Method for preparing barium hydroxide by using barium carbonate

A barium hydroxide and barium carbonate technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of long process flow, deteriorating working environment of workers, and high production cost, so as to reduce production cost and improve equipment Effects of volume utilization and reduction of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

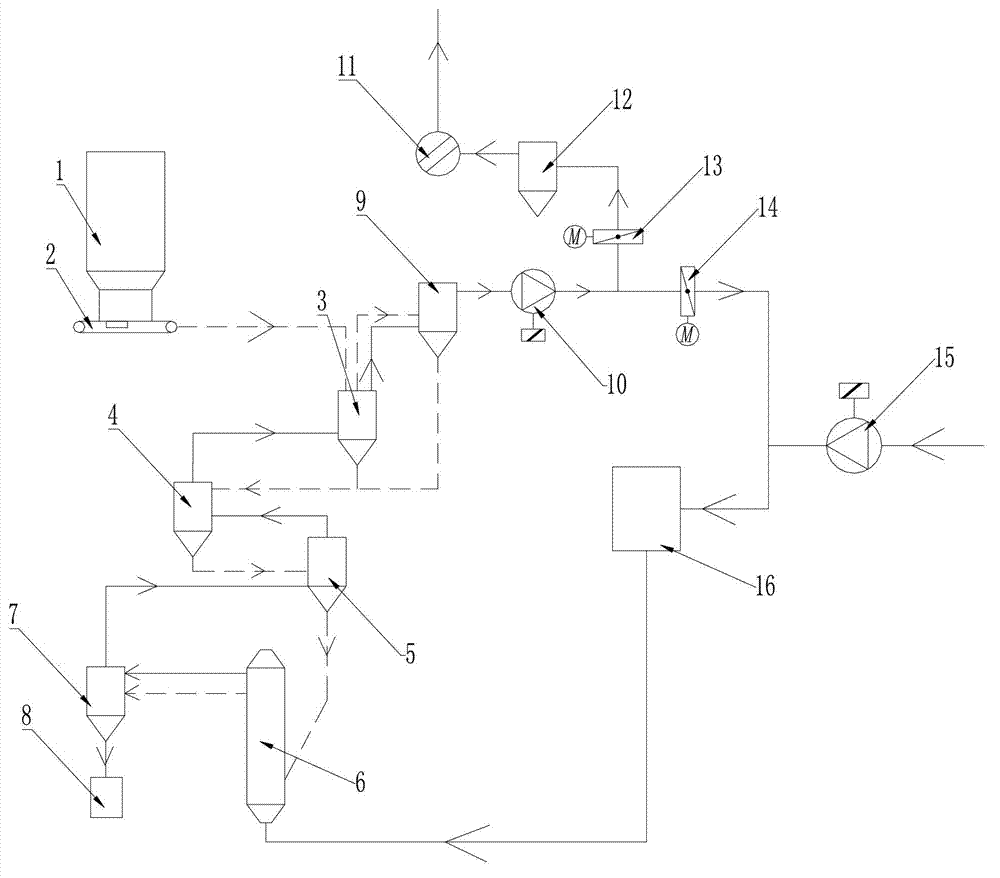

[0041] a kind of like figure 1Shown adopting witherite of the present invention is the method for raw material preparation barium hydroxide, comprises the following steps:

[0042] (1) Grinding: The witherite mineral is finely ground into mineral powder with a particle size below 1.0mm. During the grinding process, the mineral is dried at the same time to make the water content of the mineral powder less than 3%.

[0043] (2) Preheating: The barium carbonate particles in the powder bin 1 are weighed and measured by the electronic belt scale 2, and then enter the first-stage cyclone preheater 3, the second-stage cyclone preheater 4 and the third-stage cyclone preheater 5 During the preheating process, the heat exchange with the hot flue gas is carried out countercurrently, and the feed rate is controlled at 5t / h; during the preheating process, the hot flue gas continuously introduced makes the ore powder in a suspended fluidized state, and the hot flue gas comes from the subseq...

Embodiment 2

[0048] a kind of like figure 1 Shown the present invention adopts the BaCO produced by a certain chemical industry 3 Powder is raw material and prepares barium hydroxide, and this method specifically comprises the following steps:

[0049] (1) Grinding: the BaCO produced by a chemical production 3 The powder is finely ground to make mineral powder with a particle size of less than 1.0mm. During the grinding process, the mineral is dried at the same time to make the water content of the mineral powder less than 3%.

[0050] (2) Preheating: The barium carbonate particles in the powder bin 1 are weighed and measured by the electronic belt scale 2, and then enter the first-stage cyclone preheater 3, the second-stage cyclone preheater 4 and the third-stage cyclone preheater 5 During the preheating process, the heat exchange with the hot flue gas is carried out countercurrently, and the feed rate is controlled at 5t / h; during the preheating process, the hot flue gas continuously i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com