Spherical silver powder with controllable granularity and preparation method thereof

A technology of spherical and silver powder, which is applied in the field of precious metal raw material powder and its preparation in the electronic industry, can solve the problems such as difficulty in obtaining micron silver powder, and achieve the effect of uniform shape, uniform particle size and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

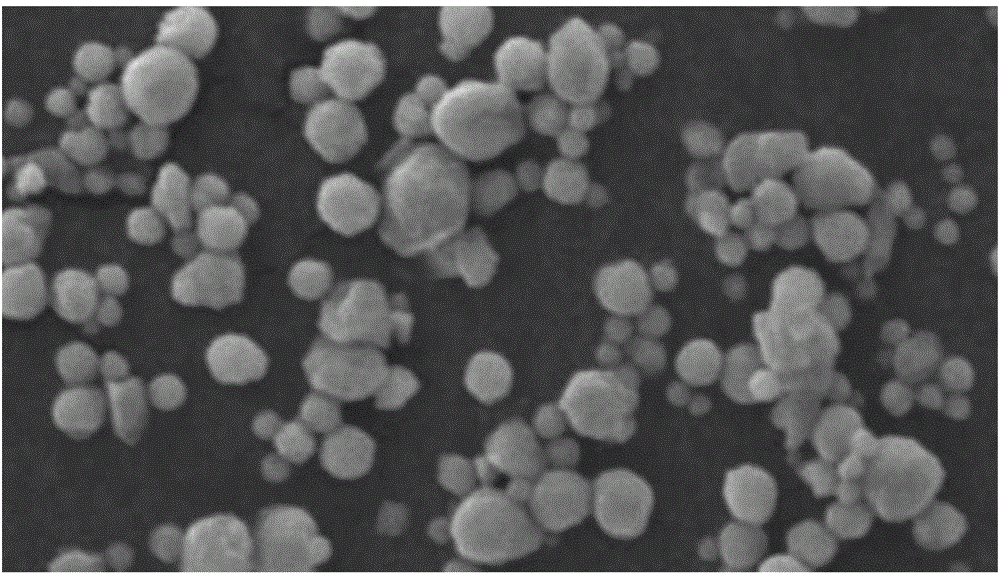

Image

Examples

Embodiment 1

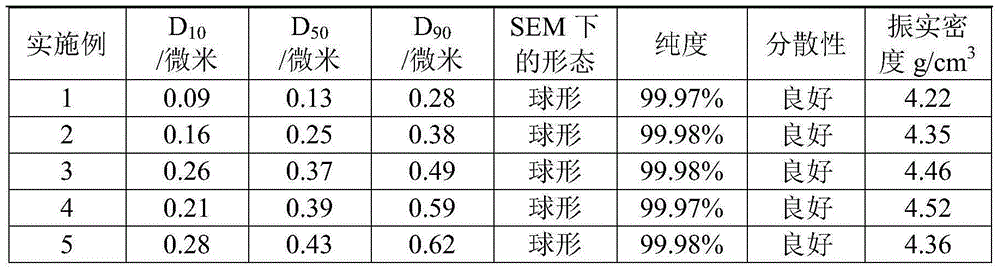

[0025] A spherical silver powder with controllable particle size of the present invention has a purity of 99.97%, and a tap density of the spherical silver powder of 4.22g / cm 3 , the particle size D of the spherical silver powder 10 、D 50 、D 90 They are 0.09 μm, 0.13 μm and 0.28 μm respectively, and the particle size is achieved based on the control of the reaction system formulation and reaction conditions during the preparation process.

[0026] The preparation method of the above-mentioned spherical silver powder of the present embodiment specifically comprises the following steps:

[0027] (1) First weigh 1g of silver nitrate and dissolve it in 100ml of deionized water, add 0.7g of sodium dodecylbenzenesulfonate, and mix the two evenly under stirring conditions; add sodium hydroxide to adjust the pH of the mixed solution to 8; Weigh 3ml of formaldehyde solution with a mass fraction of 37%, and add it to the aforementioned mixed solution; immediately transfer the reactio...

Embodiment 2

[0031] A spherical silver powder with controllable particle size of the present invention has a purity of 99.98%, and a tap density of the spherical silver powder of 4.35g / cm 3 , the particle size D of the spherical silver powder 10 、D 50 、D 90 They are 0.16 μm, 0.25 μm and 0.38 μm respectively, and the particle sizes are realized based on the control of the reaction system formulation and reaction conditions during the preparation process.

[0032] The preparation method of the above-mentioned spherical silver powder of the present embodiment specifically comprises the following steps:

[0033] (1) First weigh 1g of silver nitrate and dissolve it in 100ml of deionized water, add 0.6g of PVP, and mix the two evenly under stirring conditions; add sodium hydroxide to adjust the pH of the mixture to 8; and weigh another 3ml with a mass fraction of 37 % formaldehyde solution was added to the aforementioned mixed solution; the reaction solution was immediately transferred to a h...

Embodiment 3

[0037] A spherical silver powder with controllable particle size of the present invention has a purity of 99.98%, and a tap density of the spherical silver powder of 4.46g / cm 3 , the particle size D of the spherical silver powder 10 、D 50 、D 90 They are 0.26 μm, 0.37 μm and 0.49 μm respectively, and the particle sizes are realized based on the control of the reaction system formulation and reaction conditions during the preparation process.

[0038] The preparation method of the above-mentioned spherical silver powder of the present embodiment specifically comprises the following steps:

[0039] (1) First weigh 0.6g of silver nitrate and dissolve it in 50ml of deionized water, add 0.5g of sodium dodecylbenzenesulfonate, and mix the two evenly under stirring conditions; add sodium hydroxide to adjust the pH of the mixed solution to 7; Another 1.3g reductant ferrous sulfate was weighed and dissolved in 50ml deionized water, and added to the aforementioned mixed solution after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com