall of the furnace body, directly passes through the furnace body and is communicated with the induction system and the molten pool; the mechanical stirring system comprises a mixing propeller and a control box; the mixing propeller is inserted into the molten pool and controls the rotating speed when working through the control box; the blowing system comprises a gas source and a high-pressure carrier gas transmission pipeline, and is connected with the bottom part of the furnace body through the high-pressure carrier gas transmission pipeline; an air outlet of the pipeline is opposite to the air brick; the induction system comprises an induction coil, an electromagnetic induction body, the refractory crucible and the thermal insulation material; the induction coil is in tight contact with the thermal insulation material on the inner wall of the furnace body; the thermal insulation material is arranged between the induction coil and the electromagnetic induction body; and the refractory crucible is located on the innermost layer.

Owner:NORTHEASTERN UNIV

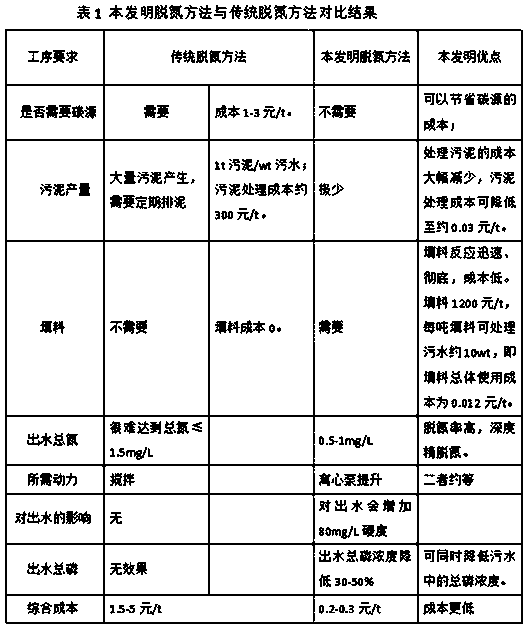

Denitrification filler and method for deep denitrification of municipal sewage

ActiveCN108033557ALow costAbundant sources of raw materialsSpecific water treatment objectivesWater contaminantsSodium silicateMunicipal sewage

The invention discloses denitrification filler and a method for deep denitrification of municipal sewage. The denitrification filler is prepared from the following raw materials by weight percent: 0.5-1.5% of aluminum powder, 8-12% of aluminum hydroxide, 3-8% of sulfur powder, 15-25% of sodium thiosulfate, 1.5-3% of sodium silicate, 40-55% of calcium hydroxide, 1.5-3% of fine sawdust and the balance of water. The denitrification filler is insoluble in the water, can react for a long time, is not powdered or argillation, and is low in cost, rich in source of raw materials and simple in preparation method; the method for the deep denitrification of the municipal sewage combines a chemical method and a biological method, thus having the advantages of being rapid and thorough of the chemical reaction as well as the advantages of being low in cost and having environmental adaptability of the biological method; therefore, the method provided by the invention is an efficient deep denitrification method.

