Micro-via type chemical heat pump reactor

A chemical heat pump and microchannel technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of slow heat and mass transfer rate, high equipment cost, complicated disassembly and assembly, etc. , to achieve the effect of convenient replacement of reactants and parts, fast heat and mass transfer, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

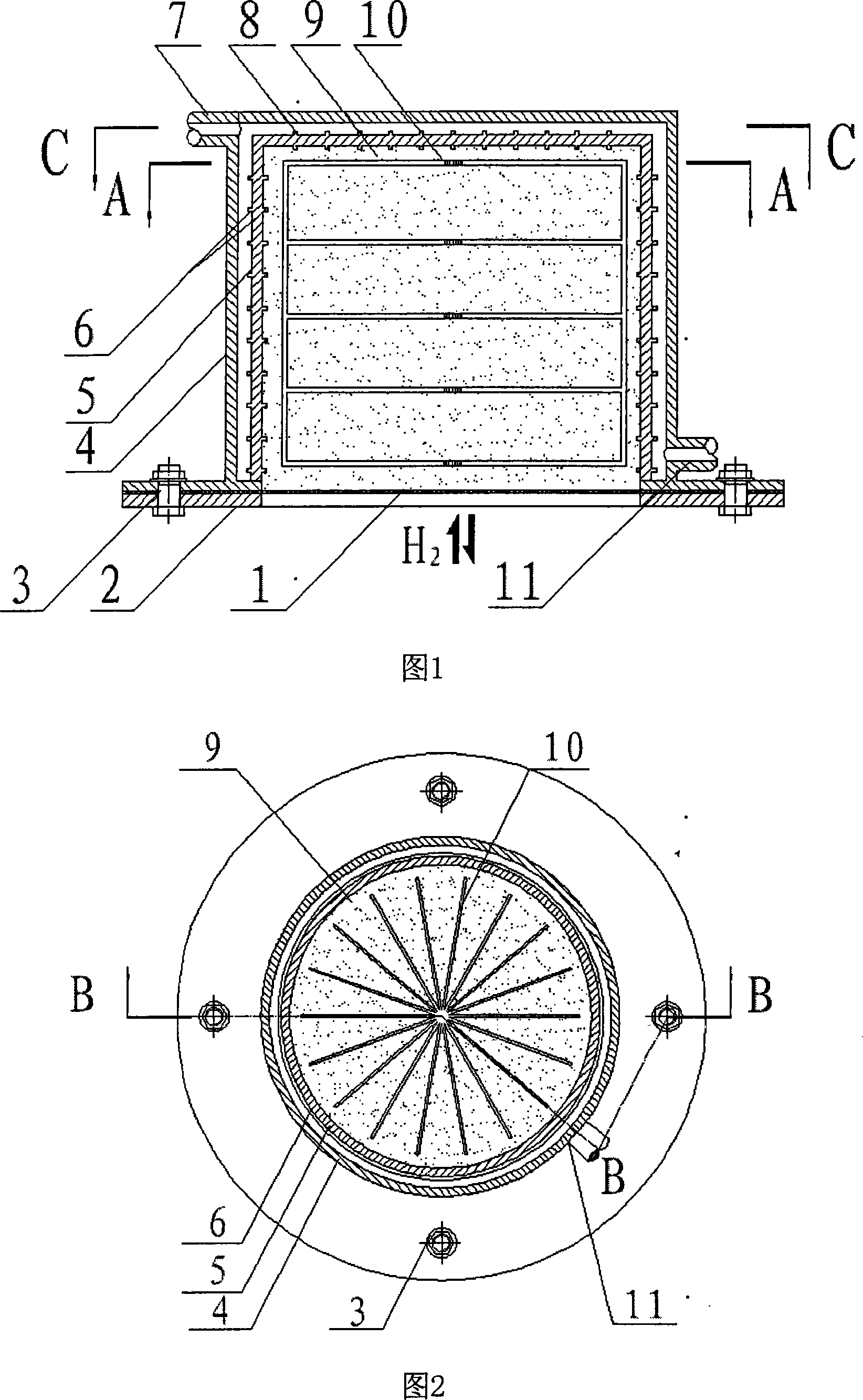

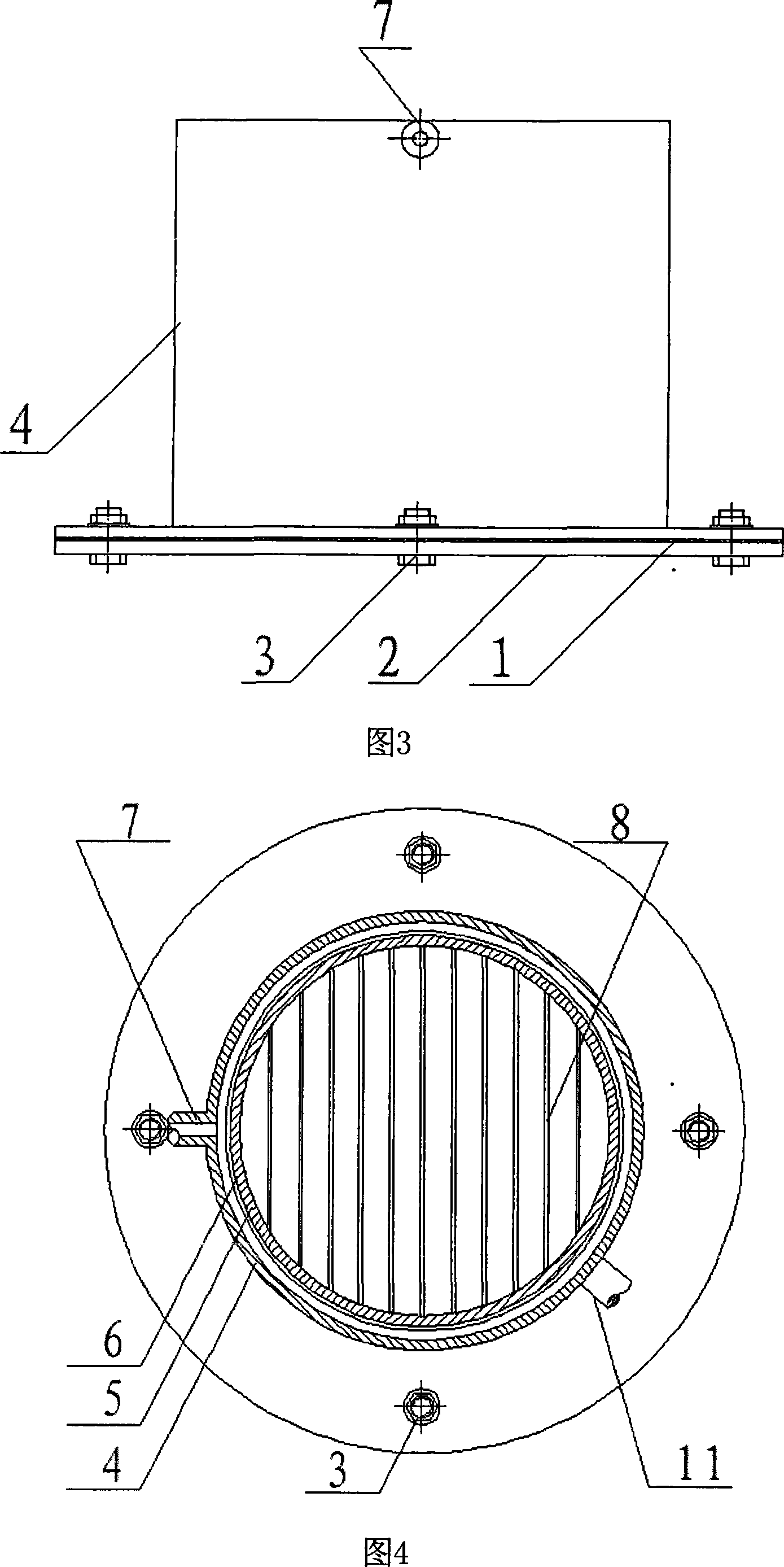

[0017] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] Referring to Figures 1-4, the present invention includes a shell with a heat exchange fluid outlet 7 and a heat exchange fluid inlet 11 on the upper and lower sides, and a weight plate 2 is provided at the bottom of the shell, and the hole diameter on the gas inlet 1 is larger than The 300-mesh filter screen 1 and the weight blue plate 2 are fixedly connected to the shell through bolts 3. The shell is composed of an outer cylinder 4 and an inner cylinder 5 made of heat-insulating materials. The outer cylinder 4 and the inner cylinder 5 form a The cavity for accommodating the heat exchange fluid communicates with the heat exchange fluid outlet 7 and the heat exchange fluid inlet 11. On the inner and outer side walls of the inner cylinder 5, annular ribs 6 are evenly arranged along the circumference. Stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com