Patents

Literature

38results about How to "Fast heat and mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

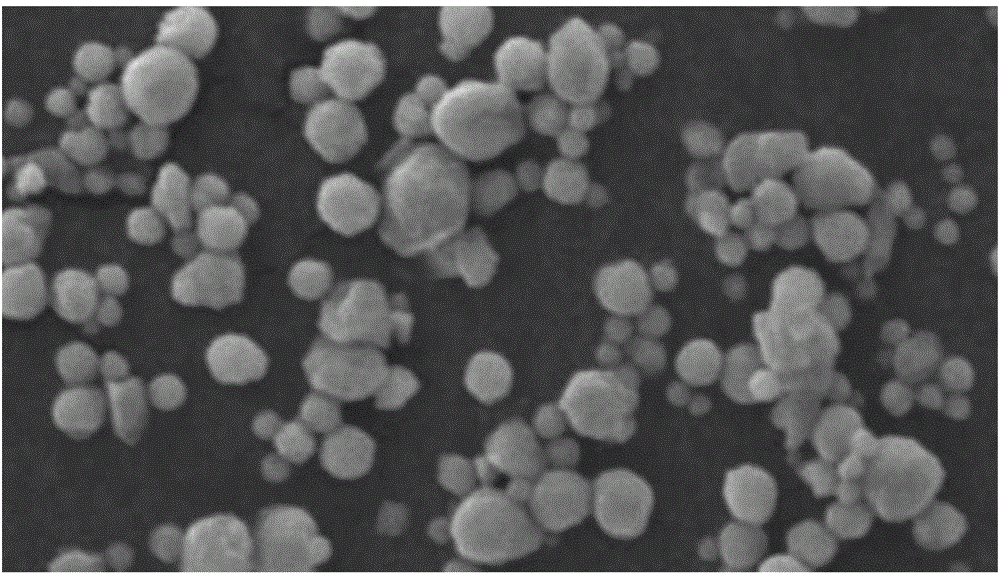

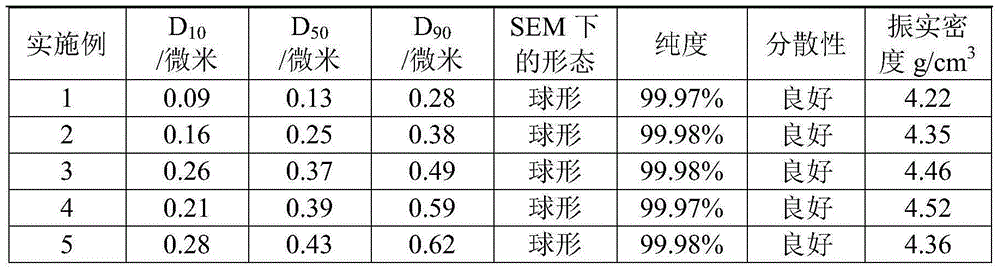

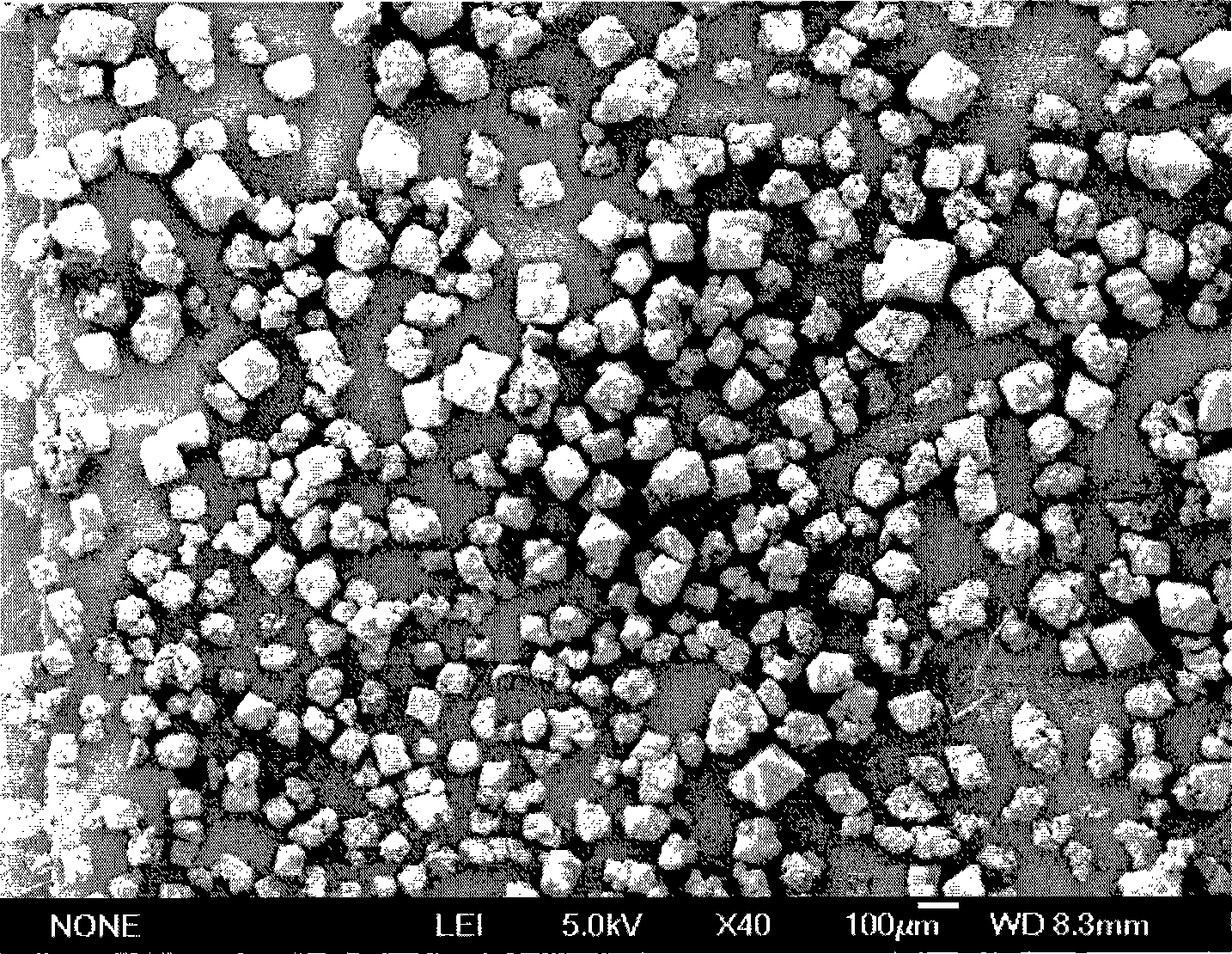

Spherical silver powder with controllable granularity and preparation method thereof

The invention relates to spherical silver powder with controllable granularity. The spherical silver powder has more than 99.9 percent of purity and more than 4.2g / cm<3> of tap density, and the granularity D90 of the spherical silver powder keeps being adjustable within an interval ranged from 0.2 mu m to 0.65 mu m based on a reaction system formula and reaction condition changes during a preparation method thereof. The preparation method of the spherical silver powder comprises the following steps of adopting soluble silver salt as raw materials, and preparing to obtain the nanoscale spherical silver powder through a hydrothermal method; adopting the nanoscale spherical silver powder as silver seed crystal, utilizing sediment reaction to induce the silver seed crystal to grow up uniformly, adjusting the growth degree of the silver seed crystal through controlling a reaction system formula and reaction conditions of the sediment reaction, and further obtaining the spherical silver powder with controllable granularity. The spherical silver powder is regular in shape, uniform in granularity, and can realize controllable granularity through process operation.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