Owner:中原环保股份有限公司

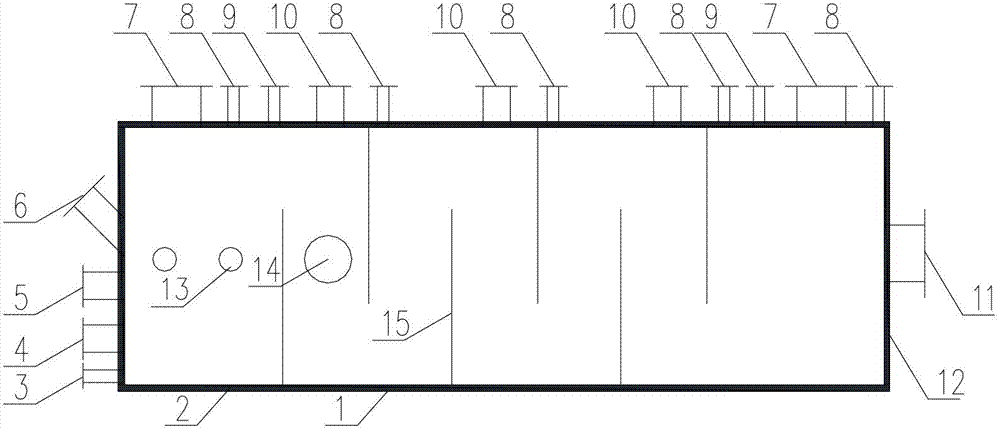

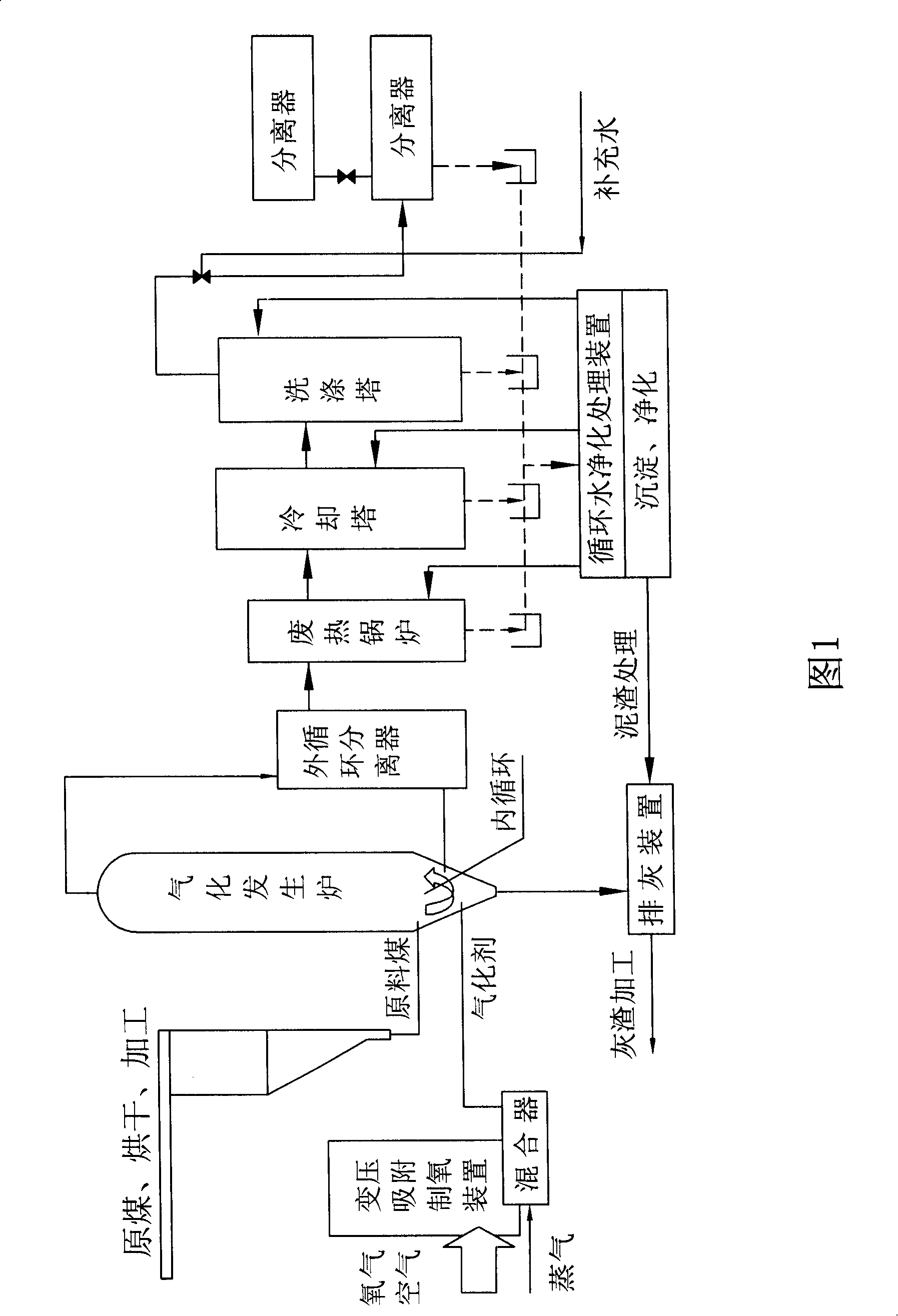

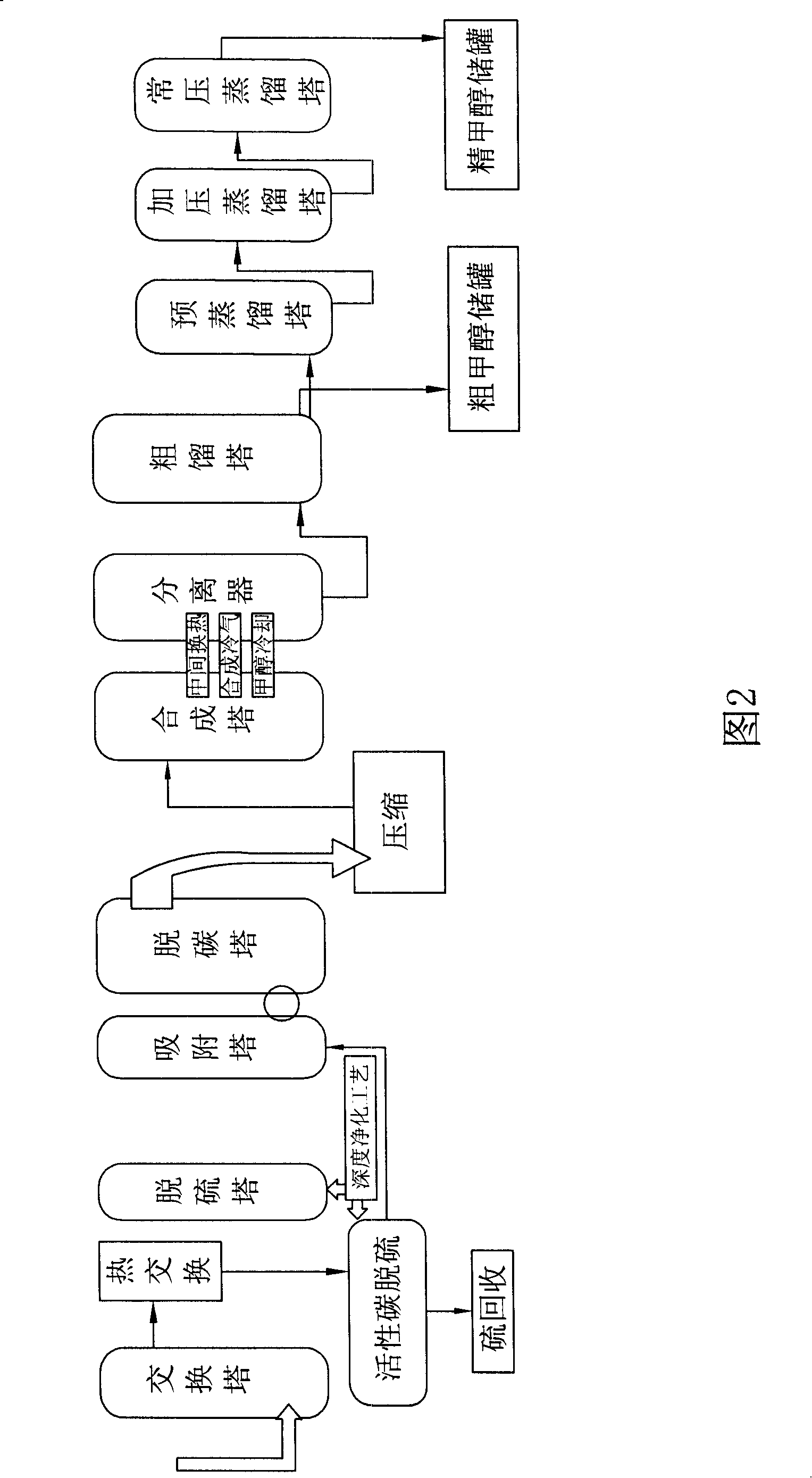

Preparation technique of methanol by lignite gasification and special equipment thereof

InactiveCN101200408AFully contactedComplete chemical reactionOrganic compound preparationHydroxy compound preparationWater vaporMixed materials

The invention relates to a process for preparing methanol from brown coal in gasification, which is characterized in that: the brown coal is crushed to brown coal powder of less 8; the brown coal powder is arranged into a totally-enclosed processing warehouse for being dried, and then is delivered into a direct-injection fluidization and gasification gas furnace in inside and outside cycle; the air and vapor are mixed to prepare the gasification agent with rich oxygen by adopting a transformation oxygen-enrichment adsorption process unit; the gasification agent is delivered into a furnace from the bottom of the direct-injection fluidization and gasification gas furnace in inside and outside cycle; and the clean water is sprayed into the furnace from the bottom. The fully mixed material in the furnace is implemented on high temperature and high pressure, so that which is cracked to generate the air with rich methanol, further, the high-purity methanol can be generated when the air with rich methanol is processed through separation, desulfurization, decarbonization and purification. The adaptability of low-quality feed coal can be expanded by taking the low-quality as raw material according to the process for preparing methanol, thereby the utilization rate of the desulfurization and gasification on the feed coal can be improved; the energy consumption can be lowered, the environmental quality can be improved; and the economical efficiency is stronger. The invention also provides special equipment so as to meet the needs of the process.

Owner:单晓强 +2

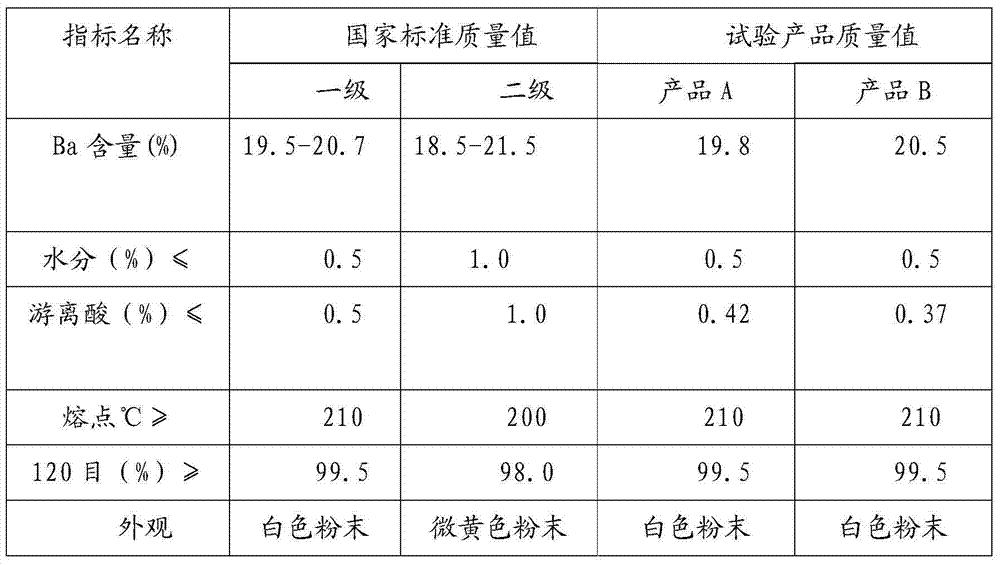

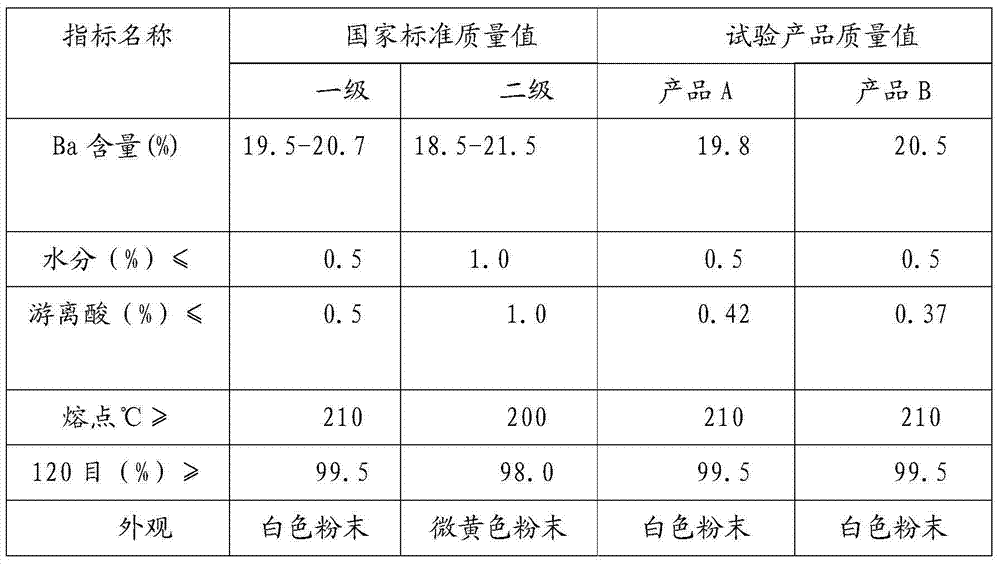

Production method for barium stearate

InactiveCN103694100AAvoid clumpingTo prevent the disadvantages of unqualified high free acid contentOrganic compound preparationCarboxylic acid salt preparationChemical reactionWastewater

