Online precision chemical descaling device and method of industrial tube nest type water cooler

A water cooler and tube-and-tube technology, which is applied in the field of chemical cleaning of industrial heat exchangers, can solve the problems of not reaching the cleaning concentration and wasting chemical cleaning agents, so as to reduce the amount of use, reduce the amount of chemicals, and improve the cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

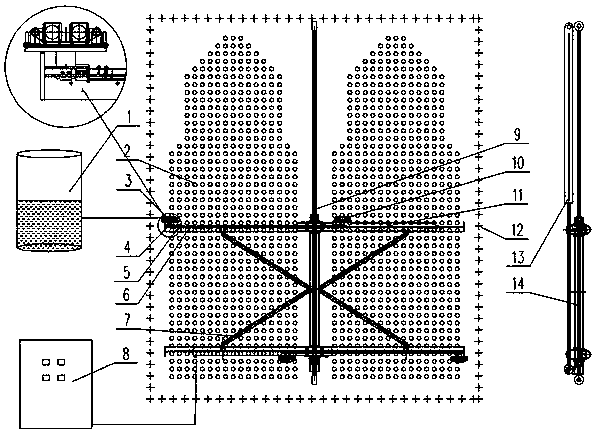

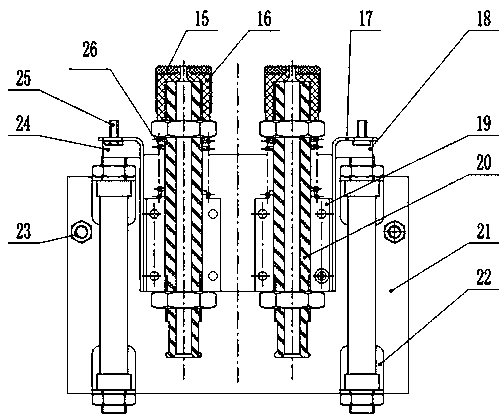

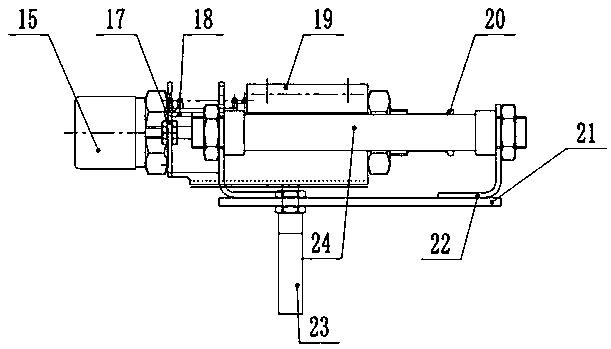

[0033] like figure 1 , figure 2 , image 3 , Figure 4 as shown, figure 1 It is the structure and system construction diagram of the positioning device of the present invention, figure 2 It is a top view of the descaling agent injection device of the present invention, image 3 It is the left view of the descaling agent injection device of the present invention, Figure 4 It is the front view of the descaling agent injection device of the present invention.

[0034] An on-line precise chemical descaling device for an industrial tubular water cooler, including a descaling agent liquid dispensing device 1 and a servo control device 8 arranged outside the water chamber 12 of the cooler, and an underwater positioning device installed in the water chamber 12 of the chiller device, descaling agent injection device 3, the underwater positioning device is connected to the servo control device 8 through a waterproof cable, and the descaling agent dosing device 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com