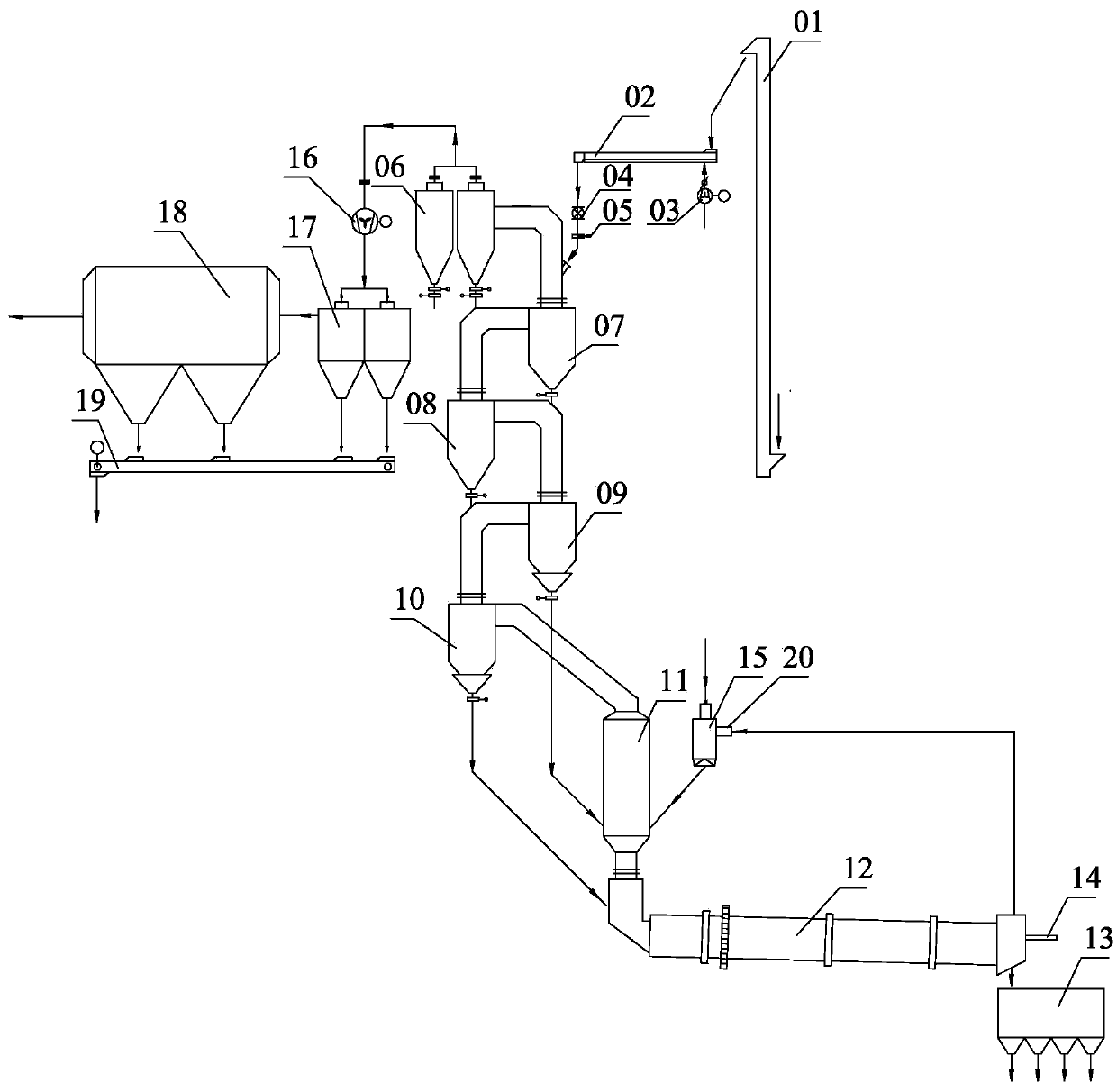

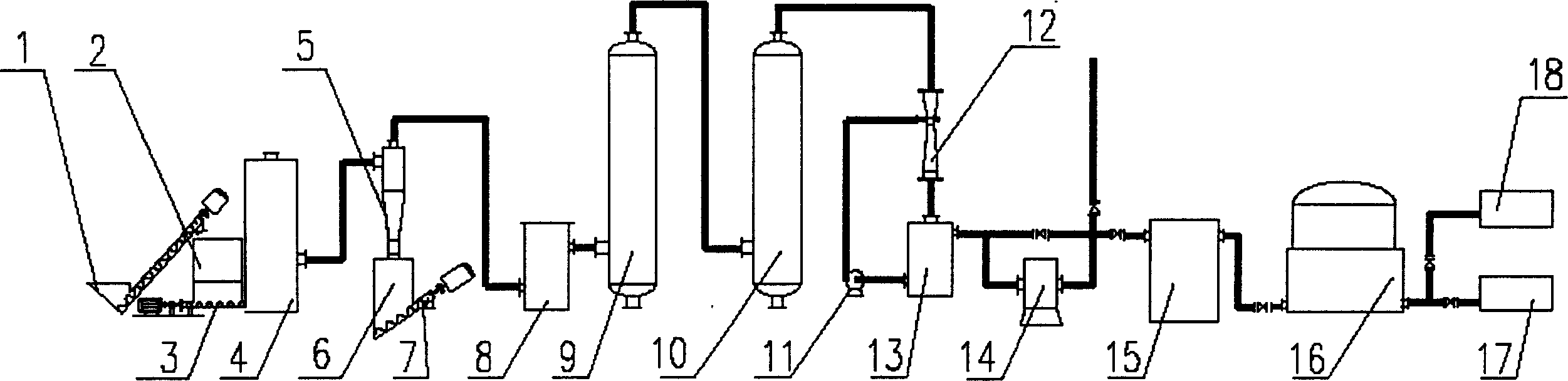

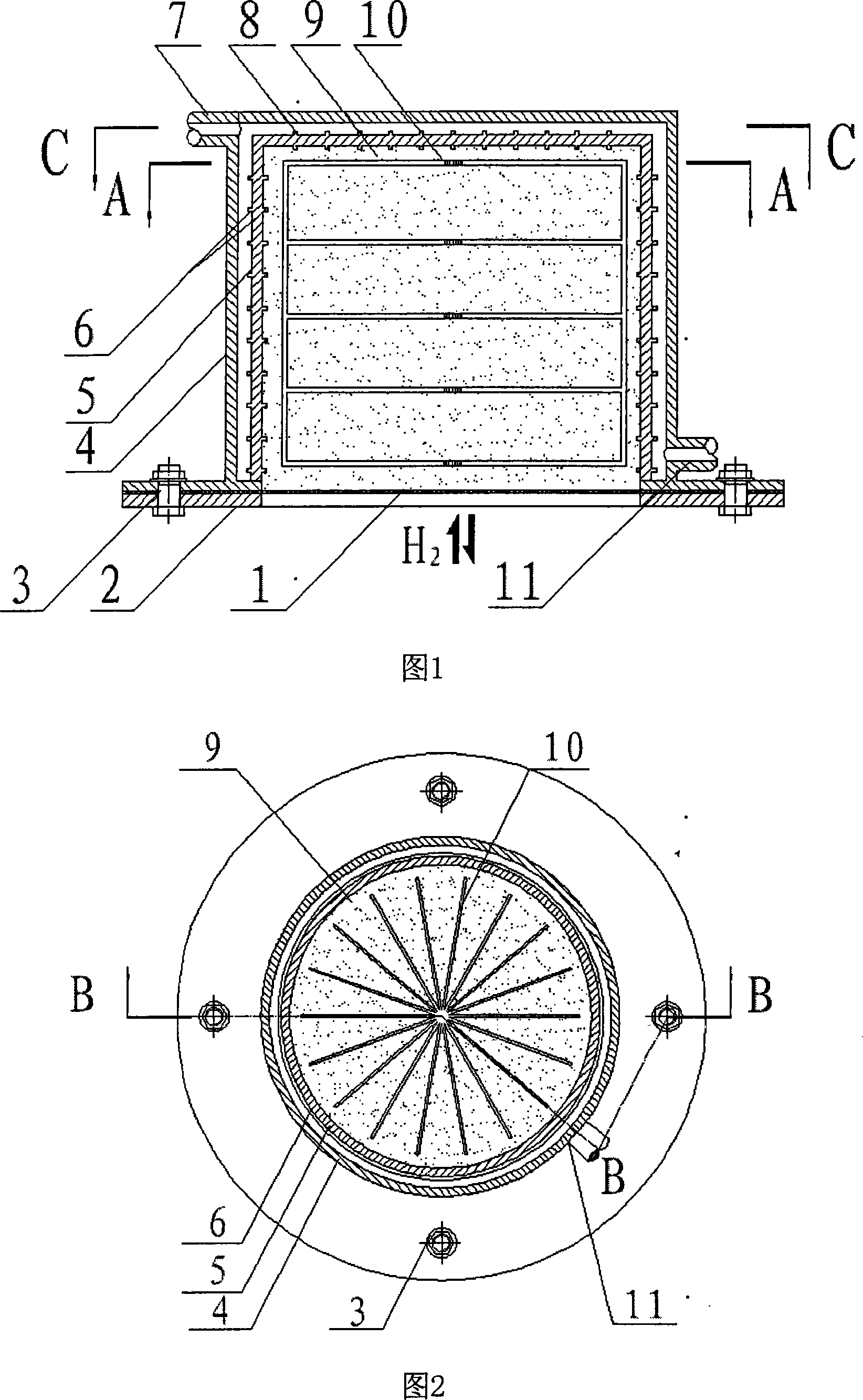

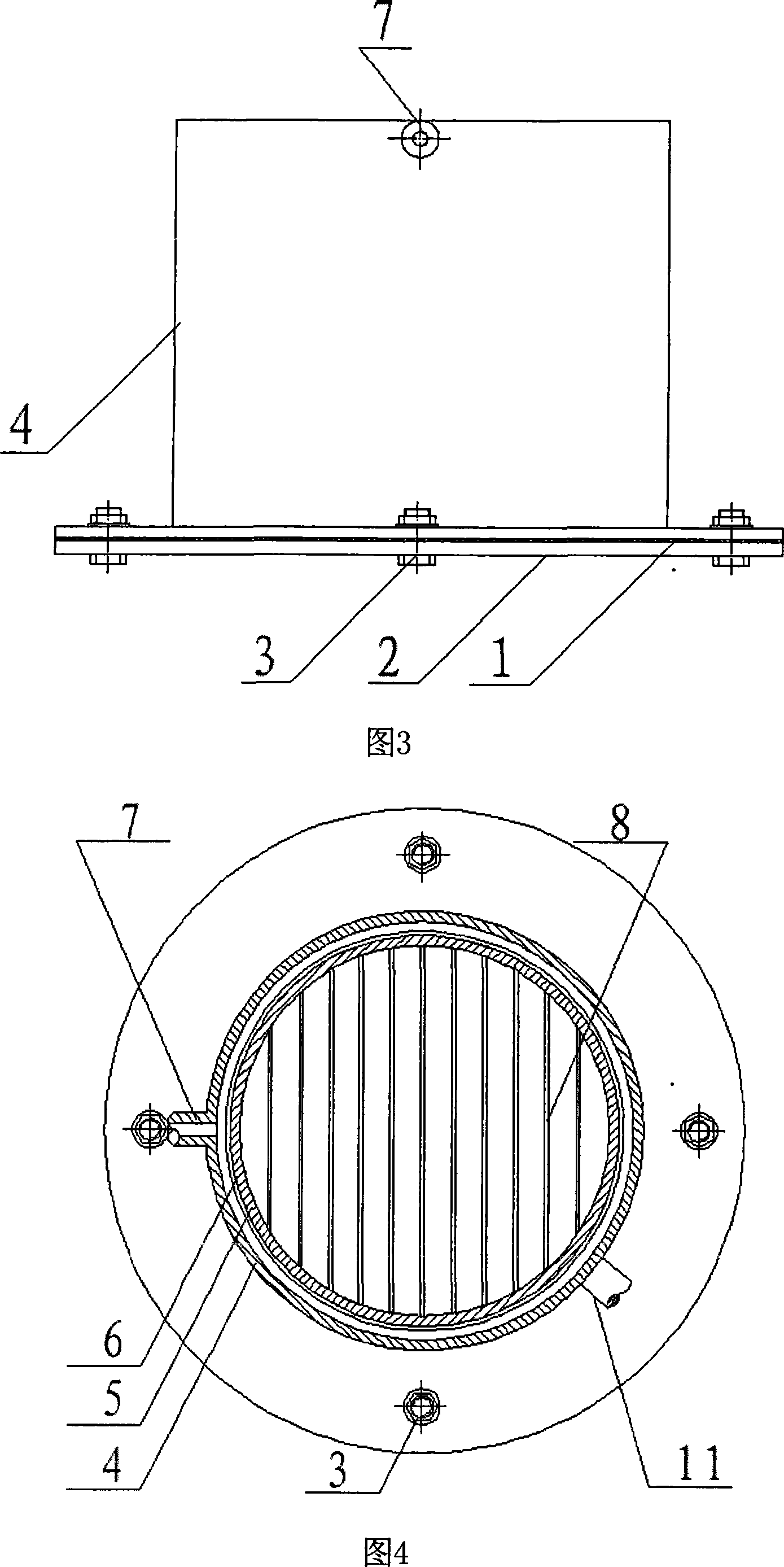

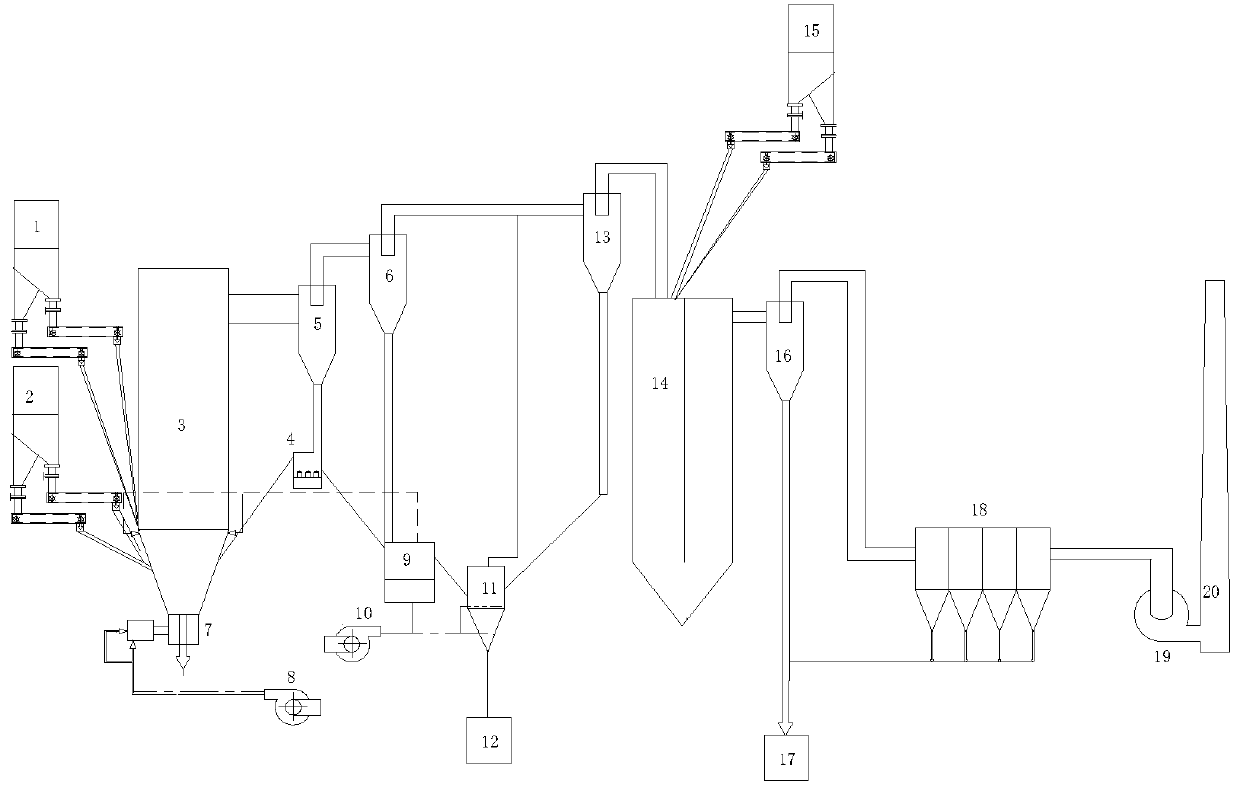

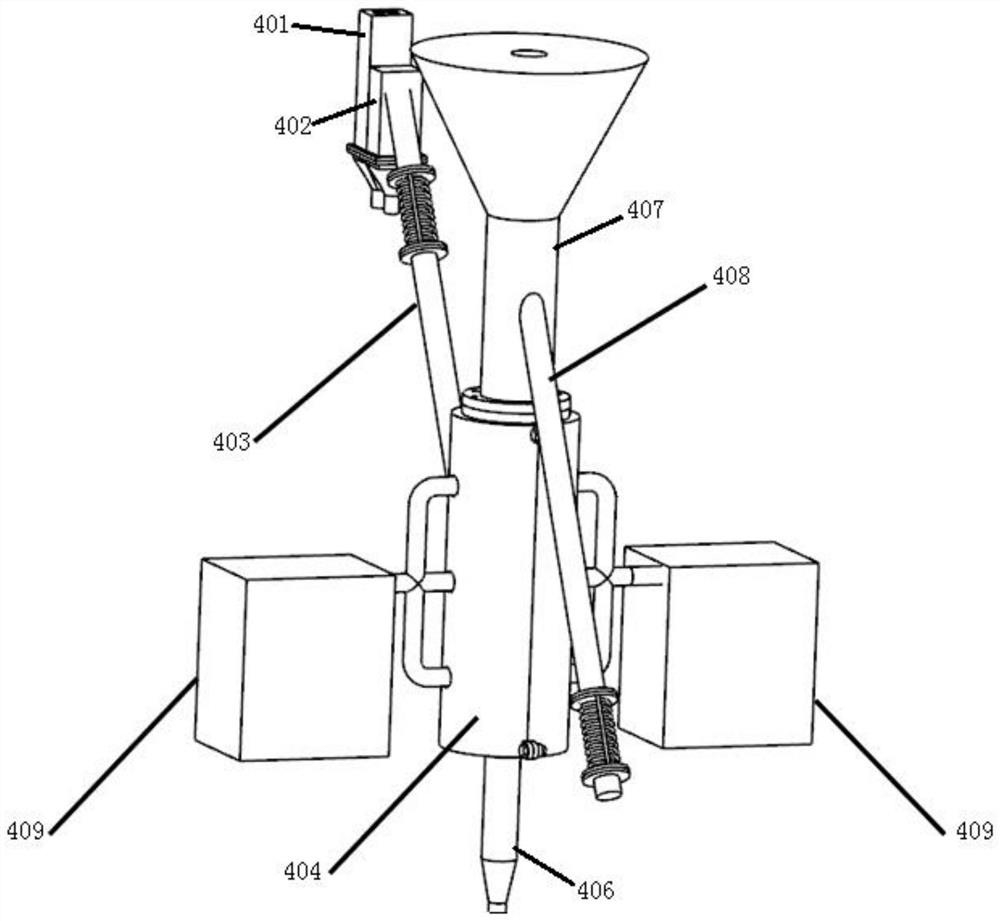

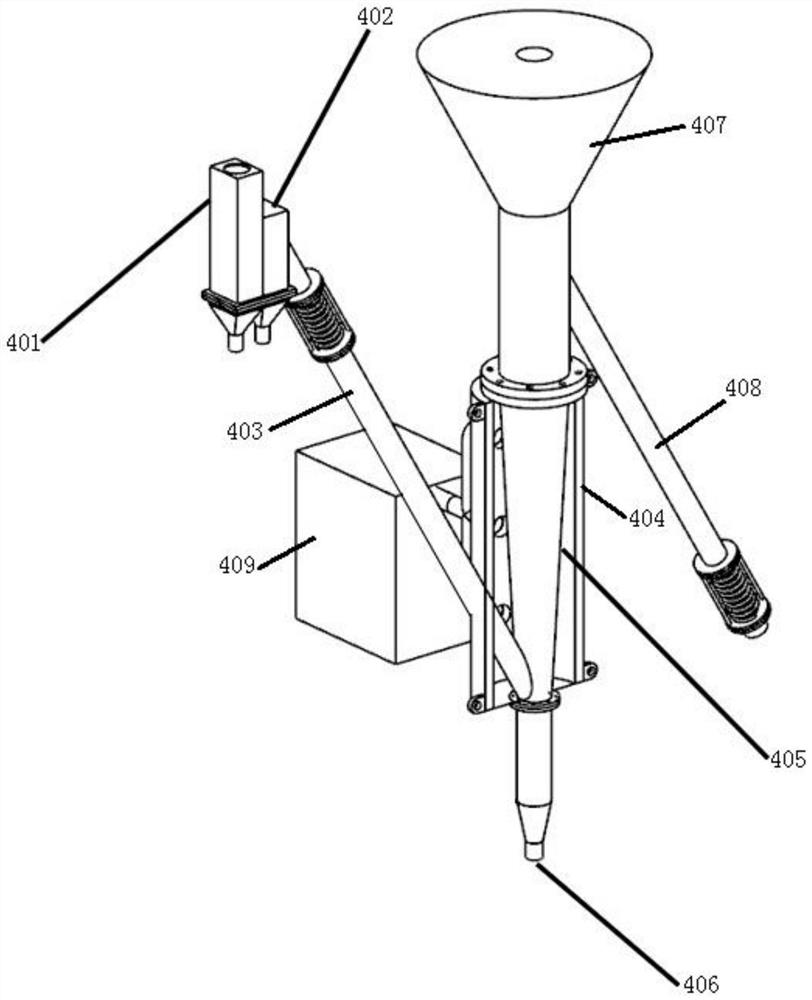

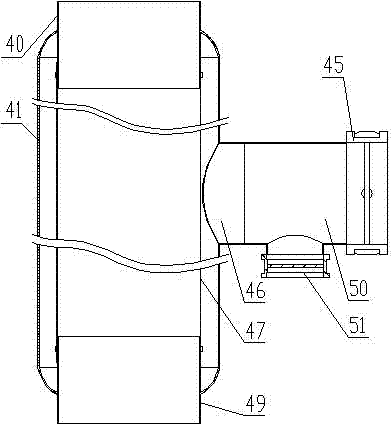