The invention discloses a production method for barium stearate. The production method comprises the following steps: 1) adding water into a reactor and starting stirring and heating; 2) with water as a reaction dispersion medium and under the conditions of stirring and heating, adding powdery barium hydroxide at normal pressure so as to form a barium hydroxide suspension, then adding subparticle stearic acid while stirring when temperature reaches 50 to 60 DEG C, stopping heating when temperature reaches 65 to 66 DEG C and carrying out a reaction for 20 to 30 min when temperature rises to 69 to 70 DEG C caused by reaction exotherm; and 3) subjecting a reaction product to filtering separation, drying and crushing so as to obtain a barium stearate product. The production method provided by the invention realizes a complete chemical reaction of stearic acid with barium hydroxide under the reaction condition that a catalyst is not added and has low requirements on equipment; process flow is simple; the reaction medium water can be cyclically used, so no waste water is discharged, causing no pollution to the environment; reaction temperature is low, and little energy is consumed; no catalyst is needed, and production cost is reduced.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

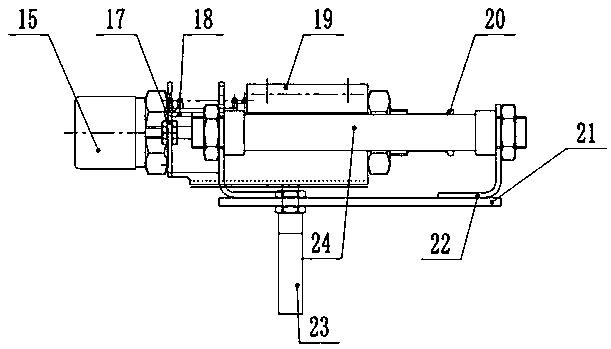

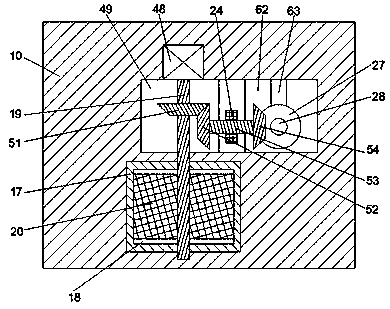

Online rapid pickling device and method for condenser in power plant

ActiveCN104596350ASimple structureReduced positioning accuracy requirementsFlush cleaningPropellerEngineering

The invention discloses an online rapid pickling device and method for a condenser in a power plant. The online rapid pickling device comprises a pickling liquid distribution device and a servo motor which are arranged outside a condenser water chamber, wherein an underwater positioning device for accurately positioning and a rapid filler for injecting pickling liquid are arranged in the condenser water chamber; the servo device is connected with the underwater positioning device; the pickling liquid distribution device is connected with the rapid filler; the servo device is used for transmitting a command to an underwater vertical positioning device in order to drive the rapid filler on a vertical coupler support to arrive at a specified area; a propeller on the support is used for driving the rapid filler to move forwards to be in hermetical butt joint with a condenser tube plate; the liquid distribution device is used for supplying pickling liquid to the rapid filler; the rapid filler is used for filling the pickling liquid into a plurality of rows of condenser heat exchange tubes in a covered area; after set cleaning and soaking time is reached, the rapid filler is separated from the condenser tube plate under the driving action of the propeller, and moves to a next area according to a set program for cleaning continually. By adopting the online rapid pickling device and method, the cleaning time is shortened greatly, the equipment running reliability is enhanced, and the cleaning cost of the condenser is lowered.

Owner:徐州比此智能科技有限公司

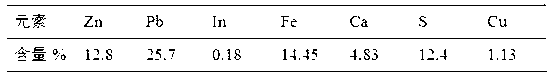

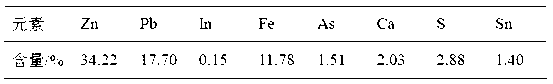

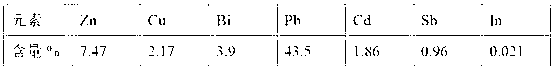

Method for pre-treating complex indium-containing smoke dust by microwave roasting

The invention provides a method for pre-treating complex indium-containing smoke dust by microwave roasting. The method comprises the following steps of: uniformly mixing the complex indium-containing smoke dust with concentrated sulphuric acid, and then roasting the mixture for 0.5 hour to 3 hours at 100 DEG C to 250 DEG C under the condition with microwave powder or 300W-500W to obtain a roasted product; crushing the roasted product, stirring and soaking the crushed rotated product in a sulphuric acid solution for 0.5 hour to 2 hours at 23 DEG C to 50 DEG C, so as to obtain leachate and leached residue by carrying out solid-liquid separation, wherein the leaching efficiency of easy-soluble valuable metals such as indium, zinc and the like in the materials is higher than 95%; and extracting the indium in the complex indium-containing smoke dust by leafing most of the metals such as lead, iron and the like in the slag. The method disclosed by the invention has the technical characteristics of being high in metal leaching efficiency, small in reagent consumption amount, short in treatment time, low in energy consumption, concentrated in valuable metals. Most of the metals such as the lead, the iron and the like are left in the slag, so that beneficial conditions are created for the subsequent indium treatment process.

Owner:KUNMING UNIV OF SCI & TECH

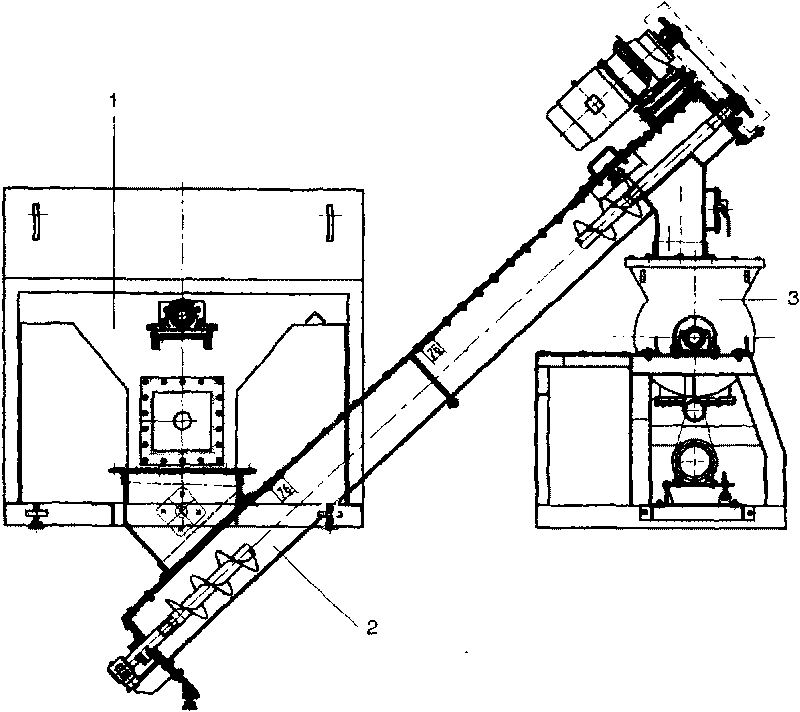

Non-pollution treatment device

InactiveCN101733269AEfficient removalImprove efficiencySludge treatmentSolid waste disposalMaterials preparationReactor system

The invention relates to a non-pollution treatment device, which comprises a raw material pre-treatment system, a raw material hoister, an auxiliary material batching system, a reactor system and a belt conveyor. The device is characterized in that stirring claws of the raw material pre-treatment system have bar-shaped structures; two spiral pushing shafts are arranged at two ends of a feed port of the raw material pre-treatment system respectively, wherein one shaft rotates leftwards, while the other shaft rotates rightwards; the raw material pre-treatment system and the raw material hoister are connected; the raw material hoister feed raw materials into the reactor system by adopting spiral hoisting; the auxiliary material preparation system and the raw material hoister are connected to feed auxiliary materials into the reactor system; and a discharge port of the reactor system is connected with the belt conveyor. The whole device has a closed structure, has simple and convenient operation and high treatment efficiency on putrid wastes.

