Dye waste liquid treatment device

A technology for treating device and dye waste liquid, applied in filtration treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as failure to meet discharge standards, insufficient water quality purification, and difficulty in manual cleaning. , to achieve the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

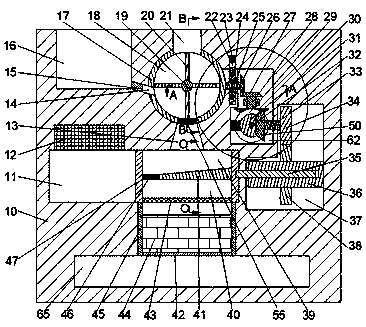

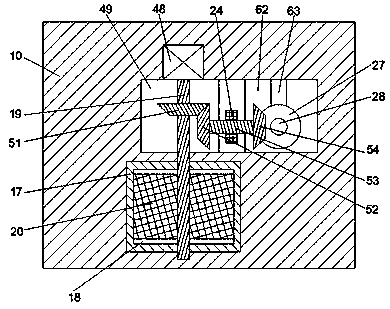

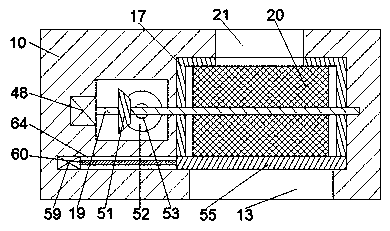

[0018] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] A dye waste liquid treatment device of the device of the present invention comprises a body 10, an input chamber 21 with an opening facing upward is arranged above the body 10, and a cylindrical drum wall 17 is arranged below the input chamber 21, so that The inside of the drum wall 17 is provided with a mixing chamber 18 communicating with the input chamber 21, the mixing chamber 18 is provided with a filtering device, and the left side of the mixing chamber 18 is provided with a medicament cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com