Production method for barium stearate

A technology of barium stearate and production method, applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation and other directions, can solve problems such as inability to overcome waste water discharge, and achieve the effects of reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

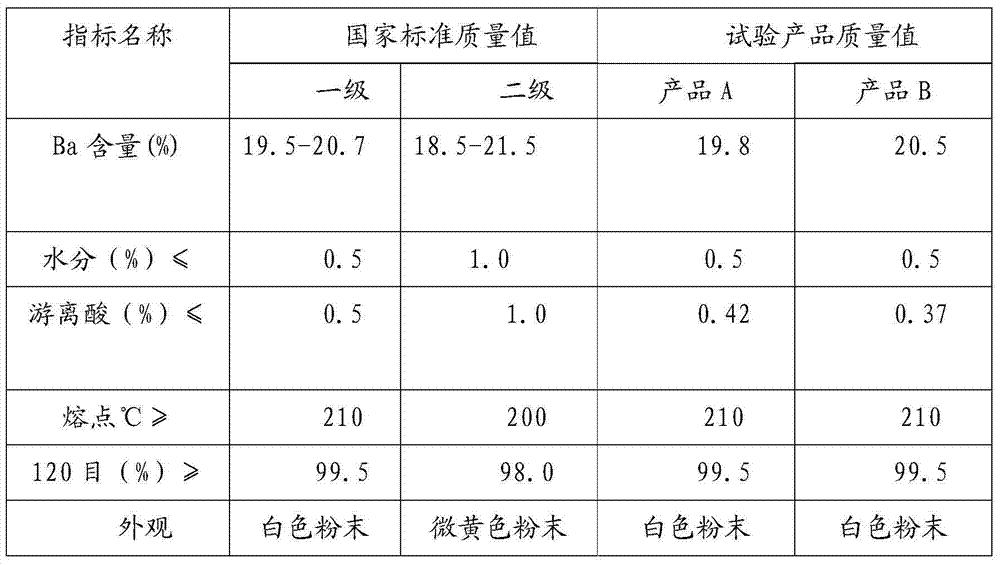

Examples

Embodiment 1

[0029] The production method of barium stearate described in this embodiment is carried out according to the following steps:

[0030] 1) In a 5000ml flask with heating, stirring and temperature measuring devices, add 1200ml of water to start stirring and heating;

[0031] 2) Under normal pressure, using water as the reaction dispersion medium, while stirring and heating, first add powdered barium hydroxide octahydrate (Ba(OH)) to the flask in step 1) 2 ·8H 2 O) 132.0g, stir evenly to form a barium hydroxide suspension; when the temperature reaches 58℃, add 222.2g of stearic acid while stirring, stearic acid is fine granular industrial stearic acid; when the temperature reaches At 66°C, the heating was stopped; the temperature was further increased due to the exotherm of the reaction, and the reaction was maintained at 70°C for 30 minutes; the reaction ended. The barium hydroxide octahydrate is powdered barium hydroxide octahydrate with an industrial-grade purity greater than 98%. ...

Embodiment 2

[0035] The production method of barium stearate described in this embodiment is carried out according to the following steps:

[0036] 1) In a 5000ml flask equipped with heating, stirring and temperature measuring devices, add 1200ml of the circulating mother liquor obtained in Example 1 and heat while stirring, and then start stirring and heating;

[0037] 2) Under normal pressure, with water as the reaction dispersion medium, while stirring and heating, first add 132.1g of powdered barium hydroxide octahydrate to the flask in step 1), and stir evenly to form a barium hydroxide suspension Turbid liquid; when the temperature reaches 56°C, add 222.05g of stearic acid while stirring. Stearic acid is a fine granular industrial grade stearic acid; when the temperature reaches 65°C, stop heating; due to the exothermic reaction The temperature rose further, maintained at 69°C, and reacted for 30 minutes; the reaction ended. The barium hydroxide octahydrate is powdered barium hydroxide o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com