Owner:高均

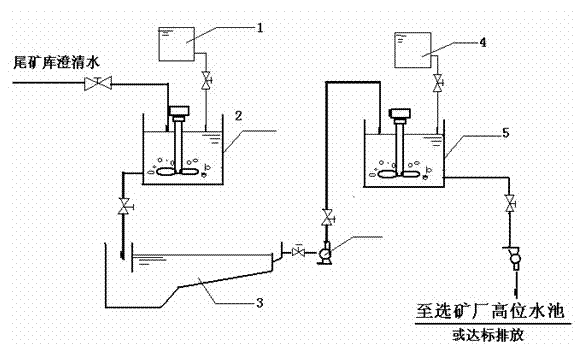

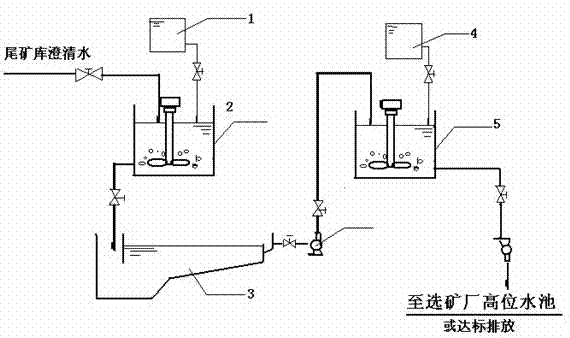

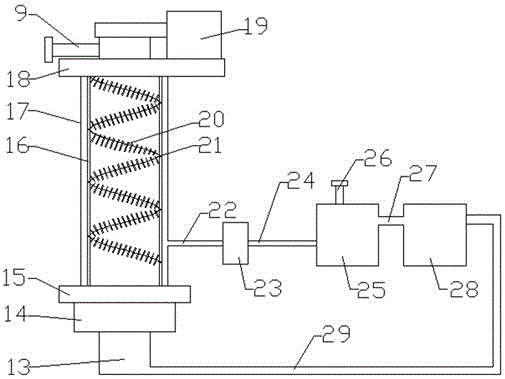

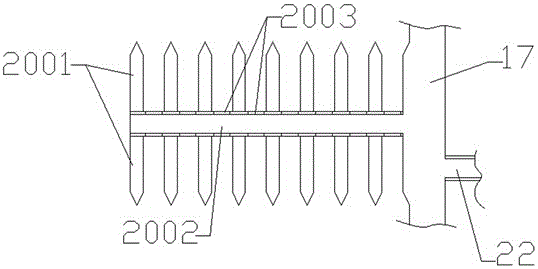

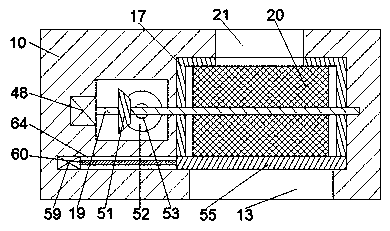

Online precision chemical descaling device and method of industrial tube nest type water cooler

The invention discloses an online precision chemical descaling device and method thereof of an industrial tube nest type water cooler. A descaling agent distribution device and a servo control device are arranged outside a water chamber of the water cooler, an underwater positioning device and a descaling agent injection device are mounted in the water chamber of the water cooler, the underwater positioning device is connected with the servo control device through a waterproof cable, the descaling agent distribution device is connected with the descaling agent injection device through a guide tube, the servo control device transmits commands to the underwater positioning device, descaling agent injection nozzles on a driving support and orifices of cooler heat exchange tubes are docked, and the descaling agent distribution device supplies descaling agent to the descaling agent into the descaling agent injection nozzles. After set washing and soaking time is up, the descaling agent injection nozzles are separated from docking with the orifices of the cooler heat exchange tubes under drive of the servo control device and automatically move to inlets of the next group of cooler heat exchange tubes. On the premise of zero emission, reliability of operating of the equipment is improved, cleaning cost of the cooler is greatly reduced, and cleaning effect is greatly improved.

Owner:徐州比此智能科技有限公司

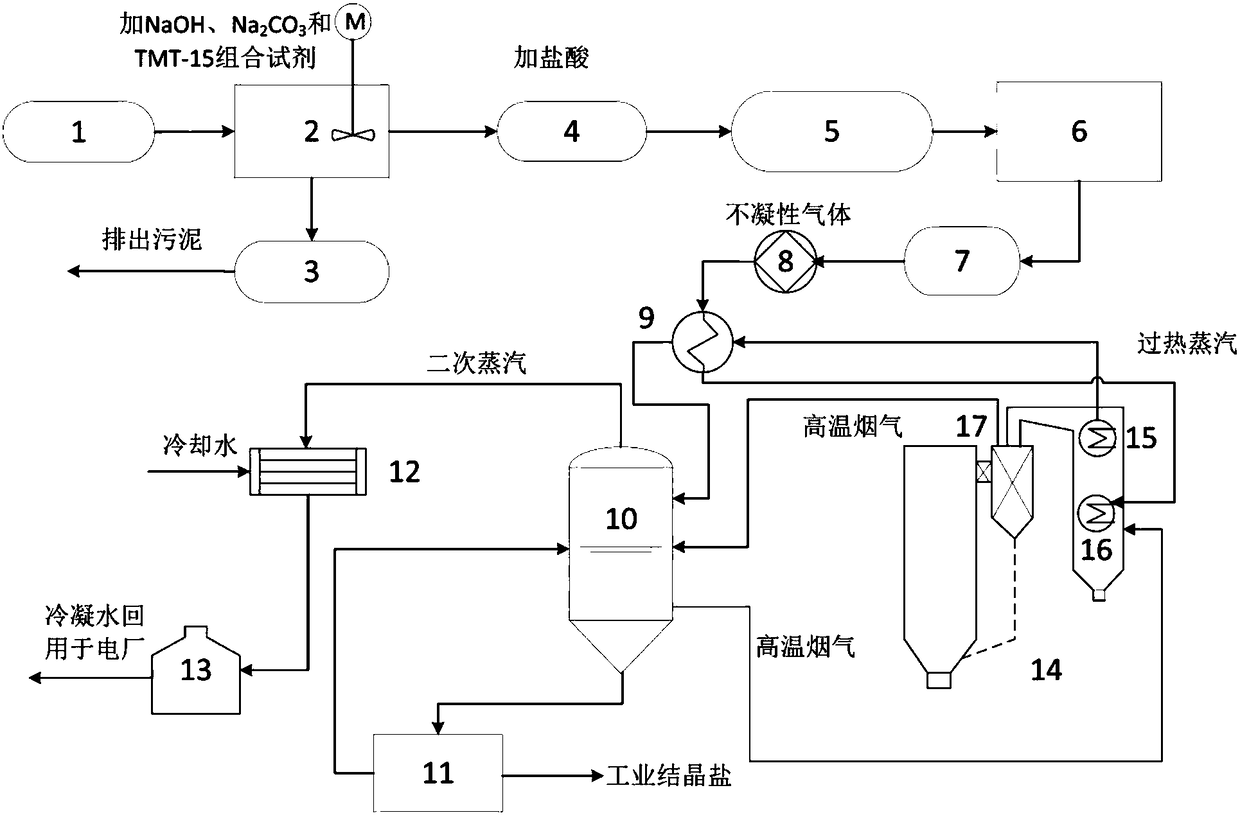

Zero emission treatment system and zero emission treatment method for desulfurization waste water from ultra-supercritical circulating fluid bed (CFB) boiler

PendingCN108558110AEfficient use ofIncrease heat transfer temperature differenceSludge treatmentWater contaminantsFiltrationHigh energy

The invention discloses a zero emission treatment system and a zero emission treatment method for desulfurization waste water from an ultra-supercritical circulating fluid bed (CFB) boiler. The zero emission treatment system comprises a chemical pretreatment system, a membrane filtration system, an electrodialysis system, a desulfurization waste water preheating system, a desulfurization waste water evaporator, a solid-liquid separation device and a vapor condensation device. High-temperature flue gas at an exit position of a cyclone separator of the ultra-supercritical CFB boiler is used as aheat source to evaporate and crystallize the desulfurization waste water, superheated steam at an inlet header of a rear platen superheater of the super-supercritical CFB boiler is used as a heat source for the preheated desulfurization waste water, and the membrane filtration system provided with a microfiltration device and the electrodialysis system used for concentration reduction are additionally arranged, so that the defects of high energy consumption and high equipment investment cost of the existing multi-effect evaporation technology are overcome, the desulfurization efficiency can be improved, equipment scaling is effectively avoided, system handling load is reduced, economic benefit is significantly improved, the energy is saved, and the operating cost is reduced.

Owner:XI AN JIAOTONG UNIV

Novel battery structure

ActiveCN104577037AComplete chemical reactionSolve technical bottlenecksActive material electrodesSecondary cells manufactureChemical reactionElectrical battery

The invention relates to a novel battery structure. The novel battery structure comprises a positive electrode material, a negative electrode material and a dynamic charging-discharging part, wherein the dynamic charging-discharging part is used for enabling the positive electrode material and the negative electrode material, which enter the dynamic charging-discharging part, to move or move oppositely at two sides of an exchange membrane, and is used for charging / discharging or is ready to charge or discharge in a movement or opposite moving process. According to the novel battery structure, the positive electrode material and the negative electrode material are in movement statuses in a discharging process, and thus, chemical reaction can be carried out fully and completely between the positive electrode material and the negative electrode material of the battery, the total ion operating distance of the exchange membrane is further shortened, the discharging speed is high, the internal resistance is further reduced, and the technical bottleneck of the conventional battery is broken.

