A kind of multistage series microreactor and fluid mixing method

A microreactor and mixing tank technology, applied in series/parallel reactions, fluid mixers, chemical instruments and methods, etc., can solve problems affecting fluid uniformity and mixing efficiency, reaction conversion rate and production efficiency. It can improve the fluid uniformity, shorten the reaction time, and fast heat and mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

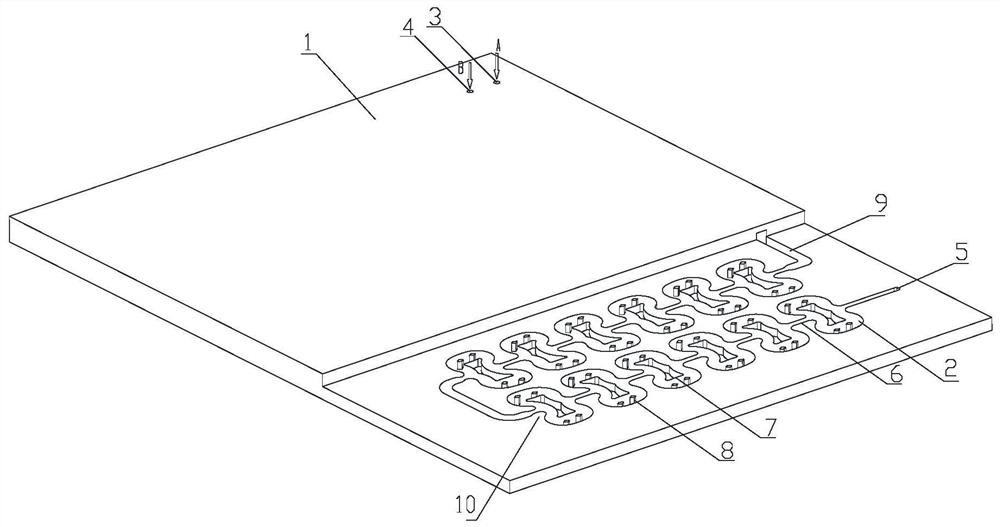

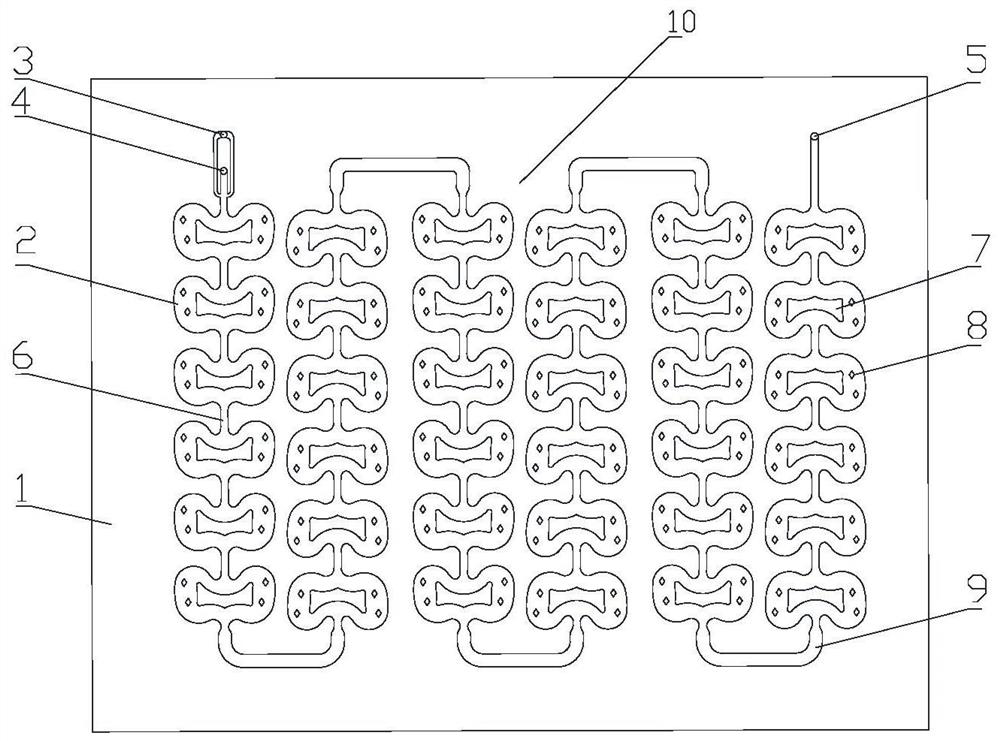

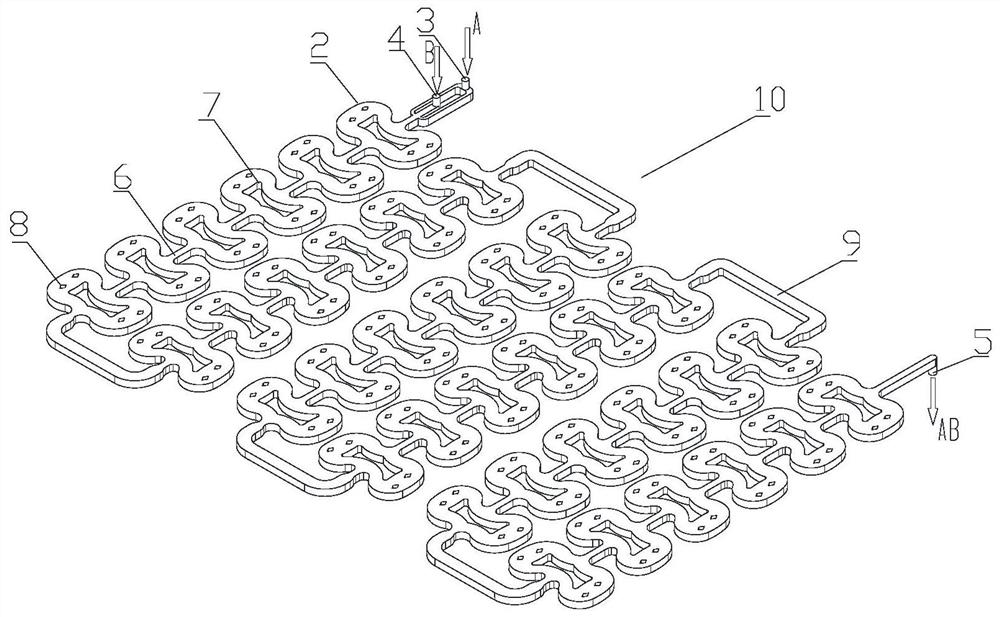

[0040] The present invention provides a multistage series microreactor, such as figure 1 As shown, the microreactor includes a substrate 1 with a fluid flow channel 10 etched therein, the substrate 1 is provided with a fluid inlet and a fluid outlet 5 communicating with the fluid flow channel 10, and the fluid inlet includes a first A fluid inlet 3 and a second fluid inlet 4 are respectively used for the feeding of the two fluids to be mixed; combined figure 2 and image 3As shown, the fluid flow channel 10 includes a plurality of micro-mixing tanks 2, which are connected by a constricted section 6. The micro-mixing tank 2 is provided with a butterfly-shaped diverter plate 7, which is used to divide and guide the flow. The mixed fluid flowing into the micro-mixing tank 2, several micro-columns 8 are arranged on both sides of the butterfly-shaped dividing plate 7 for further shearing, stretching and folding of the fluid micelles, increasing the contact between the fluids are...

Embodiment 2

