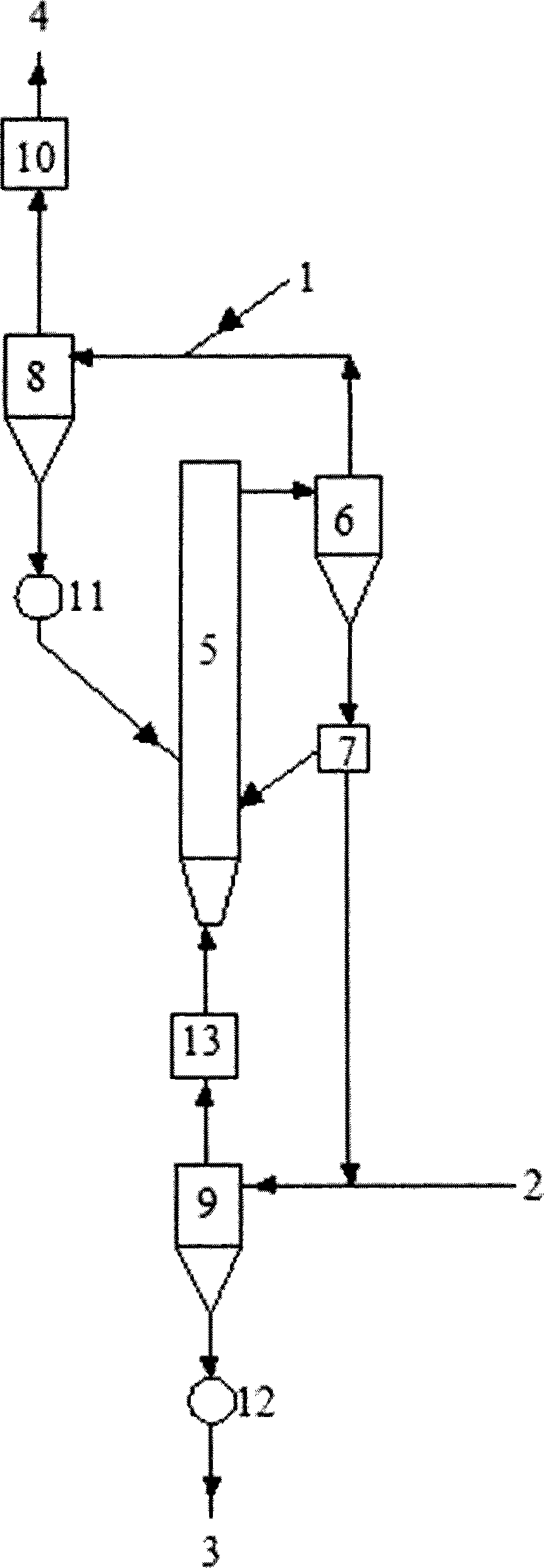

Method for circulating fluidized bed pyrolysis and deamination of magnesium chloride hexammoniate and equipment thereof

A technology of circulating fluidized bed and hexaammoniated magnesium chloride, which is applied in the field of pyrolysis of hexaammoniated magnesium chloride, can solve the problems of uneven product quality, high product energy consumption, high labor intensity, etc., and achieve good gas-solid contact and stable product quality , The effect of fast heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

