Blowing-type induction melting furnace

An induction melting furnace and injection technology, which is applied in the field of metallurgy, can solve the problem that induction heating cannot be applied, and achieve the effects of intensified purification and impurity removal, less difficulty in operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

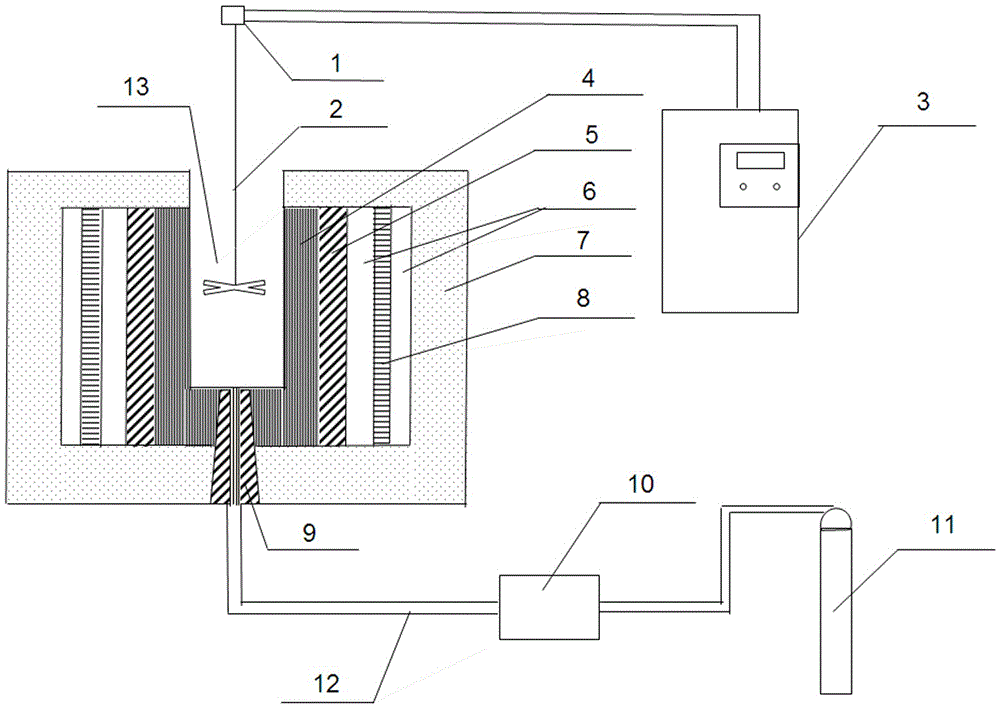

[0022] A blown induction melting furnace, such as figure 1 As shown, it includes a furnace body 7, a slit-type ventilation brick 9, a mechanical stirring system, a storage tank 10, a gas source 11, a high-pressure carrier gas delivery pipeline 12, and an induction system; wherein the furnace body 7 has an upper opening, and the inner wall and the induction system The refractory crucibles 4 are separated and sealed by insulating materials; the stirring paddle 2 of the mechanical stirring system is inserted into the molten pool 13 formed by the furnace body 7 and the refractory crucibles 4, and the rotating speed during operation is controlled by the control box 3. The box 3 is connected to the stirring head 1 of the stirring paddle 2; the storage tank 10 is located between the gas source 11 and the furnace body 7, and is connected to each other through a high-pressure carrier gas delivery pipeline 12, which is connected to the furnace body 7 The air outlet is facing the slit of...

Embodiment 2

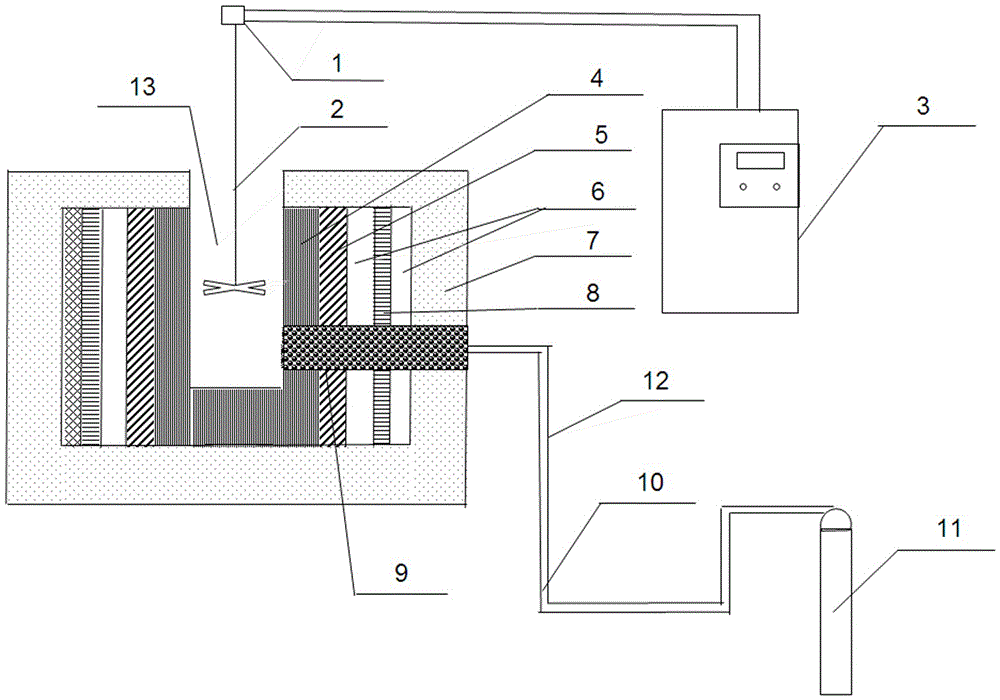

[0026] A blown induction melting furnace, such as figure 2 As shown, the structure of the induction melting furnace is the same as that of Example 1, the difference is that: the ventilation brick 9 is a diffuse type ventilation switch, which is arranged on the side wall of the furnace body 7, and the electromagnetic induction body is selected from lanthanum hexaboride, and the induction melting furnace structure does not have Storage tank 10.

[0027] Utilize the injection type induction smelting furnace of this embodiment to carry out copper slag depletion treatment, the process is as follows: join molten copper slag in the melting pool, start induction heating system to keep material temperature at 1150 ~ 1350 ℃; Insert it into 1 / 3~1 / 2 of the melt height in an eccentric manner, start mechanical stirring; at the same time, open the high-pressure carrier gas source of the injection system, inject reducing gas for reduction smelting, and remove iron, copper, etc. in copper sla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com