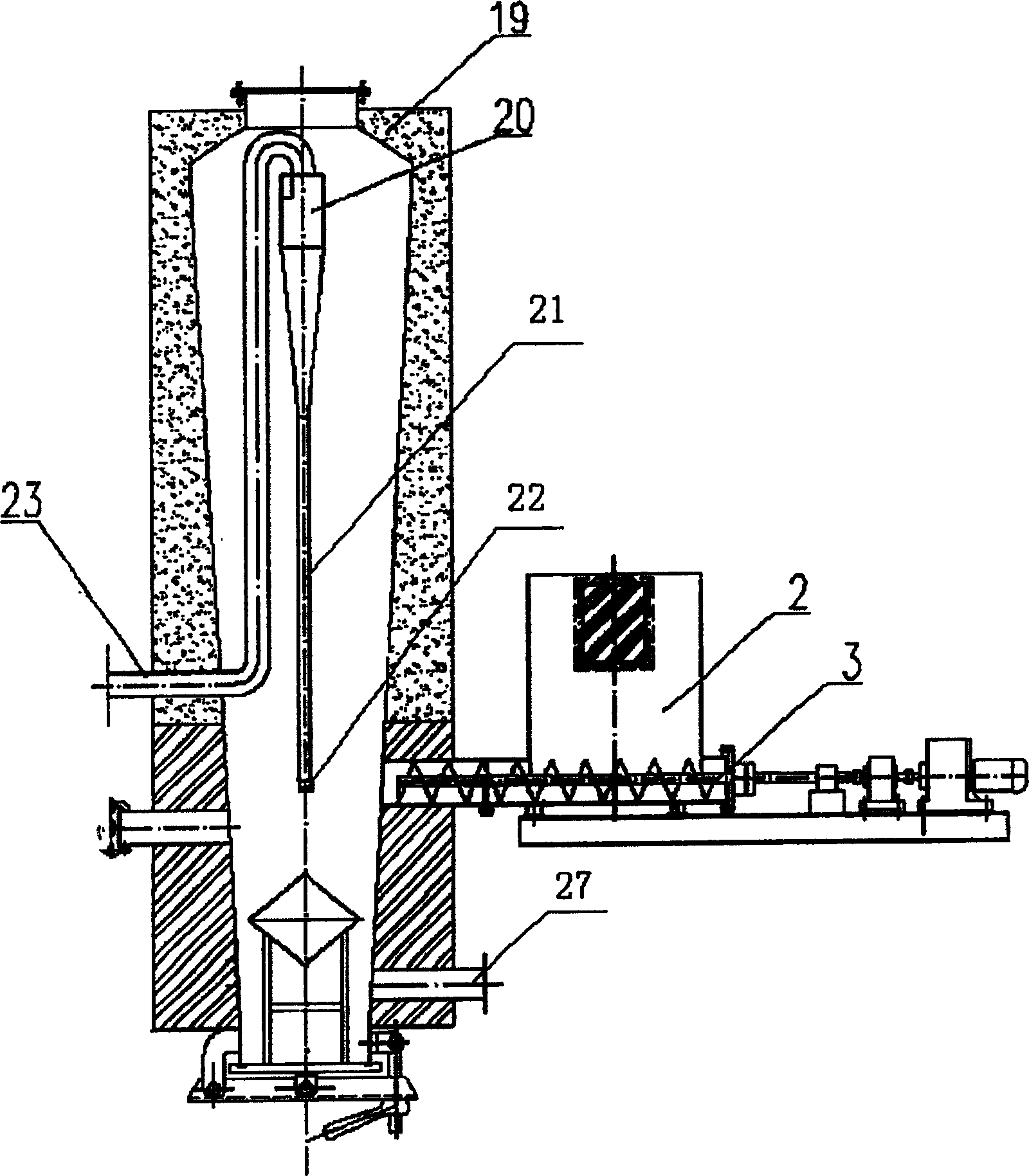

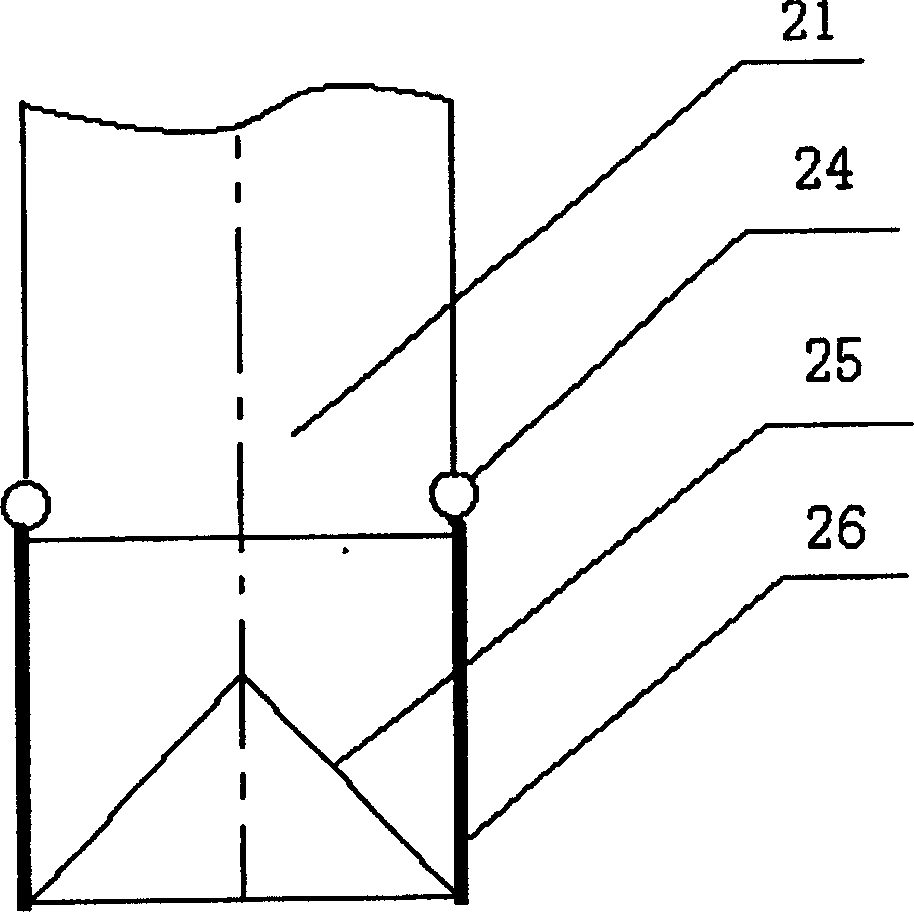

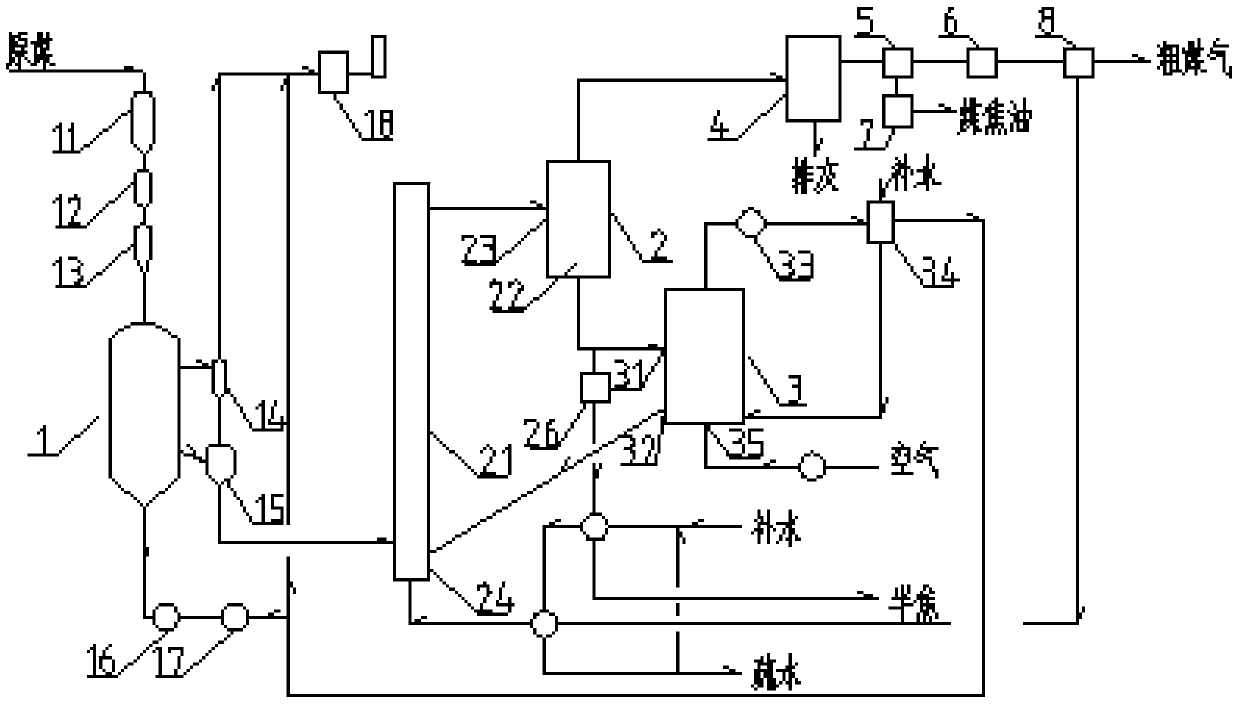

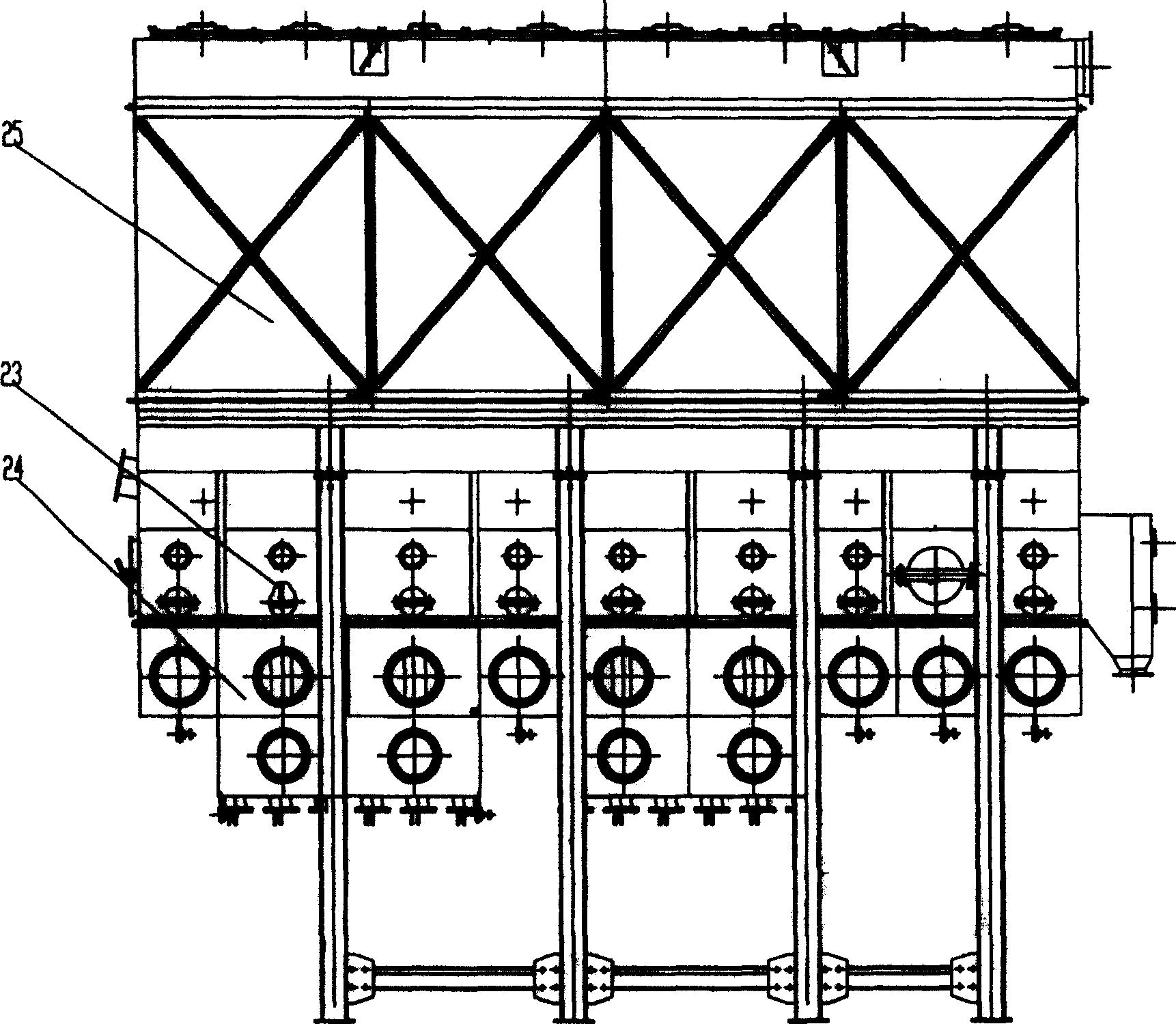

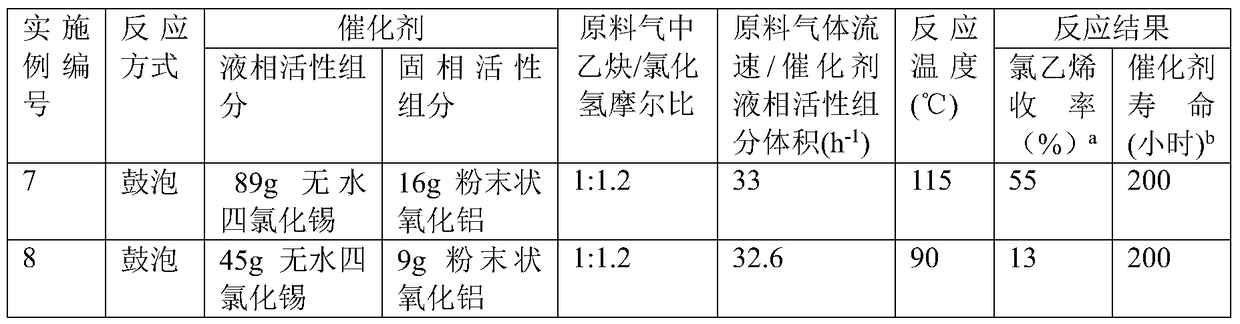

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

ActiveCN103468930AFast heat and mass transferShorten decrystallization wateChemical reactionLaterite

