Non-pollution treatment device

A treatment device and pretreatment technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as odor generation, long waste cycle, and secondary pollution of the environment, so as to promote Thoroughly, the effect of improving the stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

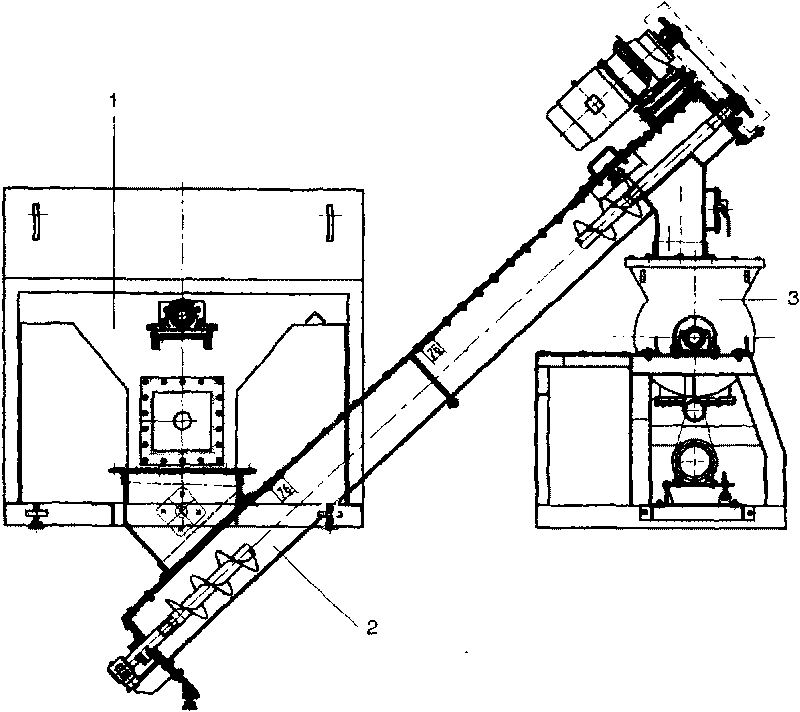

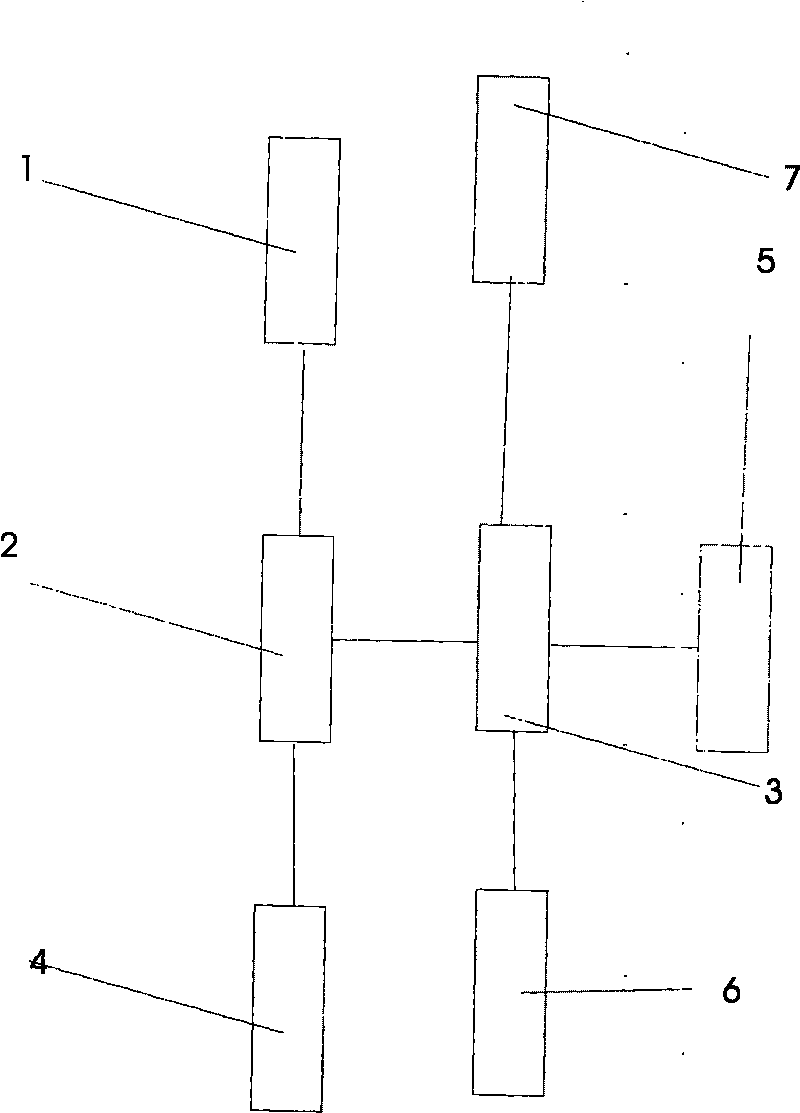

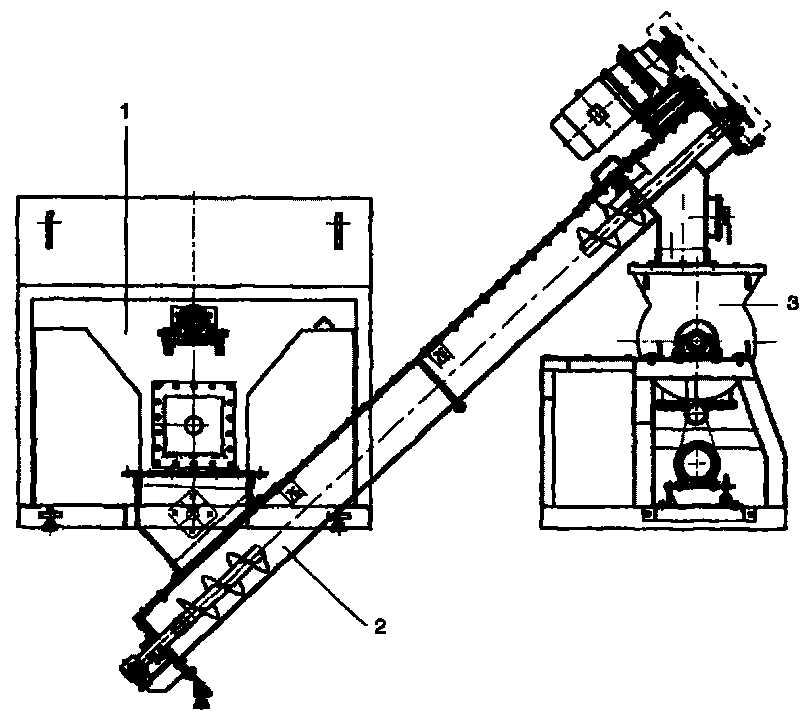

[0016] A pollution-free treatment device, comprising a raw meal pretreatment system 1, a raw meal hoist 2, an auxiliary material batching system 4, a reactor system 3, and a belt conveyor 5, characterized in that the stirring claw of the raw meal pretreatment system 1 is in a rod-shaped structure ; Two screw pusher shafts are arranged at both ends of the feeding port of the raw meal pretreatment system 1, one is left-handed and the other is right-handed; the raw meal pretreatment system is connected with the raw meal elevator 2, and the raw meal elevator 2 adopts a spiral The raw material is lifted into the reactor system 3; the auxiliary material batching system 4 is connected with the raw material elevator 2, and the auxiliary material is sent into the reactor system 3; the outlet of the reactor system 3 is connected with the belt conveyor 5.

[0017] The raw meal hoist 2 is a closed structure.

[0018] In the reactor system, the stirring shaft is vertically fixed on the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com