Owner:LANZHOU JINFULE BIOTECH CO LTD +3

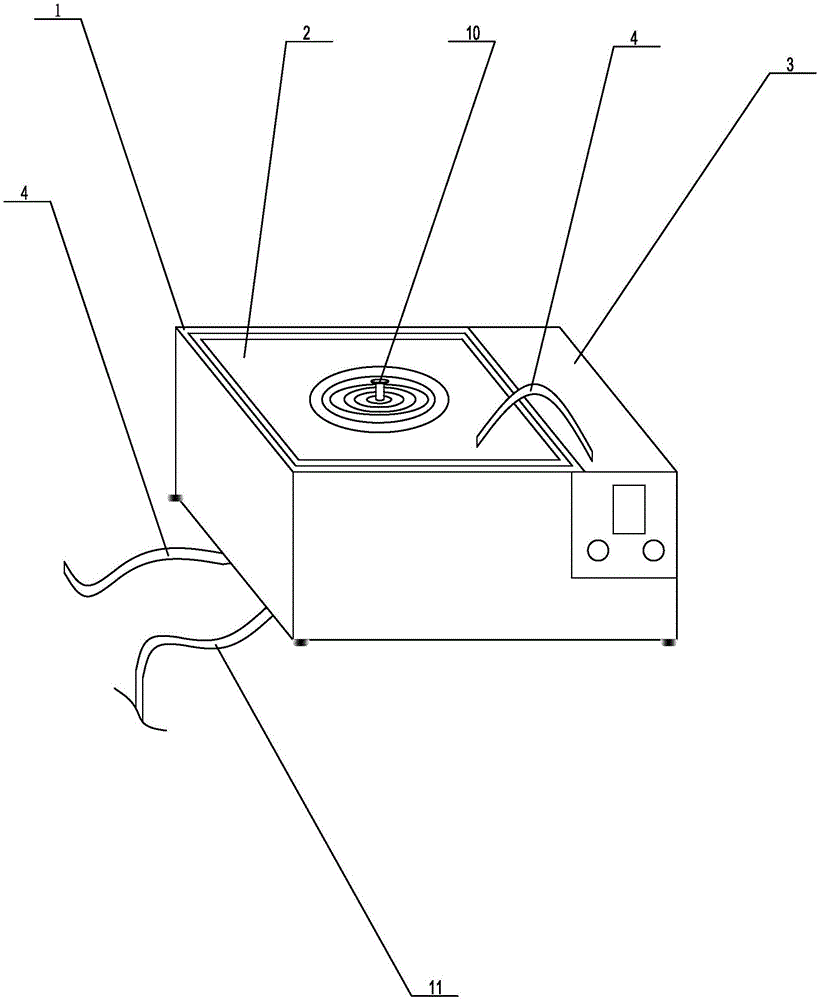

Isothermal self-compensating type liquid level adjusting water bath kettle

InactiveCN105498882ARealize the function of automatic water replenishment (water with the same water temperature)Added automatic compensation functionWater/sand/air bathsTemperature controlWater baths

