Catalyst for producing vinyl chloride by hydrochlorination of acetylene and application method thereof

An acetylene hydrochlorination and catalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as limited production capacity per unit catalyst, reduced catalyst life, overheating, etc., and achieve good industrial applications. Prospects, improving catalyst life, and the effect of fast heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

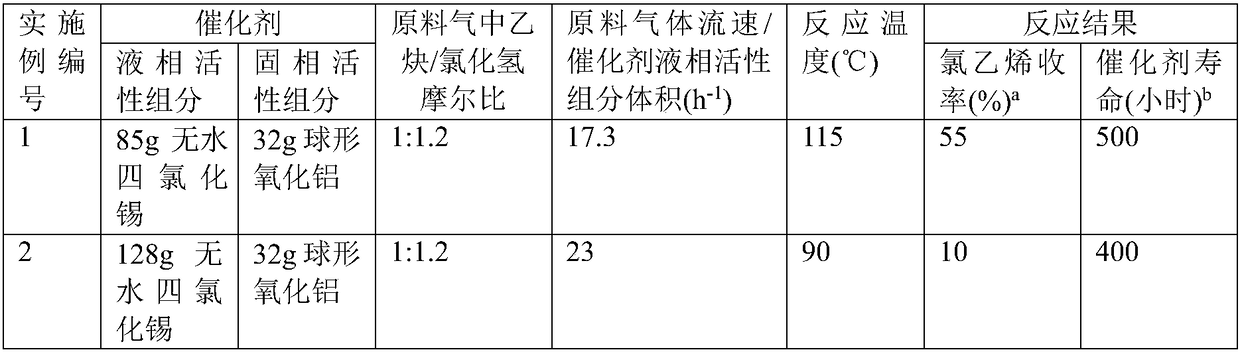

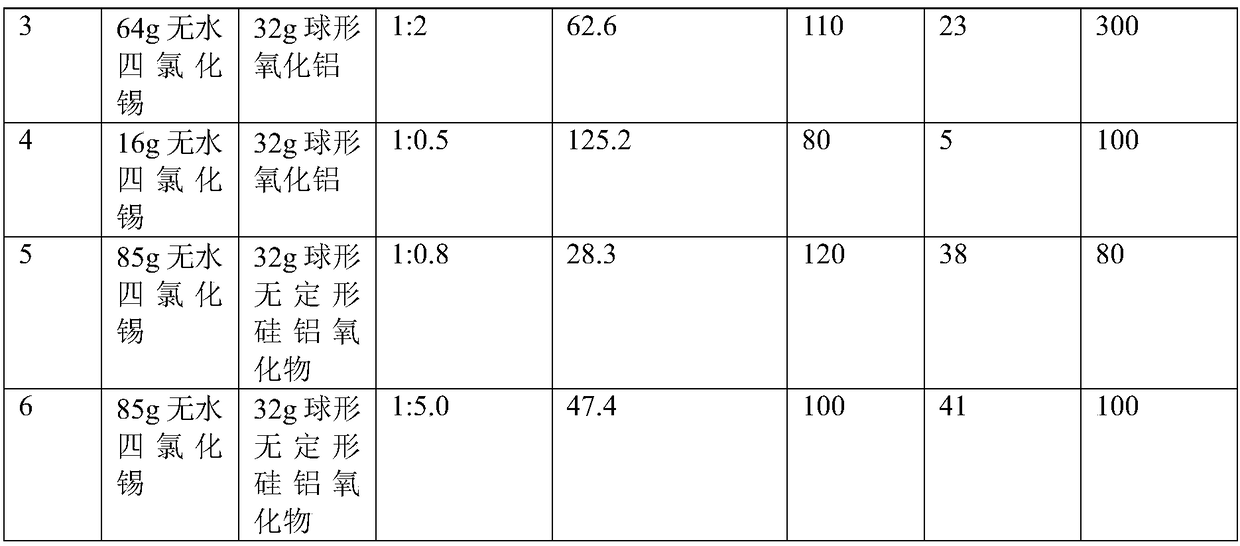

[0036] Embodiment 1-6 tubular fixed bed reactor

[0037] Fill a certain amount of solid-phase active components into the tubular fixed-bed reactor, the reactor raw material gas inlet is equipped with a gas distributor, and the product outlet is equipped with a cooling reflux device, and then a certain amount of liquid-phase active components are loaded into the reactor, The reaction raw material gas is introduced from the lower part of the reactor, and the reaction product flows out from the upper part. The reaction raw material gas acetylene and hydrogen chloride are passed into the reactor according to the molar ratio of 1:0.5~5, and the reaction gas flow rate / liquid phase catalyst volume=1~130h -1 , The reaction temperature is 80-120°C, and the reaction product is analyzed by gas chromatography to determine the space-time yield. The diameter of the reactor used is 15mm, the height is 300mm, and the cooling temperature at the outlet of the reactor is 0-5°C. See Table 1 for ...

Embodiment 7-12

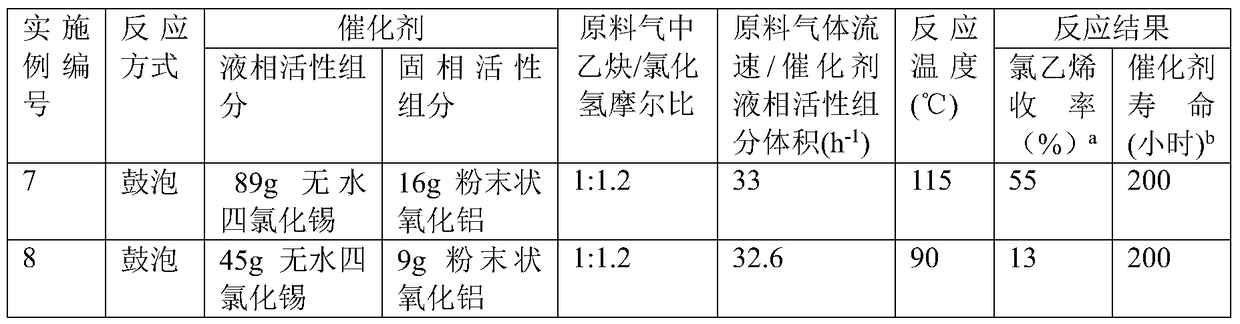

[0043] Embodiment 7-12 tank type slurry bed reaction:

[0044] Fill a certain amount of powdery solid-phase active components into the kettle-type slurry bed reactor, the particle size is 10-500 microns, the reactor raw material gas inlet is equipped with a gas distributor, and the product outlet is equipped with a cooling reflux device, and then the A certain amount of liquid-phase active components are loaded into the reactor, the reaction raw material gas is introduced from the lower part of the reactor, and the reaction product flows out from the upper part, and the reaction raw material gas acetylene and hydrogen chloride are passed into the reactor according to the molar ratio of 1:0.5~5, and the reaction Gas flow rate / liquid phase catalyst volume=1~130h -1 , The reaction temperature is 80-120°C, and the reaction product is analyzed by gas chromatography to determine the space-time yield. See Table 2 for the types, shapes and amounts of the solid-phase active components...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com