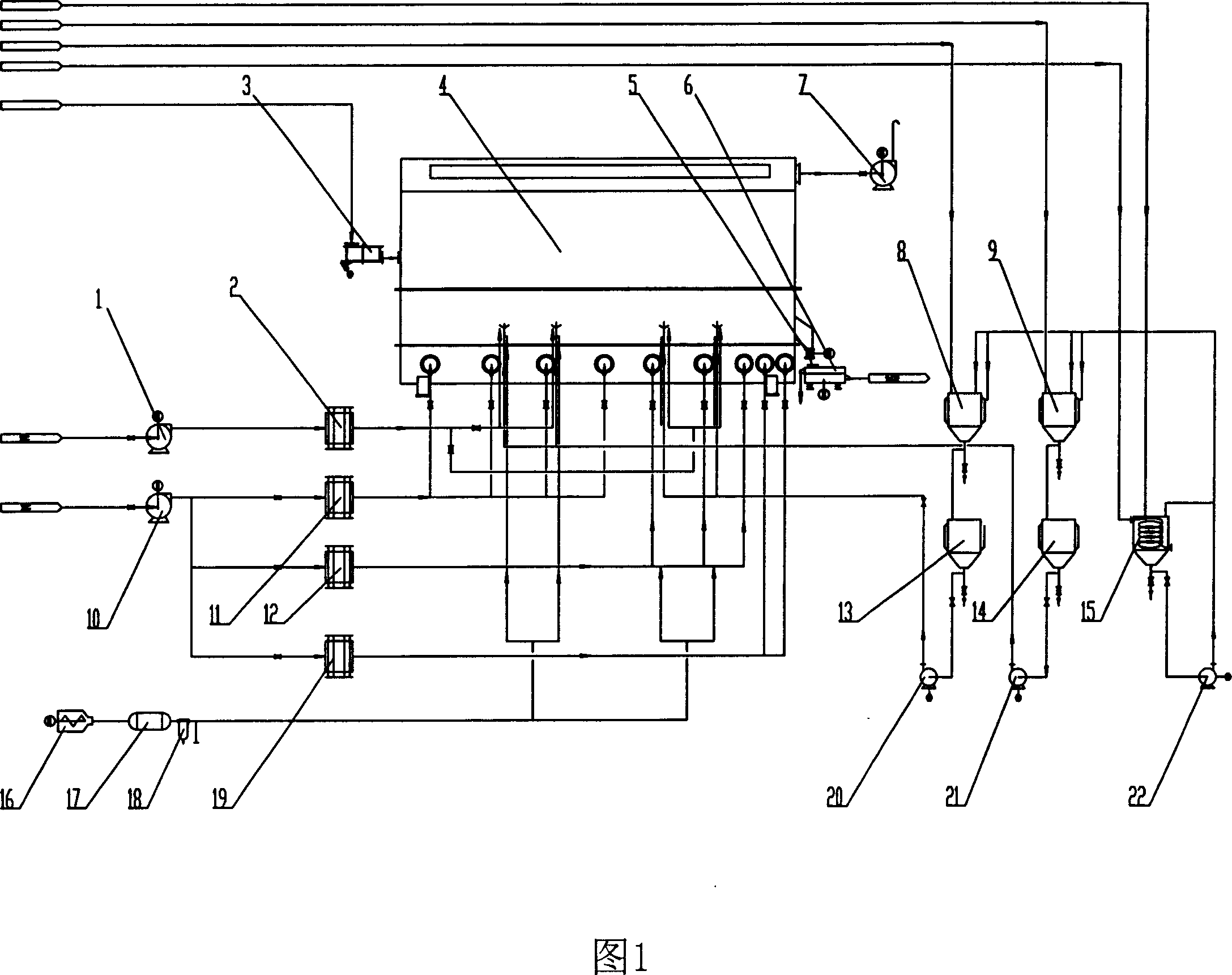

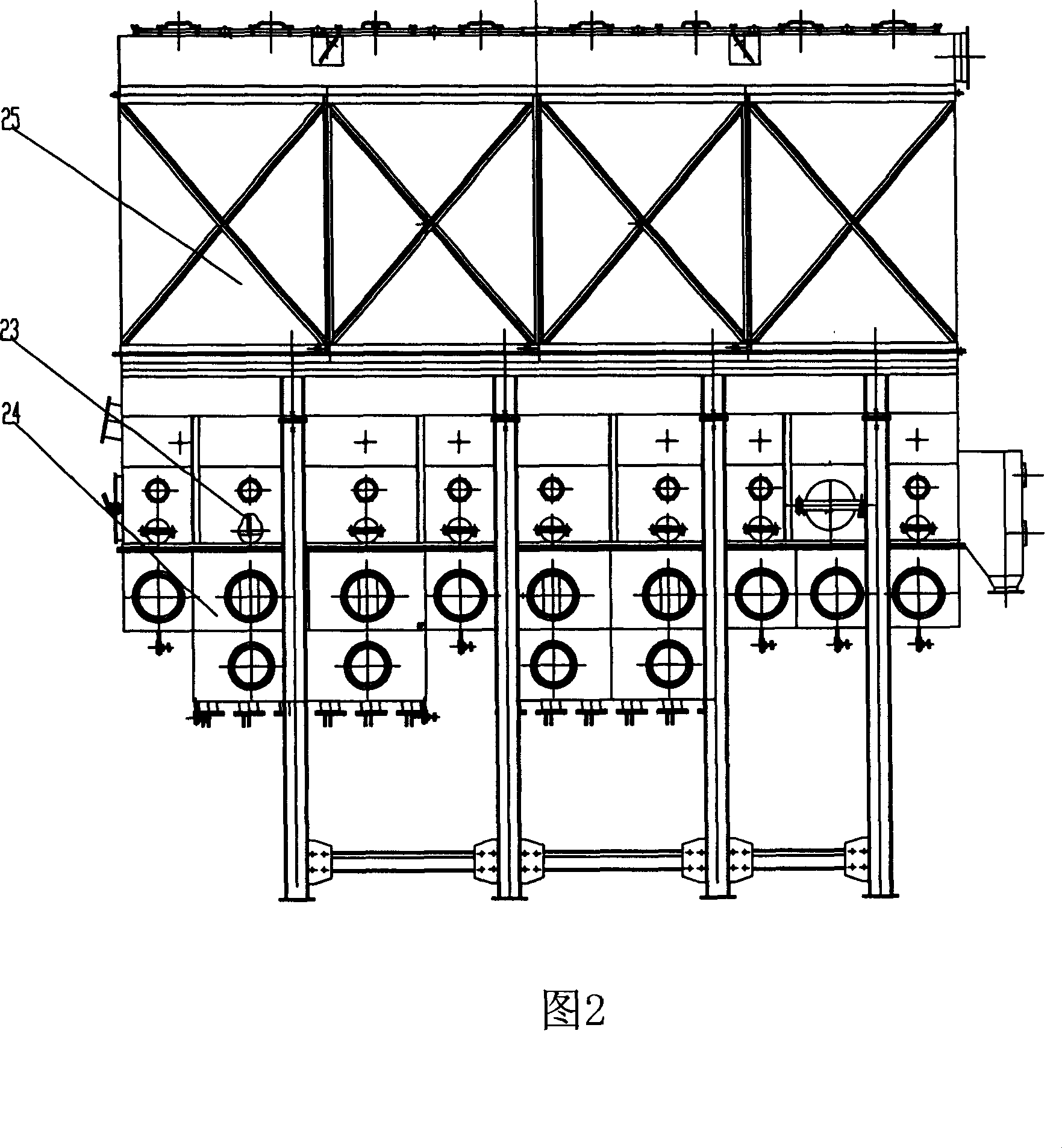

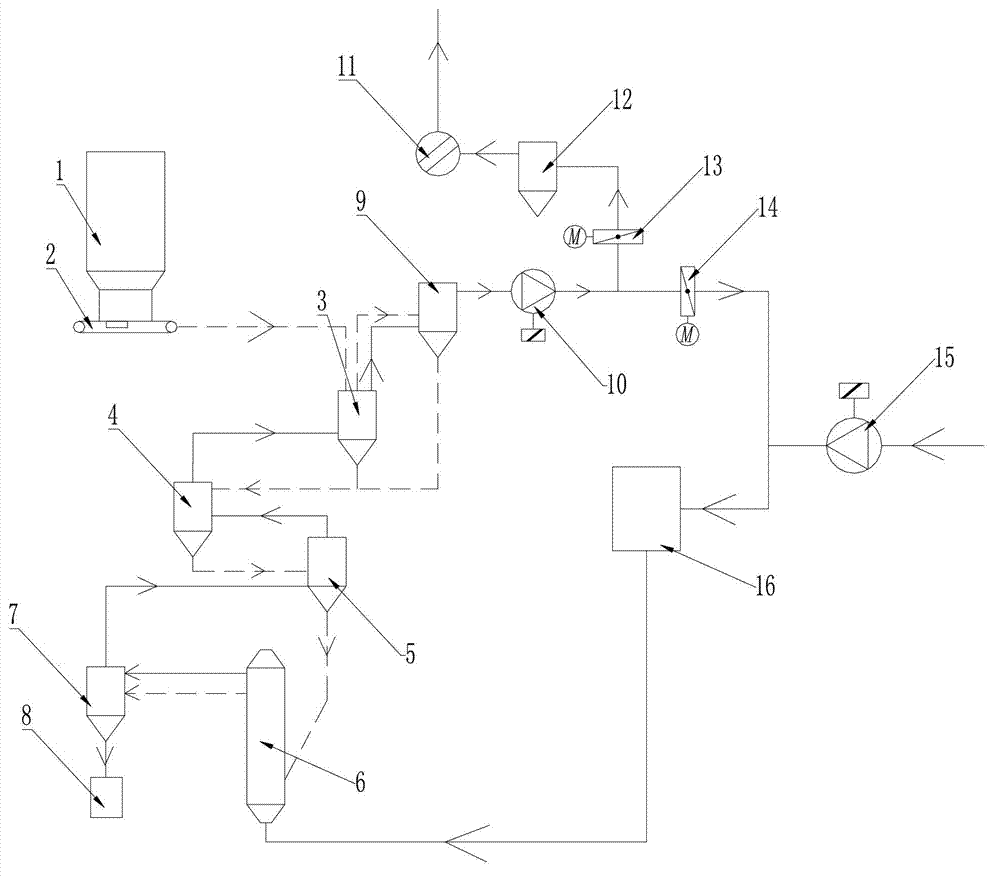

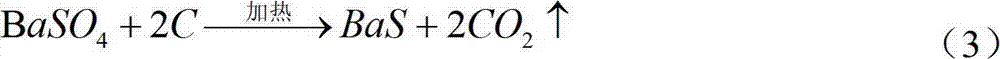

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

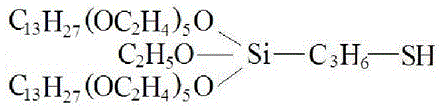

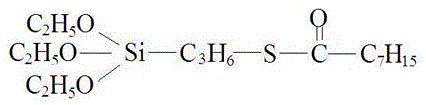

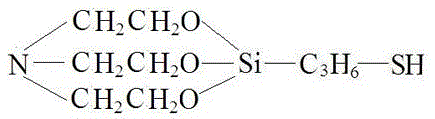

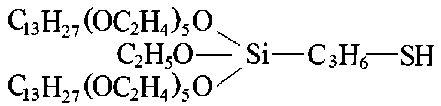

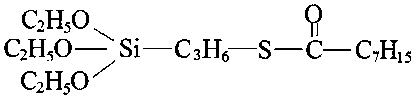

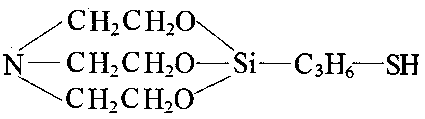

Method for preparing mercaptosilane coupling agent by using channel reactor

ActiveCN105601661AGuarantee continuous and stable operationIncrease in sizeGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