Owner:TIANJIN ENVIRONMENT MONITORING CENT

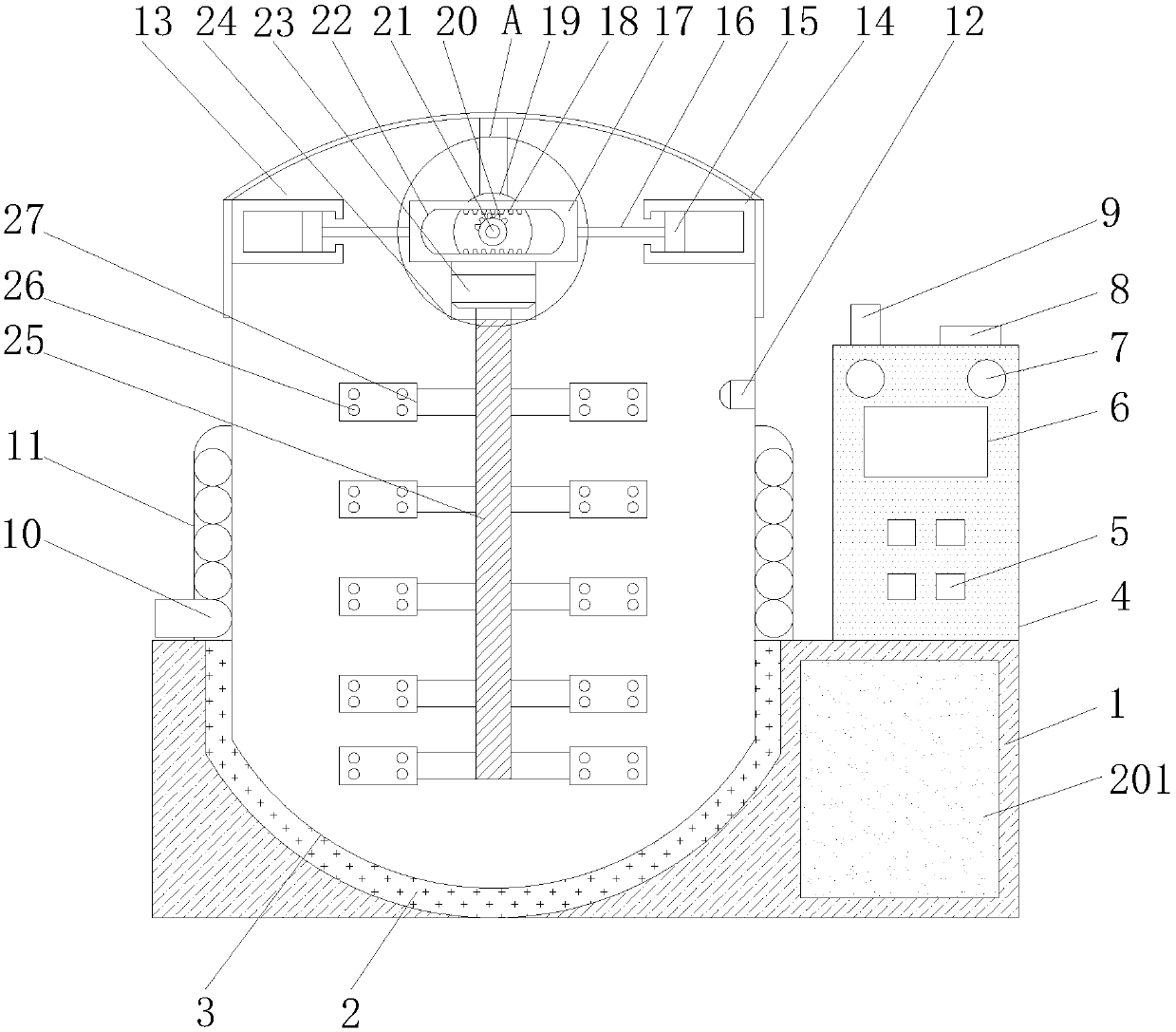

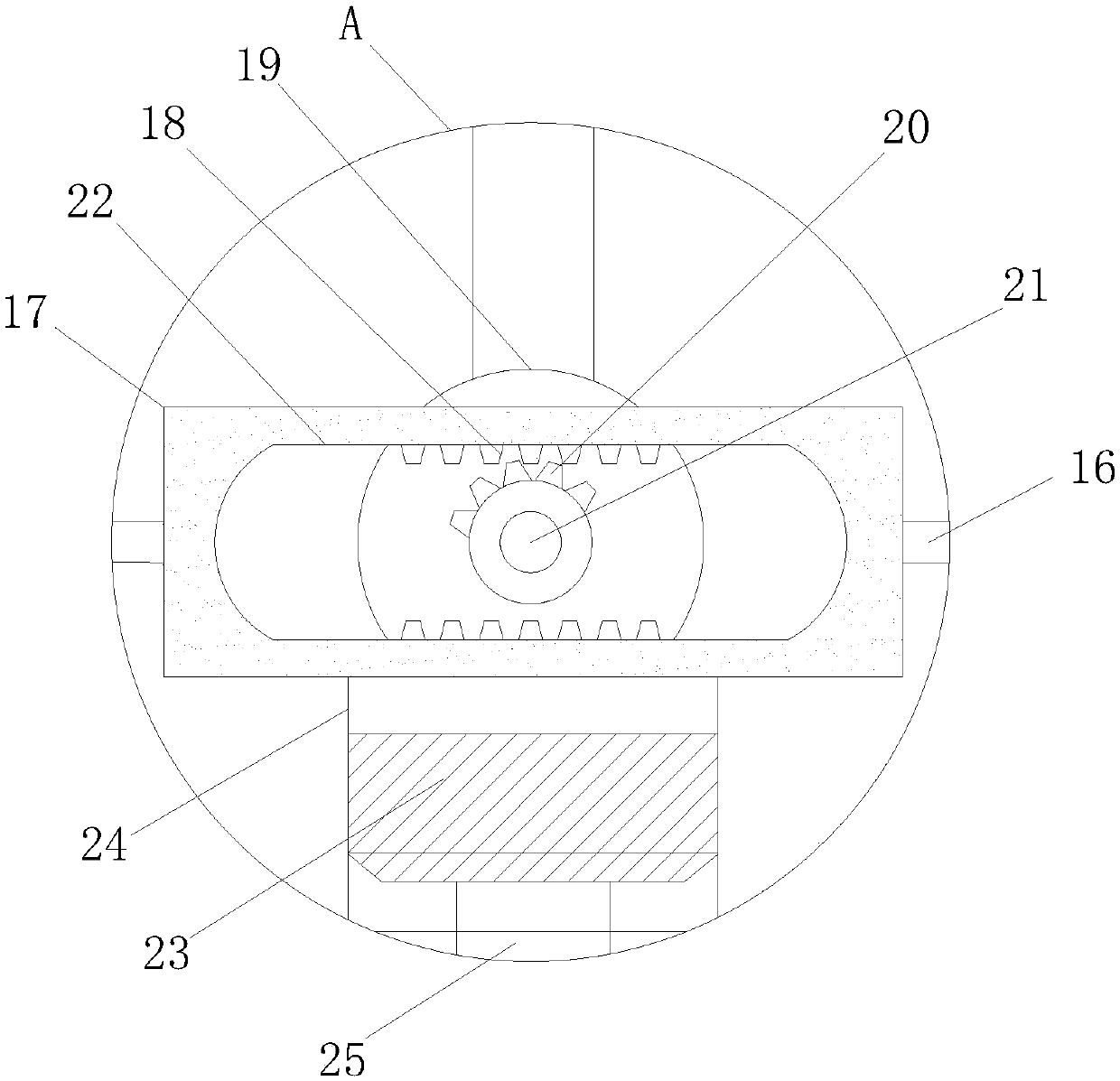

Chemical reaction kettle with automatic temperature changing function

InactiveCN109603722AReasonable structureInnovative designChemical/physical/physico-chemical stationary reactorsHeating timeChemical reaction

The invention belongs to the technical field of reaction kettles, and particularly discloses a chemical reaction kettle with an automatic temperature changing function. The chemical reaction kettle comprises a base, an electric heating wire plate, a lithium battery, a kettle body, a control box, a control panel, a displayer, an indicator lamp, a timer, a buzzer, a cooling pipe, a fixing ring, a temperature sensor, a top cover, a fixing pipe, a slider, a connecting rod, a movable frame, a rack plate, a fixing plate, a half gear, a first motor, an arc-shaped groove, a second motor, a fixing block, a stirring shaft, a stirring plate and side holes. The chemical reaction kettle is reasonable in structure; the temperature in the kettle body is detected through the temperature sensor, the temperature in the kettle body is displayed on the displayer, the kettle body is heated through the electric heating wire plate, the temperature in the kettle body is raised, cold water is guided into the cooling pipe for cooling the interior of the kettle body, the heating time and cooling time are calculated through the timer, temperature changing is more accurate, the heating or cooling state is displayed through the indicator lamp, and workers are reminded through the buzzer.

