Process and apparatus for preparing coal gas by using bulky biomass materials

A technology for biomass raw materials and gas, which is applied in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problems of unsatisfactory use effect of fluffy biomass raw materials, large tar-containing sewage, secondary environmental pollution, etc. The effect of flying carbon amount, high production intensity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

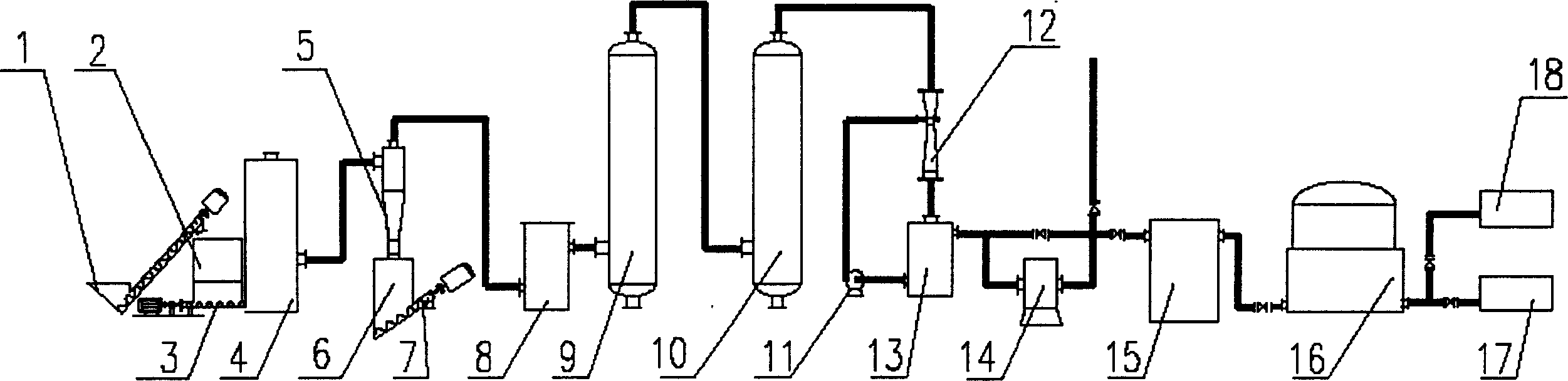

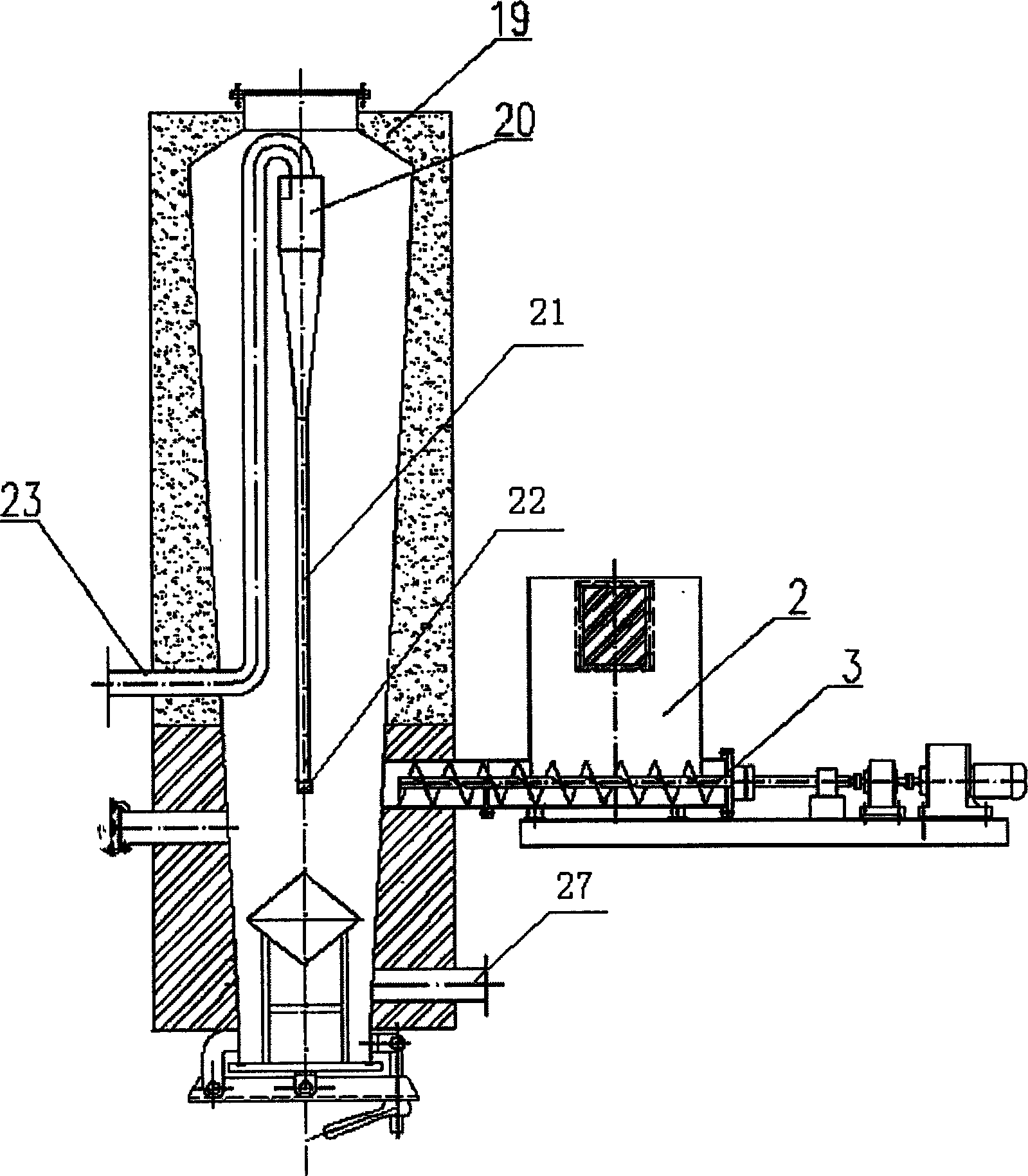

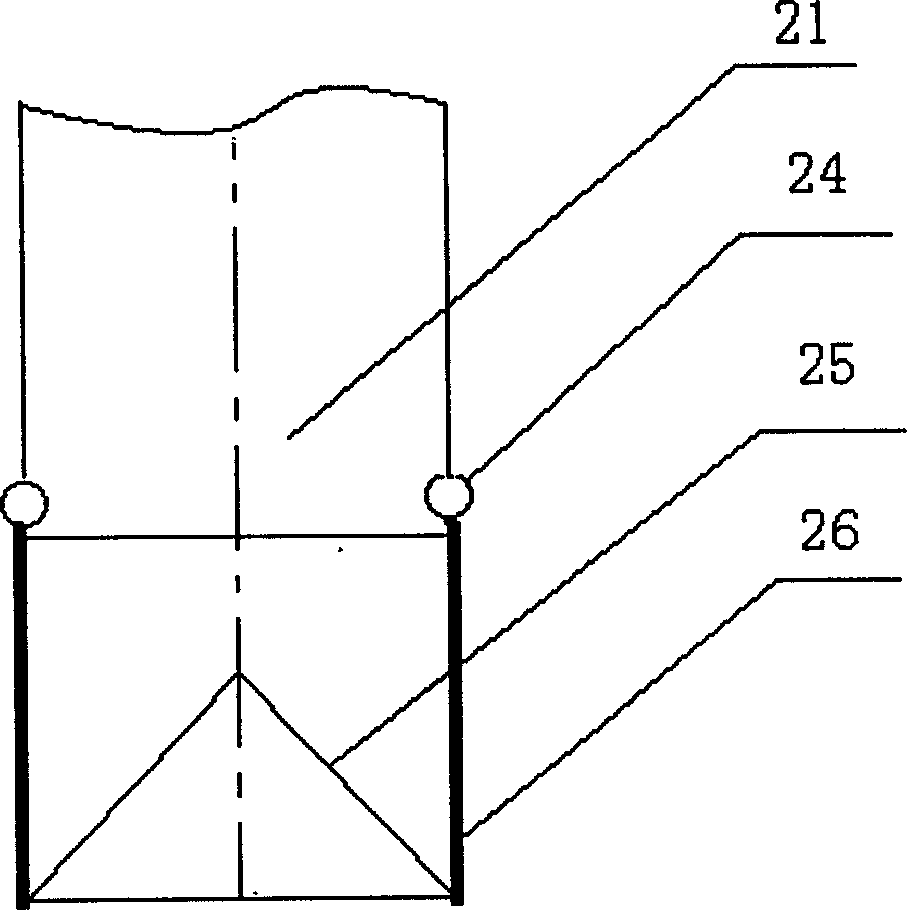

[0036] combined with figure 1 , 2, 3, the technique of the present invention is: fluffy type biomass raw material is pulverized into the fragment of 8-10mm with pulverizing device, is added into hopper 2 by lifting screw 1, is sent into built-in fast fluidized bed gas by screw feeder 3 again. The lower part of the gasification furnace 4; air is sent into the furnace from the air inlet 27, and the gasification reaction temperature is controlled at 800°C to 900°C by adjusting the amount of gasification air and the feeding speed of raw materials, and the amount of gasification air (Nm3) and raw material are controlled. The ratio of addition amount (kg) is 1.15. The fluidization gas velocity in the gasifier is 2.5m / s, and the biomass raw material is boiling in the gasifier and undergoes partial redox reaction with the gasification medium (air) to generate coal gas. The coal gas entrained with solid materials and ash enters the built-in cyclone separator 20, and the solid materia...

Embodiment 2

[0038] combined with figure 1 , 4 , 5, the technique of the present invention is: fluffy biomass raw material is pulverized into 3-5mm fragment with crushing device, is added into hopper 2 by lifting screw 1, is sent into built-in fast fluidized bed gas by screw feeder 3 again. The lower part of the gasification furnace 4; air is sent into the furnace from the air inlet 27, and the gasification reaction temperature is controlled at 700°C to 800°C by adjusting the amount of gasification air and the feeding speed of raw materials, and the amount of gasification air (Nm3) and raw material are controlled. The ratio of addition amount (kg) is 1.05. The fluidization gas velocity in the gasifier is 1.4m / s, and the biomass raw material is boiling in the gasifier and undergoes partial redox reaction with the gasification medium (air) to generate coal gas. The gas entrained with solid materials and ash enters the built-in cyclone separator 20, and the solid materials captured by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com