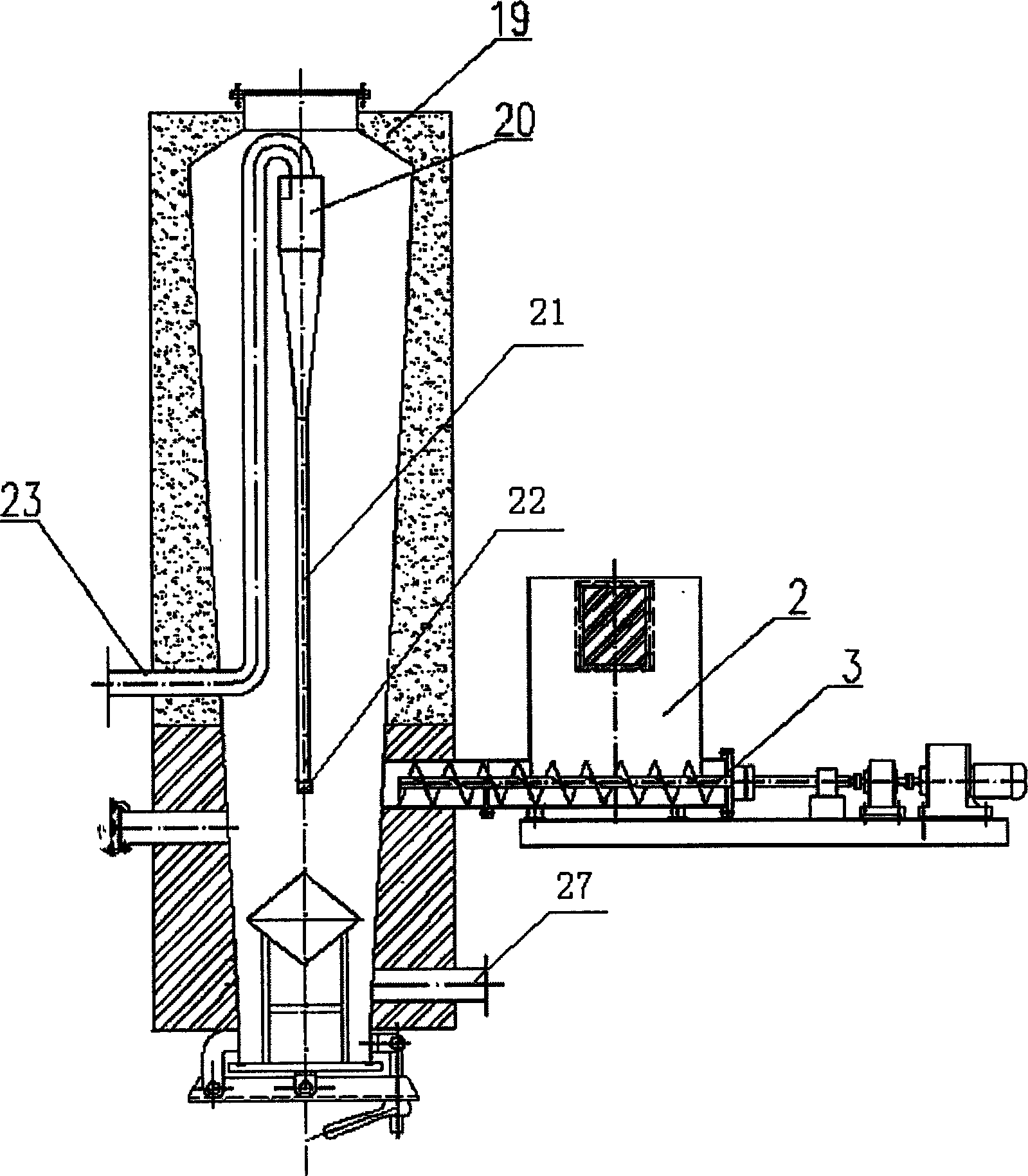

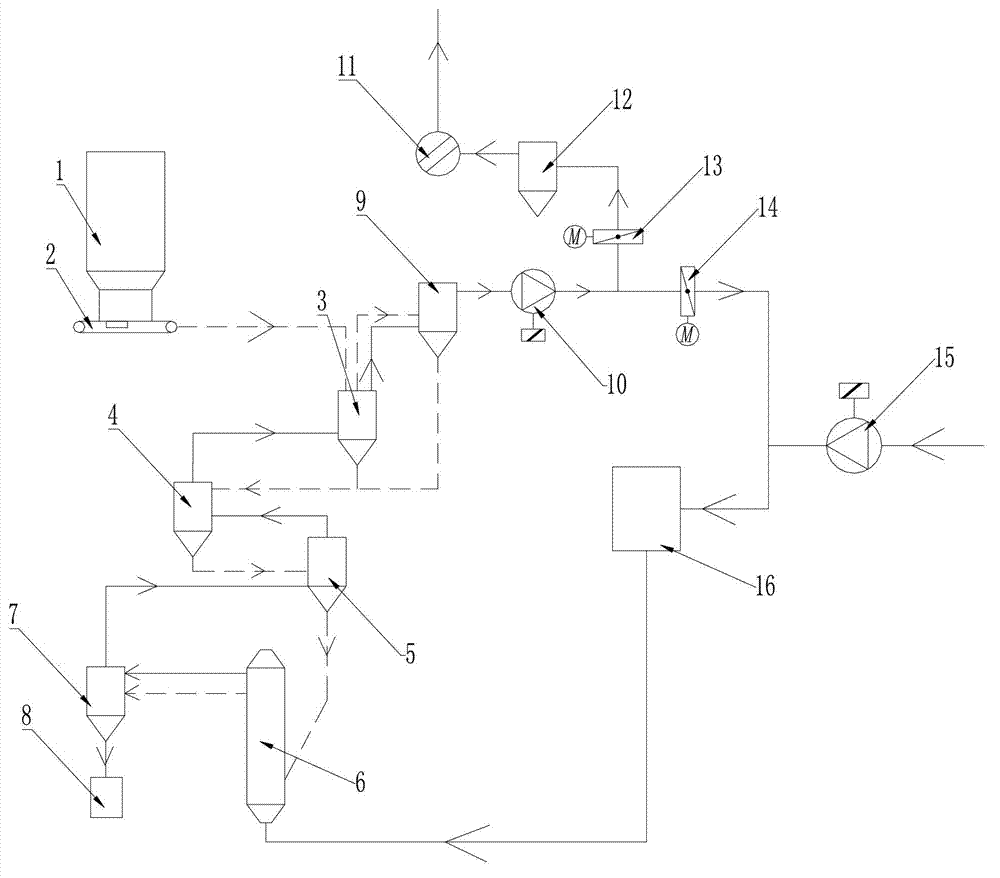

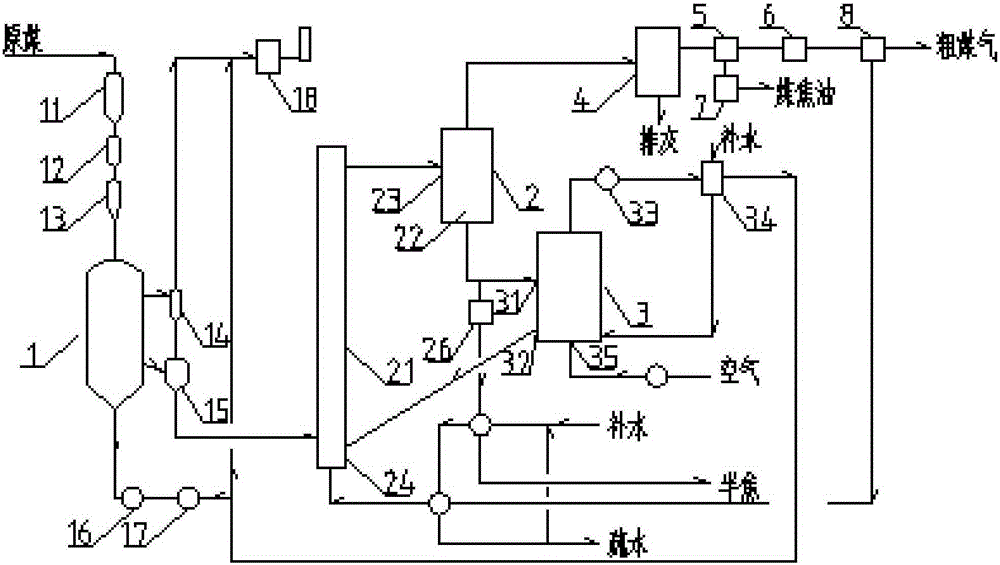

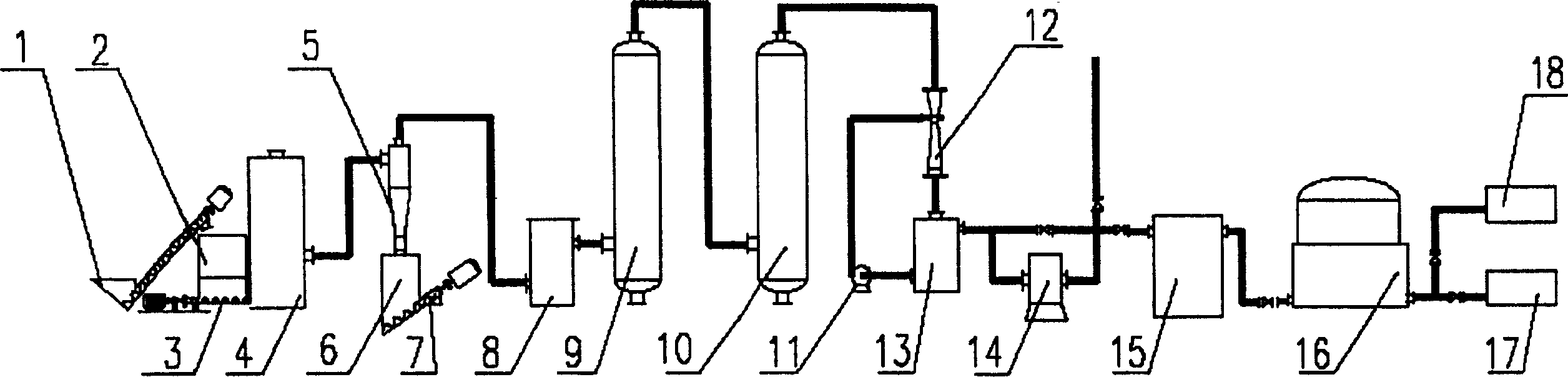

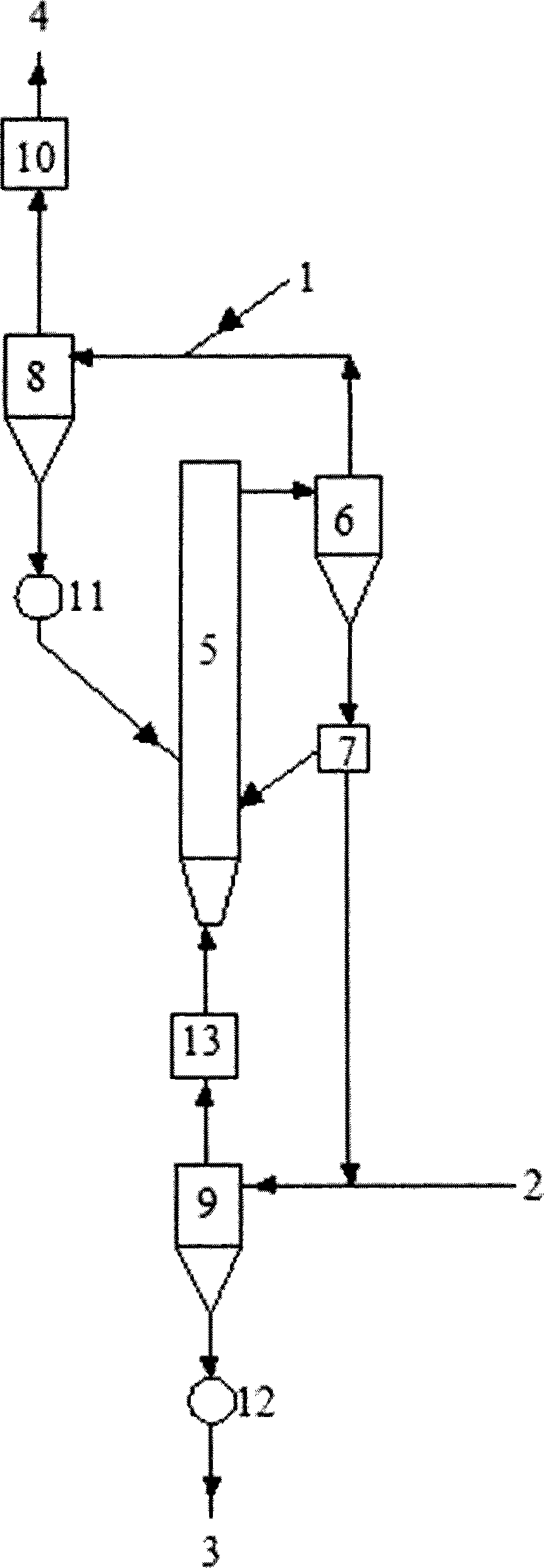

Process and apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1603388ASimple structureLow costSpecial form destructive distillationPhysical strengthCoal gasification

The invention discloses a kind of use fluffy biology raw material preparation coal gas craft and the equipment. The craft including the raw material pretreatment, the raw material gasification, is divided the principle to leave the dregs, the coal gas purifies, the coal gas transportation step; The equipment including the raw material pretreatment system, the coal gas has the system, the coal gas purification system, the coal gas transportation storing system. In this invention uses sets at the type fast fluidized gasification furnace and furnace accessories to have the production intensity in a big way, the gasified efficiency high, the gas tar content low, the operation stability is good and so on the characteristic. The gasification responded completes under the physical strength transfer rate, in sets at in the type separator realization gasification stove fresh material raw material fast circulation, the coal gas purification uses the method which the laundering and the organic solvent washes unifies, has tar removing rate to be high, in the coal gas the tar content change undulates slightly and so on the characteristic. The invention craft and the equipment may continuously gasify the fluffy fresh material raw material, gasifies the coal gas which produces to be possible to serve as the fuel gas generator the gas source, also may pass the pipe network to all around the side inhabitant user air feed.

Owner:NANJING TECH UNIV

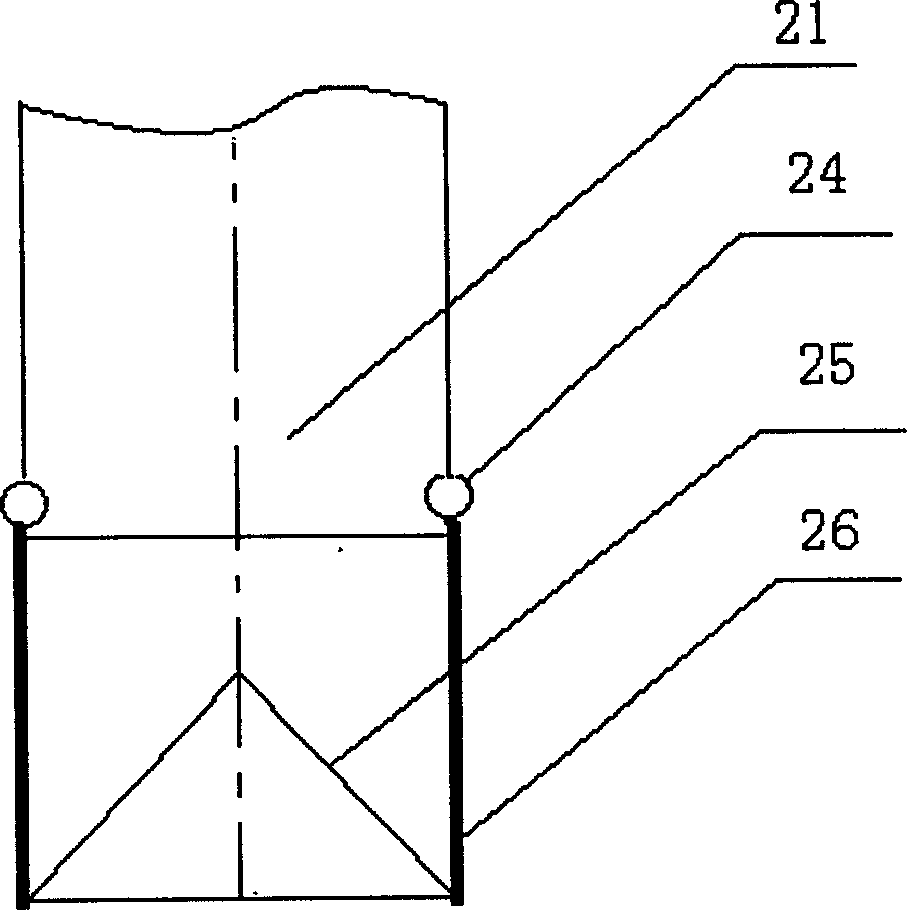

Micro-via type chemical heat pump reactor

InactiveCN101143310ALarge loading capacityEasy to replaceChemical/physical/physico-chemical processesCompound (substance)Heat transfer efficiency

A micro-channel typed chemical heat pump reactor contains a casing. A heat exchange fluid outlet is arranged on the upper part of the external wall of the casing. The reactor contains an inner cylinder, an outer cylinder, and an interlayer, which is used for accommodating heat exchange fluid, is formed between the inner and outer cylinders. A filter screen and a flange are arranged on the bottom of the casing. Hydride powder is filled in the casing. A totally enclose typed ring micro-channel is arranged inside the reaction bed. High efficiency heat exchange fluid is poured into the micro-channel. The gas enters into the reactor through the filter screen, and reacts with the hydride powder. The reaction heat is brought to the inner cylinder wall of the reactor by fluid circulation of reaction inside the micro-channel, and is taken away by exchange heat fluid. The target of quick speed and high efficiency of heat exchanging is achieved. The invention is characterized by compact device structure, large reagents filling capacity, high heat transfer efficiency, high operation elasticity, and convenient regulation and control and so on.

Owner:XI AN JIAOTONG UNIV

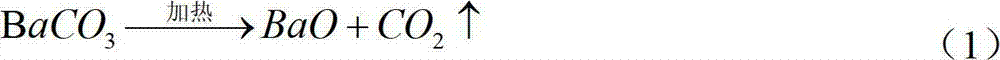

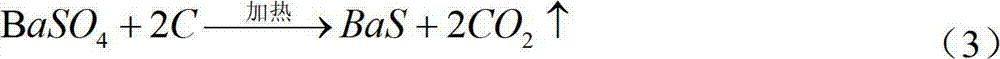

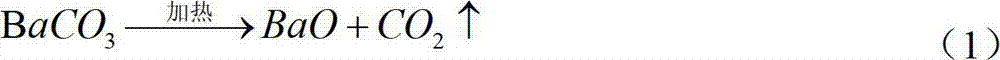

Method for preparing barium hydroxide by using barium carbonate

ActiveCN102923748AFast heat and mass transferShorten the timeCalcium/strontium/barium oxides/hydroxidesChemical reactionBarium peroxide

The invention discloses a method for preparing barium hydroxide by using barium carbonate. The method comprises the following steps of firstly grinding ores containing barium carbonate into ore powder, carrying out high-temperature roasting on the ore powder in a suspension fluidized state to obtain roasted ore containing barium hydroxide, soaking the roasted ore in water to react and generate a barium hydroxide solution, carrying out solid-liquid separation on the barium hydroxide solution, cooling and crystallizing to obtain barium hydroxide products. The method for preparing the barium hydroxide by using the barium carbonate, disclosed by the invention, has the advantages that the heat transfer area of the ore powder is large, each ore particle can uniformly and totally finish a chemical reaction, the reaction time is short, and the utilization rate of barium carbonate is high.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

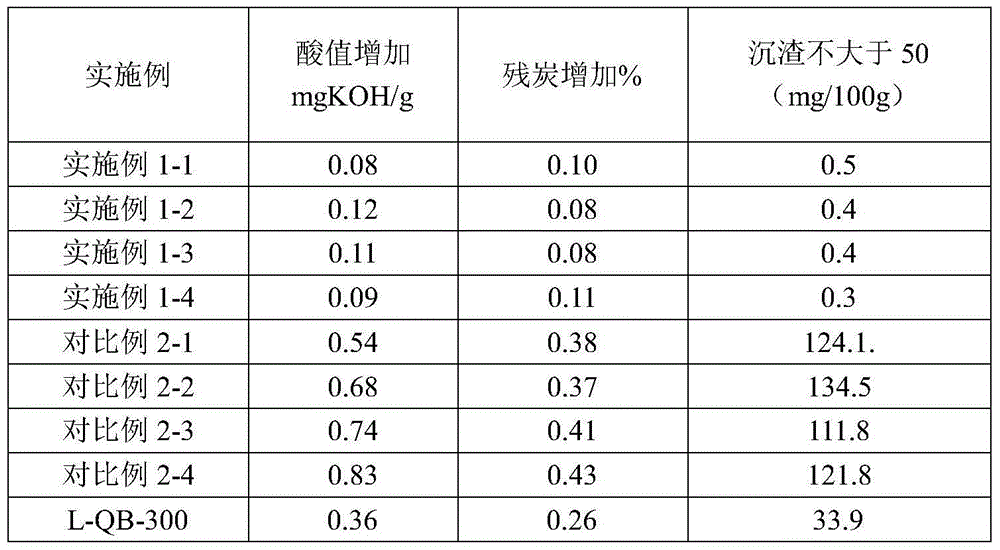

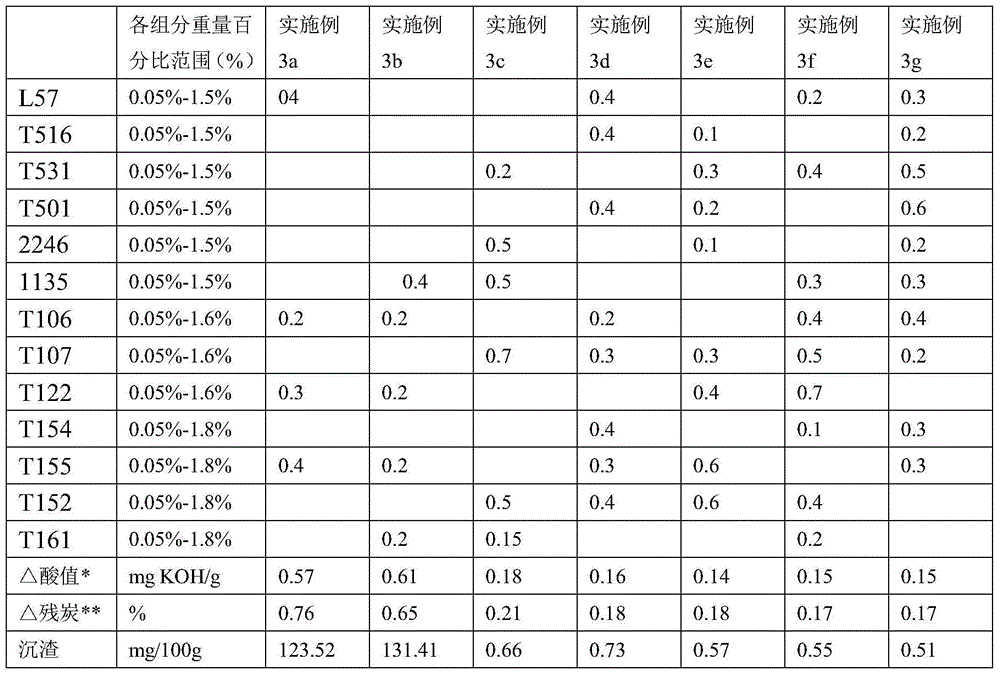

Anti-coking alkylbenzene synthesis heat conduction oil and preparation method thereof

ActiveCN104893683AExcellent detergency and dispersibilityReduce high temperature degradationHeat-exchange elementsOxidation resistantComponents of crude oil

The invention discloses anti-coking alkylbenzene synthesis heat conduction oil. The anti-coking alkylbenzene synthesis heat conduction oil mainly comprises the following ingredients: alkylbenzene base oil, amine antioxidants, phenolic antioxidants, clearing agents and dispersing agents, wherein the content of the alkylbenzene base oil is not lower than 95 in percentage by weight; the initial boiling point of the alkylbenzene base oil is greater than 320 DEG C; the density of the alkylbenzene base oil is greater than 0.83g / cm(3); the flashing point of the alkylbenzene base oil is greater than 180 DEG C; the carbon residue of the alkylbenzene base oil is smaller than 0.02%; the acid value of the alkylbenzene base oil is smaller than 0.02mg KOH / g; the pour point of the alkylbenzene base oil is smaller than minus 55 DEG C; and copper corrosion is smaller than 1 level. The anti-coking alkylbenzene synthesis heat conduction oil has the advantages of high clearing performance, high dispersing performance, low high-temperature degradation, high oxidation resistance, high coking resistance, high sedimentation resistance and long service life. The self-cleaning property is high, and the high cleanliness of the anti-coking alkylbenzene synthesis heat conduction oil can be kept for a long time.