[0055] The multi-stage series microreactor described in Example 1 was used to mix water and alcohol at a ratio of 1:1 at different flow rates, and the mean square error of the single-phase concentration distribution at each point on the outlet plane was used as the mixing index M to evaluate the mixing effect. , the closer the mixing index M is to 1, the better the mixing effect is, and vice versa, the worse the mixing effect is. And the advanced flow reactor of Corning company is used as a comparison. The structure diagram of the fluid flow channel of the advanced flow reactor of Corning company is as follows Figure 10 shown.

[0056] The results are shown in the following table as the mixing index M under different flow conditions. Using the microreactor of the present invention in three cascade units, that is, through three series-connected micromixing tanks, a mixing degree of more than 99% can be achieved. The phase mixing capability is comparable to Corning's Advanced ...

Embodiment 3

[0059] The multi-stage series microreactor described in Example 1 was used to mix water and alcohol at a ratio of 1:1 under different flow rates, and the advanced flow reactor of Corning was used as a comparison, and the residence time distribution density function E ( The variance σ of t) 2 and asymmetric s 3 As a reference index of residence time distribution, the smaller the value, the better the fluid distribution performance.

[0060] The results are shown in the following table as the variance σ of the residence time distribution density function E(t) under different flow conditions 2 and asymmetric s 3 As shown, the variance σ of the residence time distribution density function E(t) of the microreactor provided by the present invention 2 Reduced by 12.6% to 56.5%, asymmetric s 3 It is reduced by 19.0% to 50.0%, and the uniform distribution performance of the fluid is better.

[0061]

[0062] According to the analysis results of Corning's advanced flow reactor g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com