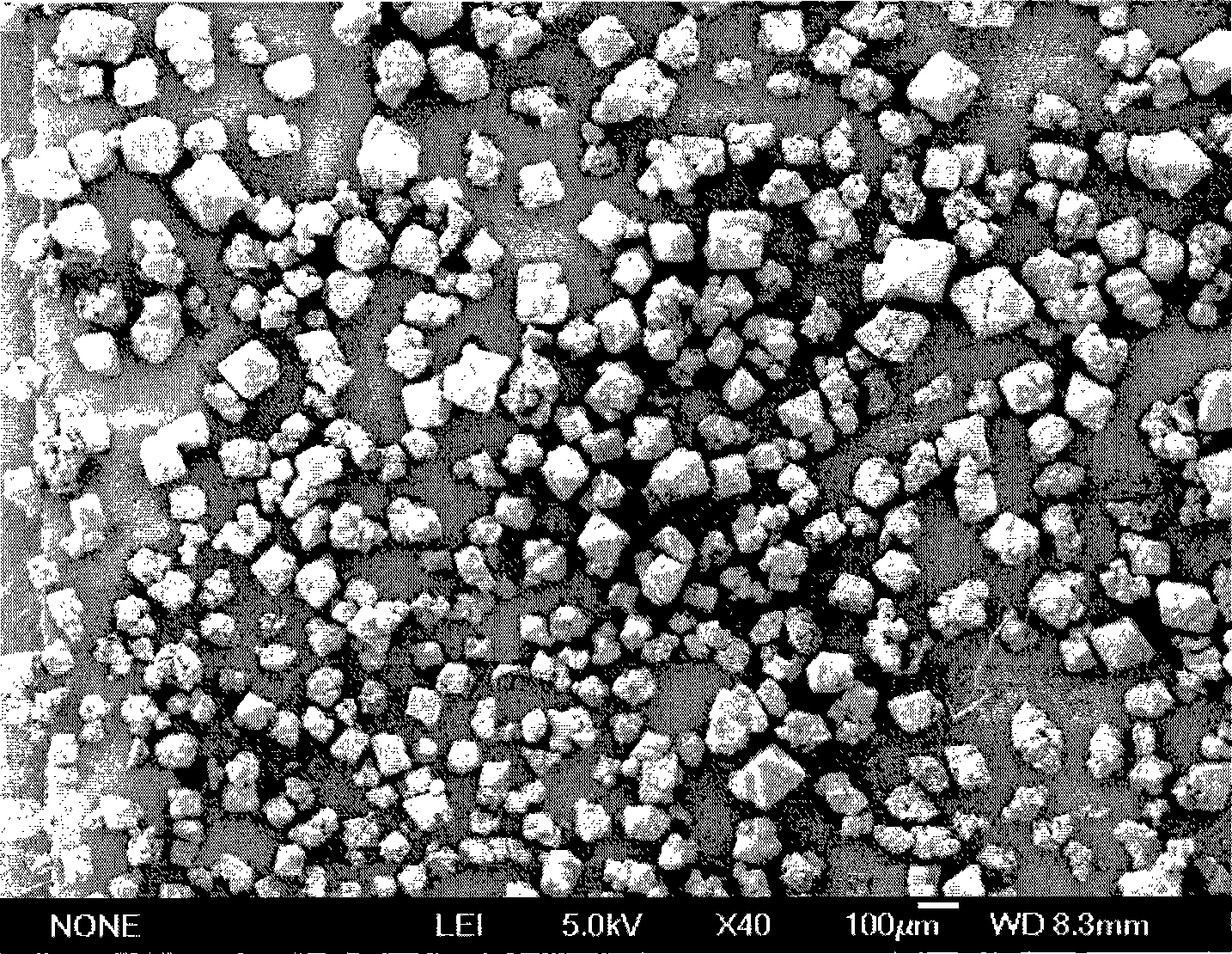

[0051] Using magnesite as raw material, first crush magnesite and thermally decompose it into highly active magnesium oxide at 750°C, then react active magnesium oxide with equimolar ammonium chloride in ethylene glycol, and the completely reacted solution passes through After vacuum distillation and dehydration, an ethylene glycol solution of magnesium chloride was obtained. Ammonia gas is passed into the ethylene glycol solution of magnesium chloride, and reaction crystallization is carried out to obtain hexaammoniated magnesium chloride crystals. Washing, filtering, drying obtains magnesium chloride hexaammoniate crystal material ( figure 2 ).

[0052] The magnesium chloride hexaammoniate crystal (average particle diameter is about 100um) obtained above is sent into the gas-solid countercurrent cyclone preheating system 8, utilizes the tail gas of the circulating fluidized bed pyrolysis furnace to preheat the magnesium chloride hexaammoniate; Magnesium chloride ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com