Owner:CHENGDU MAX TOP NEW ENERGY LUBRICATING MATERIALS

Phosphogypsum circulating fluidized bed reduction roasting comprehensive utilization process and device thereof

The invention discloses a phosphogypsum circulating fluidized bed reduction roasting comprehensive utilization process and a device thereof. The device comprises a circulating fluidized bed reactor body provided with a slag discharging opening. An air inlet is formed in the bottom of the circulating fluidized bed reactor. A coal feeding hole, a phosphogypsum / mineral mixture inlet, a circulating material inlet and a secondary air inlet are respectively formed in the lower part of a dense-phase zone; a flue gas outlet is formed in the top of the circulating fluidized bed reactor; a primary cyclone separator is connected with a circulating material inlet and a first-stage fluidized bed cooling device; a flue gas outlet of the primary cyclone separator is connected with a secondary cyclone separator; the lower portion of a second-stage separator is connected with the first-stage fluidized bed cooling device; a flue gas outlet of the secondary cyclone separator is connected with a third-stage cyclone separator; the lower portion of the third-stage cyclone separator is connected with a second-stage fluidized bed cooling device; and meanwhile the first-stage fluidized bed cooling device is connected with the second-stage fluidized bed cooling device. The invention aims to realize activation of a phosphogypsum / tailing mixture under a reduction roasting condition at a temperature of about 850 DEG C by blending phosphogypsum / tailing mixed raw material components. Therefore, the efficient roasting technology and the device are the key to efficient and clean utilization of the phosphogypsum / tailings mixed raw materials. On the other hand, semi-hydrated gypsum is a good building material and has a good application market at present. Therefore, the application value of the phosphogypsum can also be improved by making the existing water-containing gypsum into the semi-hydrated gypsum through processes such as drying and the like.

Owner:车建青

Fluidization-chlorination method for carbonized slag

InactiveCN107601555AHigh recovery rateAvoid sticking loss problemTitanium halidesChemical industryTetrachloride

The invention belongs to the technical field of metallurgy and chemical industry and particularly relates to a fluidization-chlorination method for carbonized slag. According to the fluidization-chlorination method, the technical problems that the chlorination rate of an existing carbonized slag chlorination process is low, and the cementation and defluidization of a chlorination furnace are easily caused are solved. The fluidization-chlorination method comprises the following steps: (a) putting carbonized slag particles into a fluidized bed, and introducing chlorine gas for chlorination, wherein the chlorination temperature is 400-650 DEG C, and the chlorination time is 1-10 minutes; and (b) carrying out drip-washing on a mixture obtained in the step (a) by virtue of a titanium tetrachloride drip-washing system, cooling, and separating, so as to obtain the chlorination gas and liquid-state titanium tetrachloride. By chlorinating the carbonized slag by virtue of a rapid fluidized bed,the heat and mass transfer speeds are high, the chlorination speed is high, the problems of cementation and defluidization of the fluidized bed can be effectively avoided, meanwhile, the chlorine gasand the carbonized slag can be recycled, and the production cost is saved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing mercaptosilane coupling agent by channel reaction device

ActiveCN105601661BIncrease in sizeGreat operating flexibilityGroup 4/14 element organic compoundsSolventImpurity

The invention provides a method for preparing a mercaptosilane coupling agent by using a channel reactor. In a solvent, a channel reactor is utilized to prepare the mercaptosilane coupling agent. The structural general formula of the mercaptosilane coupling agent is XmSiC3H6S(C=O)nY, wherein each X is independently alkyl group, alkoxy group, hydroxy group, R(OR')LO-, -ORO- or N(RO-)3, and at least one X is alkoxy group, hydroxy group or N(RO-)3; Y is hydrogen or alkyl group; R and R' are respectively independently straight-chain or branched-chain alkyl group; the average value of L is 1-30; m is 1, 2 or 3; and n is 0 or 1. The corrected diameter of the channel reactor channel is one micrometer to several centimeters; and the channel reactor is connected with an after-treatment device. The method solves the problems of long reaction period, poor stability, existence of impurity polymers and the like in the large-size reactor, and especially reduces the odor caused by the large-size reactor production.

Owner:南京曙光新材料有限公司

Drying coating technology for sodium percarbonate

ActiveCN1923907ASimple production processHigh degree of automationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPigment physical treatmentDielectricPolymer science

The invention discloses a specific dressing drying technology of sodium percarbonate, which comprises the following steps: adopting hot air as drying dielectric; utilizing energy and reflecting heat of sodium percarbonate particle and dressing solution bulk to condense on the surface of sodium percarbonate; coating; evaporating; crystallizing; drying; cooling; adopting different fluidization wind temperature and speed for guide coating area and drying area in the drying course; making the operation more stable.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Preparation method of honeycomb ceramic heat storage material

The invention discloses a preparation method of a honeycomb ceramic heat storage material, and belongs to the technical field of energy-saving and environment-friendly materials. According to the method, bauxite, cyanite, organic matters, refractory clay, charing rice husks, moss homogenate, biogas slurry, glycerol, plant oleic acid and the like are used as raw materials and are subjected to mixing, aging and circulation to prepare pug; then, the pug is subjected to extrusion forming to obtain a ceramic blank; then the ceramic blank is put into a constant-temperature and constant-humidity environment to be subjected to segmented illumination treatment; then, vacuum freeze drying is matched to obtain a dry ceramic blank; finally, the dry ceramic blank is prefired in a nitrogen gas protection state and is then sintered and shaped again; the honeycomb ceramic heat storage material is obtained. The product obtained by using the technical scheme has the advantages that the thermal shock resistance is excellent; the heat expansion coefficient is low; the high-temperature stability is high; the heat transfer efficiency is high; the application prospects are wide.

Owner:唐山华纤科技有限公司

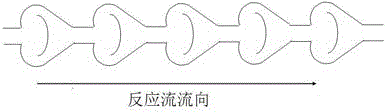

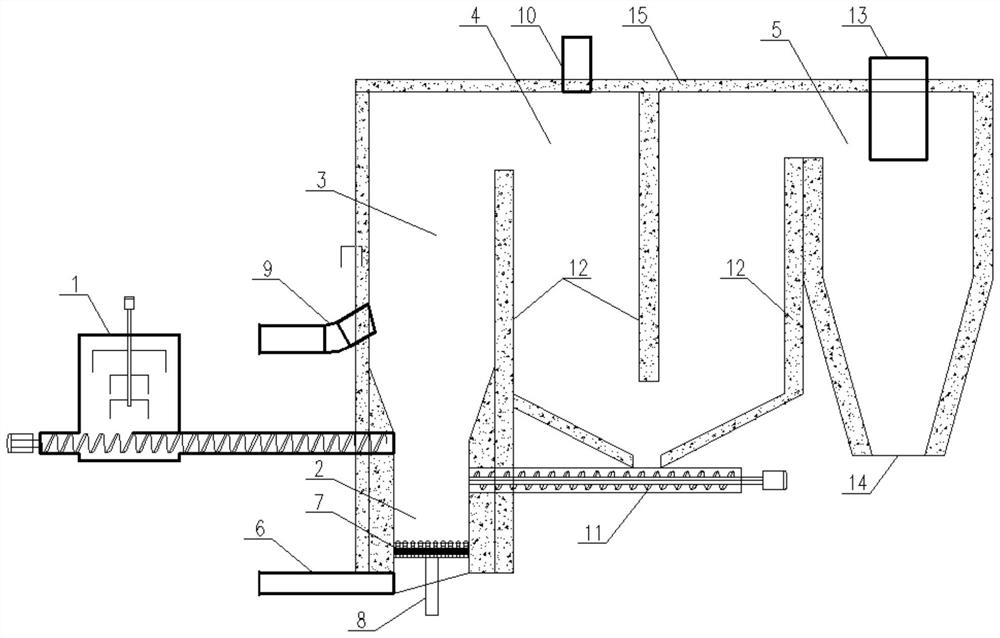

Quick pyrolysis technology for coal

ActiveCN105176547AFast heat and mass transferIncrease profitDirect heating destructive distillationSpecial form destructive distillationStraight tubeDiameter ratio

The invention provides a quick pyrolysis technology for coal. Feed coal with the particle size of 0-50 mm is firstly fed into a straight tube pyrolysis section with the length-diameter ratio being 40:1, mixed with a high-temperature carrier with the temperature of 850-950 DEG C and subjected to dry distillation under fluidization of raw gas, wherein the rising speed of the raw gas ranges from 2 m / s to 8 m / s. Thus, when the pyrolysis technology is used for conducting coal pyrolysis treatment, heat and mass transfer of cold materials and hot materials can be achieved, pyrolysis is quick, the whole pyrolysis process is controlled to be within 10-30 s, the utilization rate of raw materials is up to 100%, and the tar yield is high.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

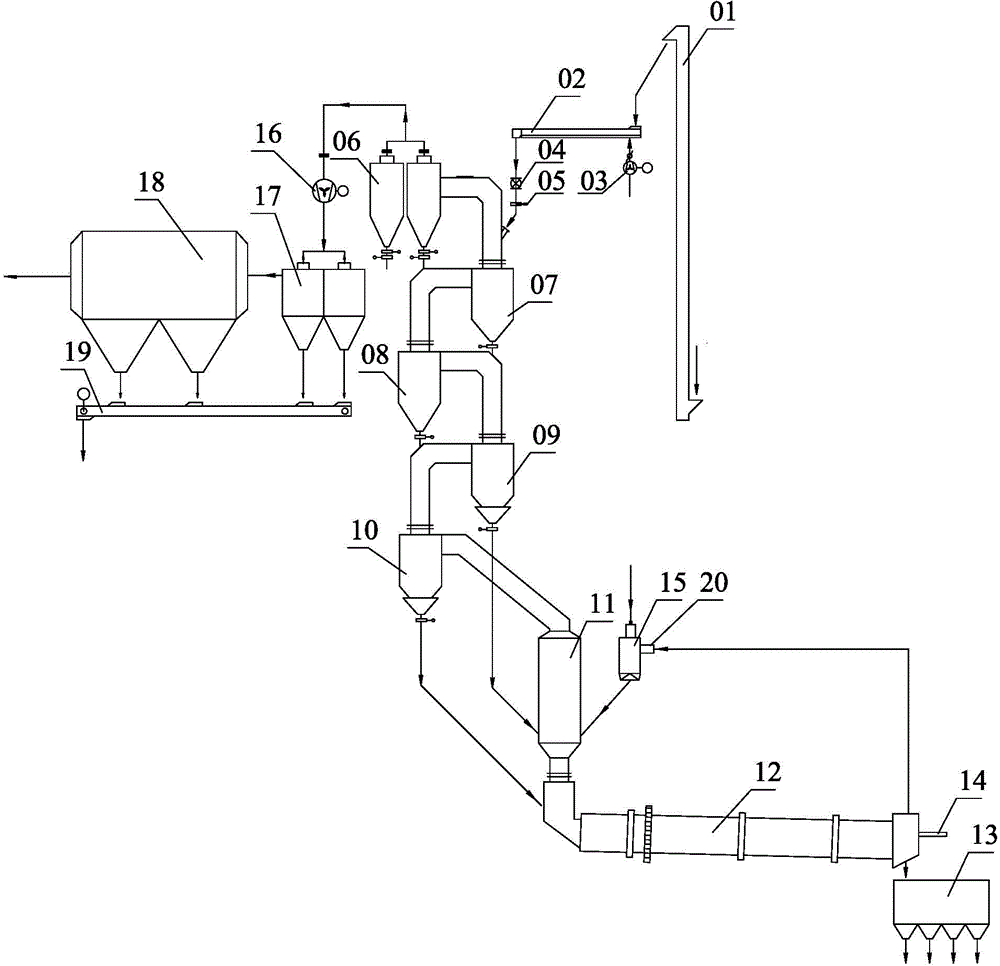

Device and method for microwave-enhanced fluidized phosphogypsum dehydration

The invention discloses a device and method for microwave-enhanced fluidized ardealite dehydration. The method comprises the following steps: ardealite is added into a system through a screw feeder; hot air provided by a hot blast stove is subjected to venturi drying, attached water in phosphogypsum is removed by a cyclone preheater, and then the hot air enters a wave-transparent heating section of the fluidized bed together with a wave-absorbing powder substance for mixing fluidization; and microwaves penetrate through the wave-transparent heating section in the resonant cavity and are absorbed by the wave-absorbing powder substance and the ardealite, and the removal of ardealite crystal water is simultaneously realized in solid-solid, gas-solid and microwave heating modes by utilizing heat generated by high-speed movement of molecules. Due to the change of the fluidization height of the ardealite without crystal water, the ardealite is separated from the wave-absorbing powder substance. The method and the device are wide in applicability, can realize continuous production of two products by one set of device, and are high in heat efficiency, high in heating speed, uniform in material heating, high in product stability, enhanced in polar component on the surface of hemihydrate gypsum molecules, reduced in contact angle, low in tail gas temperature and small in heat loss.

Owner:云南云天化环保科技有限公司

Method for preparing chloropropyl alkyl alkoxy silicon hydride by passage reaction device

ActiveCN105693759AStable temperatureGuarantee continuous and stable operationGroup 4/14 element organic compoundsAlcoholGas phase

The invention aims at providing a method for preparing chloropropyl alkyl alkoxy silicon hydride by a passage reaction device for industrial chloropropyl alkyl alkoxy silicon hydride production, so that chloropropyl chloride-containing silicon hydride and excessive alcohol take esterification reaction in the passage reaction device for preparing the chloropropyl alkyl alkoxy silicon hydride, wherein (1) the structure general formula (a) of the chloropropyl chloride-containing silicon hydride is ClC3H6SiCl<n>R<3-n>, in the formula, R is methyl or ethyl, and n=1, 2 or 3; (2) alcohol is methanol or ethanol, and enters the passage reaction device in a gas phase form; (3) the passage reaction device is at least connected with a posttreatment device and a hydrogen chloride absorption device. The problems of difficulty in regulation of yield and amplification effect and the like of large-sized reaction equipment are solved; the defects caused by the large-sized equipment are weakened or even eliminated.