Owner:陆挚译

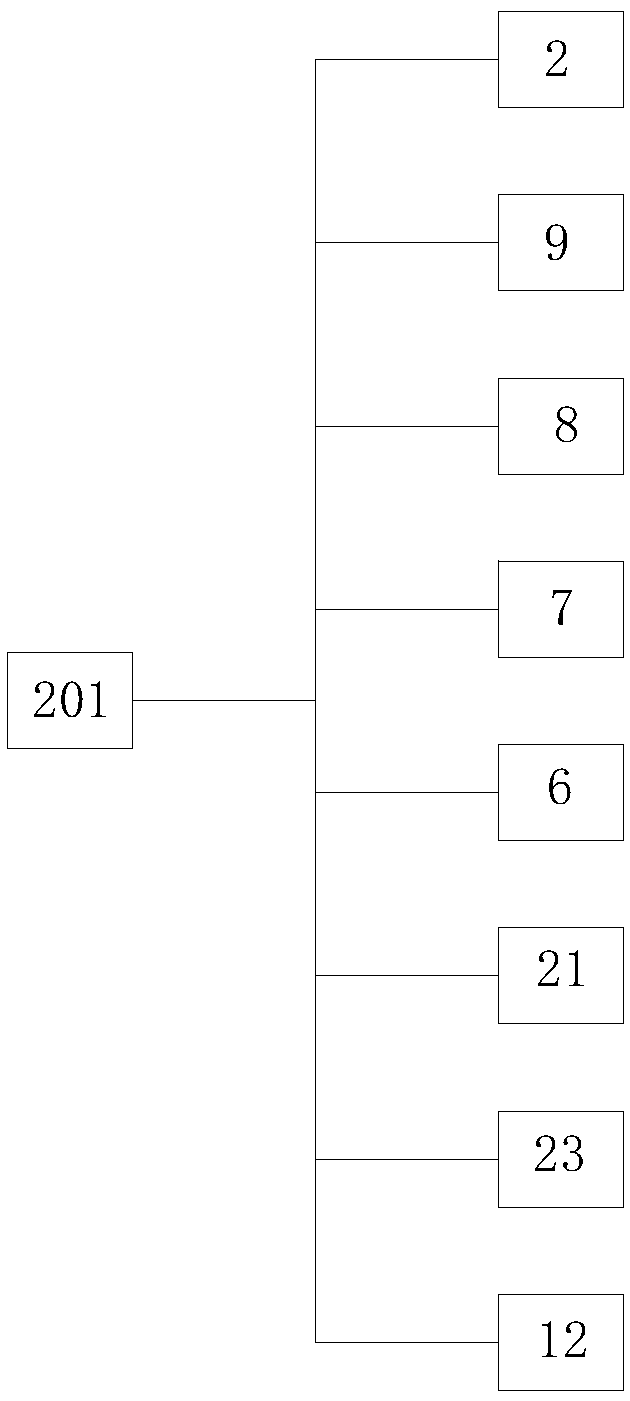

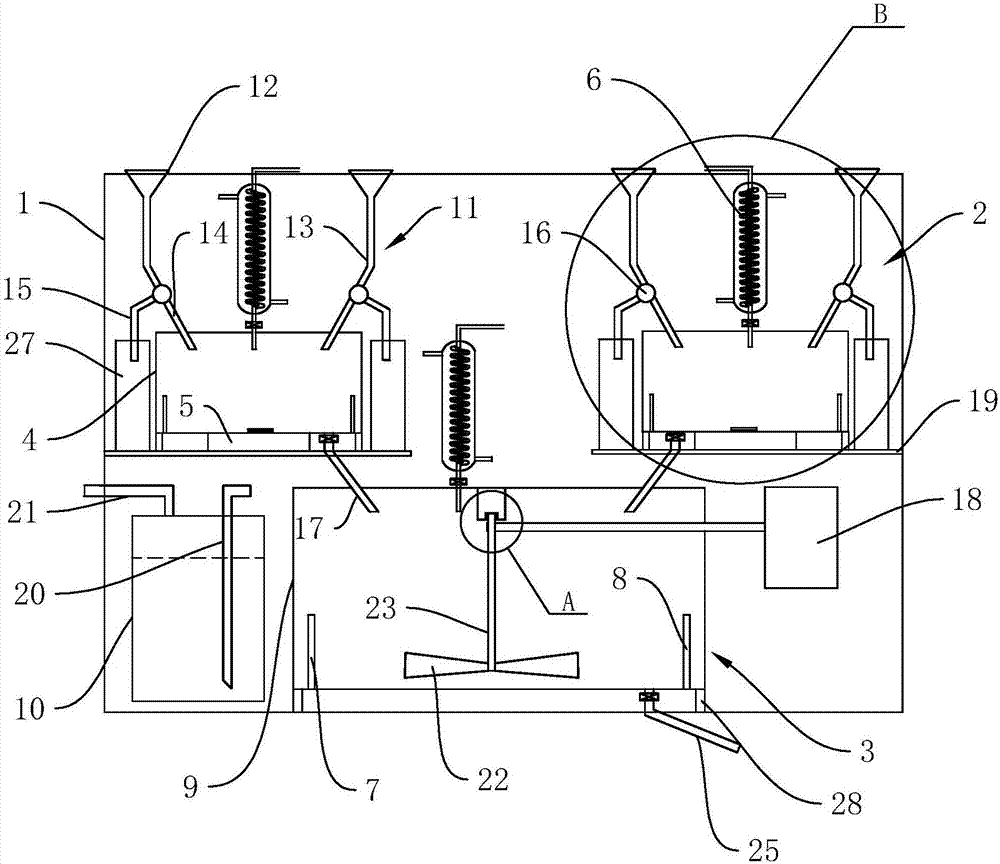

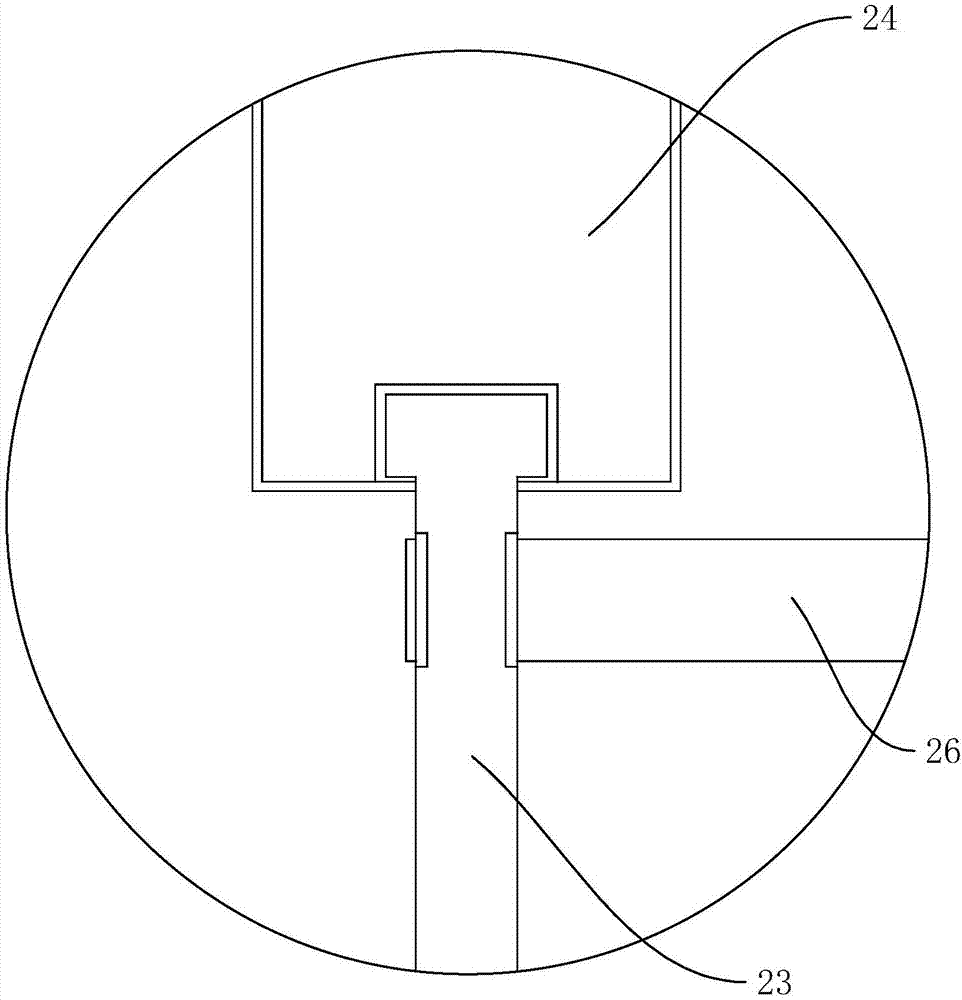

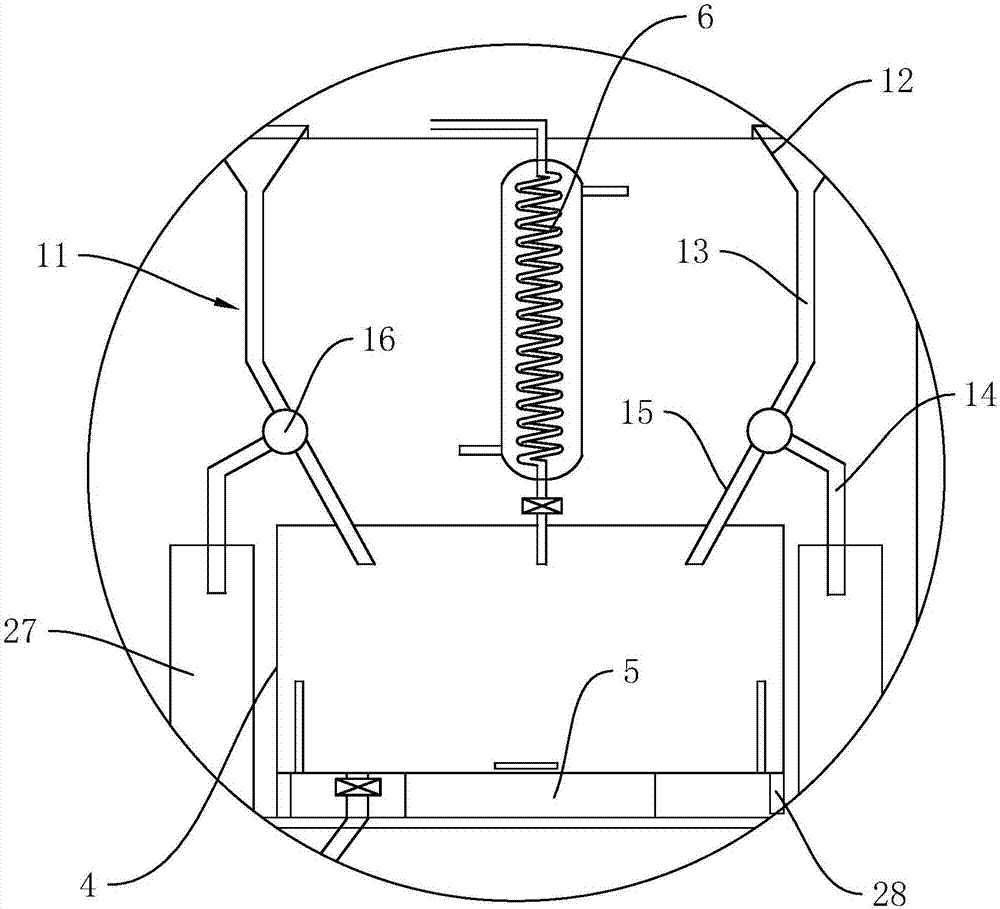

Multi-step preparation chemical reaction device

InactiveCN106955659AReduce volatilityEasy to cleanProcess control/regulationChemical/physical/physico-chemical stationary reactorsChemical reactionMagnetic stirrer

The invention belongs to the technical field of chemical reaction and provides a multi-step preparation chemical reaction device. The multi-step preparation chemical reaction device comprises a box body, wherein the box body is internally provided with at least two first-grade reaction devices and a two-grade reaction device; each first-grade reaction device comprises a first-grade reaction tank and an electromagnetic stirrer; a thermoelectric couple and a heating rod are arranged at two ends of each first-grade reaction tank respectively; each first-grade reaction tank is provided with at least two material injection devices and a condensation pipe; the two-grade reaction device is arranged below the first-grade reaction devices; the two-grade reaction device comprises a two-grade reaction tank; the two-grade reaction tank is further internally provided with a thermoelectric couple and a heating rod; the two-grade reaction tank is provided with a stirring device and a condensation pipe; an outlet end of a discharging pipe stretches into the two-grade reaction tank; the multi-step preparation chemical reaction device further comprises a tail gas absorption bottle; each material injection device is provided with a funnel; a metering pipe, a material injection pipe and a recycling pipe are arranged below each funnel; a recycling bottle is arranged below each recycling pipe. The multi-step preparation chemical reaction device provided by the invention is simple to operate and easy to wash; multi-step reaction can be rapidly carried out and a surplus reaction reagent is recycled.

