Process for producing novel puffing nitramon

A technology of expanded ammonium nitrate explosives and preparation process, which is applied in explosive processing equipment, explosives, offensive equipment, etc., and can solve the problems of automatic and continuous production of expanded ammonium nitrate explosives, uneven composition of local components, and low power per unit volume, etc. problems, to achieve the effect of reducing processing and production links, reducing production facilities, and reducing the amount of online storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

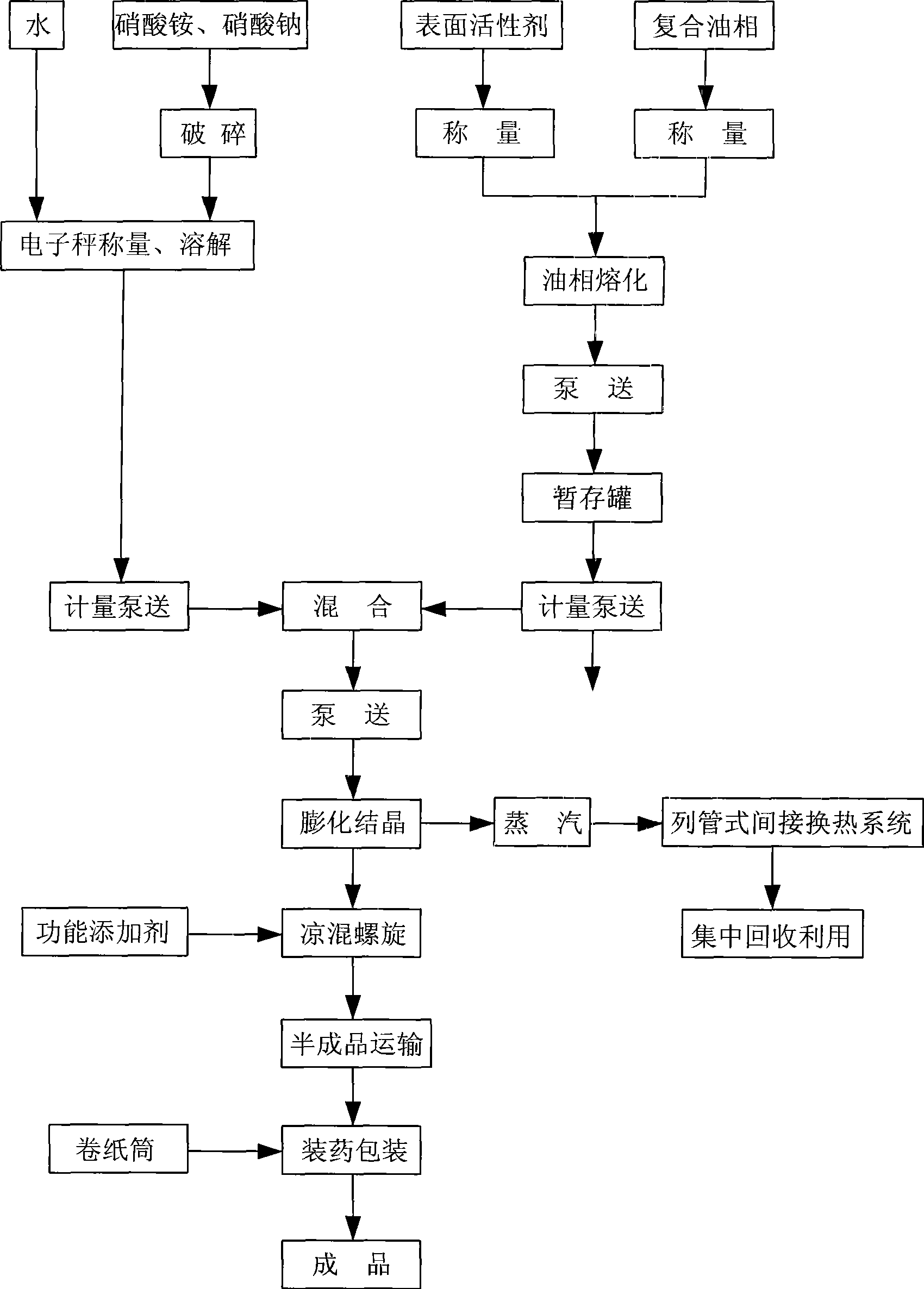

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0022] see figure 1 , a kind of preparation technology of novel expanded ammonium nitrate explosive, its processing step is:

[0023] The first step is to dissolve in the water phase: add a certain amount of water to the water phase dissolution tank, and the ammonium nitrate and sodium nitrate that have been measured and crushed are transported to the water phase tank for dissolution by the screw conveyor, and the addition of ammonium nitrate, sodium nitrate and water The mass percent addition ratio based on the total amount of the water phase is: ammonium nitrate 92: sodium nitrate 0-3: water 8, the mass percent concentration of nitrate in the solution is controlled at 90-93%, and the temperature after dissolution is controlled at 110 ~ 120 ℃, and set up multiple water phase dissolution tanks for alternate use. Multiple water phase dissolving tanks can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com