Owner:南京曙光新材料有限公司

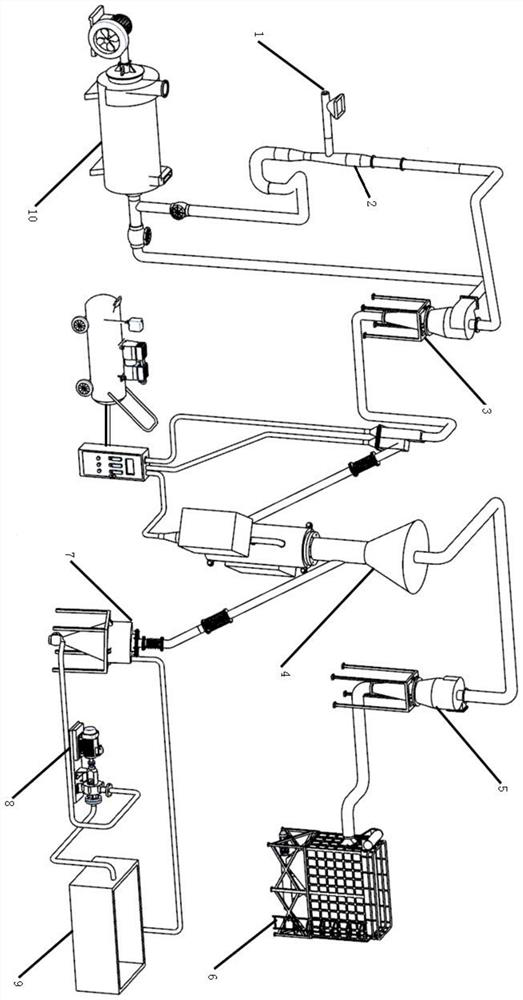

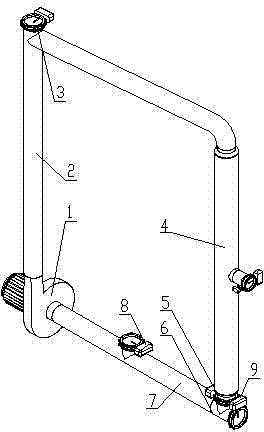

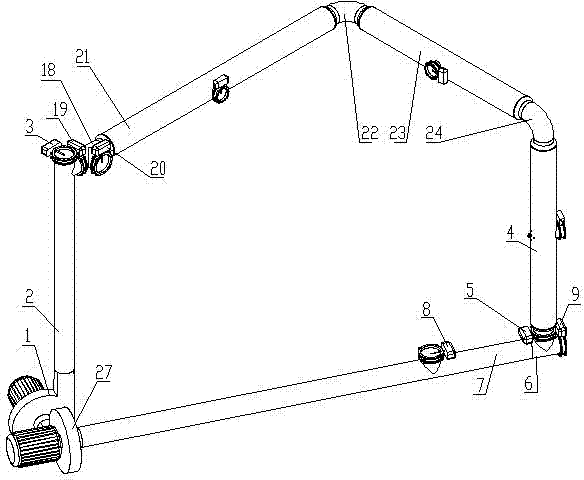

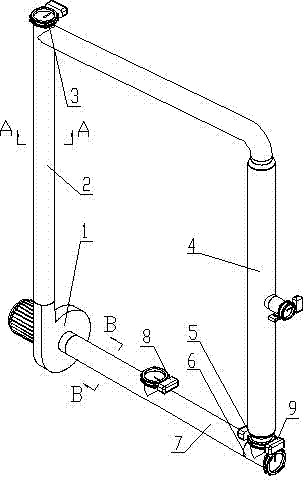

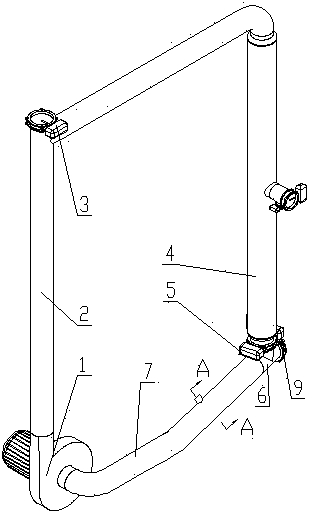

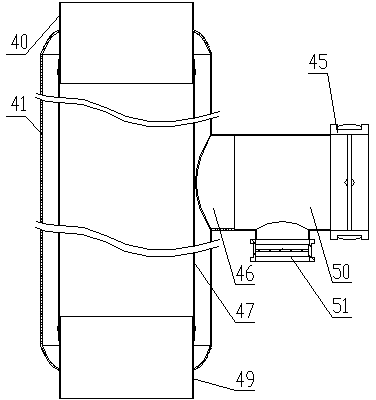

Pneumatic drying device of circulating fluidized bed

ActiveCN103673514APromote circulationImprove fluidization stateDrying solid materials with heatHearth type furnacesEngineeringMoisture

The invention discloses a pneumatic drying device of a circulating fluidized bed. According to the pneumatic drying device, a draught fan (1), a circulation pipe I (2), a dust remover (4), a regulating valve (5), an air inlet tee joint (6) and a circulation pipe II (7) form a circulation passage. The draught fan (1) sucks airflow in through the air inlet tee joint (6). Under the action of the airflow, materials are in a fluidization state and flow in the circulation passage at a high speed, heat exchange and water exchange are rapidly carried out between the fluidized materials and the air, and then moisture is discharged out through an exhaust port of the dust remover (4). The process is carried out repeatedly until the moisture content of the materials meets the requirement.

Owner:云南彝医药开发有限公司

Apparatus for preparing coal gas by using bulky biomass materials

InactiveCN1279145CSimple structureLow costSpecial form destructive distillationGranular/pulverulent flues gasificationRaw materialWater washing

The invention discloses a process and device for preparing coal gas using fluffy biomass raw materials. The process includes raw material pretreatment, raw material gasification, slag separation, gas purification, and gas transportation steps; the device includes a raw material pretreatment system, a gas generation system, a gas purification system, and a gas transportation and storage system. The built-in rapid fluidized bed gasifier used in the present invention has the characteristics of high production intensity, high gasification efficiency, low gas tar content, and good operating stability. The gasification reaction is completed at pneumatic conveying speed, and the built-in separator realizes rapid circulation of biomass raw materials in the gasification furnace. The gas purification method uses a combination of water washing and organic solvent washing, which has a high tar removal rate and a low tar content in the gas. Characteristics include small changes and fluctuations. The process and equipment of the present invention can continuously gasify fluffy biomass raw materials, and the gas generated by gasification can be used as a gas source for gas generators, and can also be used to supply gas to surrounding residential users through the pipeline network.

Owner:NANJING TECH UNIV

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

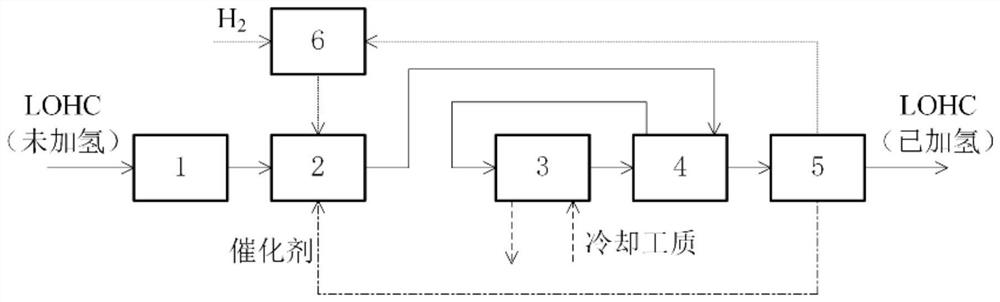

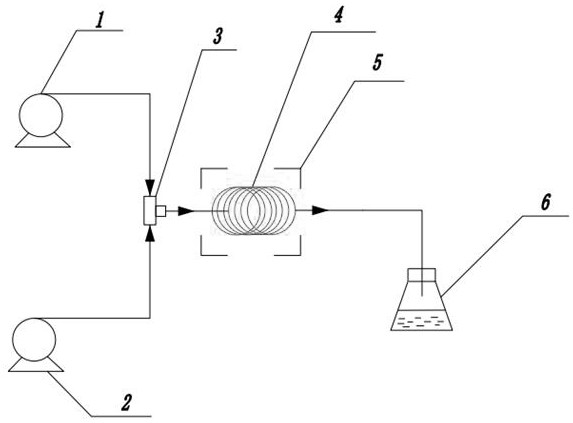

Micro-channel LOHC hydrogenation system and method

PendingCN113083180AEvenly dispersedOptimum hydrogenation reaction temperatureChemical/physical/physico-chemical microreactorsFeed devicesMicroreactorThermodynamics

The invention discloses a micro-channel LOHC hydrogenation system and method. According to the invention, the outlet of a pressure pump is connected with the LOHC inlet of a micro-mixer; the outlet of the micro-mixer is connected with the three-phase flow inlet of a micro-reactor; the three-phase flow outlet of the micro-reactor is connected with the inlet of a phase separator; the H2 outlet of the phase separator is connected with the inlet of a compressor; the outlet of the compressor is connected with the H2 inlet of the micro-mixer; and the catalyst outlet of the phase separator is connected with the catalyst inlet of the micro-mixer. LOHC, H2 and a catalyst are mixed in the micro-mixer; H2 is a dispersed phase; LOHC and H2 in the micro-reactor react under the action of the catalyst, and reaction heat is taken away by a cooling working medium; and the catalyst in the phase separator is separated from LOHC mainstream and is sent back to the micro-mixer for recycling. The advantages of high area-volume ratio of microchannels and high specific surface area of the fine-particle catalyst are utilized, so a heat and mass transfer speed is increased, and a hydrogenation reaction speed is increased. According to the invention, the dehydrogenation catalyst and the heat released by the reaction are recycled, and efficient utilization of substances and energy in the chemical process is realized.

Owner:XI AN JIAOTONG UNIV

A rapid pyrolysis process for coal

ActiveCN105176547BFast heat and mass transferIncrease profitDirect heating destructive distillationSpecial form destructive distillationStraight tubeDiameter ratio

The invention provides a quick pyrolysis technology for coal. Feed coal with the particle size of 0-50 mm is firstly fed into a straight tube pyrolysis section with the length-diameter ratio being 40:1, mixed with a high-temperature carrier with the temperature of 850-950 DEG C and subjected to dry distillation under fluidization of raw gas, wherein the rising speed of the raw gas ranges from 2 m / s to 8 m / s. Thus, when the pyrolysis technology is used for conducting coal pyrolysis treatment, heat and mass transfer of cold materials and hot materials can be achieved, pyrolysis is quick, the whole pyrolysis process is controlled to be within 10-30 s, the utilization rate of raw materials is up to 100%, and the tar yield is high.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

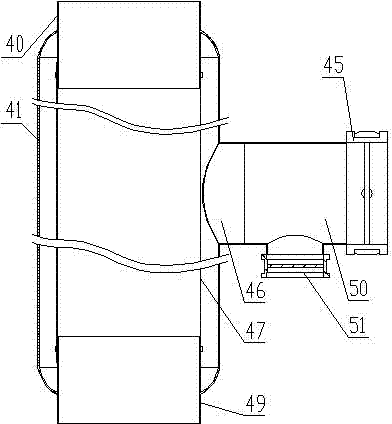

Method for circulating fluidized bed pyrolysis and deamination of magnesium chloride hexammoniate and equipment thereof

ActiveCN102336422BLow costGood gas-solid contactMagnesium chloridesEnergy inputMaterials scienceInert gas

The invention relates to a method for circulating fluidized bed pyrolysis and deamination of magnesium chloride hexammoniate. The method comprises the steps of: preheating a magnesium chloride hexammoniate material in a cyclone preheater; subjecting the preheated magnesium chloride hexammoniate to pyrolysis in a circulating fluidized bed pyrolysis furnace, heating the fluidized gas in an indirectheating mode; cooling the pyrolysed and dehydrogenized hot material in a cyclone cooler, conducting sealing reception and preservation to the cooled magnesium chloride material; meanwhile preheating the fluidized gas with the waste heat of the hot material; separating and recycling the ammonia and inert gases in the tail gas. The method of the invention fully makes use of the tail gas of the circulating fluidized bed pyrolysis furnace and the sensible heat of the hot material, thus having high thermal efficiency. Also, the gas and solid contact fully, heat and mass transfer is rapid, and deamination is thoroughly. The invention also provides equipment for realizing the method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing barium hydroxide by using barium carbonate

ActiveCN102923748BFast heat and mass transferShorten the timeCalcium/strontium/barium oxides/hydroxidesChemical reactionBarium peroxide

The invention discloses a method for preparing barium hydroxide by using barium carbonate. The method comprises the following steps of firstly grinding ores containing barium carbonate into ore powder, carrying out high-temperature roasting on the ore powder in a suspension fluidized state to obtain roasted ore containing barium hydroxide, soaking the roasted ore in water to react and generate a barium hydroxide solution, carrying out solid-liquid separation on the barium hydroxide solution, cooling and crystallizing to obtain barium hydroxide products. The method for preparing the barium hydroxide by using the barium carbonate, disclosed by the invention, has the advantages that the heat transfer area of the ore powder is large, each ore particle can uniformly and totally finish a chemical reaction, the reaction time is short, and the utilization rate of barium carbonate is high.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Drying coating technology for sodium percarbonate

ActiveCN100487066CSimple production processHigh degree of automationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPigment physical treatmentDielectricPolymer science

The invention discloses a specific dressing drying technology of sodium percarbonate, which comprises the following steps: adopting hot air as drying dielectric; utilizing energy and reflecting heat of sodium percarbonate particle and dressing solution bulk to condense on the surface of sodium percarbonate; coating; evaporating; crystallizing; drying; cooling; adopting different fluidization wind temperature and speed for guide coating area and drying area in the drying course; making the operation more stable.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

An ultra-low energy consumption circulating fluidized bed air drying equipment

ActiveCN103673512BReduce lossesReduce energy consumptionDrying solid materials with heatHearth type furnacesFluidized bed dryingAbsorption capacity

The invention discloses a circulating fluidized bed pneumatic drying device with ultra-low energy consumption. According to the circulating fluidized bed pneumatic drying device, a circulating channel is formed by a draught fan (1), a circulating pipe I (2), a dust remover (4), an adjusting valve (5), an air inflow three-way joint (6) and a circulating pipeline II (7). Air flow is sucked from an air inlet of the air inflow three-way joint (6), under the action of the draught fan, materials and the air flow are mixed inside the circulating channel to form a fluidized state and flow circularly at high speed, water of the materials is rapidly vaporized in the flowing process, the heat absorption capacity is large during water vaporization, the wet air flow is exhausted from an exhaust port of the dust remover (4), and the temperature of the wet air flow is low; due to heat insulation materials wrapping the circulating pipe, heat losses are reduced, and drying energy consumption is low.

