Micro-channel LOHC hydrogenation system and method

A hydrogenation system and microchannel technology, applied in the field of hydrogen energy, can solve the problems of high storage and transportation costs, high efficiency, and difficulty in long-distance transportation, achieve high specific surface area, increase hydrogenation reaction speed, and enhance heat and mass transfer speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail through specific embodiments below in conjunction with schematic diagrams.

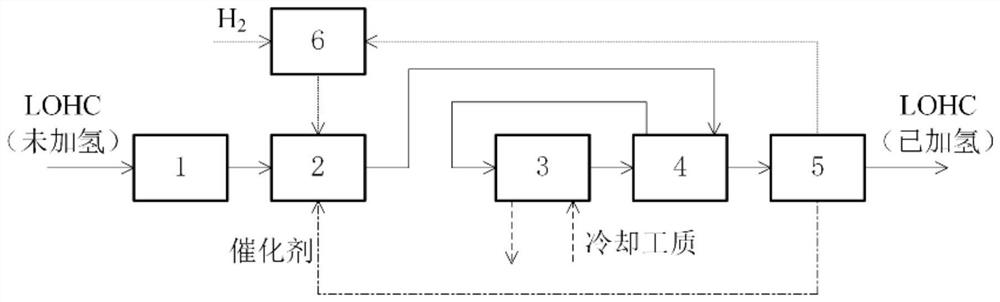

[0033] like figure 1 As shown, the present invention provides a microchannel LOHC hydrogenation system, consisting of a booster pump 1, a micromixer 2, a microreactor 3, a regenerator 4, a phase separator 5, a compressor 6, and related connecting pipes Road, bypass circuit, valves, temperature sensors, pressure sensors and other components. Among them, the outlet of the booster pump is connected to the LOHC inlet of the micro-mixer, the outlet of the micro-mixer is connected to the cold fluid inlet of the regenerator, the cold fluid outlet of the regenerator is connected to the three-phase inflow inlet of the micro-reactor, and the three-phase outflow of the micro-reactor is connected to the regenerator The hot fluid inlet of the regenerator, the hot fluid outlet of the regenerator is connected to the inlet of the phase separator, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com