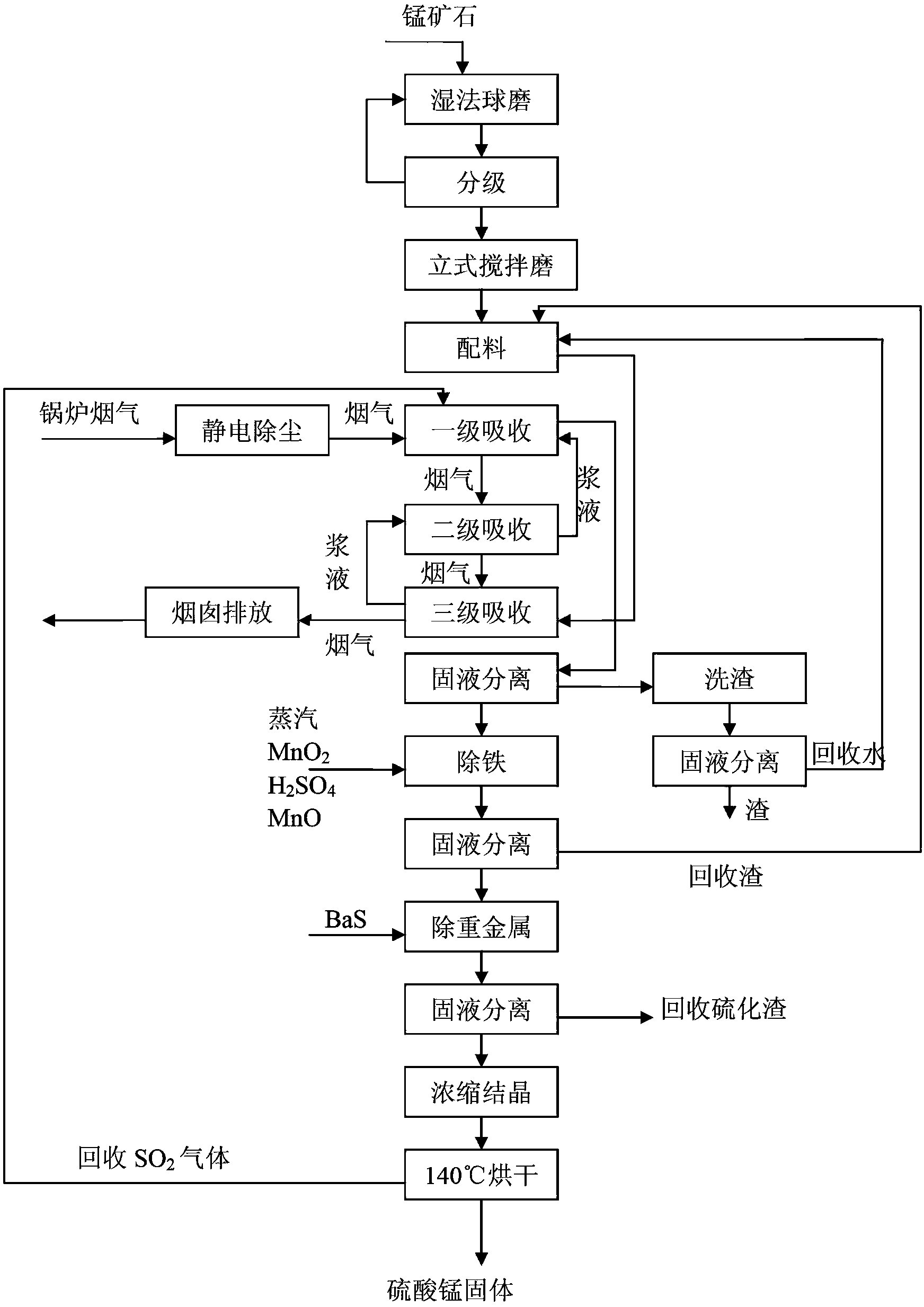

Method for preparing manganese sulfate by using manganese dioxide ore pulp to absorb sulfur dioxide in flue gases

A manganese dioxide ore, sulfur dioxide technology, applied in manganese sulfate, chemical industry, climate sustainability and other directions, can solve the problems of large investment, large area of the reactor, and narrowed airflow channels, and achieve low solid content, manganese The effect of high content and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The raw material manganese dioxide ore (referred to as manganese ore) used in this example is imported from Brazil. According to the analysis result report of ICP-AES of the Modern Analysis and Testing Center of Central South University, the analysis of the elemental content in the manganese ore is shown in Table 1 below.

[0044] Table 1: The component content analysis table of raw material manganese dioxide manganese ore in embodiment 1

[0045] element Content μg / g (except %) element Content μg / g (except %) element Content μg / g (except %) mn 42.60% Ca 5.9 S 197.6 Hg 50 In 20 As 10.1 Se 20 Au 1 Mo 2.4 sn 513.3 B 8.1 P 1120 Zn 20 Pt 1 K 9200 Sb 34.2 Mg 2181 Na 2300 Ce 383.7 V 2.7 Fe 6% Pb 342 Al 4%

[0046] The high-temperature flue gas raw material used in this example is boiler flue gas with a temperature as high as 146° C. after electrostatic precipita...

Embodiment 2

[0069] The raw material manganese dioxide ore used in this embodiment is imported from Gabon. According to the analysis result report of ICP-AES of the Modern Analysis and Testing Center of Central South University, the analysis of elemental composition in the manganese ore is shown in Table 4 below.

[0070] Table 4: The component content analysis table of raw material manganese dioxide ore in embodiment 2

[0071] element Content μg / g (except %) element Content μg / g (except %) element Content μg / g (except %) mn 46% Cd 5 S 649.3 Hg 5 In 20 As 6 Se 20 Au 1 Mo 24 sn 22.7 B 17.1 P 1120 Zn 25 Pt 1 K 9400 Sb 20 Mg 1% Na 3400 Ce 100 V 335.8 Fe 6.30% Pb 22.2 Al 4.30%

[0072] The high-temperature flue gas raw material used in this example is the boiler flue gas with a temperature as high as 146° C. after electrostatic precipitating in Example 1, and its composition con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com