Owner:廖允泰

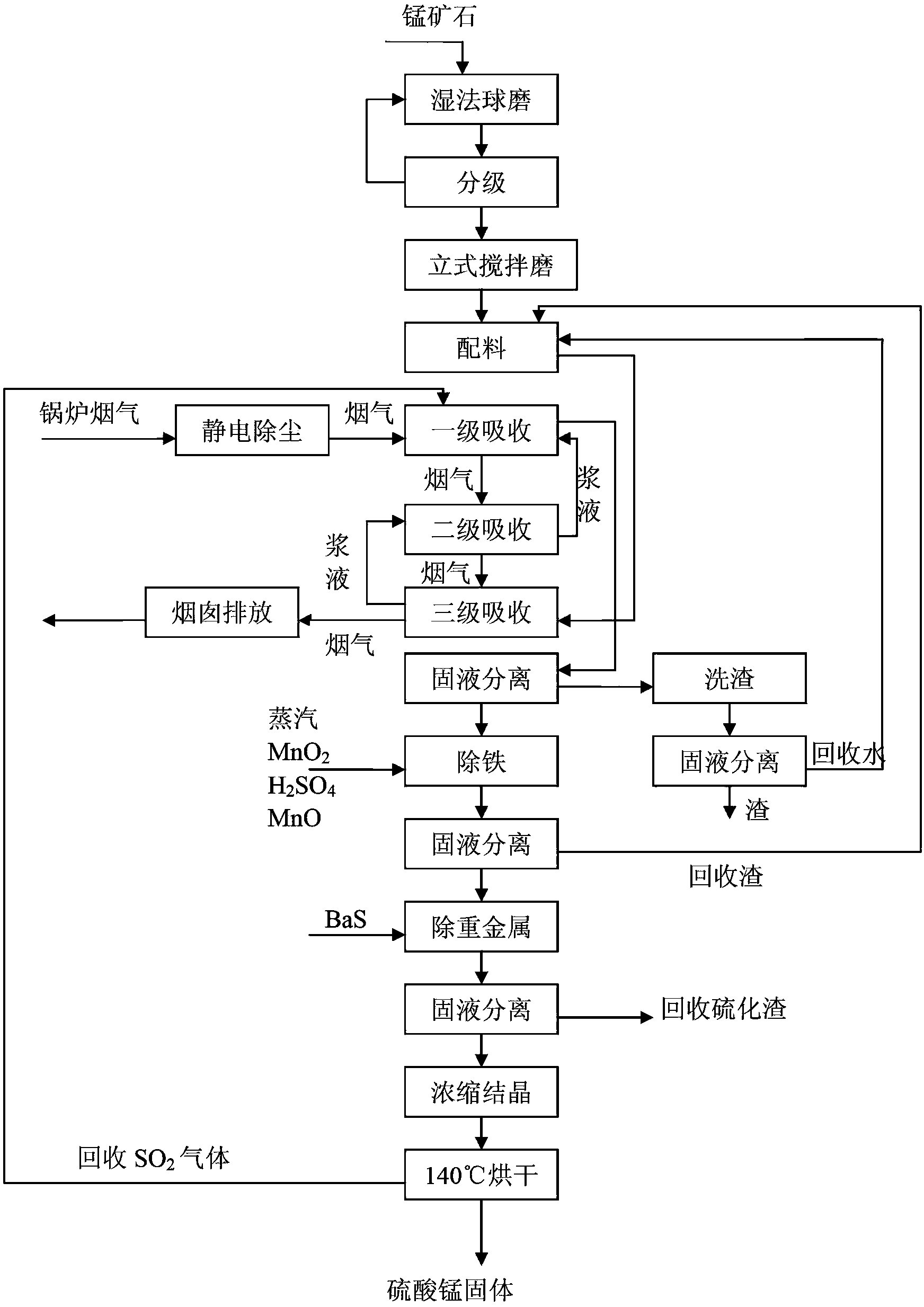

Method for preparing manganese sulfate by using manganese dioxide ore pulp to absorb sulfur dioxide in flue gases

ActiveCN102815750BLess solidMeet the requirements of flue gas desulfurizationChemical industryManganese sulfatesManganese sulphateFlue gas

The invention discloses a method for preparing manganese sulfate by absorbing sulfur dioxide in flue gas with manganese dioxide ore pulp, comprising the following steps: performing wet ball milling on manganese dioxide ore and grading to obtain initial ore pulp, and the particle size of the ore material in the initial ore pulp is less than 149 μm, the initial pulp is crushed by a vertical stirring mill to obtain a reaction pulp, and 90% of the particle size of the mineral material in the reaction pulp is below 50 μm; add a manganese sulfate solution containing Fe3+ and / or Fe2+ to the obtained reaction pulp, and then make the reaction pulp Absorption reaction with high-temperature flue gas containing sulfur dioxide, the reaction temperature is controlled at 90 ° C ~ 95 ° C; after the completion of the absorption reaction, the reaction product is subjected to solid-liquid separation, iron and heavy metal removal, and then concentrated and crystallized under normal pressure to obtain monohydrate Manganese sulfate. The method of the invention has the advantages of energy saving and environmental protection, high resource utilization rate, high product added value, good flue gas desulfurization effect, continuous and thorough reaction, low cost and the like.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

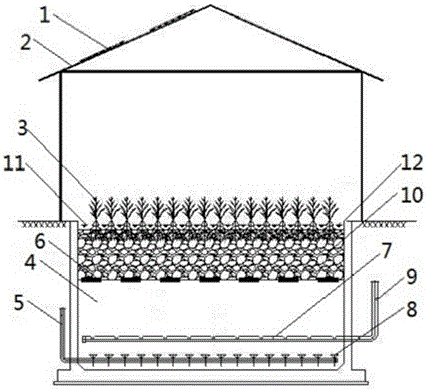

Novel semi-ecological sewage treatment process

InactiveCN106116046AImprove purification effectComplete chemical reactionWater/sewage treatment by centrifugal separationBiological treatment apparatusMicroorganismWater quality

The invention discloses a new process for semi-ecological sewage treatment, which comprises a sewage treatment tank, a sewage storage room is arranged at the lower part of the sewage treatment tank, a support layer is set above the sewage storage room, a filter material layer is provided above the support layer, and a filter material layer is arranged above the support layer. The material layer includes a filter layer and an organism ecological treatment layer. An aeration pipe is provided at the bottom of the sewage holding room. The bottom of the sewage holding room is also connected to a water inlet pipe. The other end of the water inlet pipe is connected to a sewage separator. The sewage separator includes a separation device and Circulating water treatment device. By combining physical purification and biological purification, the present invention avoids the problem of long purification time in the simple ecological treatment of sewage, and at the same time avoids the excessive pollution of sewage entering the ecological sewage treatment pool, which will cause the microorganisms to be in the sewage The environment is harsh, which leads to low sewage treatment efficiency, poor water quality after treatment, and the phenomenon that the water cannot be completely up to standard, which can ensure that the sewage can be completely purified.

Owner:王攀

Dye waste liquid treatment device

ActiveCN111320308AWell mixedStir wellTransportation and packagingRotary stirring mixersMechanical engineeringMechanics

The invention discloses a dye waste liquid treatment device including a machine body, an input cavity with an upward opening is formed in the upper portion of the interior of the machine body. A cylindrical rotary drum wall is arranged below the input cavity; a mixing cavity communicated with the input cavity is formed in the wall of the rotary drum, and a filtering device is arranged in the mixing cavity. According to the device, person entering into the device can be avoided so as to carry out the cleaning operation, such that the harm of the waste liquid precipitate on the human body can besubstantially reduced, and the overall treatment efficiency can be improved.

Owner:浙江华德利纺织印染有限公司

Water bath kettle with clamping device

The invention discloses a water bath kettle with a clamping device. The water bath kettle comprises a tank body, a water channel and a control cabinet, wherein an air pump is arranged in the control cabinet and is connected with a gas piping, and the gas piping penetrates in from the top of the water channel and out from the bottom of the water channel; a storage plate horizontally arranged is arranged in the water channel, a plurality of clamping devices are arranged on the storage plate, each clamping device comprises a containing hole formed in the storage plate, a plurality of elastic elements are arranged on the containing hole, all the elastic elements are connected with clamping assemblies, and the adjacent clamping assemblies can be matched with each other and connected. Different shapes of containers in the water channel can be stabilized, an automatic water supply device is arranged, the tank body is heat-insulating and energy-saving, and the water bath kettle has the advantages of being short in heating time, uniform in water temperature, high in accuracy of experiment results, wide in application range, good in scale-preventive performance, high in safety performance and the like, and is good in usability and worthy of wide popularization.

Owner:钦州市明大检测技术有限公司

Polyferric PAC (poly aluminium chloride) reaction tank

PendingCN109748365AEasy to useMeet the set requirementsWater/sewage treatment by flocculation/precipitationGastric tube feedingWater pipe

The invention discloses a polyferric PAC (poly aluminium chloride) reaction tank. The polyferric PAC reaction tank comprises a reaction tank body, wherein one side of the outer surface of the reactiontank body is connected with a movable baffle plate through a hinge; one side of the movable baffle plate is connected with a handle; a water inlet tube, a working panel and a feeding tube are separately arranged at the top of the reaction tank body; a temperature knob and a display are separately arranged at the top of the working panel; a reaction chamber is arranged above the inner part of thereaction tank body; and the polyferric PAC reaction tank is further equipped with a partition plate, a solid chamber and the movable baffle plate. After chemical reaction is ended, solid impurities ina solution can be blocked by the partition plate to keep in the solid chamber when the solution passes through the partition plate, and liquid enters the liquid chamber through the partition plate; and after use is ended, a user can open the movable baffle plate through the handle and the hinge so as to intensively clean the solid impurities in the solid chamber, so that the user uses the reaction tank more conveniently.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Production method for barium stearate

InactiveCN103694100BAvoid clumpingTo prevent the disadvantages of unqualified high free acid contentOrganic compound preparationCarboxylic acid salt preparationChemical reactionReaction temperature

The invention discloses a production method for barium stearate. The production method comprises the following steps: 1) adding water into a reactor and starting stirring and heating; 2) with water as a reaction dispersion medium and under the conditions of stirring and heating, adding powdery barium hydroxide at normal pressure so as to form a barium hydroxide suspension, then adding subparticle stearic acid while stirring when temperature reaches 50 to 60 DEG C, stopping heating when temperature reaches 65 to 66 DEG C and carrying out a reaction for 20 to 30 min when temperature rises to 69 to 70 DEG C caused by reaction exotherm; and 3) subjecting a reaction product to filtering separation, drying and crushing so as to obtain a barium stearate product. The production method provided by the invention realizes a complete chemical reaction of stearic acid with barium hydroxide under the reaction condition that a catalyst is not added and has low requirements on equipment; process flow is simple; the reaction medium water can be cyclically used, so no waste water is discharged, causing no pollution to the environment; reaction temperature is low, and little energy is consumed; no catalyst is needed, and production cost is reduced.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com