Owner:云南彝医药开发有限公司

A kind of multistage series microreactor and fluid mixing method

ActiveCN113198402BAchieve hybridImprove responseSequential/parallel process reactionsFlow mixersMicroreactorMicro column

Owner:EAST CHINA UNIV OF SCI & TECH

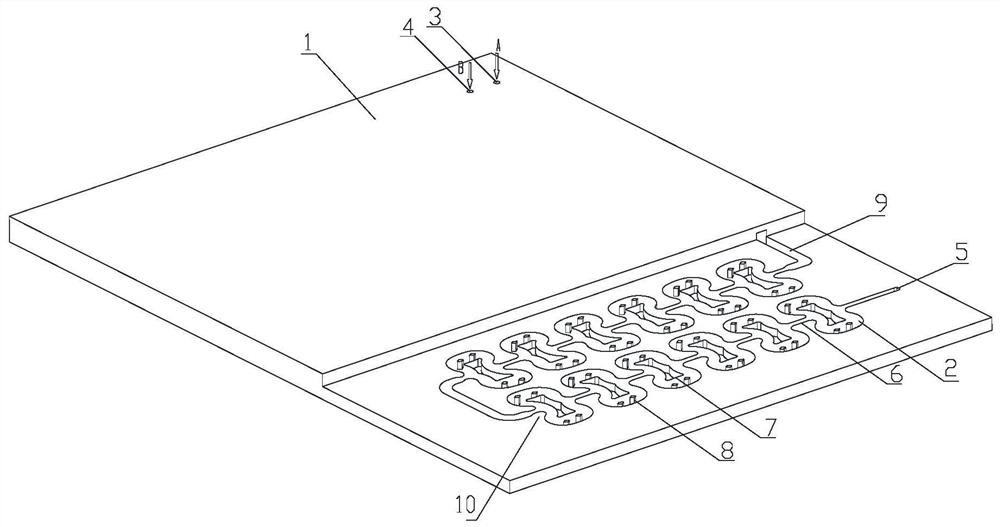

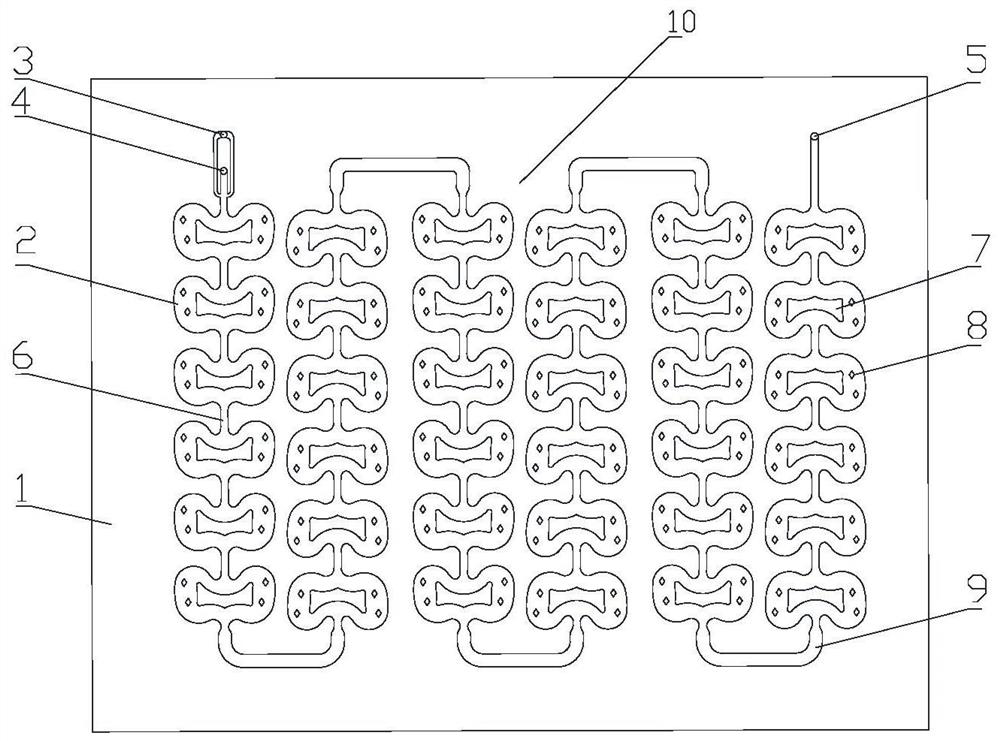

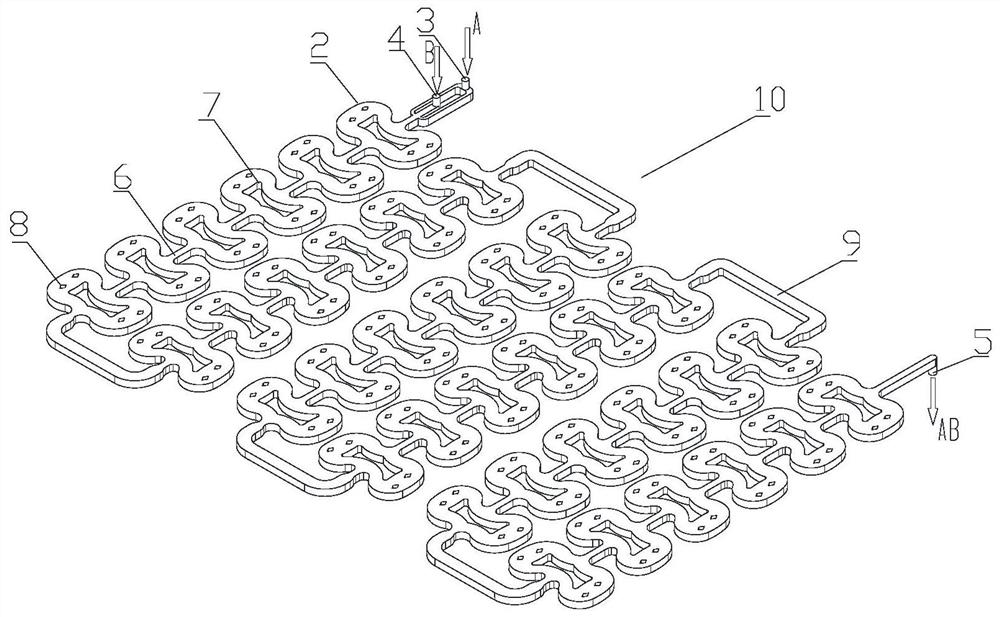

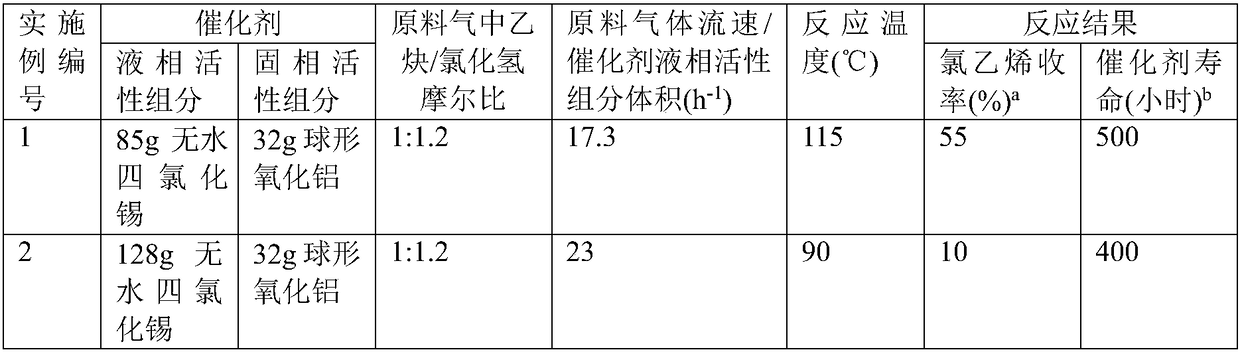

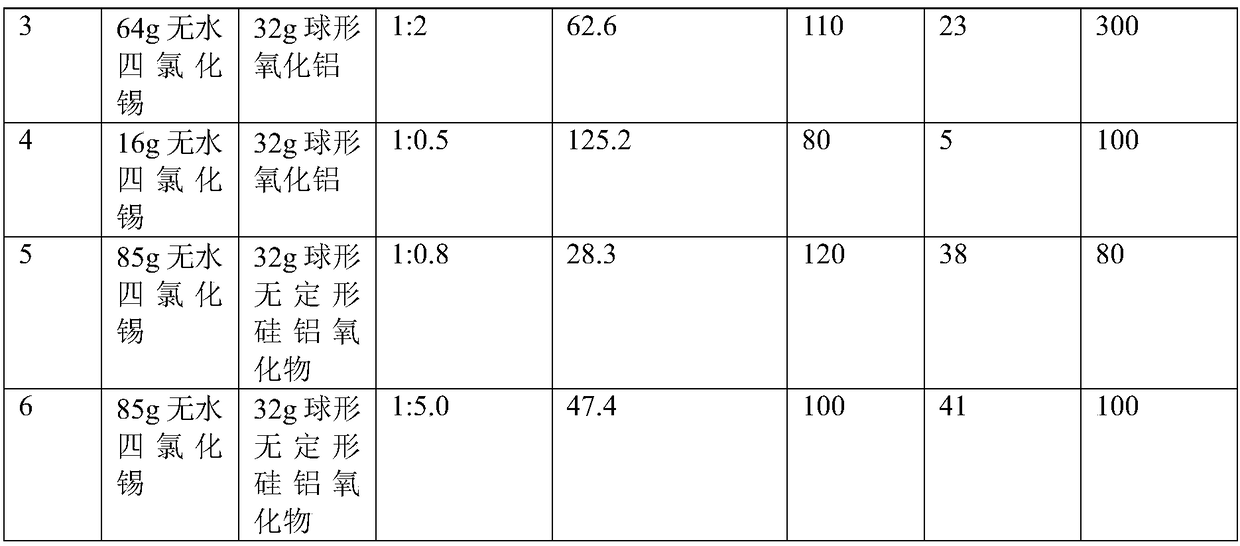

Catalyst for producing vinyl chloride by hydrochlorination of acetylene and application method thereof

ActiveCN105498813BFast heat and mass transferThe method system is simplePhysical/chemical process catalystsPreparation by halogen halide additionFixed bedSlurry

The application relates to a catalyst for producing vinyl chloride by hydrochlorination of acetylene and an application method thereof. The catalyst includes a liquid-phase active component containing anhydrous tin tetrachloride and a solid-phase active component. The solid-phase active component is amorphous silicon-aluminum oxide and / or aluminum oxide. The reactor used in the method is a fixed bed reactor or a slurry bed reactor, the reactor inlet is equipped with a gas distributor, and the outlet is equipped with a cooling reflux device. The catalytic system is simple in composition, fast in mass and heat transfer, and has no reaction hot spots; the catalyst is cheap and easy to obtain, and can be recycled, with stable reaction activity and long service life of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Novel low-pollution bubbling bed gasification combustion reaction device and method

InactiveCN113063150AFast heat and mass transferReduce carbon contentIncinerator apparatusCyclonic separationDust control

The invention discloses a novel low-pollution bubbling bed gasification combustion reaction device and method. The device comprises a feeding device, a bubbling gasification section, a second-stage combustion section, a last-stage combustion section and a cyclone separation device. Organic solid particles are fed into the bubbling gasification section through the feeding device, meanwhile, air is introduced to make contact with the organic solid particles for a gasification reaction, gasified gas and ash are generated, the gasified gas is sequentially fed into the second-stage combustion section and the last-stage combustion section and fully mixed with the air for a low-oxygen combustion reaction, flue gas is formed, solid particles which are not completely reacted and mixed in the flue gas are isolated by a dust isolation plate and fall to the bottom of the last-stage combustion section, the solid particles are conveyed to the bubbling gasification section through a high-temperature mechanical material returning device to be subjected to gasification reaction again, and the remaining flue gas is conveyed into the cyclone separator to be subjected to dust removal again and then conveyed into a subsequent energy recovery and flue gas treatment system. On the premise of meeting the combustion heat efficiency of the organic solid particles, the generation amount of NOx, SOx and fly ash can be greatly reduced, the height of the furnace body is reduced, and then the follow-up investment and operation cost are reduced.

Owner:DALIAN UNIV OF TECH

A rapid coal pyrolysis reaction device and a coal pyrolysis reaction system based on the device

ActiveCN105154111BQuick exportFast heat and mass transferDirect heating destructive distillationSpecial form destructive distillationGas solidEngineering

The invention provides a rapid coal pyrolytic reaction device. A straight pipe pyrolysis section and a gas-solid separation bin are arranged on the rapid coal pyrolytic reaction device in sequence from bottom to top, pyrolysis is conducted on raw material coal at the straight pipe pyrolysis section, a dry-distilled product is obtained and rapidly upward enters the gas-solid separation bin to be separated to obtain a carrier and a gas product, the carrier obtained after separation is discharged from a carrier outlet, the gas product is discharged from a gas outlet, the whole pyrolytic process is controlled to be within 10-20 seconds, coal pyrolysis can be completed rapidly, and meanwhile the carrier and the gas product can be led out rapidly. The utilization rate of raw materials reaches up to 100%, and the tar yield is high.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

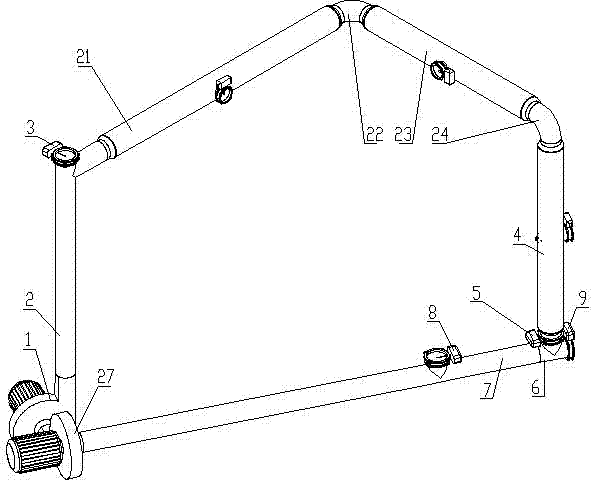

Spray drying equipment for circulating fluidized bed

ActiveCN103706134AVaporization speed is fastImprove thermal efficiencyDispersed particle filtrationEvaporator accessoriesLiquid stateInlet valve

The invention discloses spray drying equipment for a circulating fluidized bed. According to the spray drying equipment for the circulating fluidized bed, a circulating channel is formed by a fan (1), a circulating pipeline I (2), a dust collector (4), a regulating valve (5), a three-way air inlet joint (6) and a circulating pipeline II (7). An atomizer is arranged in the circulating pipeline II (7). Under the action of the fan (1), air flow enters the circulating channel through an air inlet valve (9) and circularly flows at high speed, a liquid-state material is atomized through the atomizer, enters the circulating channel, goes into a fluidization state under the action of the high-speed air flow, and flows at high speed in the circulating channel, heat exchange and water exchange are quickly performed between the material and the air flow, and wet air is discharged along with air flow separated from the dust collector, so that the liquid-state material can be dried.

Owner:KUNMING TEKANG TECH CO LTD

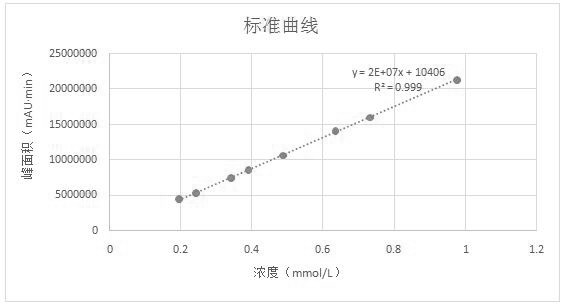

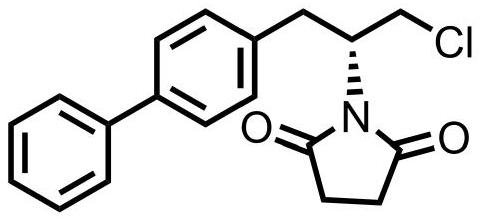

A method for pipeline synthesis of key intermediates of Shakubiqu

ActiveCN109336804BIncrease production capacityFast heat and mass transferOrganic chemistryReaction temperatureEngineering

The invention discloses a channelization synthesis method for a key intermediate of sacubitril. The method comprises the following steps: (S)-1-([1,1'-biphenyl]-4-yl)-3-chloropropan-2-ol, succinimide,triphenylphosphine, ethyl azodicarboxylate and an organic solvent are mixed, the mixed solution is fed continuously into a channelization reactor for reaction, a feed liquid obtained after the reaction is fed into a quenching kettle containing an quenching liquid, a quenching reaction is performed with the quenching liquid, (R)-1-(1-([1,1'-biphenyl]-4-yl)-3-chloropropan-2-yl)pyrrolidin-2,5-dioneis prepared, and the key intermediate of sacubitril is obtained. According to the reaction process, reaction temperature, time and material proportion can be controlled precisely; the reactor has theadvantages of large specific surface area and high mass and heat transfer efficiency, precise proportion moment of the materials can be determined, heat transfer efficiency is high, and safety of a production process is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com